Edition du 25/02/09 /18 U508219-e Revision : 26

1. Drive. The shaft, Figure 4, on the bottom of

the printer is driven by a bevel gear from a

meter register or other equipment. The

printer's bevel gear and shaft assembly turns

in a counterclockwise direction. The internal

bevel gear on the shaft drives the clutch

assembly, associated pinions and the gear

assembly of the right-hand print wheel.

2. Printing. ln printing operation, a ticket is

inserted into the slot of the ticket tray until it

bottoms on the internal stop.

a. As the printing knob is turned, the reset

drive gear, Figure 5, makes one complete

clockwise revolution until a positive stop is

reached. As the ticket tray moves into position,

by means of the tray actuating cam and gear,

the seal pin pierces the ticket, holding it in

place. This initial printing is made with wheels

as they were at the completion of the last

delivery.

b. At the completion of delivery, the knob is

turned in a clockwise direction one complete

turn until the stop is again reached. During this

cycle the second printing is made recording

the accumulative total of this delivery. At the

end of the print cycle, the ticket tray returns to

its original position and the seal pin releases

the ticket.

SECTION 3. PRINTER REMOVAL AND

INSTALLATION

A. REMOVAL.

Before maintenance, remove the printer from

the meter register as follows:

1. Break the seal and remove four bolts on the

bottom corners of the meter register.

2. Remove the screw from the center of the

printer knob and remove knob, shaft extension

and washers from the printer. Remove the

cover.

3. Remove the bolts securing the printer frame

to the meter register. Remove the printer.

B. INSTALLATION.

After maintenance, install the printer onto the

meter register as follows:

1. If the meter register is still in the case,

remove the three screws holding it and lift the

register from the case. Reset the register to

zero by turning the small gear at the left end of

the reset shaft counterclockwise.

2. Install printer knob and shaft extension on

printer and turn it until tray is in the outward

position and seal pin down. Remove printer

knob and shaft extension.

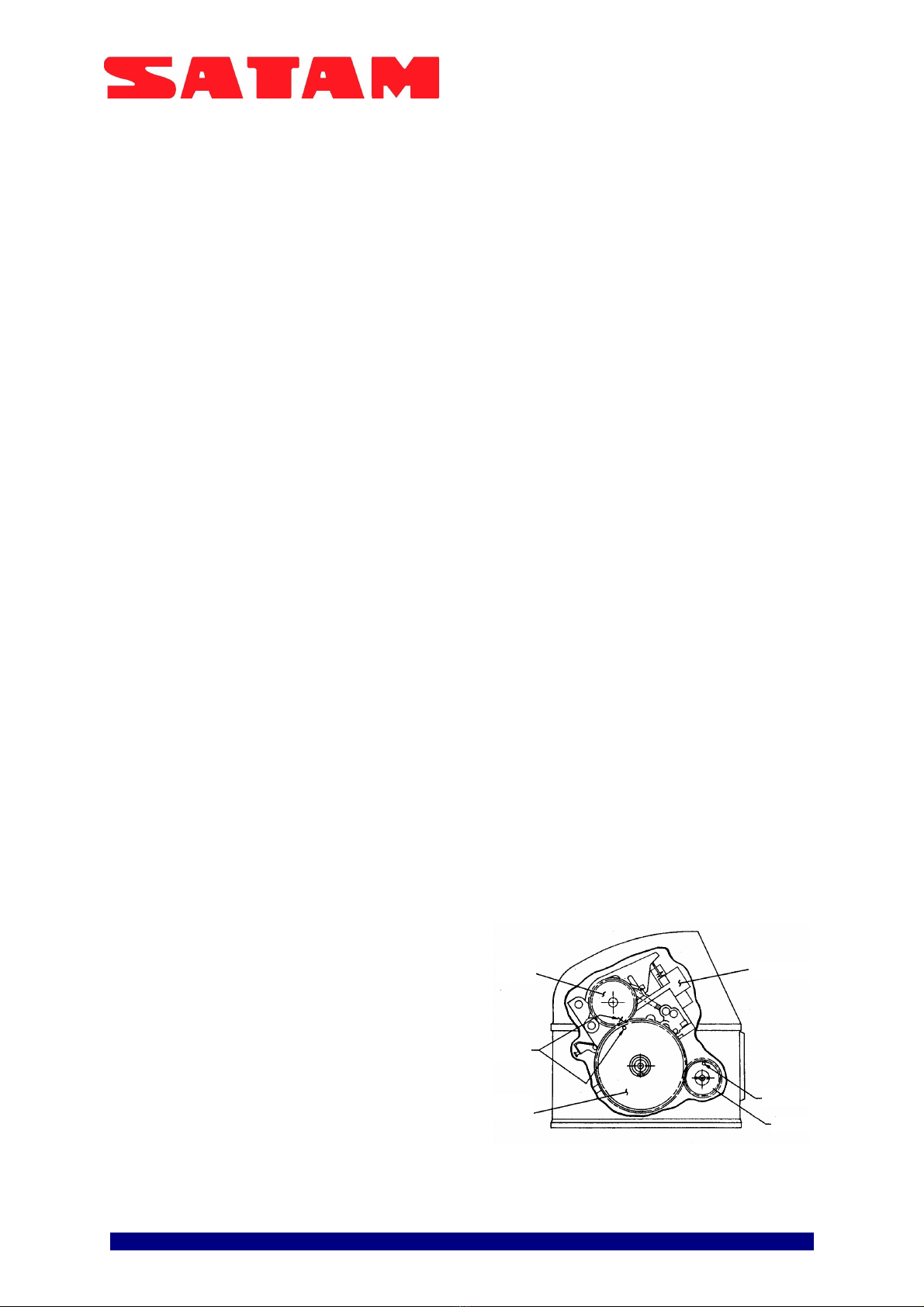

3. Rotate the large idler gear (B) so that the

timing marks on it and the printer gear (A)

align. See Figure 6. It may be necessary to

hold the idler gear in position until the printer is

mounted and the idler gear and print gear

engage.

4. Mount the printer onto the meter register

and secure with bolts.

5. Check the position of the timing marks on

the printer gear (A), idler gear (B) and register

gear (C). They must be in the position shown

in Figure 6.

6. Loosen the printer bevel gear set screw and

adjust for proper backlash between the printer

bevel gear and the meter register drive gear as

necessary (Figure 20).

7. Place assembly in register case and secure

with three screws.

8. install printer cover using four corner bolts

under the register.

9. install the large steel washer, then the

rubber washer on the slotted end of the shaft

extension.

10. lnsert shaft extension with washers through

hole in cover and engage the end of reset

shaft.

11. Position reset knob with arrow pointing up,

approximately vertical, on spline of shaft

extension and secure to printer with the 2¼

inch flat-head screw.

12. Check operation of assembly for input

torque and printing of ticket.

13. Seal units with wire through holes in corner

bolts.

Figure 6. Assembling Printer to Meter Register

PRINTER

IDLER

REGISTER