English7

PRODUCT INTRODUCTION

FEATURES

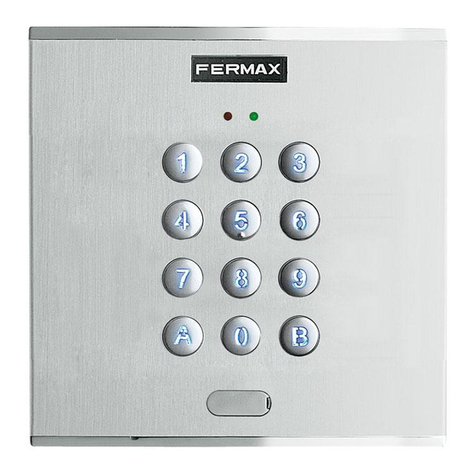

State-of-the-art Access Controller

This product is a state-of-the-art access controller that is optimal for time and attendance management, and

provides 4 input ports and 2 2Form-C relay outputs along with 2 TTL output ports and TCP/IP ports to meet the

high-level security system requirements and various customer needs.

Featuring the simplest operation as well as the highest security, this access controller can save up to 20,000 IDs

(10,000 events) and up to 20,000 events (10,000 IDs). All events can be transferred to the host PC before being

saved to the database, and output in formats of PDF, TIF or text file using the PC applications for time and

attendance management purposes.

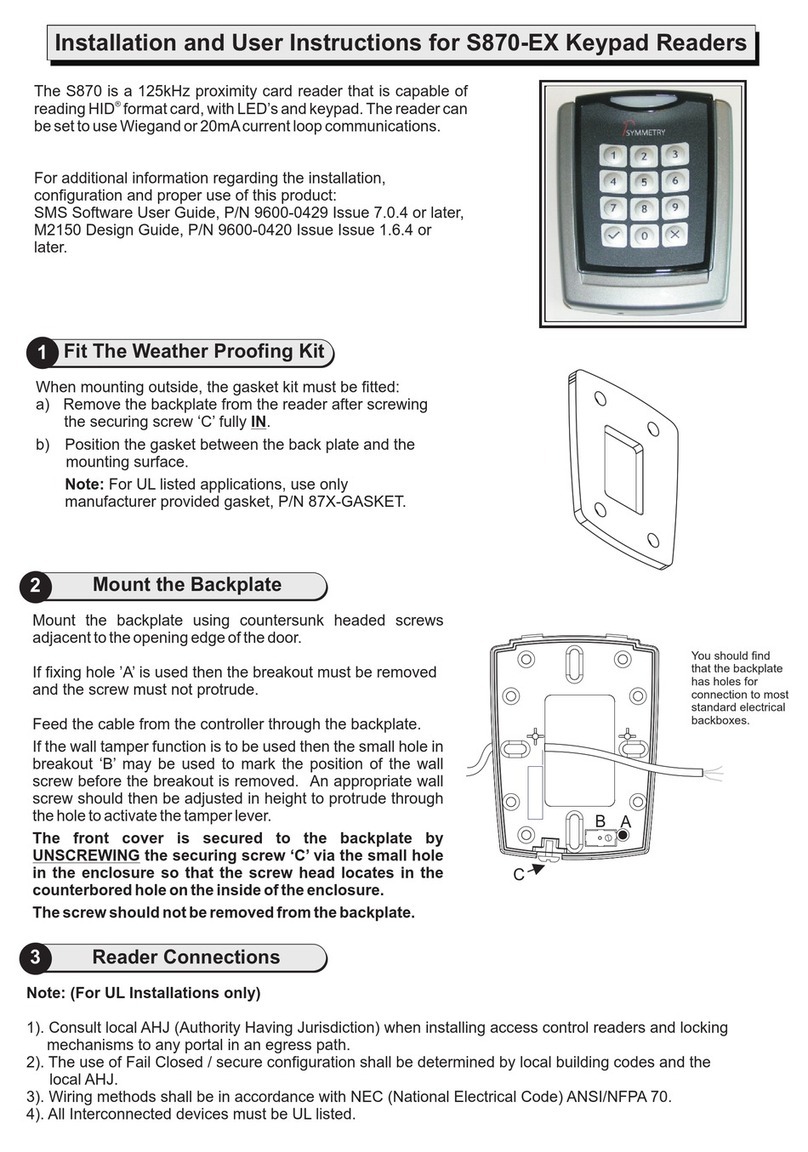

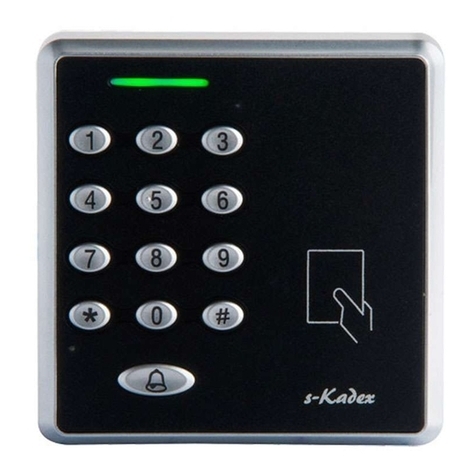

This product hires 26-bit Wiegand (SSA-S2101: 34-bit Wiegand) proximity card reader and built-in keypad of 24

buttons (including 10 numbers, 2 control buttons, and 12 menu buttons) for versatility in operations. By using this

product, users can utilize all combinations of proximity card, PIN, and password for getting accessed. This product

is featured by the Exit button, Motion Detector, Door Contact sensor and 4 external input ports connected to the

exit alarm system preventing unauthorized access.

It also has 2 relay outputs that can control the door lock and alarm relay.

In the mean time, the graphics LCD panel supports multilingual display, enabling it operated around the world

beyond the language barrier. The dual tamper switch triggers an alert if the product is forcibly disassembled.

All system settings can be configured using the front keypad or through the Windows-based software. This product

works as a standalone system and is designed to operate via the network.

Standalone Operation

SSA-S2100/SSA-S2101 is connected to the external card reader, which is used to control one entrance. It

determines to allow access by reading data from the internal or external card reader, and controls the open/close of

the door relay and other output settings.

On an external signal (from a sensor or Exit button) reception, the device (relay) corresponding to the signal starts

operating.

This product has an independent control system, assuring a normal operation regardless of problems on other

systems and, not affecting them in a reversed situation.

Computer-based Management

All records of authorized or unauthorized accesses and any external signal will be saved in the internal memory. You can

download such data onto your computer according to the specified communications protocol. With the downloaded

data, you can store, process, create a report based on your query (access and alert details, etc) on the connected

computer.

Keypad Registration

Even if SSA-S2100/SSA-S2101 is not connected to the host PC, you can use the built-in keypad and LCD module to

register or delete the card or configure necessary settings independently.

Time Scheduling

SSA-S2100/SSA-S2101 is featured by so-called time schedule, which allows you to instruct it to perform a specific

operation for a specific period of time. You can set a total of 10 time schedule codes, each of which can be assigned

to each user.

Each time schedule code has a total of 8 different time zones including Monday through Sunday (7 time zones) plus

one holiday, each of which can be divided in up to 5 different time intervals, indicating you can program different time

codes.

You can also create time schedule codes to manage separate I/Os. If a time schedule code is assigned to an input

device, for instance, that device will stay active only for the time specified. Each time schedule code is linked to the

holiday schedule, which is void only to the holiday time code of the time schedule. (refer to “Time Scheduling” on pages

51 to 52)

product introduction