8 EB 6616 EN

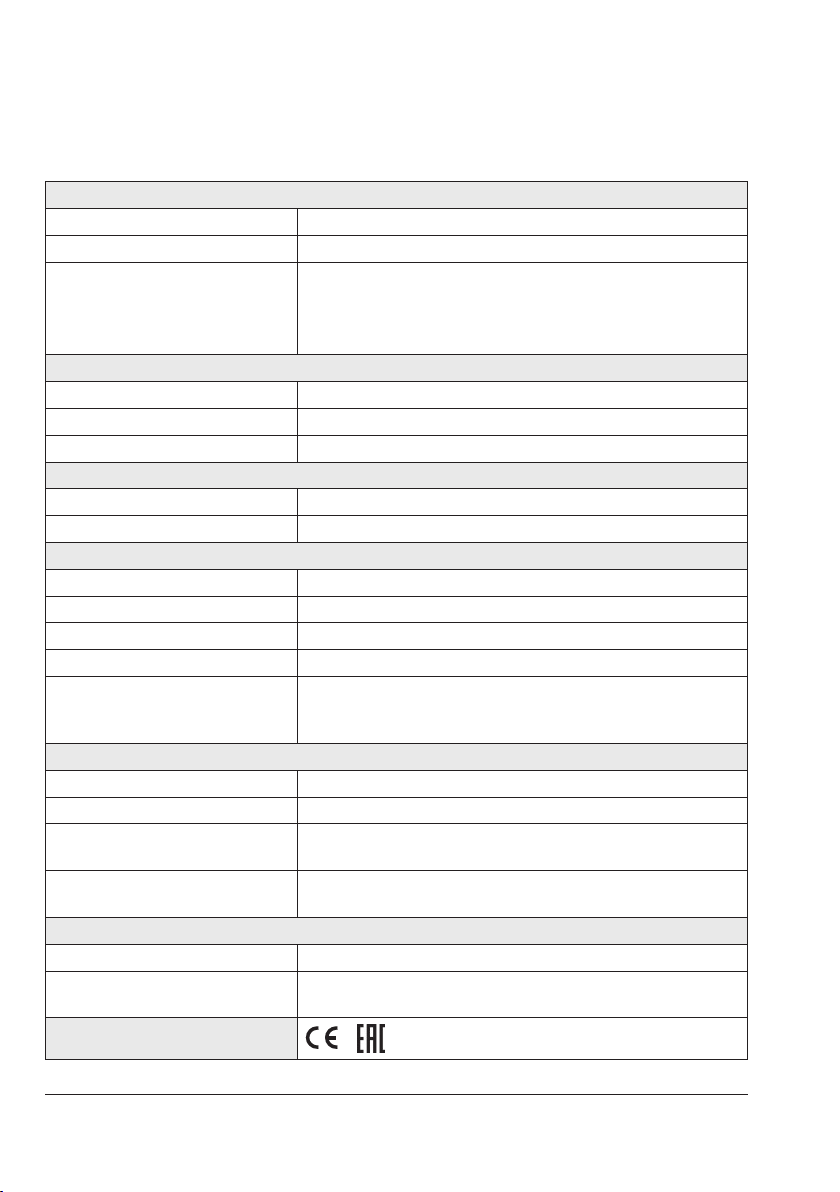

Markings on the device

2 Markings on the device

SAMSON TROVIS 6616

Web terminal

Model no. 6616-0000

S/Wrev. 1.4x

Serial no. xxxxxxxx

Var.-ID xxxxxxx

PowersupplyPoE/18-48VDC

Fig.1: Nameplate

3 Design and principle of oper-

ation

The web terminal runs as a web client under

the Android operating system. An unlimited

number of web terminals can be connected

toaCPUmodule.

TheTROVIS6616WebTerminalcanonlybe

usedinconjunctionwithaTROVIS6610

CPUModuleorTROVIS6611Controland

Automation Unit.

WhenusingaTROVIS6610CPUModule,

any graphic visualization saved on the web

serveroftheCPUmodulecanbeaccessed

using a Java-enabled browser. When using

aTROVIS6611ControlandAutomation

Unit, any saved graphic visualization can be

accessed using a HTML-enabled browser.

TheTROVIS6616WebTerminalallows

access to the visualization of several

TROVIS6610CPUModulesor

TROVIS6611ControlandAutomationUnits.

AllplantschemesaresavedintheCPU

module or automation unit. The web terminal

can be used to view, for example colored

plant schemes with dynamically refreshed

values. Data, such as set points, time

programs etc., can be conveniently changed

on the touch screen.

The alarm list shows recorded events in

chronological order with a comment.

Online or historical data can be viewed on

theTROVIS6616WebTerminalandsaved

toCSVlesforfurtherprocessingonanex-

ternal device, which can be plugged into the

USB port. Alternatively, the text-based user

interface of TROVIS Mobile can be used.

Requirements to use the TROVIS6610 CPU

Module:

−A project must be saved in the

TROVIS6610CPUModulecongured

usingtheTROVIS6690Graphical

ProjectManagementTool.

−The project requires a web application

createdusingtheTROVIS6693Web

TerminalEditororaTROVISMobileweb

application created using the

TROVIS6690GraphicalProject

Management Tool.

Requirements to use the TROVIS6611

Control and Automation Unit:

−A project must be saved in the

TROVIS6611ControlandAutomation

UnitconguredusingtheTROVIS6690

GraphicalProjectManagementTool.

−A process view application must be in-

cluded in the project.