ENGLISH

SR64OD - SR83OD

17

• Do not let liquids of any kind come into

contact with the internal or external parts

of the grinder-doser.

• Never put ground coee in the hopper

intended only for coee beans.

• Do not tamper with the grinder-doser.

• Do not touch the grinder-doser with

damp or wet hands or feet.

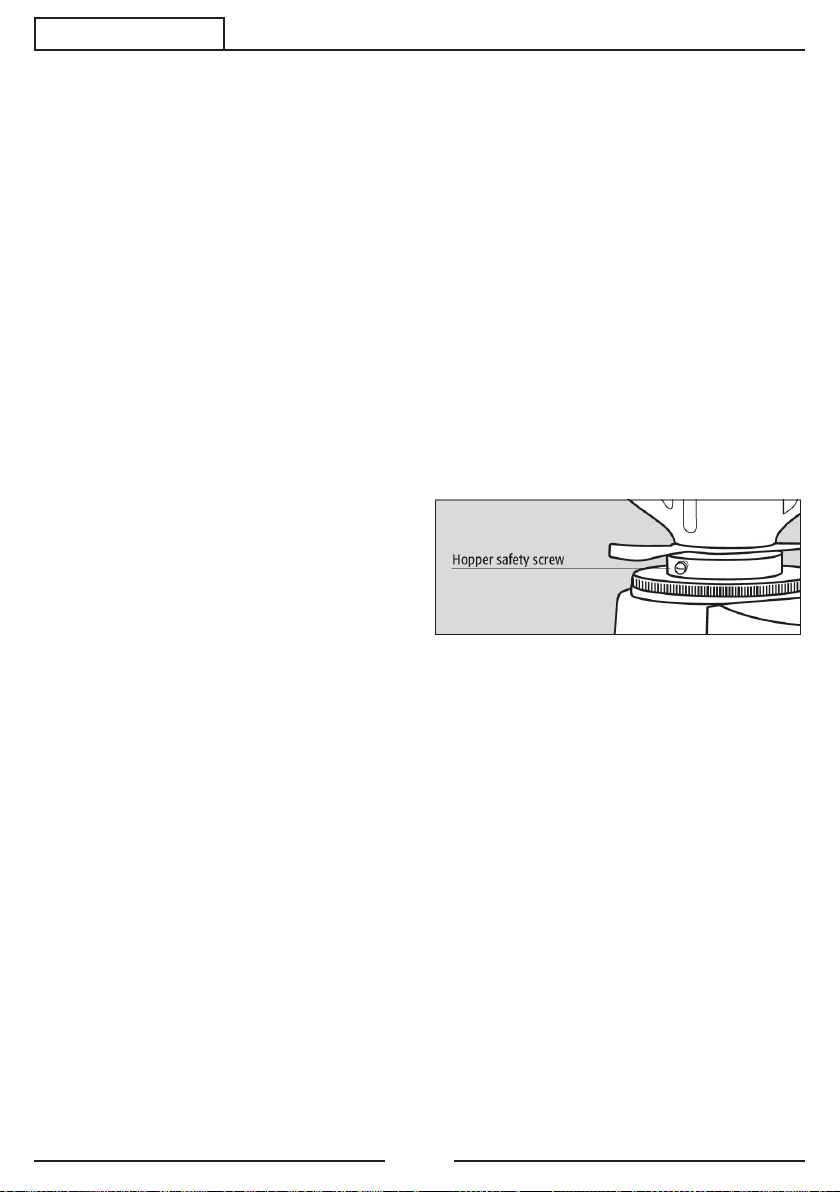

• The hopper must be fastened to the

grinder- doser grinding system by means

of the relevant screw which must be

inserted in the threaded hole located on

the upper grinding blade holder and in the

hole on the neck of the hopper.

• Make sure that the coee outlet is

free from any obstrucon otherwise the

appliance will stop.

• The manufacturer cannot be held

responsible for bodily injury or damage

to property if these regulaons are not

complied with.

• Operang temperature: -10°C +60°C

Storage temperature: -40°C +70°C

• USA & CANADA - duty cycle: 25s “ON” |

60s “OFF”

If the grinder-doser is to remain

inacve for a long period, clean it

carefully, wash and dry the hopper

and leave it open.

ATTENTION: Moving parts.

INTRODUCTION

Making coee is an art. Precise rules

need to be followed in order to

succeed. The formula for a perfect cup

of espresso coee involves various

steps and the coee machine plays a

very important role. For a successful

result and unquesonable quality, it is

necessary to correctly combine three

factors:

• A high-quality blend.

• The appropriate use of available

appliances.

• The skill and professionalism of

the person who makes it. Contrary

to belief, to enjoy a good cup of

coee, it is not enough to choose

the right blend.

The operator’s experience and skills

in following the right procedures

for making a coee and the use of

suitable appliances strongly influence

the creaon of a small masterpiece.

Therefore, professionals place

crucial importance on the espresso

machine and grinder-doser. Knowing

how to use these appliances well,

maintaining them in perfect working

order and using them at their best,

is a skill belonging to professional

coee makers. The quality of a good

espresso coee comes from a series of

operaons, including grinding which

plays an important role. Therefore,

for the operator, the grinder-doser is

one of the fundamental appliances,