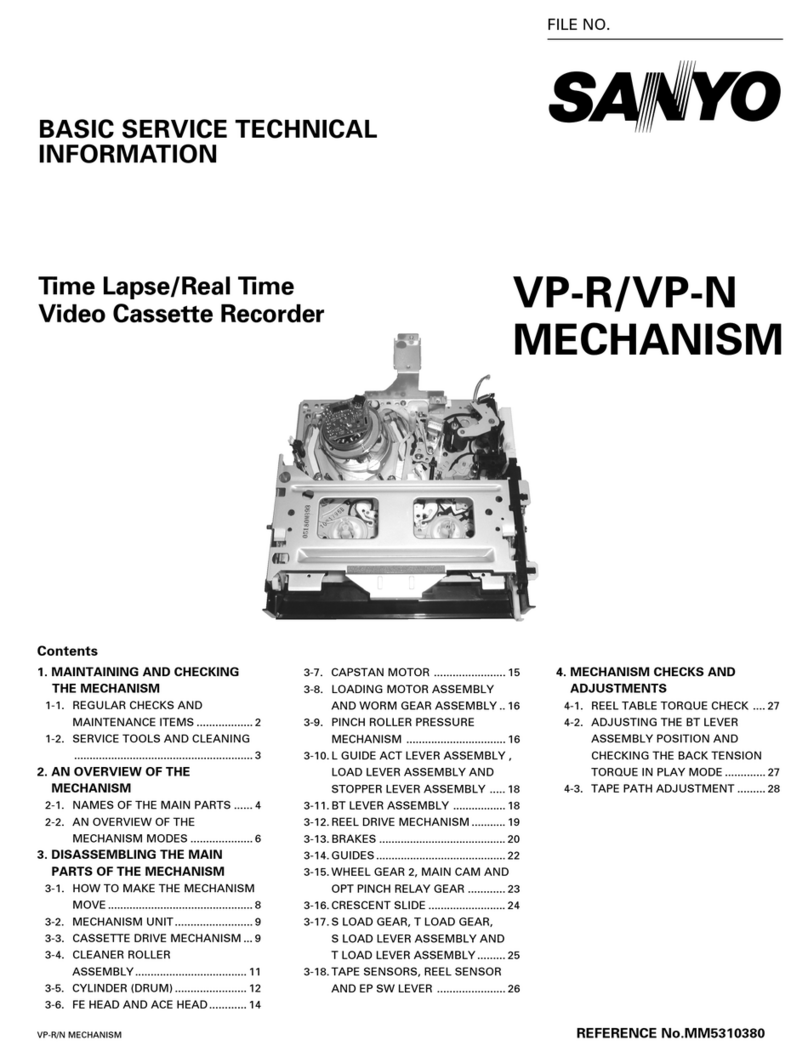

3. DISASSEMBLING THE MAIN PARTS

OF THE MECHANISM

POINTS TO NOTE

●

●

●

When fitting the parts of the mechanism, refer to the

“Assembly Notes”, and proceed in the reverse of dis-

assembly order.

Dis-assembly and assembly should be carried out in

EJECT mode unless amovement mode is explicitly

specified. EJECT mode is the state in which the cassette

tape has been ejected.

Clamps are used to prevent parts coming loose. When

removing aclamp, be careful not to force it, as this can

result in damage.

3-1. HOW TO MAKE THE MECHANISM

MOVE

In order to check amovement such as front loading, front

unloading, tape loading, tape unloading, raising/lowering

and pressing the pinch roller, you will need to operate the

loading motor. There are two methods of operating the

loading motor, and these are explained in sections 3-1-1

and 3-1-2. The above movements can also be performed

without operating the loading motor, by following the

method explained in section 3-1-3.

3-1-1. HOW TO OPERATE THE LOADING MOTOR

USING A DC VOLTAGE SUPPLY

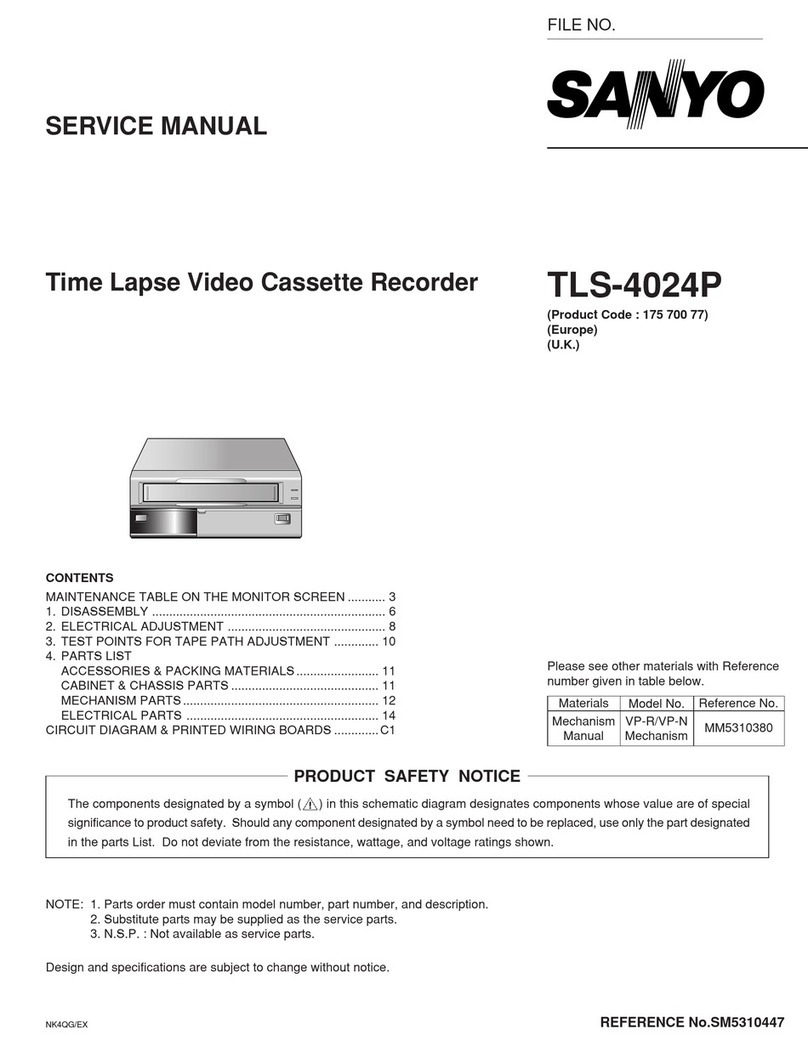

(See Fig.3-l-1)

1) Remove the power plug from the socket.

2) Remove ~he top cover, front cabinet assembly and

bottom cover.

3) Supply aDC voltage in the range 5V between the

MOTOR (+) wire and the MOTOR (-) wire on the CP-I

PWB assembly. To make the loading motor rotate in

the PLAY or FF/REW direction, the positive terminal

should be connected to the MOTOR (+) wire, and the

negative terminal to the MOTOR (–) wire. To make it

rotate in the EJECT direction, connect the positive

terminal to the MOTOR (-) wire, and the negative

terminal to the MOTOR (+) wire.

When rotating the loading motor inthe EJECT direction

with atape slacken, stop the rotation of the loading

motor before beginning front unloading.

Rotate the capstan motor with your hand, wind the

slacked part of the tape, and rotate the loading motor

in the EJECT direction again.

NOTE 1: When carrying out front loading, release the lock

by pressing down the tray lock lever@ and the lid opener

lever @of the cassette mechanism assembly (shown in

Fig.3-2-2) in the direction of the arrow.

NOTE 2: When the loading motor stops rotating, following

the completion of an operation such as tape loading or

front unloading, switch off the DC voltage supply.

Bottom side

Motor (+) wire

Motor (-) wire Front side

Fig.3-l-l

3-1-2. OPERATING THE LOADING MOTOR BY THE

MANUAL METHOD (See Fig.3-l-2)

1) Refer to section 3-2 and install the mechanism unit.

2) Using your finger, turn the loading motor located at

the rear of the mechanism unit. For EJECT, turn the

loading motor in the direction of the arrow on the

loading motor. For PLAY or FF/REW, turn it in the

opposite direction.

When rotating the loading motor in the EJECT direction

with atape slacken, stop the rotation of the loading

motor before beginning front unloading.

Rotate the capstan motor with your hand, wind the

slacked part of the tape, and rotate the loading motor _

in the EJECT direction again.

When carrying out front loading, release the lock

by pressing down the tray lock lever @and the lid

opener lever @of the cassette mechanism assembly

(shown in Fig.3-2-2).

The arrow which showtha direction of EJECT

atFig.3-l-2

d

Loading motor

3-1-3. MAKING THE MECHANISM MOVE USING

THE MANUAL METHOD

1) Refer to section 3-2 and remove the mechanism unit.

2) Refer to section 3-15 and remove the gear wheel 2.

3) If you turn the main cam anticlockwise, the mechanism

will switch to amode such as PLAY or FF/REW. To

switch from FF/REW mode to EJECT mode, turn the

main cam clockwise. L

–8–