Edition du 24/02/09 / 17 U508218-e Revision : 2

3. PERIODIC INSPECTION

3.1. GENERAL.

The Meter Register is fully lubricated and properly

adjusted at manufacture. However, periodic

cleaning a}\d lubrication are required.

Judgement of the intervals at which the meter

register requires such service must necessarily be

left to the individual user due to varying conditions

of service. Under normal conditions, this will be at

least once a year, or after each 2-1/2 million units of

measure delivered, whichever comes first.

3.2. DISASSEMBLY PRIOR TO CLEANING.

Remove the meter register from its housing as

follows:

1. Remove the bolts securing the cover (if present)

to the top of the housing. These bolts are hex head

and are located at the four corners of the bottom of

the housing. Remove the cover.

2. Remove the three button-head bolts securing the

meter register to the housing. Remove the meter

register.

3. Remove the screws securing the gear plate to the

bottom of the housing. Remove the gear plate.

3.3. CLEANING.

CAUTION: DO NOT USE A WIRE BRUSH.

1. Wipe bezel crystal with a clean lint-free rag.

2. If the wheel faces are dirty, gently clean with a

clean lint-free rag dipped in mild soapy water.

3. Clean the gears on the base plate by flushing or

with a brush dipped in solvent. Blow dry with

compressed air.

4. Clean Housing by dipping, flushing or brushing

with solvent. Blow dry with compressed air.

3.4. INSPECTION.

A periodic inspection of the en tire meter register,

housing and gear plate is required to make sure that

they function properly, parts are in place, and no

binding or excessive side-to-side motion of shafts

occurs. A checklist on such procedures follows:

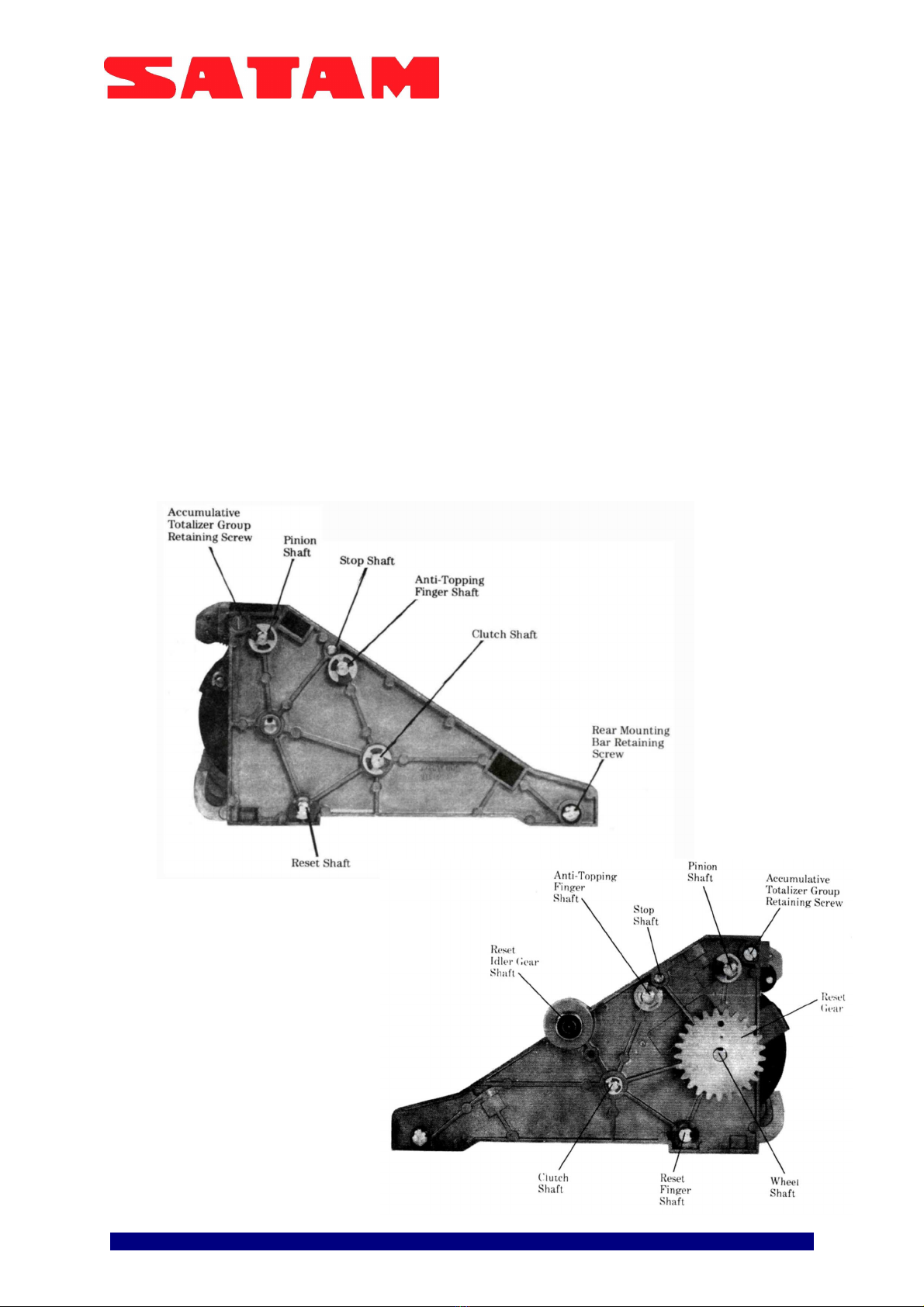

1. Check the following shafts for perceptible side-to-

side motion.

Note: Remove the meter register from the housing

before checking shaft freedom.

a. Wheel Shaft

b. Anti-Topping Finger Group Shaft

c. Reset Finger Group Shaft

d. Clutch Group Shaft

e. Pinion Shaft

2. Temporarily install the base plate and meter

register in the housing and check for proper

engagement and freedom of movement of:

a. AlI gears on gear plate.

b. Output bevel gear on gear plate with the bevel

drive gear on drive shaft.

c. 57 tooth gear on clutch assembly with gear on

right wheel assembly.

d. Gear drive shaft with gear train that operates the

totalizer, and gear connecting the drive train to the

totalizer.

3. Rotate drive shaft by hand to see that unit

operates freely and then reset, checking for proper

reset and shutter action. Adjust pointer alter reset as

required.

4. Check ail screws, retaining rings and groove pins

to see that they are tight and seated properly.

3.5. LUBRICATION.

1. Recommended Lubricants

Note: Chemlube and Vischem products are

manufactured by Ultrachem Inc.,

1400 N. Walnut St., P.O. Box 2053

Wilmington, DE 19899

Oil: Chemlube 201 or equivalent with a temperature

range of -65°F to +275°F (-54°C to + 135°C).

Grease: Vischem 352 or equivalent with a

temperature range of -65°F to +3000F (-MOC to +

149°C).

Note: All lubricants used in the register must be of a

type which remains fluid over the full temperature

range to which the register will be subjected. Also,

they should not oxidize or dry out leaving a gummy

or perceptible residue.

If the Chemlube 201 oil lubricant is not available, a

substitute with equivalent properties may be used.

To assist field personnel in obtaining suitable

lubricants for the meter register and ticket printers,

the following list showing equivalent lubricants has

been prepared: OIL

AEROSHELL FLUID NO. 3

REGENT SPINTEX OIL 60

GARGOYLE ARCTIC OIL LIGHT

CASTROL HYSPIN 40

ANDEROL 40lD

GREASE

AEROSHELL 14

ESSO BEACON 325

ANDEROL 795

2. Points to Lubricate

Oil: Ali points indicated as "Oil" on Figure 6 should

be lubricated with oil as described above. This

includes ail shafts, studs, and bosses on which a

moving part bears.

Grease: Grease should be applied to ail points

indicated as "Grease" on Figure 6. This includes

gears and the no-back ratchet and pinion.

Note: The oil and grease should be applied with a

small brush to make certain that ail areas will be

properly lubricated. In this manner, the amount of

lubricant being used will be more easily controlled.