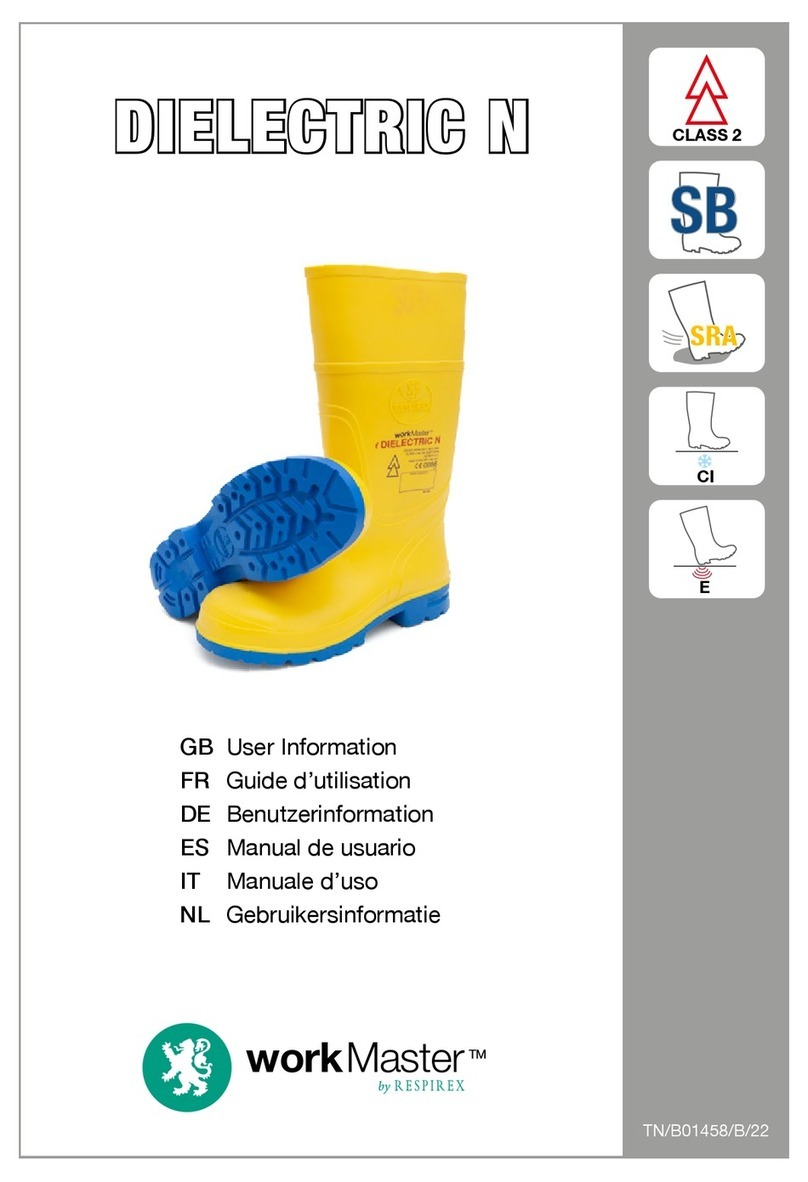

EN DIELECTRIC COMPACT OVERBOOT – USER INFORMATION

The safety footwear supplied by Respirex International Ltd complies with the PPE Regulation

(EU) 2016/425 requirements according to the European harmonized standard EN ISO 20347:2012. The

electrical properties of the footwear complies with EN 50321-1:2018 Class 2 AC (complete boot).

Module B certicate issued by SGS FIMKO OY, Takomotie 8, 00380 Helsinki, Finland.

In addition, the Dielectric overboot has been tested to the electrical requirements of ASTM F1117-03

and will withstand 20,000 Volts for 3 minutes on the complete boot, showing no leakage in excess of

18 milliamps at 20 kV with a normal safety boot worn inside. Specication is designed to reduce the

risk of interference with the heartbeat by electrical current passing through the wearer.

Workmaster™ Dielectric Compact Overboots protect against a working Voltage of 17 kV AC by

minimizing the leakage below 18 milliamps at the test voltage of 20 kV.

Footwear is manufactured using materials which conform to the relevant sections of EN ISO

20347:2012 for quality, performance, for Ergonomic features mechanical properties and slip resistance.

Marking denotes that the footwear is licensed according to PPE regulation as follows:

• Manufacturer - See sole (including post code and country of origin)

• CE 2797- See upper - Notied Body responsible for Module D BSI Group The Netherlands B.V. Say

Building, John M. Keynesplein 9, 1066 EP, Amsterdam, Netherlands

• EN ISO 20347:2012 - See upper; number of European standard

• EN 50321-1:2018 - See upper; number of insulating footwear standard

• OB - See upper; OB denotes the boot meets the basic requirements of EN ISO 20347:2012 for all-

polymeric (i.e. entirely moulded) footwear

• FO - See upper; classication ‘FO’ denotes outsole resistant to fuel oil

• SRC - See upper; denotes that the boot passes the slip resistance requirements for a ceramic tile

oor with sodium lauryl sulphate and Glycerol on Stainless Steel

• Double red triangle – See upper; suitable for Live Working

• Class 2 AC- See upper; means suitable for working up to 17 kV AC

• Class 2 DC- (if present) See upper; indicates additional DC testing, suitable for working up to 17 kV DC

• Rectangular box marked Inspection Data - See upper; the date of rst use should be written in this

box. One year after this date the boots should be electrically retested to EN 50321-1:2018.

• Size - See Sole; Medium (sizes 6 - 8 UK, 39 - 42 EU), Large (sizes 9 - 11 UK, 43 - 45 EU), X-Large

(sizes 12 - 14 UK, 46 - 48 EU)

• Date of Manufacture - See upper; Week and Year

It is important that the footwear selected is suitable for the protection required and the working

environment. The suitability of the boots for a particular task can only be established once a full risk-

assessment has been carried out.

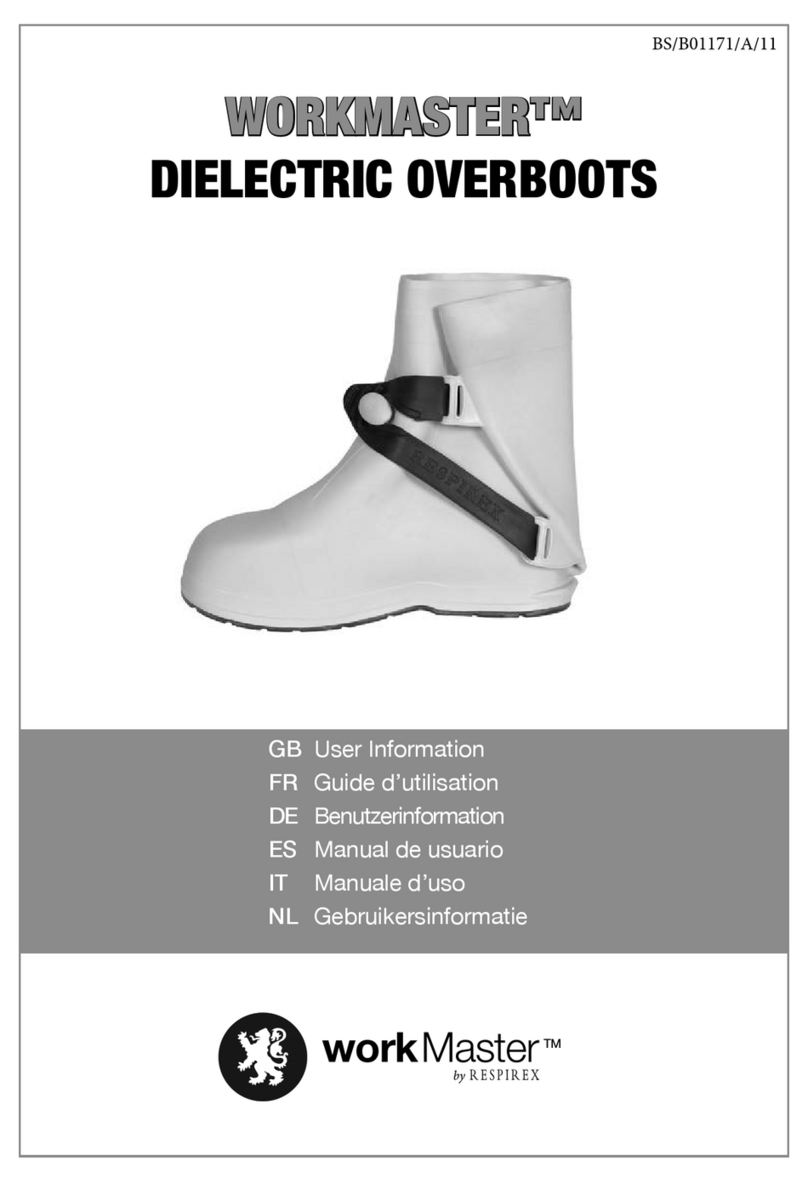

FITTING AND REMOVAL

Like all Personal Protective Equipment, Dielectric Compact-Overboots must be checked for damage

before use. Dielectric overboots are designed to be worn over a pair of non-conductive and non-anti-

static safety shoes or trainersthat conform to EN ISO 20345. To put on the overboots, unhook the

eyelet securing strap from the button located near the front of each boot.The top of the overboots will

now open out sufciently to allow the wearer’s safety shoes to be easily slid inside. Once the wearer’s

safety boots are fully inside the overboots, the securing straps should be folded back and hooked over

the button. The overboots can be removed by unfastening the securing strap and using the kick-off lug

located at the heel.