3 APPROVED April 18

1Contents

2INTRODUCTION........................................................................................................................... 5

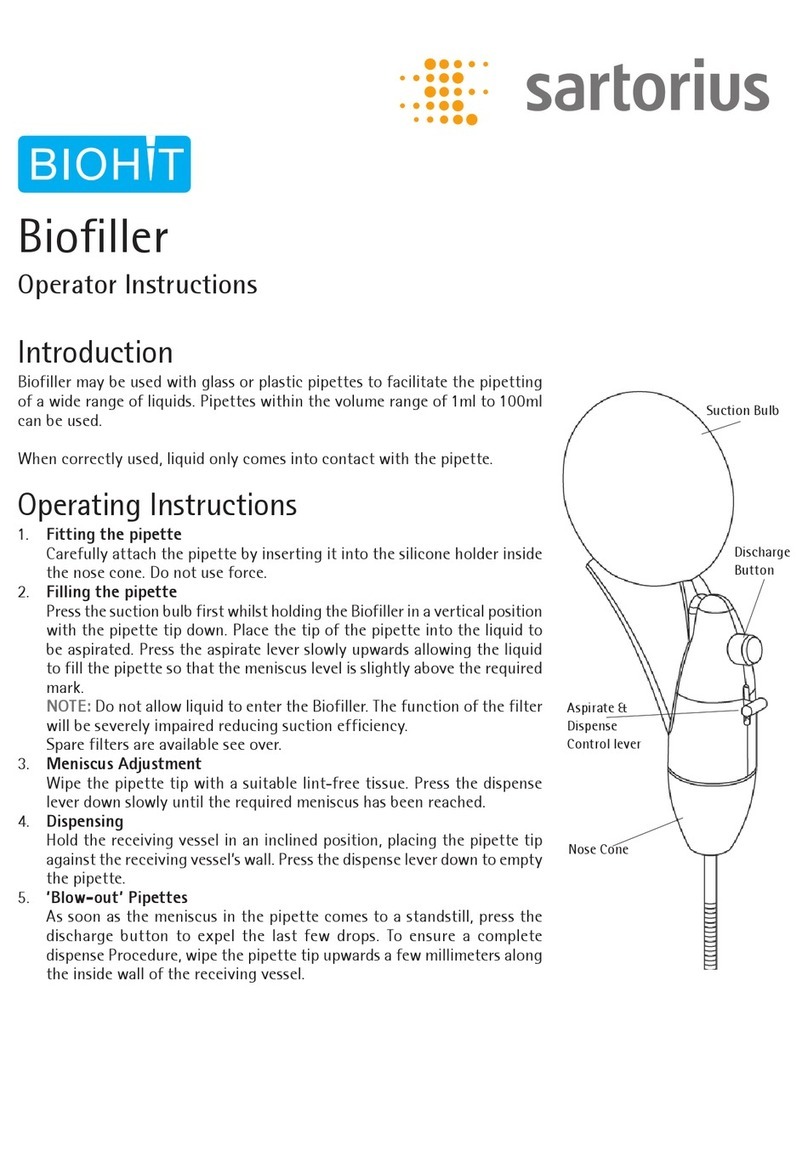

3BASICS OF LIQUID HANDLING ...................................................................................................... 6

4RLINE TERMINOLOGY .................................................................................................................. 8

Step........................................................................................................................................8

Address...................................................................................................................................8

Position ..................................................................................................................................8

Drive cycle..............................................................................................................................9

Level sensing, LS.....................................................................................................................9

5TECHNICAL SPECIFICATIONS ...................................................................................................... 10

Liquid handling specifications..............................................................................................10

Aspirating and dispensing speeds ........................................................................................10

Repeatability ........................................................................................................................11

Mechanical...........................................................................................................................12

Electrical specifications........................................................................................................14

Serial communication ..........................................................................................................14

Cable connector ...................................................................................................................14

Liquid level detection (LS models only)................................................................................15

6MESSAGING AND INITIALIZATION.............................................................................................. 16

Non configurable settings....................................................................................................16

Messaging ............................................................................................................................17

Communicating with the module ........................................................................................18

Configuration commands.....................................................................................................19

Initialization commands.......................................................................................................20

Drive commands...................................................................................................................21

Status commands.................................................................................................................22

7ERROR HANDLING..................................................................................................................... 24

8MAINTENANCE ......................................................................................................................... 25

9TROUBLESHOOTING .................................................................................................................. 25