10 EB 8356 EN

Attachment to the valve

3 Attachment to the valve

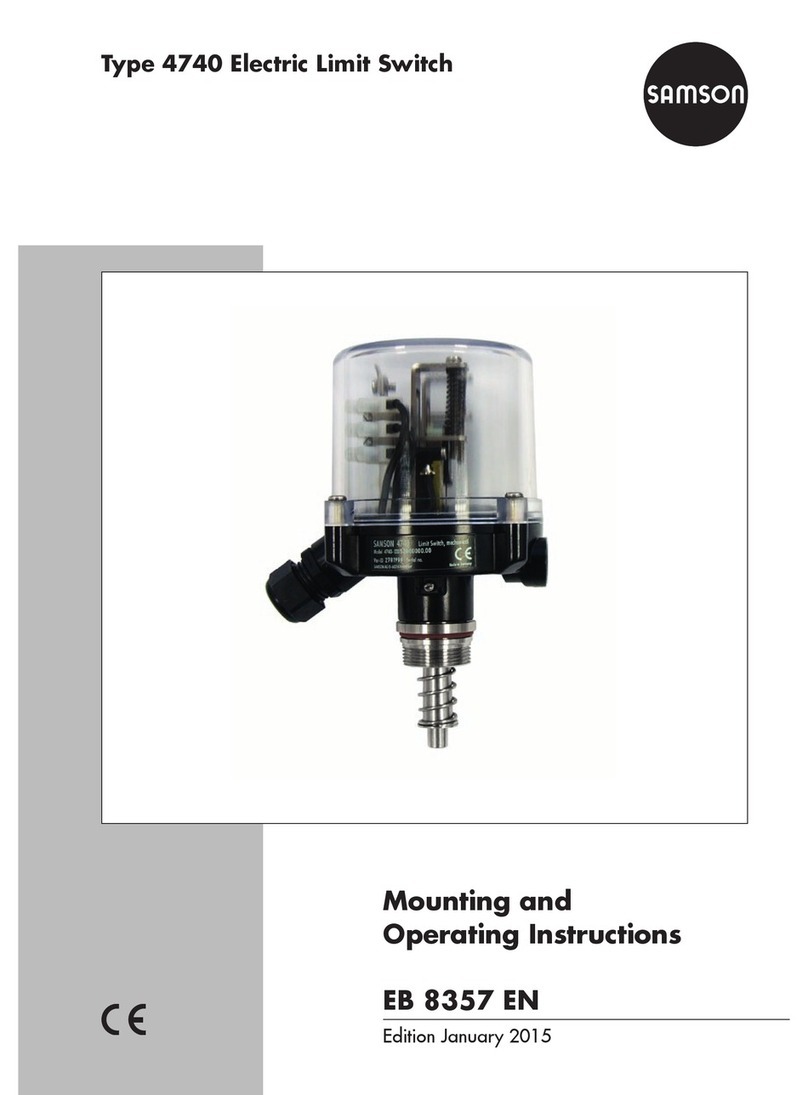

The limit switch can be mounted either di-

rectly to SAMSON Type3277 Actuator or to

valves with cast yokes or rod-type yokes ac-

cording to IEC60534-6 (NAMUR).

Combined with an intermediate piece, the

limit switch can also be mounted on rotary

actuators.

The standard limit switch is delivered without

accessories. Any additionally required ac-

cessories are listed together with their order

numbers in the tables on page20 on-

wards.

The limit switch may be mounted on the

right-hand or left-hand side of the valve.

Any subsequent changes to the mounting

position cause the switching function of the

limit switch to change as well. See section5.

3.1 Direct attachment

1. Fasten the clamp (1.2) to the actuator

stem, making sure that the fastening

screw rests in the groove of the actuator

stem.

2. Fasten the associated lever D1 or D2 to

the lever of the limit switch.

3. Secure the intermediate plate (15) with

the gasket facing towards the yoke.

4. Position and fasten the limit switch onto

the intermediate plate, making sure that

the lever D1 or D2 slides in line over the

pin(1.1) of the clamp (1.2).

5. Mount cover (18).

6. Mount the vent plug suitable for the cor-

responding degree of protection on the

cover (18).

3.1.1 Attachment of version

with solenoid valve

To establish the signal pressure connection to

the actuator, use a connection block or swi-

tchover plate listed in the tables in

page20 onwards. An M3 screw plug is

located on the back of this device version.

Actuators with 240 to 700cm² effective

areas

1. Make sure that the tip of the gasket(16)

projecting from the side of the connec-

tion block (Fig. 2, middle) is positioned

to match the actuator symbol for the ac-

tuator's fail-safe action "actuator stem

extends" or "actuator stem retracts".

If this is not the case, unscrew the three

fastening screws and lift off the cover.

Turn the gasket (16) by 180° and re-in-

sert it.

The old connection block version requires

the switch plate (13) to be turned to align

the actuator symbol with the arrow mark-

ing.

2. Place the connection block with the asso-

ciated gaskets against the limit switch

and the yoke. Fasten it using the screw.

For actuators with fail-safe action "actua-

tor stem retracts", additionally mount the

external signal pressure pipe.