Contents

Contents....................................2

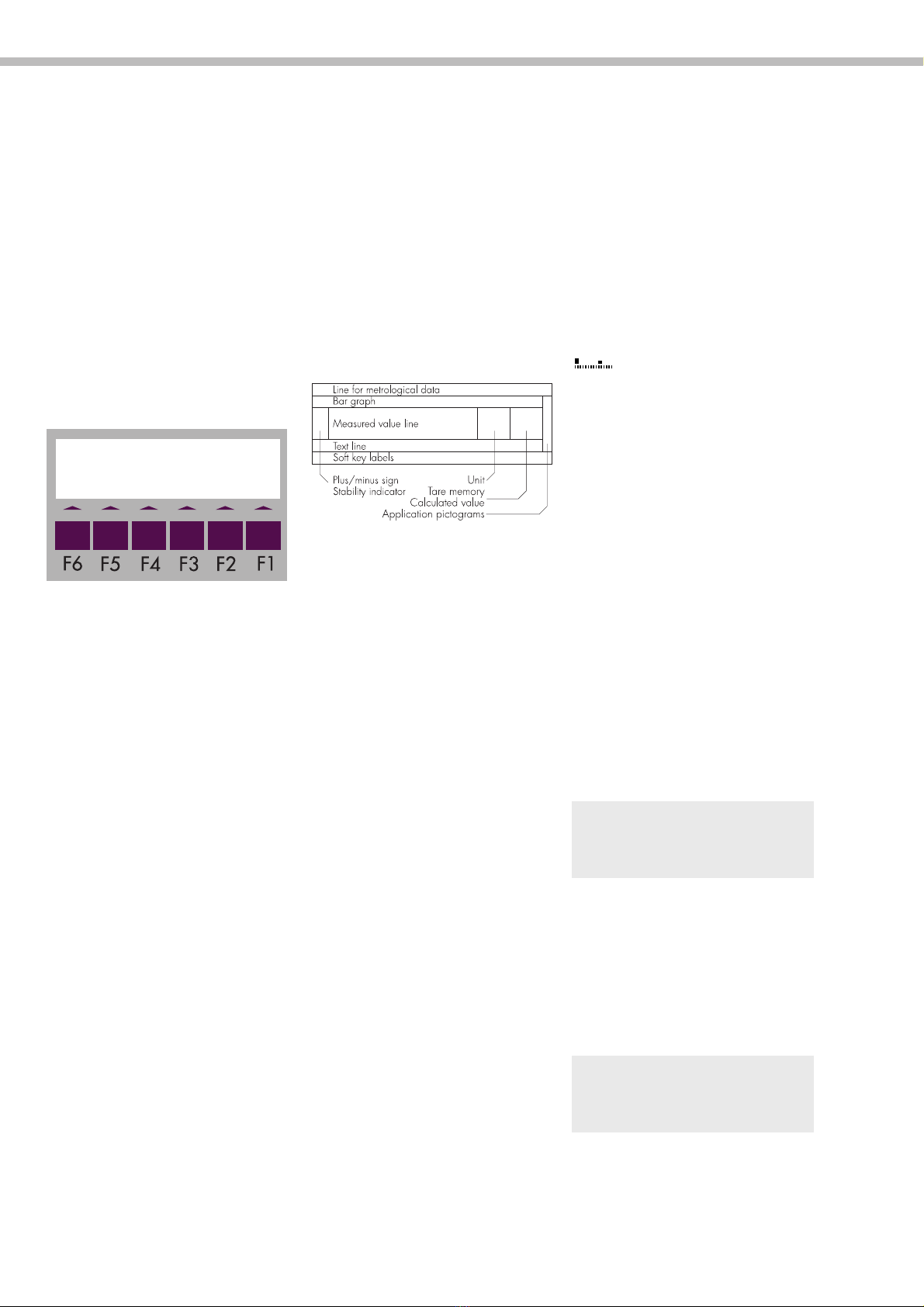

Operating Design ......................3

Configuring the Scale

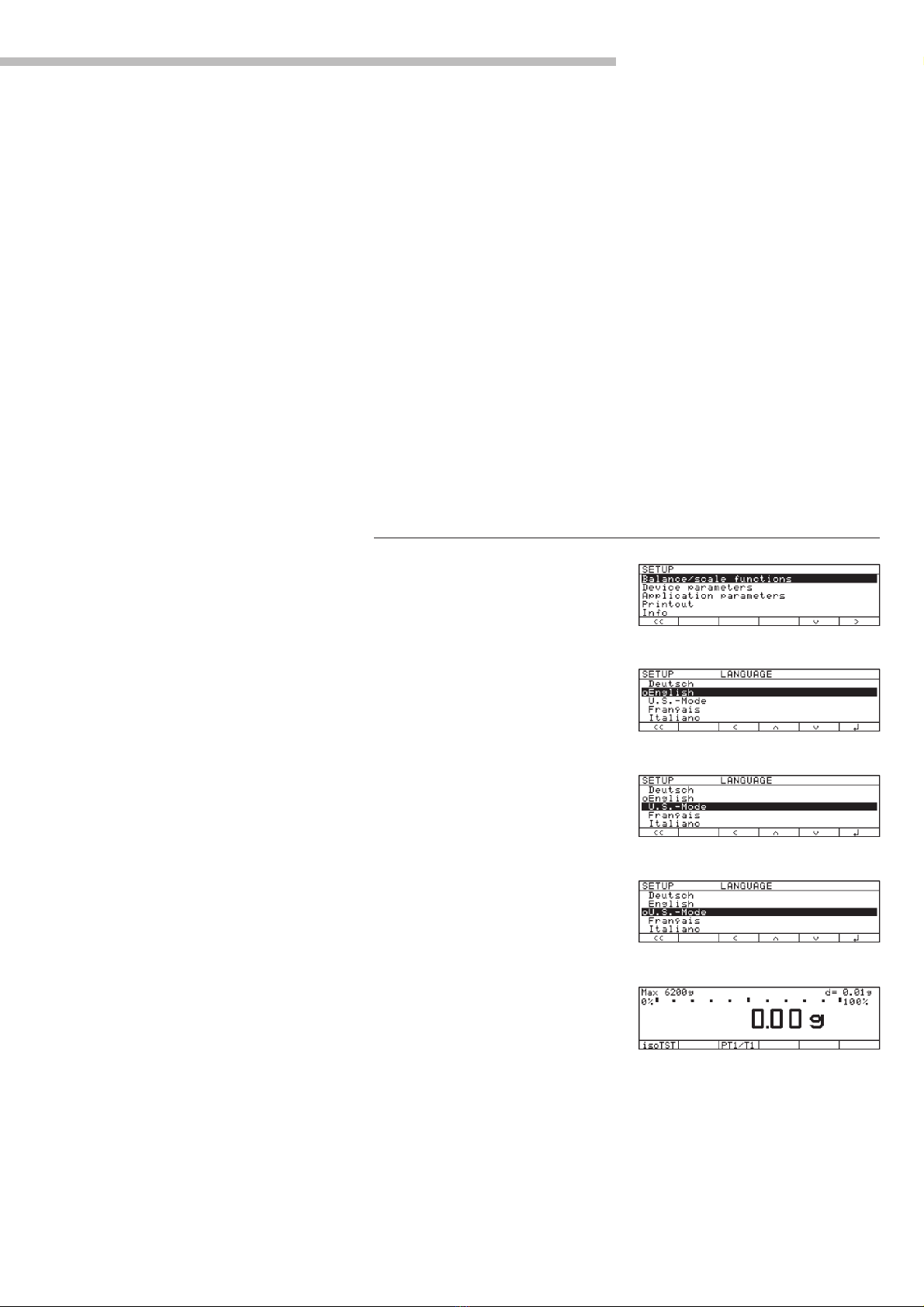

Setting the Language..................7

Navigating in the Setup Menu ....8

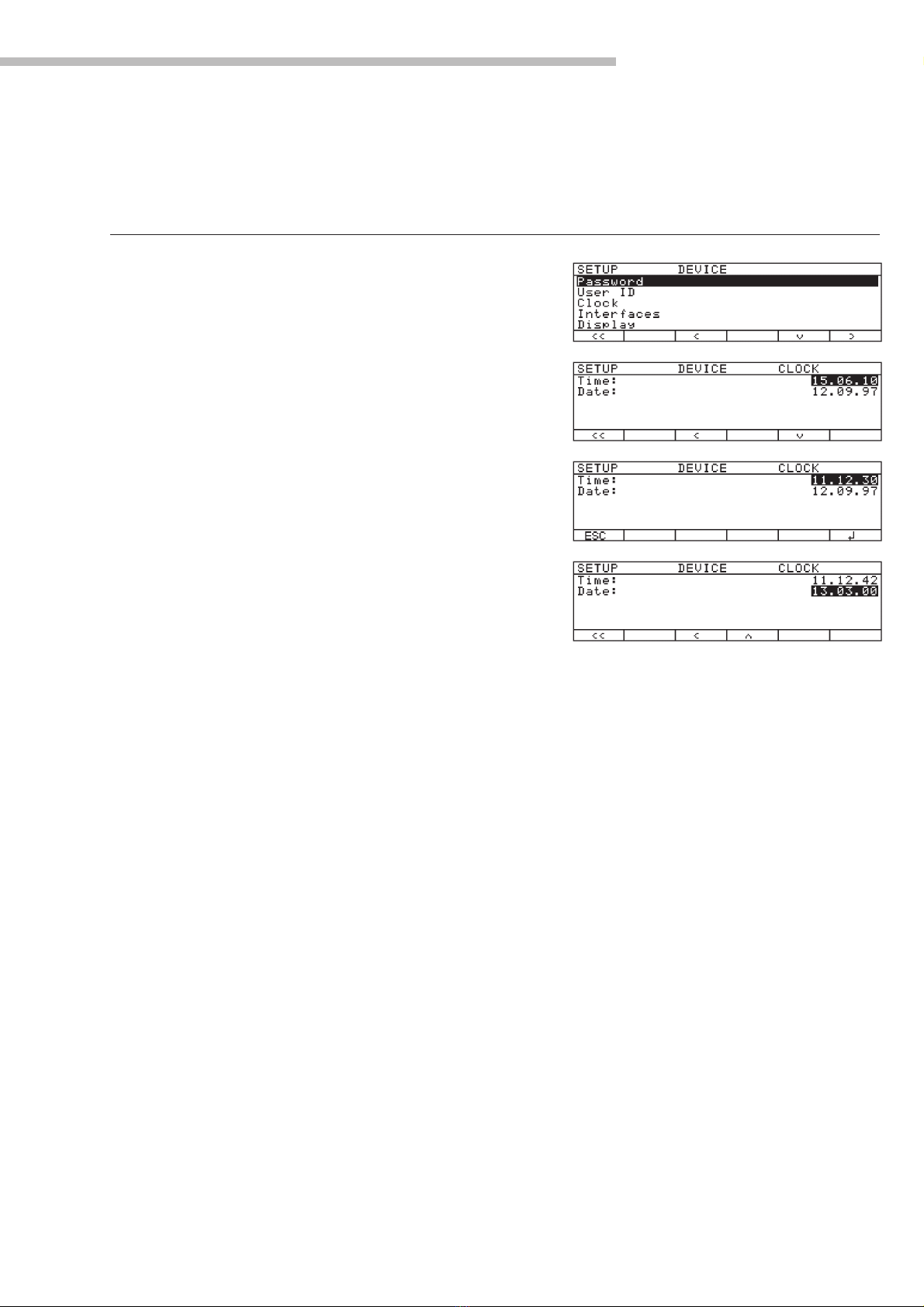

Entering the Time and Date ........ 9

Setting the Scale Functions ........10

Setting the Device Parameters ....13

Entering a Password ..............13

Setting the Application

Parameters ............................17

Selecting the Printout Function.... 25

Configured Printout ................27

Generate FlexPrint ................30

Displaying Info........................32

Device Information ................32

FlexPrint Information ..............32

MP8 Interface Emulation ..........33

Factory Settings ......................33

Operating the Scale

Basic Weighing Function ..........35

Device Parameters ..................38

Calibration, Adjustment ............40

Application Programs ..............47

Toggle between

Two Weight Units ..................48

Counting ............................50

Weighing in Percent ..............53

Animal Weighing ..................57

Recalculation ........................61

Calculation ..........................66

Differential Weighing ............69

Checkweighing ....................81

Time-Controlled Functions ...... 86

Totalizing ............................ 89

Formulation ........................ 93

Statistics.............................. 97

Extra Functions .................... 102

Second Tare Memory ..........102

Individual Identification

Codes ..............................104

Saving Values Manually

in M+ ..............................108

Product Data Memory ..........109

Combining Applications ........ 112

Practical Combination of Several

Applications (Example) .......... 114

Data Output Functions .......... 116

Interface Port .................... 119

Pin Assignment Charts ........ 130

Cabling Diagram ................131

Service..................................136

A/D Converter Configuration ..136

Activating the Service Mode ....141

Calibration/Adjustment in the

Service Mode ......................141

Set/Delete Preload ................143

Replacing the PCB ................144

SBI/BPI Toggling ..................145

Replacing Fuses on the PCB ....145

Error Codes and Messages ......146

Overview

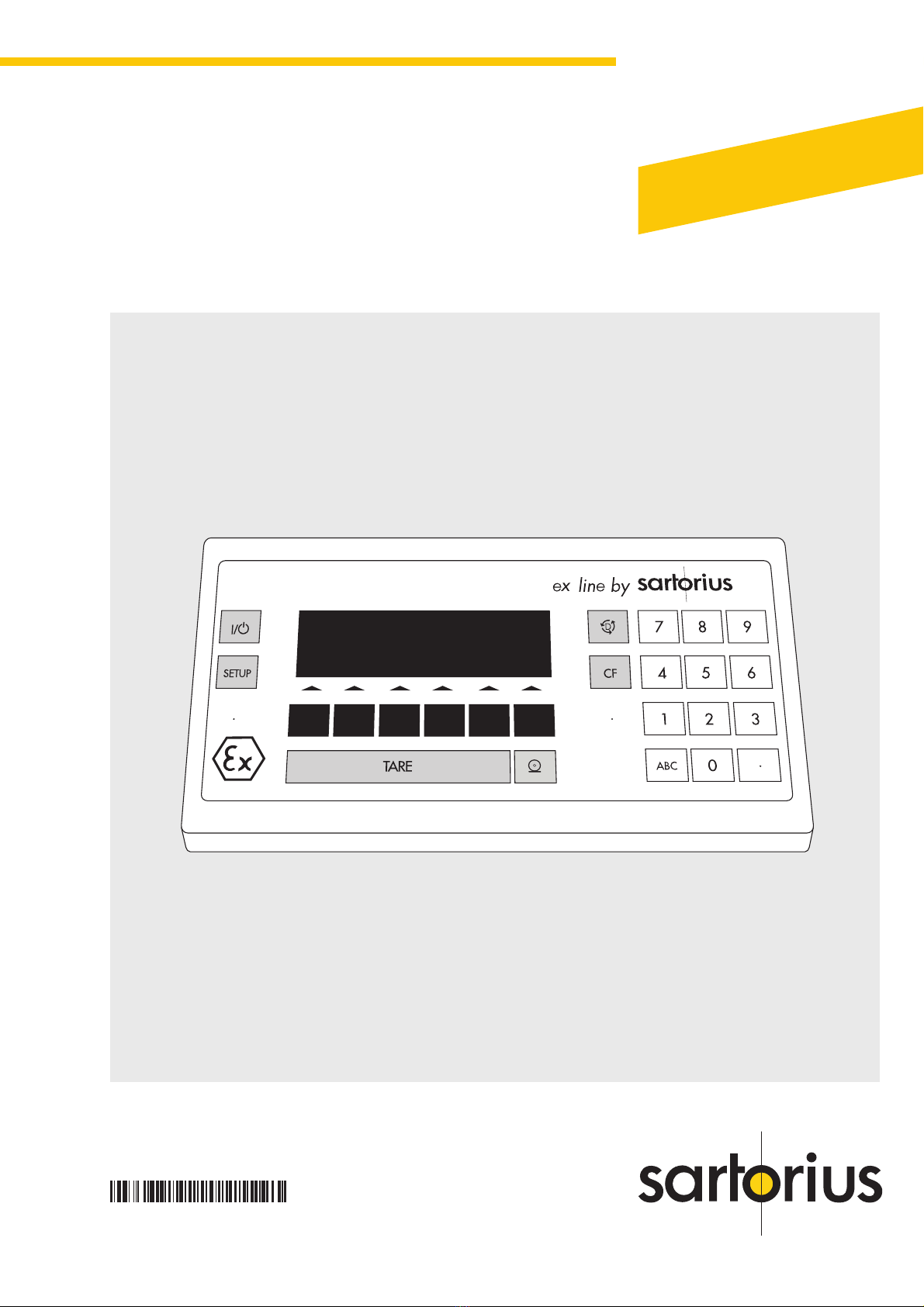

General View of the Terminal ..150

Specifications ......................151

Dimensions (Terminal Drawings)152

Accessories (Options) ............153

EC Type Examination

Certificates ..........................155

CMarking ........................170

Plates and Markings ..............171

Notes on Checking Verification

..172

Index ..................................173

Appendix

Entering the General Password

Symbols

The following symbols are used in

these instructions:

§indicates steps you must perform

$indicates steps you must perform

only under certain conditions

> describes what happens after you

have performed a certain step

– precedes an item in a list

!indicates a hazard

Note Concerning Verified Scales

Approved for Use as Legal

Measuring Instruments in the EU*:

The notes in this manual that refer to

scales verified for use in legal

metrology apply only if the scale has

been approved for verification. For

more information, contact your local

Sartorius office or dealer.

* including the Signatories of the

Agreement on the European

Economic Area

For technical advice on applications

Phone (in Germany):

+ 49 (0551) 308-4440

Fax (in Germany):

+ 49 (0551) 308-3791

2