Contents

EB 3773 EN

1 Safety instructions and measures ................................................................1-1

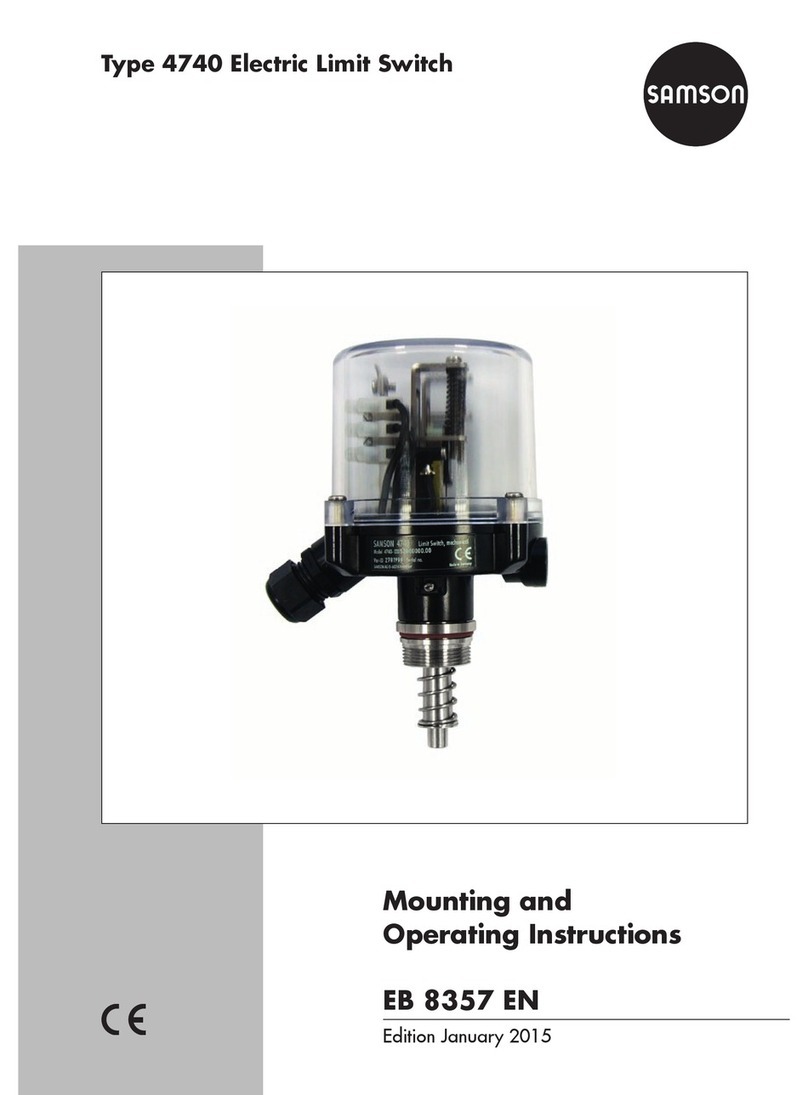

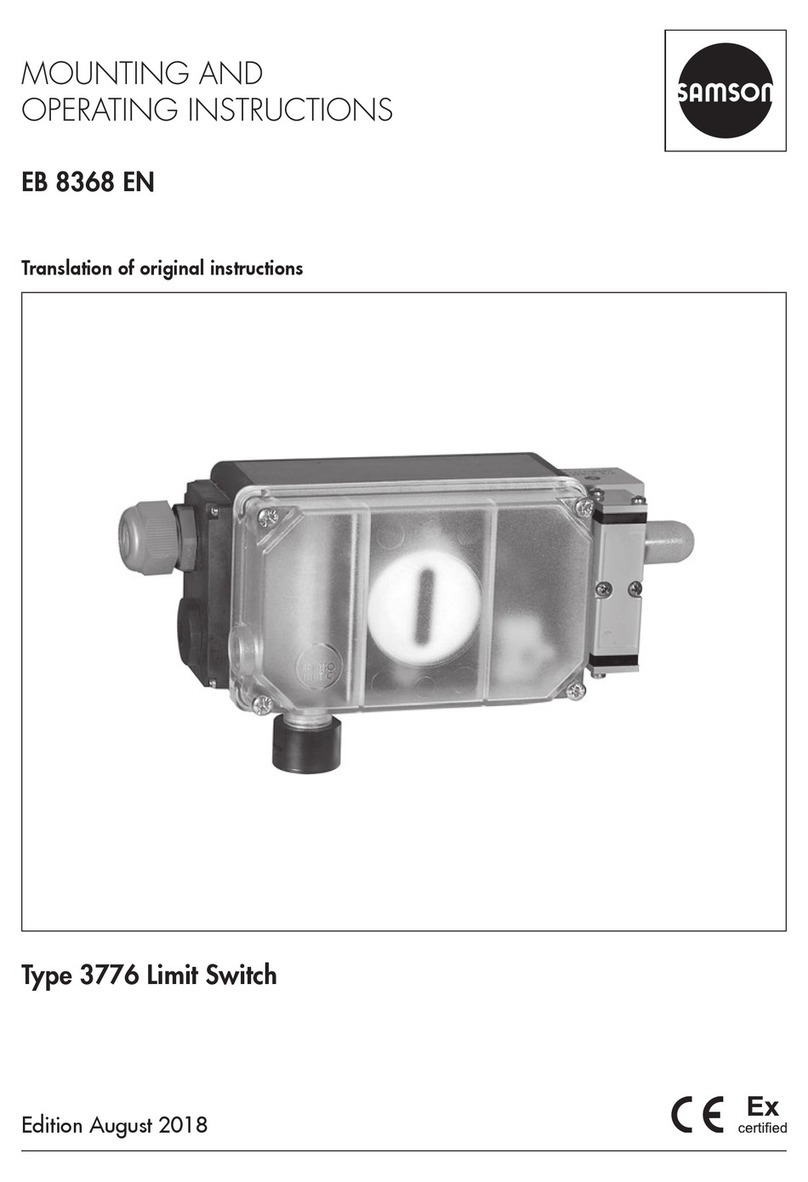

1.1 Notes on possible severe personal injury ......................................................1-3

1.2 Notes on possible personal injury ................................................................1-3

1.3 Notes on possible property damage.............................................................1-4

2 Markings on the device ..............................................................................2-1

2.1 Nameplate .................................................................................................2-1

2.2 Article code................................................................................................2-2

3 Design and principle of operation ...............................................................3-1

3.1 Technical data ............................................................................................3-3

3.2 Dimensions in mm.......................................................................................3-6

4 Shipment and on-site transport ...................................................................4-1

4.1 Accepting the delivered goods .....................................................................4-1

4.2 Removing the packaging from the limit switch ...............................................4-1

4.3 Transporting the limit switch.........................................................................4-1

4.4 Storing the limit switch.................................................................................4-1

5 Installation.................................................................................................5-1

5.1 Installation conditions..................................................................................5-1

5.2 Preparation for installation...........................................................................5-1

5.3 Mounting the limit switch .............................................................................5-2

5.3.1 AttachmentaccordingtoVDI/VDE3845,level1...........................................5-2

5.3.2 AttachmentaccordingtoVDI/VDE3845,level2...........................................5-2

5.4 Electrical connections ..................................................................................5-3

6 Start-up .....................................................................................................6-1

6.1 Adjusting the limit contacts ..........................................................................6-1

7 Operation..................................................................................................7-1

8 Malfunction................................................................................................8-1

8.1 Emergencyaction .......................................................................................8-1

9 Servicing....................................................................................................9-1

9.1 Servicing explosion-protected devices...........................................................9-2

9.2 Maintenance, calibration and work on equipment .........................................9-2

9.3 Preparation for return shipment....................................................................9-3

9.4 Cleaning the housing cover..........................................................................9-3

9.5 Periodic inspection and testing of the limit switch ...........................................9-3

10 Decommissioning .....................................................................................10-1

11 Removal ..................................................................................................11-1