Edition du 24/02/09 / 12 U508217-e Revision : 24

SECTION 2. DESCRIPTION

A. GENERAL

1. The Series 7889 Meter Preset is used in fluid flow

applications where it is desired to close a valve after a

predetermined amount of liquid has passed through.

2. In technical terms, the Preset is a non-repeating,

predetermining counter that is driven by and normally

mounted on a flow meter. It has a two-stage output

that is normally used to close a valve in two stages.

3. The Preset is used in combination with other

Veeder-Root meter accessories.

B. SPECIFICATIONS.

1. Input. The Preset is driven by a rotating shaft from a

customer-supplied flow meter. The type of input

coupling should be specified when ordering. Maximum

torque to drive the Preset through a knockoff is 40

ounces per inch. Average running torque is below 4

ounces per inch.

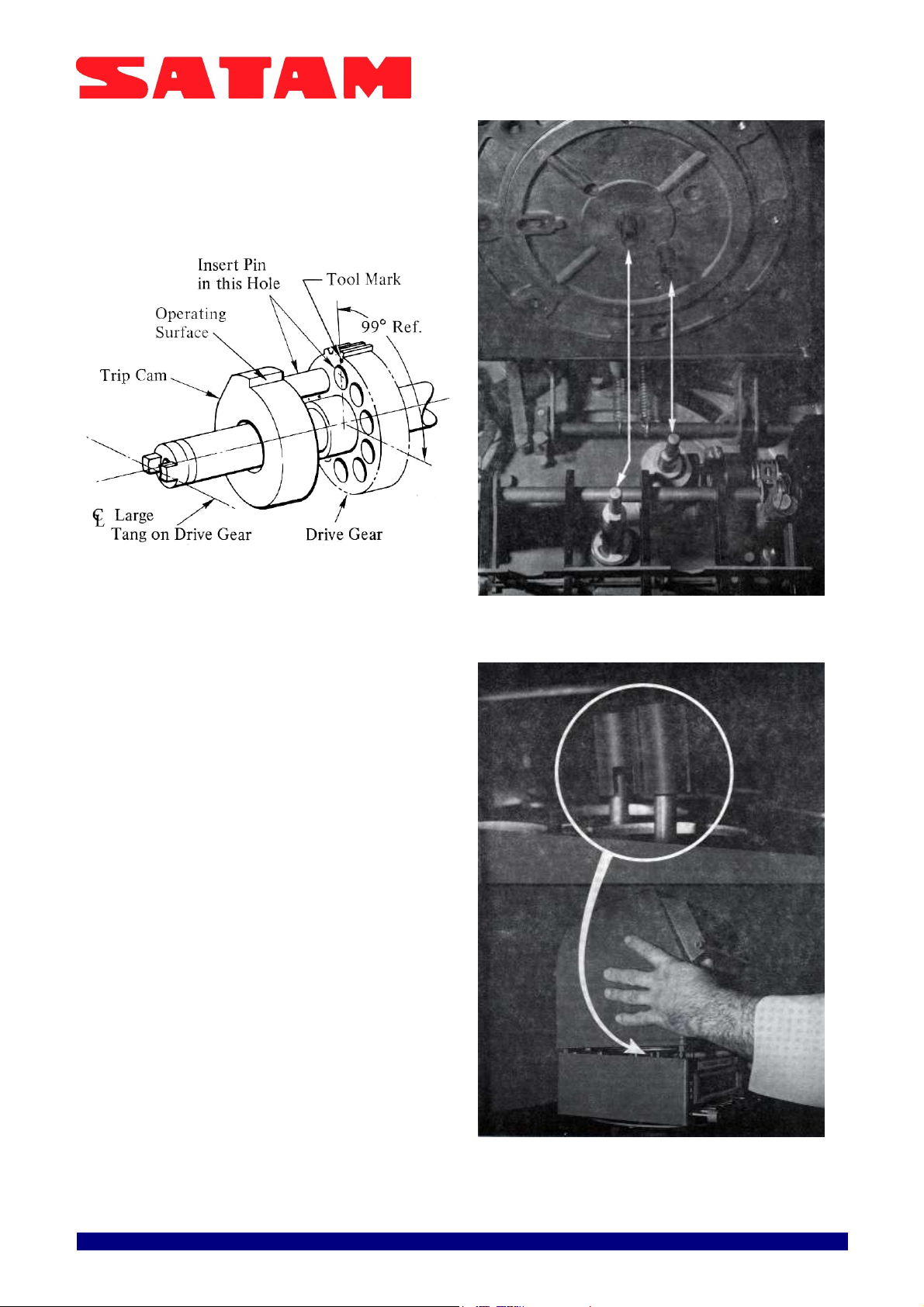

2. Mounting. See Figure 1. There are eight tapped

mounting holes for use with ¼-28 screws. The Preset

is designed to mount directly on a.

3. Valve and Switch Connections. The Preset can be

connected to a two-stage valve by customer supplied,

direct linkage or by an electrical switch with linkage.

Either linkage connects to a rotating knockoff plate on

the bottom of the Preset case with a 114-28 screw

(Figure 1). The rated first-stage valve load is 60

pounds.

4. Outline Dimensions. See Figure 1.

5. Flow Rate. The maximum speed of the right-hand

wheel (least significant digit) is 250 rpm. With a 1:1

ratio between the input and the right-hand wheel, the

maxi- mum input speed would also be 250 rpm. If one

revolution of the right-hand wheel represents 10

gallons, the maxi- mum flow rate would be 2500

gallons per minute. Gear plates are available to

provide various ratios of input revolutions of the right-

hand wheel.

6. Preset Number. 4 or 5 digits. Preset in additive

direction by individually actuating five preset buttons

(maximum preset capacity 99999)

7. Display. 4 or 5 wheels with ½ inch white digits on

black background.

8. Output (Knockoff). Two-stage knockoff. Unit

counts down from preset number. First stage knockoff

point is set at the factory to customer's specification at

90, 80, 70, 60, 50, 40, 30, 20, 10, 9, 8, 7, 6, 5,4, or 3.

An option al three-finger rake provides first stage

knockoff at a number between 900 through 100 in

increments of 100. The setting can be internally

changed by the customer in the field. Second (final

stage) knockoff occurs when aIl wheels reach zero.

See Figure 1 for angular travel of knockoff plate.

9. Interlock. The Preset has a unique interlock feature.

The Preset buttons cannot be actuated until the SET

button is depressed (latched). The SET button cannot

be latched with the valve load applied. Therefore, the

preset number cannot be changed while fluid is

flowing.

WARNING: IF THE PRESET OPERATING HANDLE IS

MOUNTED IN THE 5 O'CLOCK POSITION, THE HANDLE

COULD STRlKE THE OPERATOR'S HAND WHEN

DEPRESSING THE EMERGENCY STOP BUTTON.

10. Emergency Stop. The STOP button will "dump"

both first and final stages of the valve to provide

complete shutdown.

11. Options. Presets are available with a Series 7856

explosion-proof switch for use with electrically

operated valves. The Preset can be integrally mounted

to a Veeder-Root Meter Register or to a Meter Register

with Ticket Printer.

Figure 1. Dimensions