24

ENGLISH SR64OD EVO

in conformity with current safety

regulaons. If in any doubt, have

the system thoroughly checked by

personnel with the appropriate

professionalskills.

•Itiscompulsorytoearththegrinder-

doser.Themanufacturercannotbe

held responsible in the event of

non-observanceofthisregulaon.

•It is essenal to make sure the

rangs of the system are suitable

for the power absorbed by the

grinder-doser (as indicated on the

label featuring the technical data)

andthatthewallsocketisprotected

againstovercurrents.

•Do not use extension cables, plug

adapters for mulple sockets or

makeshiconnecons.

•Themotormustrotateclockwise.If

therotaonofthreephasemotors

is to be inverted,by inverng the

two power supply wires inside the

plug, this must be carried out by

skilledpersonnel.

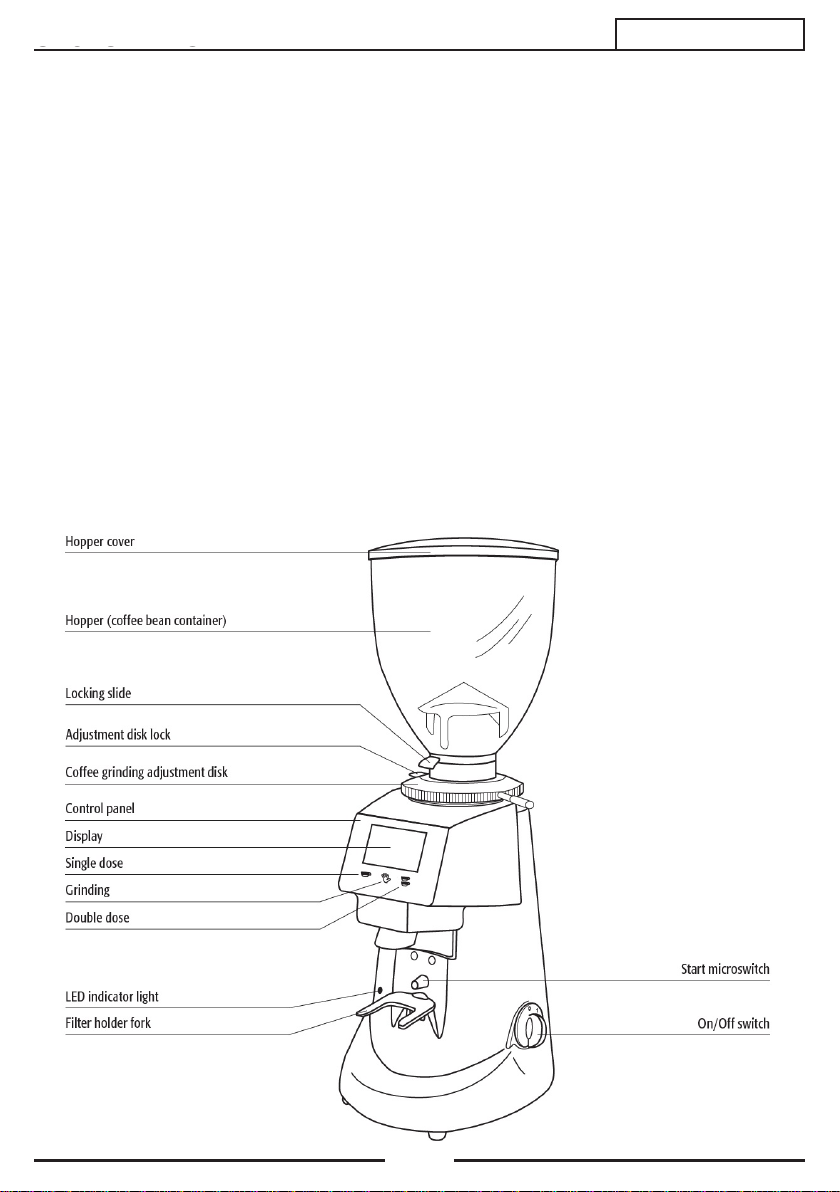

OPERATING THE GRINDER-DOSER

Preliminaries

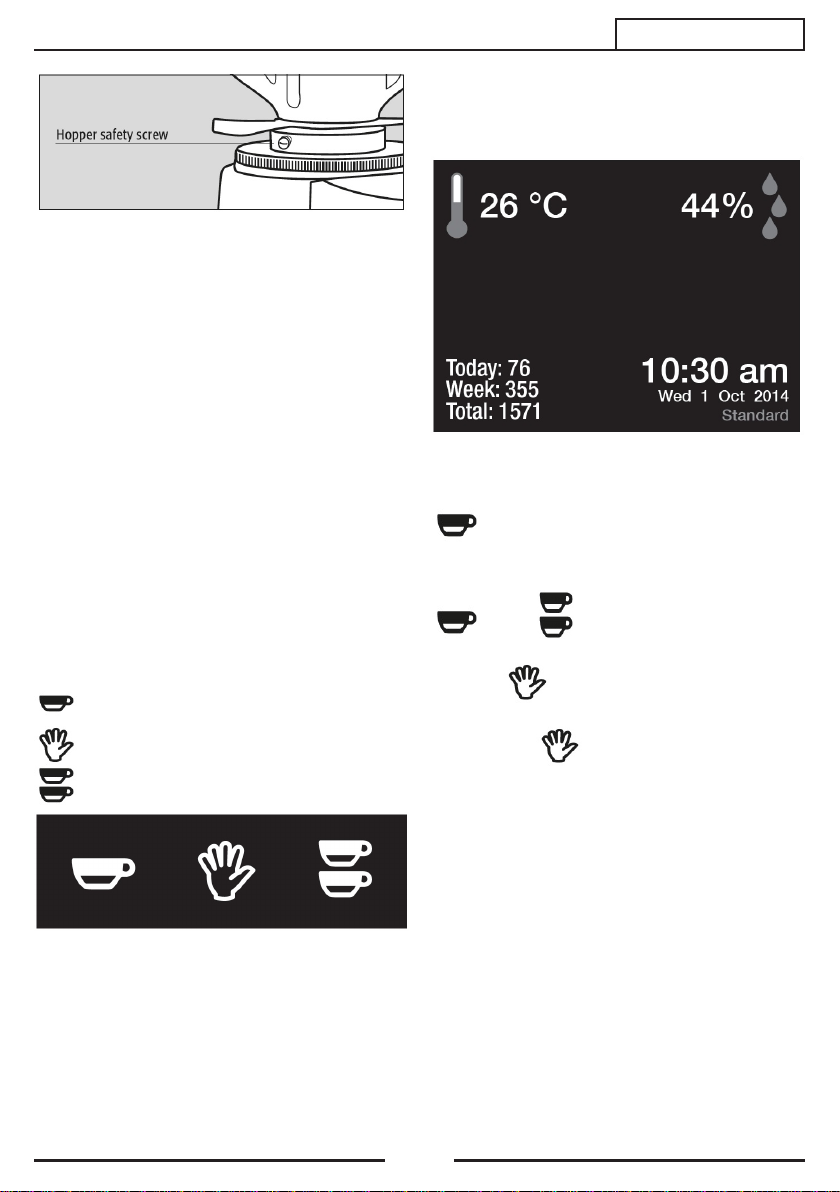

Make sure the hopper is posioned

correctly on the coee grinder-doser

and is fastened to the upper grinding

blade holder by means of the relevant

screw. Close the locking slide and fill

the hopper with coee beans. Open

the locking slide so that the beans are

allowedtodropintothegrindingsystem.

USE

This grinder-doser has been designed

solely for grinding coee beans. Any

other use must be understood as

improper,andconsequentlyhazardous.

The manufacturer cannot be held

responsible for any damage as a result

of improper or incorrect use. Do not

use the grinder-doser for grinding

other types of food, or anything else.

The grinder-dosers and coee grinders

manufactured by our company are

intended for skilled personnel for

professionaluseonly,notforhousehold

use

WARNINGS FOR INSTALLATION

AND ELECTRICAL CONNECTIONS

The grinder-doser must be installed

by skilled technical personnel in

compliance with the safety regulaons

inforce.Incorrectinstallaonmayresult

ininjurytopeople,animalsorthings,for

whichthemanufacturercannotbeheld

responsible.

•The grinder-doser must be placed

onastable,flatsurface.

•Before plugging in the grinder-

doser, make sure the voltage and

frequency values of the supply

mains correspond to the rangs

indicatedonthelabelfeaturingthe

grinder-dosertechnicaldata.

•The wall socket must be fied

with an efficient earth contact.

Consequently,itisessenaltomake

suretheearthsystemisefficientand