Hawk Sit Harness

Conform to EN813:2008 & EN12277:2015+A1:2018 Type C and is rated to 150kg.

Conform to EN361 when used with any of our chest harness range & Link Sling.

Important

Please read and understand these instructions before use. This product should only be

used by trained & competent operatives, or under the supervision of such a person.

Use

The Hawk sit harness has been designed for your protection and is therefore (PPE)

personal protective equipment. The Hawk sit harness is for climbing, mountaineering,

rescue, intervention and technical access (in normal climatic conditions). They are

suitable for many other applications but please check with the manufacturer first. Use

only as instructed and with compatible items of equipment. Twists in the webbing and

buckles fastened incorrectly, can cause problems, weakness, serious injury or death.

Neatness is strength. Before use in a safe environment, move around and hang in the

harness from the tie-in points to verify that the harness is comfortable and properly

adjusted.

It is the user’s responsibility to ensure that any items of PPE or other equipment used

with the Hawk are compatible and do not interfere with the safe function of any other

component. Any item of equipment used must comply to the relevant standard(s).

Note: The information in this guide meets the requirements of the EU PPE Regulation

2016/425 . It is not comprehensive and cannot be substituted for the correct training,

which can be provided if required. If in any doubt, contact SAR Products using the

supplied information.

Safety

The safety provided by the Hawk sit Harness is dependant on the scenario, the anchors

used and the skill of the user. The strength and suitability will be reduced through

factors such as, but not limited to, age, wear & tear, abrasion, cuts, high impact loads,

tight/sharp edges, knots, some chemicals (e.g. strong alkalis), UV exposure,

environment (damp or icy conditions), failure to store & maintain as recommended, etc.

An appropriate connection method must always be used between the harness and the

anchor or system.

A rescue plan should always be in place prior to any work at height. Do not alter or

repair the product in any way. Any component subjected to a dynamic loading should

be examined and discarded if there is any sign of defect, or any doubts about its safety.

Check fitting and adjustment elements regularly.

Lifespan

The lifespan of any product will be affected by the conditions in which it is used and

stored/ maintained. This product is manufactured using high grade polyester webbing.

Textile components should be retired no later than 10 years after the Date of

Manufacture.

Metal components will have an indefinite lifespan, depending on use.

The working life will be reduced through general wear and tear, abrasion, cuts, damage

to component parts, inappropriate ancillary equipment, high impact load, prolonged

exposure to UV light including sunlight, elevated temperature (50°C max), exposure to

some chemicals (e.g. strong alkalis) or failure to store and maintain as recommended.

This list is not exhaustive.

Inspection

Before each use, conduct a visual inspection and function test to ensure the product is

in serviceable condition and operates correctly. A periodic examination should be

carried out at by a competent person at least every 12 months. These inspections

should be recorded, paying particular attention to areas of potentially high wear such

as attachment points, textiles, cams, bearings, etc. In the UK, the frequency of periodic

inspection should be at least every 6 months; it is the user’s responsibility to ensure

they comply with the guidance for inspection in their own country or region.

Inspect as follows:

Textiles: Check for cuts, tears & abrasions, damage due to deterioration, contact

with heat, alkalis or other corrosives, label legibility.

Sewing: Check for broken, cut, loose or worn threads.

Metals: Check for cracks, distortion, corrosion, wear by abrasion, burrs, worn or

loose rivets or screws, discolouration caused by extreme heat (greater

than 100° C) broken springs, seizure of moving parts, broken or missing

components, marking legibility.

Immediately withdraw from service any items showing defects. Any repairs must be

carried out by the manufacturer or their authorised agent.

Anchorage

Anchor points should always be assessed for strength and suitability for the task

(EN795, minimum 12kN). Sharp edges, abrasive or high temperature surfaces should be

avoided or protected against.

Anchor points, wherever possible, should be above the user.

Maintenance

Always keep the product clean and dry. Any excess moisture should be removed with

a clean cloth and then allowed to dry naturally in a warm room away from direct heat.

Metal parts may be lubricated with a dry PTFE lubricant or WD40 type spray. Excess

lubricant should be wiped off to avoid attracting dirt.

Cleaning

Rinse in clean cold water. If still soiled, wash in clean warm water (max. 40°C) with pure

soap or a mild detergent (within pH range of 5.5 to 8.5). A machine wash may be used,

but care must be taken to protect against mechanical damage, for example by placing

the item in a bag prior to washing. Rinse thoroughly in clean cold water.

Chemicals

Avoid contact with any chemicals which could affect the performance of the product.

If contact occurs, or is suspected, then remove the product from service immediately.

If used in a marine environment, thoroughly rinse in clean cold water and dry after

each use.

Storage

After cleaning, store unpacked in a cool, dry, dark place away from excessive heat

sources or other possible causes of damage. Do not store wet.

Transport in a suitable protective bag.

If a long shelf life is required it is advisable to store in a moisture proof package.

Warning

Work at Height and Rescue are hazardous activities. It is the user’s responsibility to

ensure understanding of the correct and safe use of this equipment, to use it only for

the purposes for which it is designed and to practise all proper safety procedures. The

time that a casualty is suspended should be kept to a minimum.

Attention should be paid to the dangers suspension trauma.

The user shall ensure that the safe function of this product is not impaired by, and does

not impair, the safe function of another component or system.

Sit harnesses must not be used for fall arrest purposes unless paired with an approved

SAR chest harness.

Markings

Each individual component is marked, where applicable, with:

• The name, trademark or any other means of identification provided by the

manufacturer or supplier.

• The batch or serial number

• The date of manufacture (DoM)

• Product description and/or reference

• The British &/ or EN standard(s) to which the item conforms

• Waist size

• Load rating

• UKCA &/or CE mark with approved &/or notified body number

Strengths quoted are when the product is tested new and are in accordance with the

manufacturer’s test methods to the appropriate standard. Any weights and

measurements are within the standard’s specified tolerances.

Nothing in this document affects the consumer’s statutory rights.

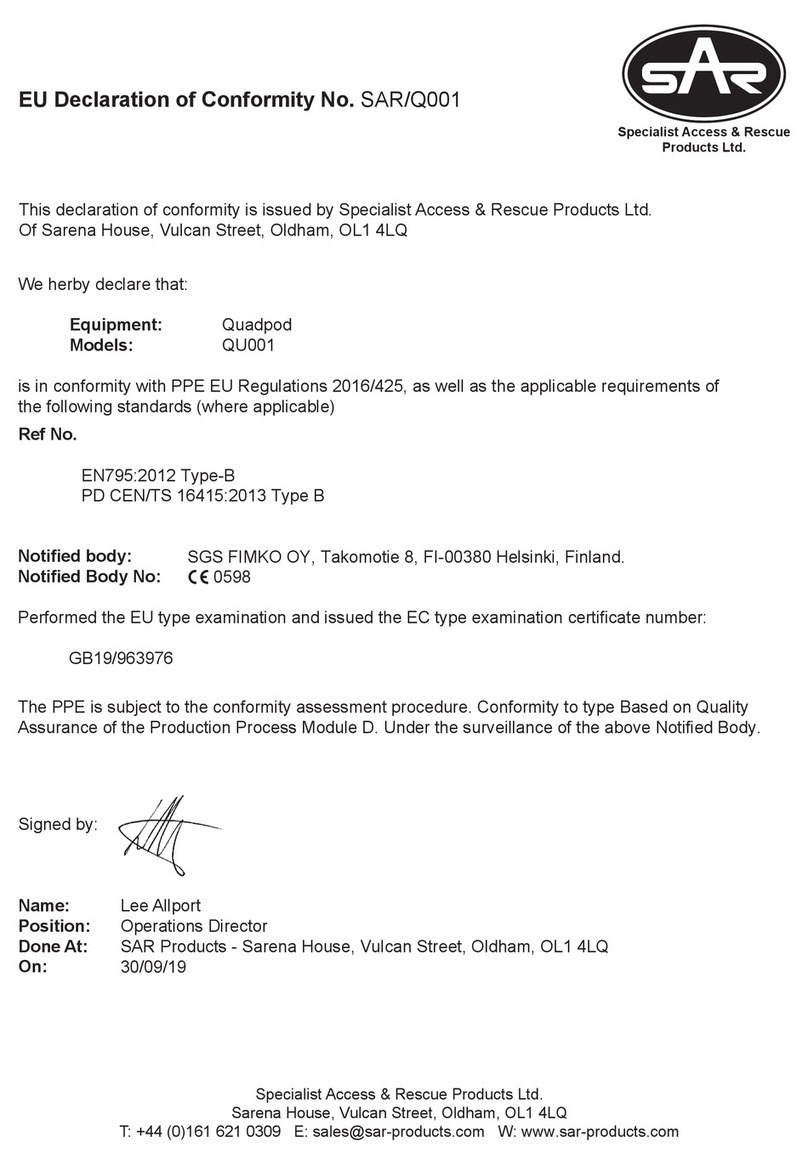

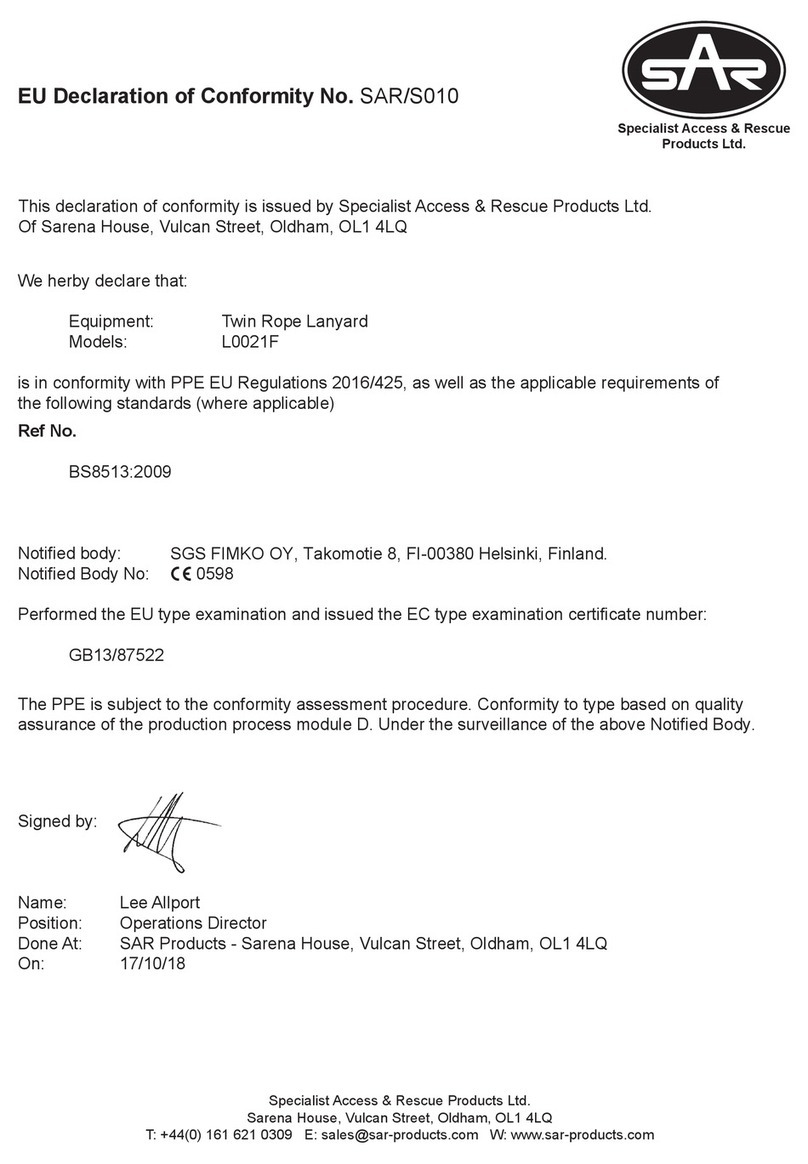

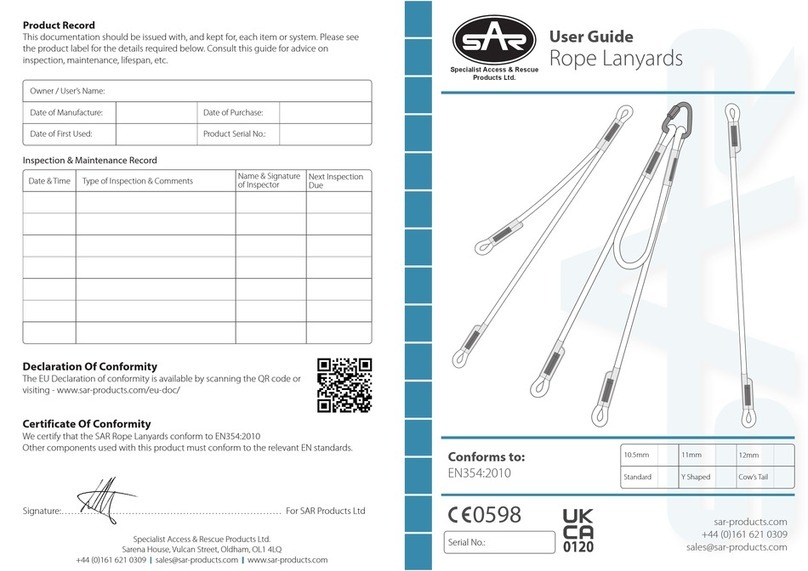

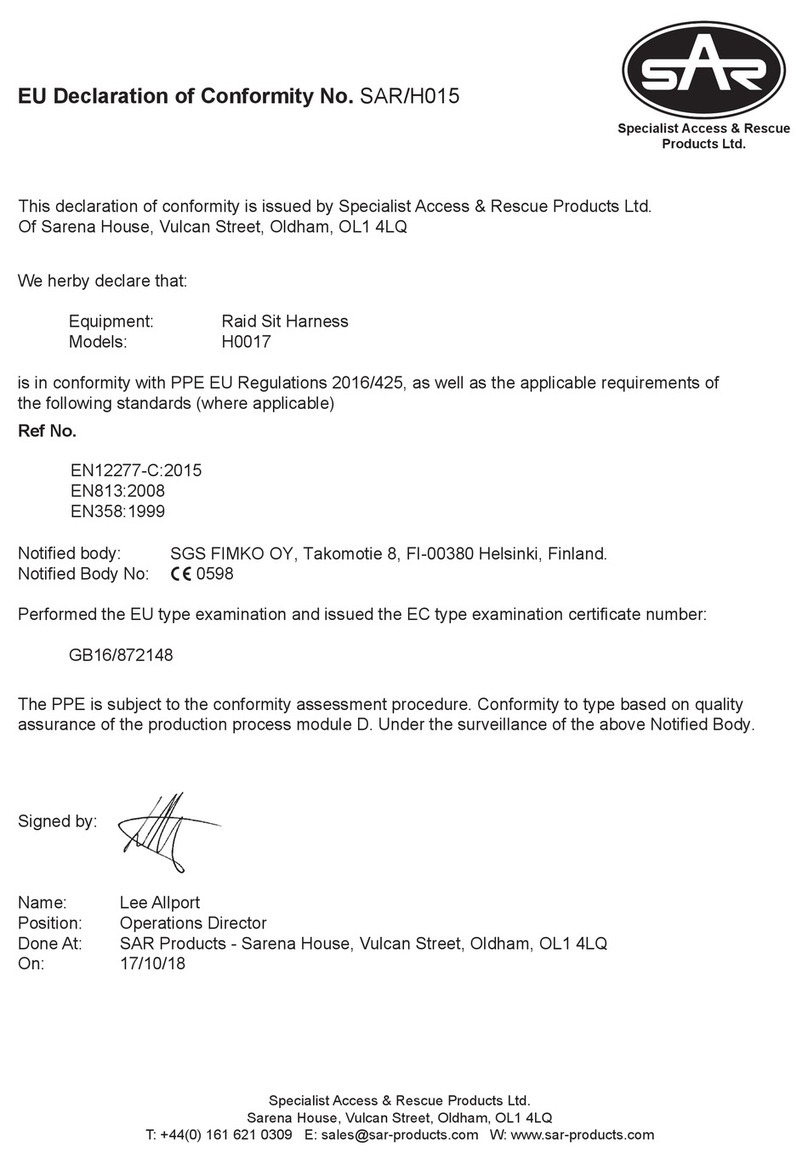

Approved Body UKCA

SGS United Kingdom Limited

Rossmore Business Park, Ellesmere Port, Cheshire, CH65 3EN

Approved Body No: 0120

Notified Body

SGS FIMKO OY, Takomotie 8, FI-00380 Helsinki, Finland.

Notified Body No: 0598

Specications

• Fully adjustable waist and legs

• Wrap around or step in fitting

• Well-established, easy interlocking buckling system or QC

• Laminated, high quality, sandwiched closed cell foam padding

• High quality polyester webbing, with hidden locking stitch

• Reinforced, catch free gear loops

• Working Load Limit: 150kg

Standard Sizing:

• Waist Size: 74cm to 120cm

• Leg/Thigh Size: 42cm to 70cm

• Weight Approx.: Std Hawk = 814g

It is essential for the safety of the user that if the product is re-sold outside the original

country of destination the reseller shall provide instructions for use, for maintenance,

for periodic examination and for repair in the language of the country in which the

product is to be used.

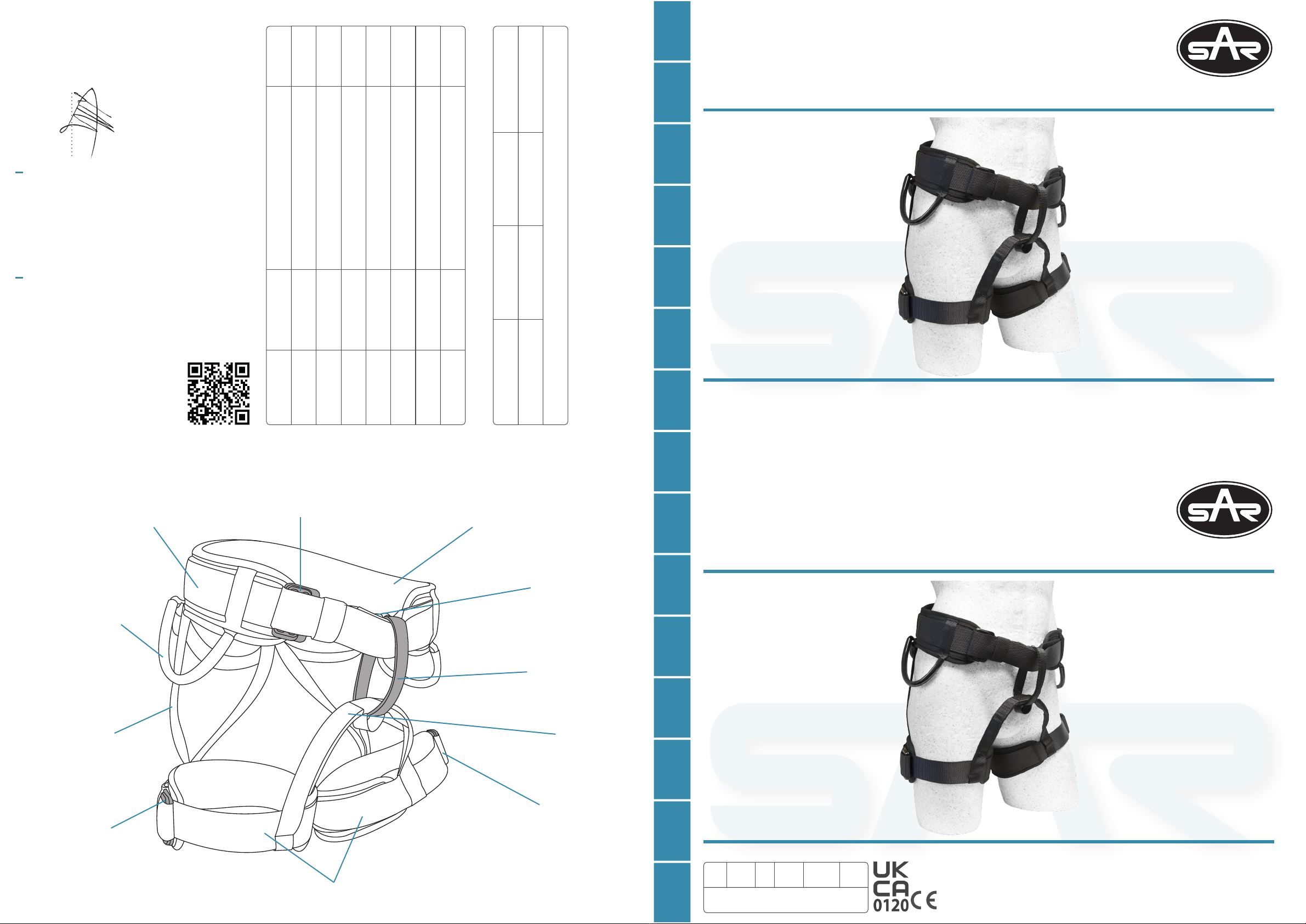

Fitting Instructions

Note: the following instructions are to fit the harness as it was designed so that

chemicals or mud etc. would not soil it from your footwear. However you can still fit the

harness as a step in type without disconnecting the waist and leg buckles by stepping

into the harness and adjusting the buckles.

1. Open the harness out and check there are no twists and it is following the lines of its

design.

2. Place around waist and hold in position on waist using your inner arms/elbows. Fig: 1.

3. Bend forward and pull belay loop up through your legs using your right hand still

holding waist in position. Fig. 2.

4. Position belay loop over waist belt buckle and fit into position around belt using clip

buckle. Figs. 3

5. Fit waist buckle as shown in Figs. A-D/E-G. Centralising position of belay to your body

and adjusting to fit comfortably on waist. Fig. 4.

6. Fit each leg firmly around upper thigh and lock. Fig. 5.

7. Once the harness is fitted check all is correct and there are no twists, all buckles are

locked correct and secured back through elastic tidies, the belay loop is around waist

belt and waist pad and belay loop are central. Figs. 6.

IMPORTANT:

Ask a partner to do a BUDDY check on your harness, equipment and set systems prior

to use.

Tying into the belt and crutch system using a figure of 8 knot.

WARNING: No other part of the harness should be tied into.

Fig. 1 Fig. 2

Fig. 3 Fig. 4

Fig. 5 Fig. 6

Fig A

Standard Buckles QC Buckles

Fig B

Fig C

Fig E

Fig F

Fig G

Fig D