Sanyo LCD-DP42410 User manual

Other Sanyo LCD TV manuals

Sanyo

Sanyo DP50842 User guide

Sanyo

Sanyo LCD-32XF7 User manual

Sanyo

Sanyo CE32LD17E-B User manual

Sanyo

Sanyo DP42851 User manual

Sanyo

Sanyo LCD-42XF8T User manual

Sanyo

Sanyo LCD-40XR10F User manual

Sanyo

Sanyo LCE-22A100F User manual

Sanyo

Sanyo LCD-47XF5 User manual

Sanyo

Sanyo 263 User manual

Sanyo

Sanyo DP24E14 User manual

Sanyo

Sanyo LCD-42K40TD User manual

Sanyo

Sanyo LCD55L4 User manual

Sanyo

Sanyo FW65C78F User manual

Sanyo

Sanyo LCD-26E30A User manual

Sanyo

Sanyo LCD-32CA8Z User manual

Sanyo

Sanyo FW50C36F User manual

Sanyo

Sanyo LCD-40XAZ10F User manual

Sanyo

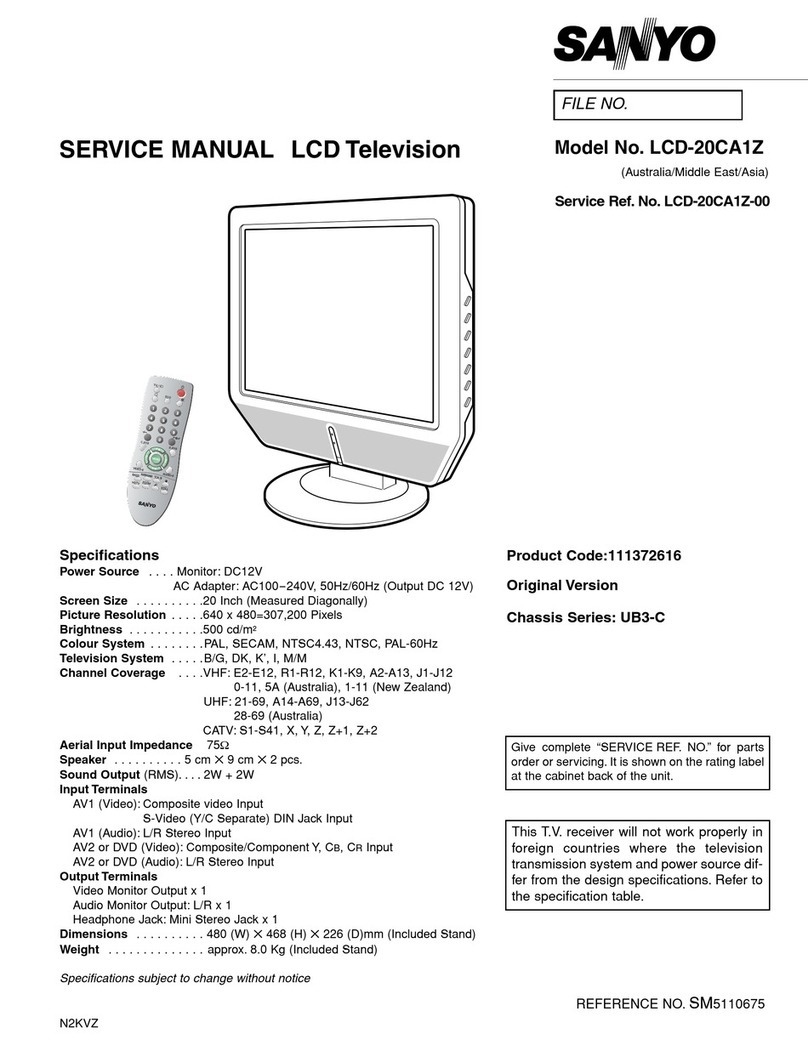

Sanyo LCD-20CA1Z User manual

Sanyo

Sanyo DP42841 User manual

Sanyo

Sanyo DP19649 - 720p 18.5" LCD HDTV User manual