Sargent ASSA ABLOY 10 Series User manual

Other Sargent Lock manuals

Sargent

Sargent ASSA ABLOY IDP-H1 User manual

Sargent

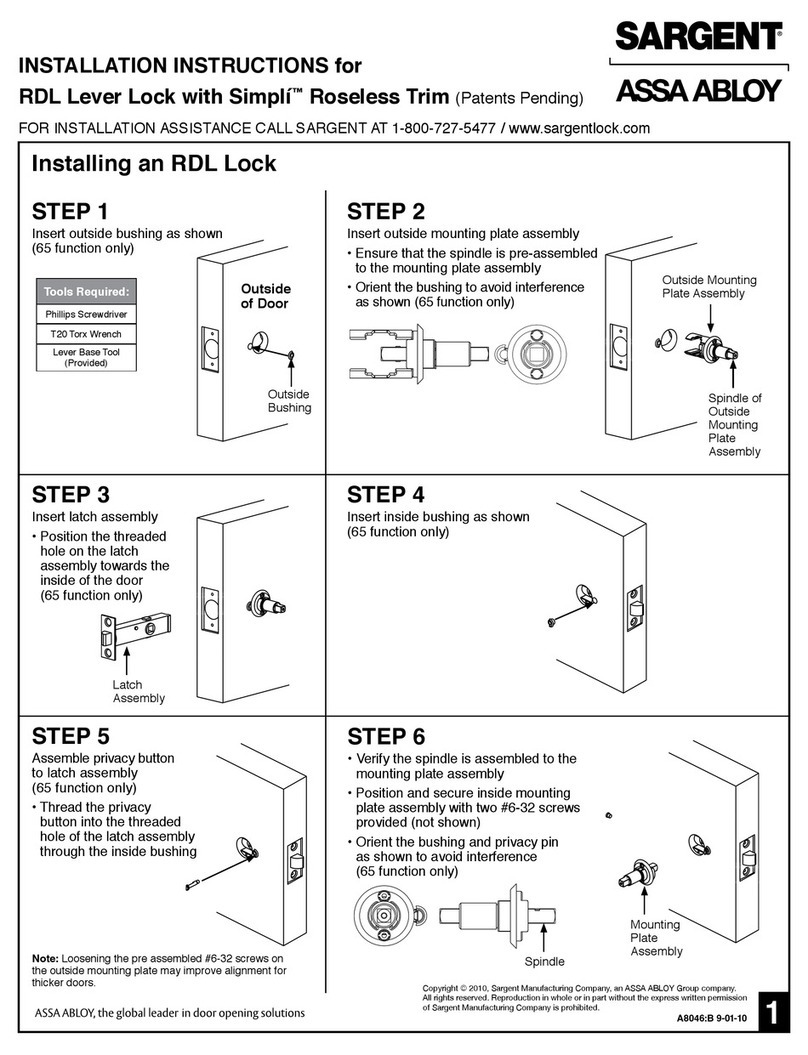

Sargent RDL User manual

Sargent

Sargent EK Exit Device Retrofit Kit User manual

Sargent

Sargent ASSA ABLOY Harmony Series User manual

Sargent

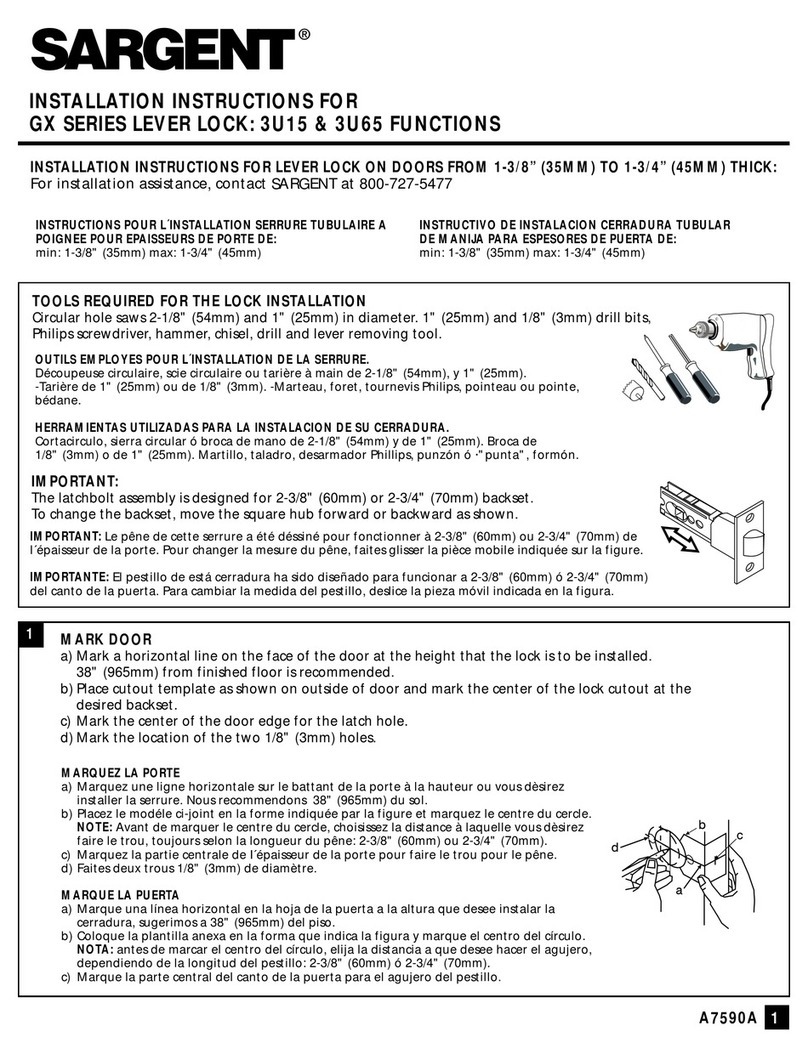

Sargent GX Series User manual

Sargent

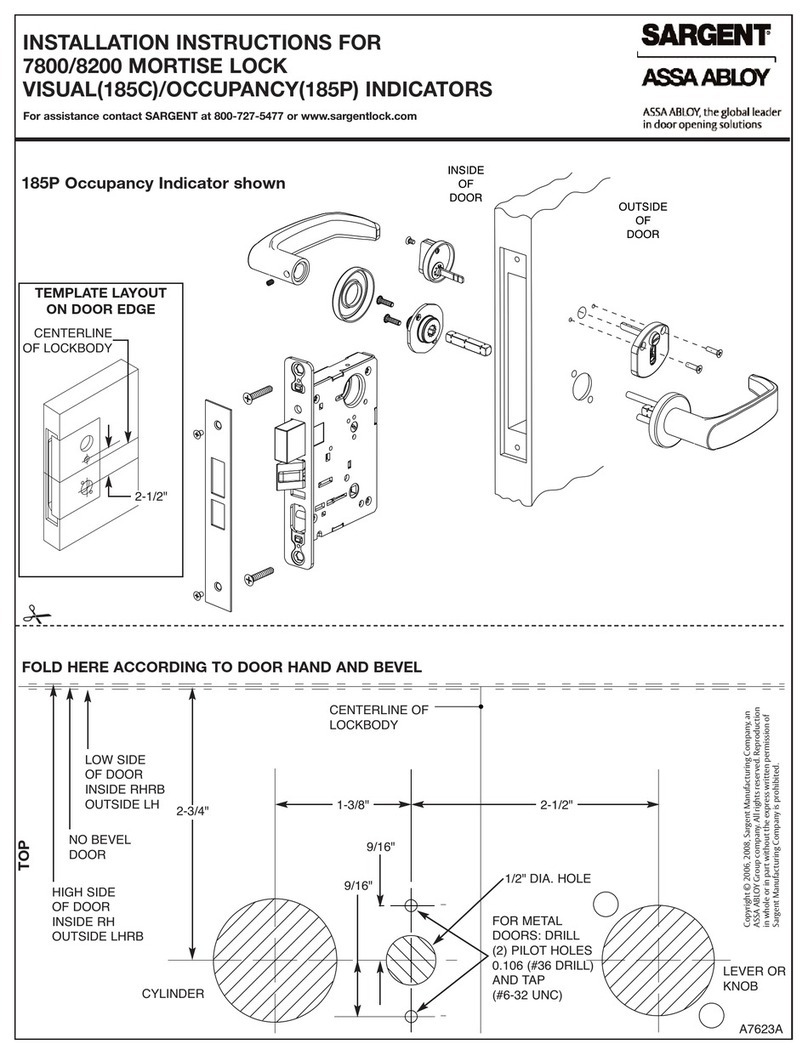

Sargent 7800 User manual

Sargent

Sargent Profile Series v.S2 User manual

Sargent

Sargent H1 User manual

Sargent

Sargent IN100 User manual

Sargent

Sargent v.G1.5 User manual

Sargent

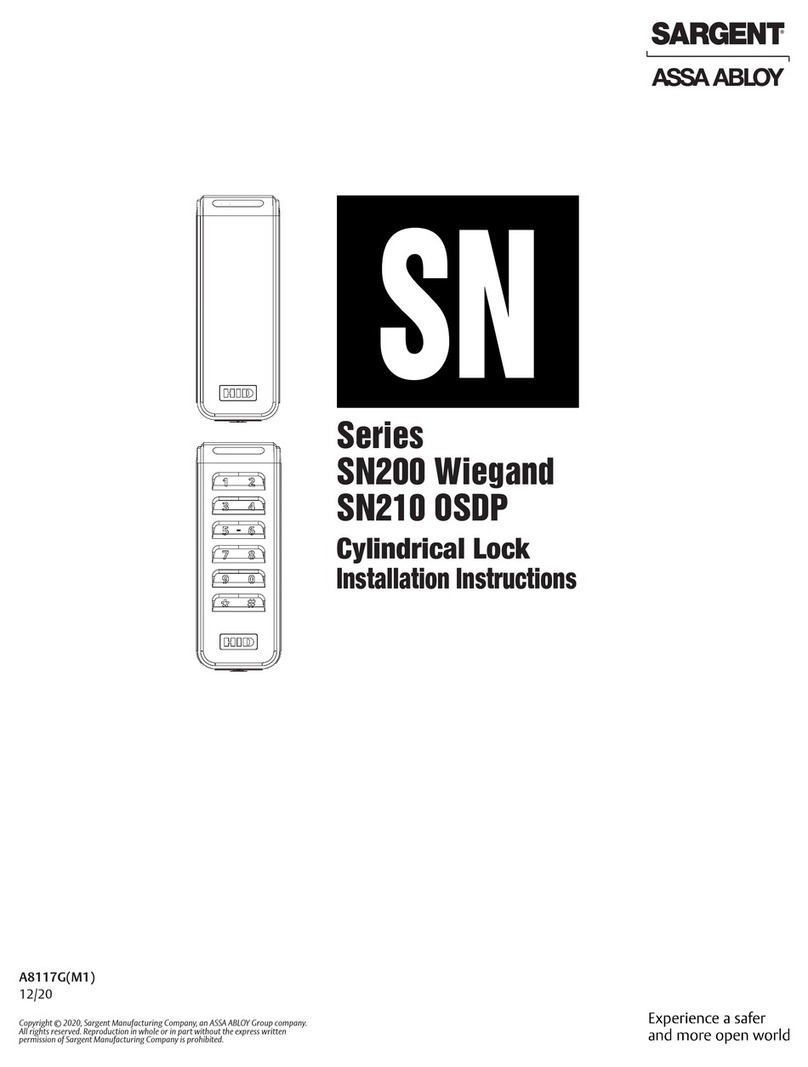

Sargent ASSA ABLOY SN Series User manual

Sargent

Sargent Profile Series User manual

Sargent

Sargent ASSA ABLOY FM7100 Series User manual

Sargent

Sargent Assa Abloy IN120 User manual

Sargent

Sargent IN100 User manual

Sargent

Sargent ASSA ABLOY SE LP10 User manual

Sargent

Sargent ASSA ABLOY PR100 User manual

Sargent

Sargent IN220 Service manual

Sargent

Sargent 7800 User manual

Sargent

Sargent IN220 User manual

Popular Lock manuals by other brands

Auslock

Auslock T11 user manual

Stealth SAFES

Stealth SAFES ShadowVault Instructions & Troubleshooting

Knox

Knox KeySecure 5 Admin & user guide

Kwikset

Kwikset 48334/01 Quick installation guide

Metra Electronics

Metra Electronics Door Access Terminal Combo Technical manual

Kilitronik

Kilitronik miniK10m operating manual