2

2

X

X-

-M

Mi

in

nd

d®

®

D

DC

C

INTRODUCTION page 2

SUMMARY page 3

PRELIMINARY INFORMATION page 4

INSTALLER INFORMATION page 5

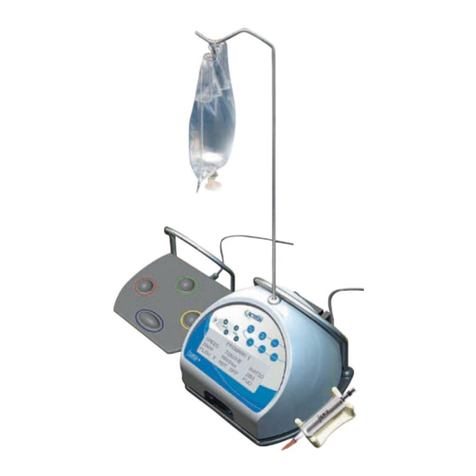

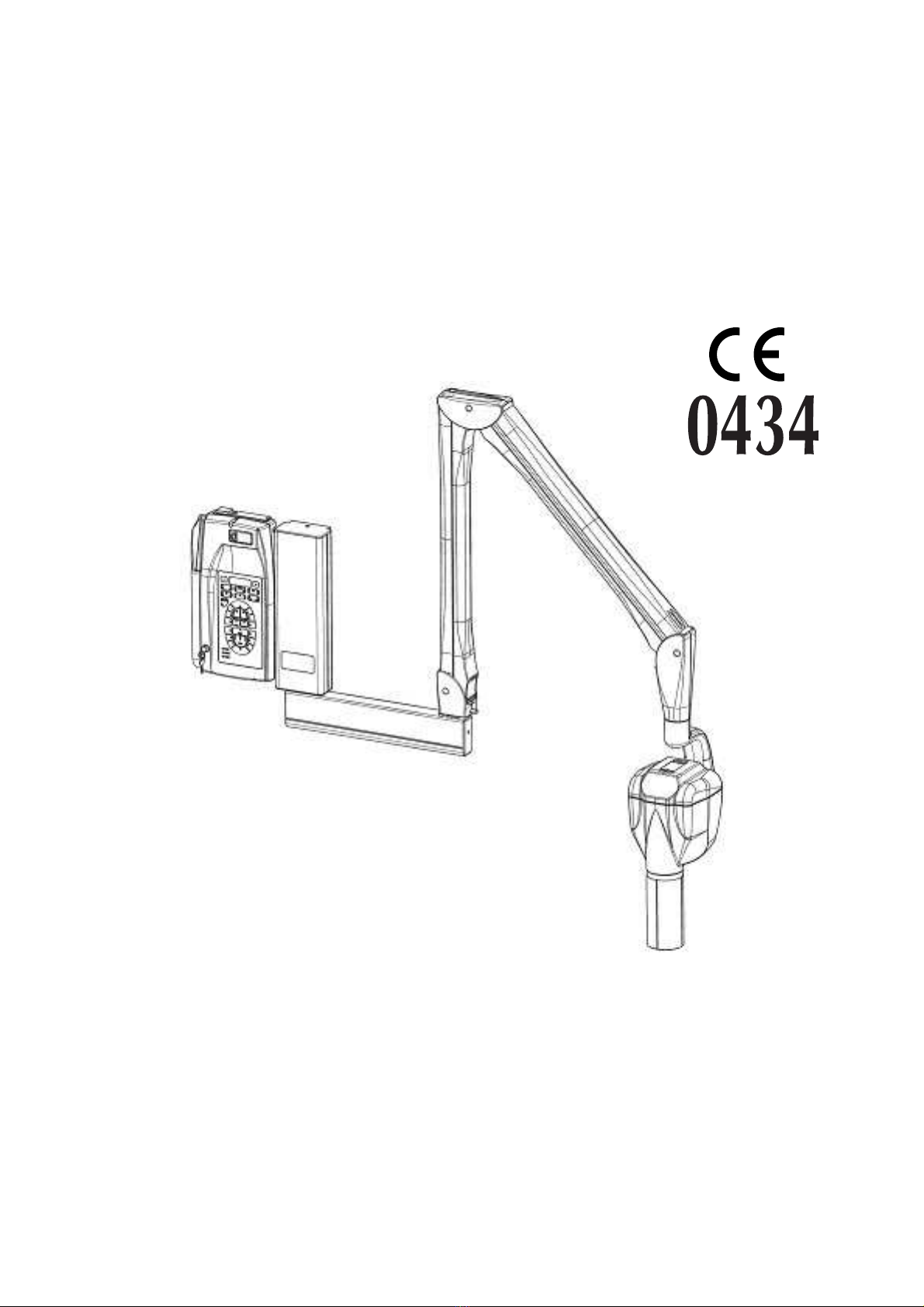

1. “X-Mind DC” X-RAY SYSTEM page 6

2. IDENTIFICATION TAGS page 7

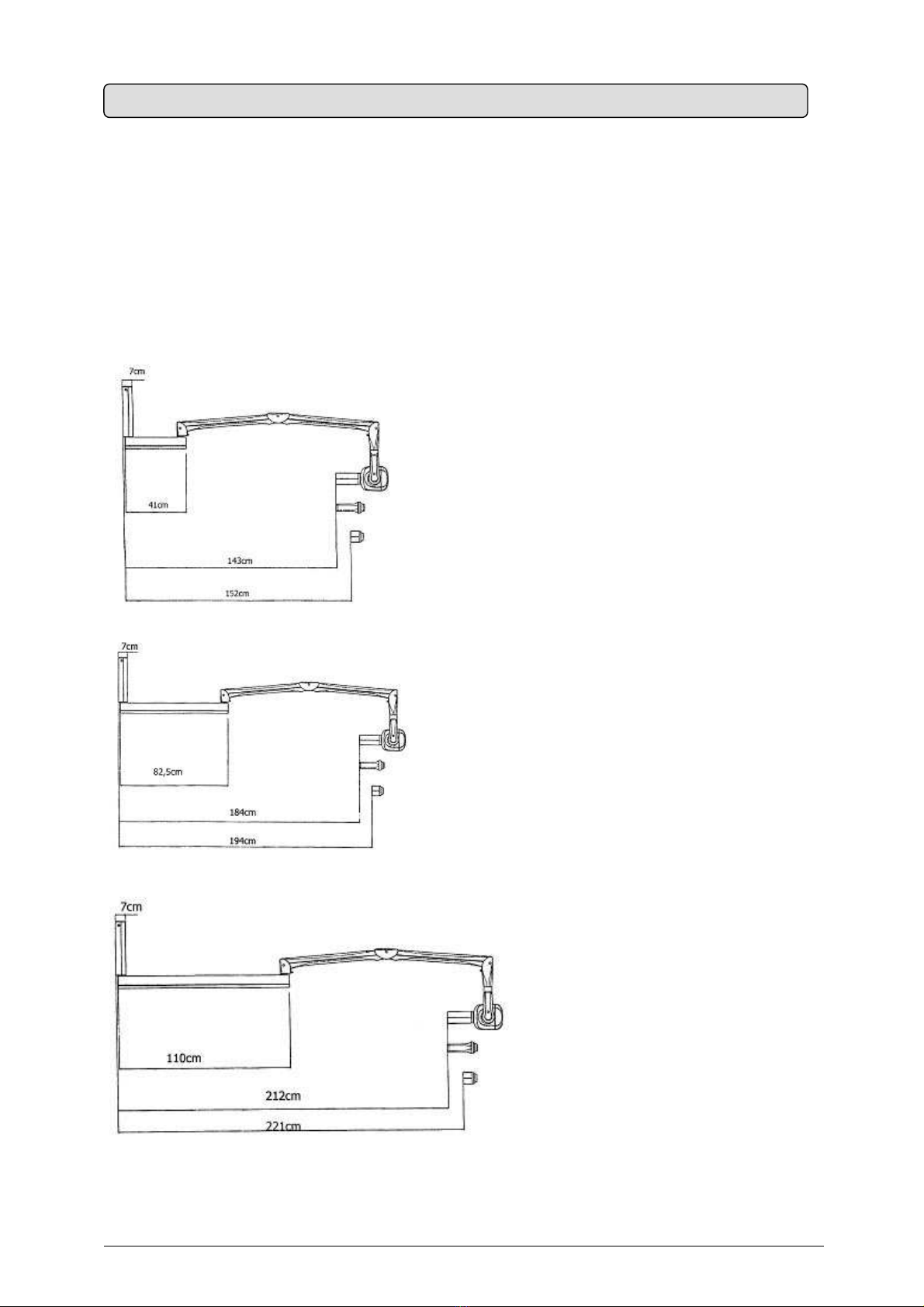

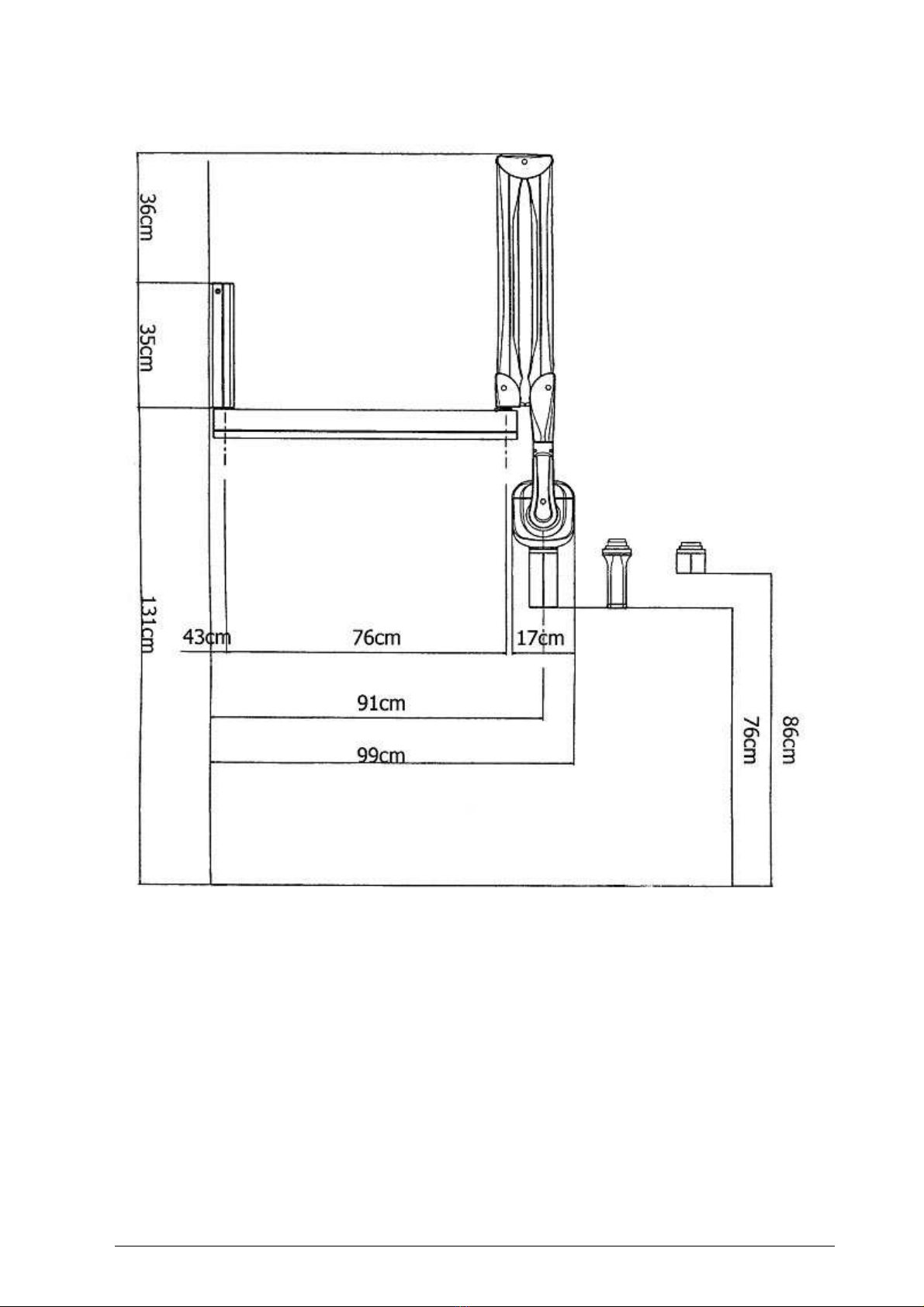

3. OVERALL DIMENSIONS page 8

4. INSTALLATION SPECIFICATIONS page 12

5. INSTALLATION page 15

5.1 UNPACKING page 15

5.2 ASSEMBLING THE WALL PLATE page 16

5.3 ASSEMBLING THE BRACKET page 18

5.4 ASSEMBLING THE PANTOGRAPH-TYPE ARM page 20

5.5 CONNECTION TO THE FEEDING TERMINAL BOARD page 21

5.6 ASSEMBLING THE TUBEHEAD page 24

5.7 BALANCING THE PANTOGRAPH-TYPE ARM page 27

5.8 ASSEMBLING THE “X-Mind DC” TIMER page 30

5.9 TIMER ELECTRIC CONNECTION page 32

6. CONTROL PANEL page 34

7. SYSTEM CONFIGURATION page 36

8. CHANGING THE CONFIGURATION page 38

9. START-UP page 40

10. CHECKING THE INSTALLATION page 41

11. CHECKING THE EXPOSURE FACTORS page 43

12. DIAGNOSTICS page 44

13. CALIBRATION page 45

13. ERROR MESSAGES page 46

14. FUSE REPLACEMENT page 48

15. MAINTENANCE page 49

16. CLEANING OUTER SURFACES page 50

17. SHOULD A REPAIR BECOME NECESSARY page 51

18. DISPOSAL page 51

19. ATTACHMENTS page 52

SUMMARY