SATO M-8485Se Series User manual

M-8485Se Standard

OEM Print Engine

Service Manual

PN 9001080

Rev. A

®

SATO America, Inc.

545 Weddell Drive

Sunnyvale, CA 94089

Main Phone: (408) 745-1300

Tech Support Hotline: (408) 745-1379

Fax: (408) 745-1309

http:\\www.satoamerica.com

Copyright 2000

SATO America, Inc.

The information supplied in this manual was current at time of

publication. If you come across procedures that need clarification or

Warning: This equipment complies with the requirements in Part 15 of FCC

rules for a Class B computing device. peration of this equipment in a

residential area may cause unacceptable interference to radio and TV

reception requiring the operator to take whatever steps are necessary to

correct the interference.

All rights reserved. No part of this document may be reproduced or issued to

third parties in any form whatever without the express permission of SAT

America, Inc. The materials in this document are provided for general

information and are subject to change without notice. SAT America, Inc.

assumes no responsibility for any errors that may appear.

PN 9001080

Rev. A SATO M-8485Se Standard Print Engine

Service Manual

Page 1-1

PN 9001080

Rev. A SATO M-8485Se Standard Print Engine

Service Manual

Overview and Specifications

1.1 Overview

Section

The sections in this manual cover the following:

•Section 1. Overview and Specifications

•Section 2. Configuration

•Section 3. Interface Specifications

•Section 4. Electrical Checks and Adjustments

•Section 5. Mechanical Adjustments

•Section 6. Replacement Procedures

•Section 7. Factory Resets

•Section 8. Troubleshooting

•Section 9. Optional Accessories

•Section 10. Parts list

The SATO M-8485Se Service Manual provides information for installing and

maintaining M-8485Se Thermal Transfer Print ngines. Step-by-step

maintenance instructions are included in this manual with typical problems and

solutions. It is recommended that you become familiar with each section in this

manual before installing and maintaining the printer.

The SATO M-8485Se Print ngines are designed to be integrated into high

performance on-site labeling systems. All printer parameters are user

programmable, using front panel controls and DIP switches. All popular bar

codes and 14 human-readable fonts, including a vector font, are resident in

memory providing literally thousands of type styles and sizes.

The M-8485Se with its 203 dpi head provides an economical labeling solution

for most applications. It will print on labels from 1 inch wide x .25 inches long

to 5.25 inches wide x 14 inches long using internal memory. Labels up to 5.25

inches wide x 49.2 inches long can be printed by installing a PCMCIA memory

card option. The maximum print width is 5.0 inches.

Page 1-2

Section 1. Overview and Specifications

SATO M-8485Se Standard Print Engine

Service Manual PN 9001080

Rev. A

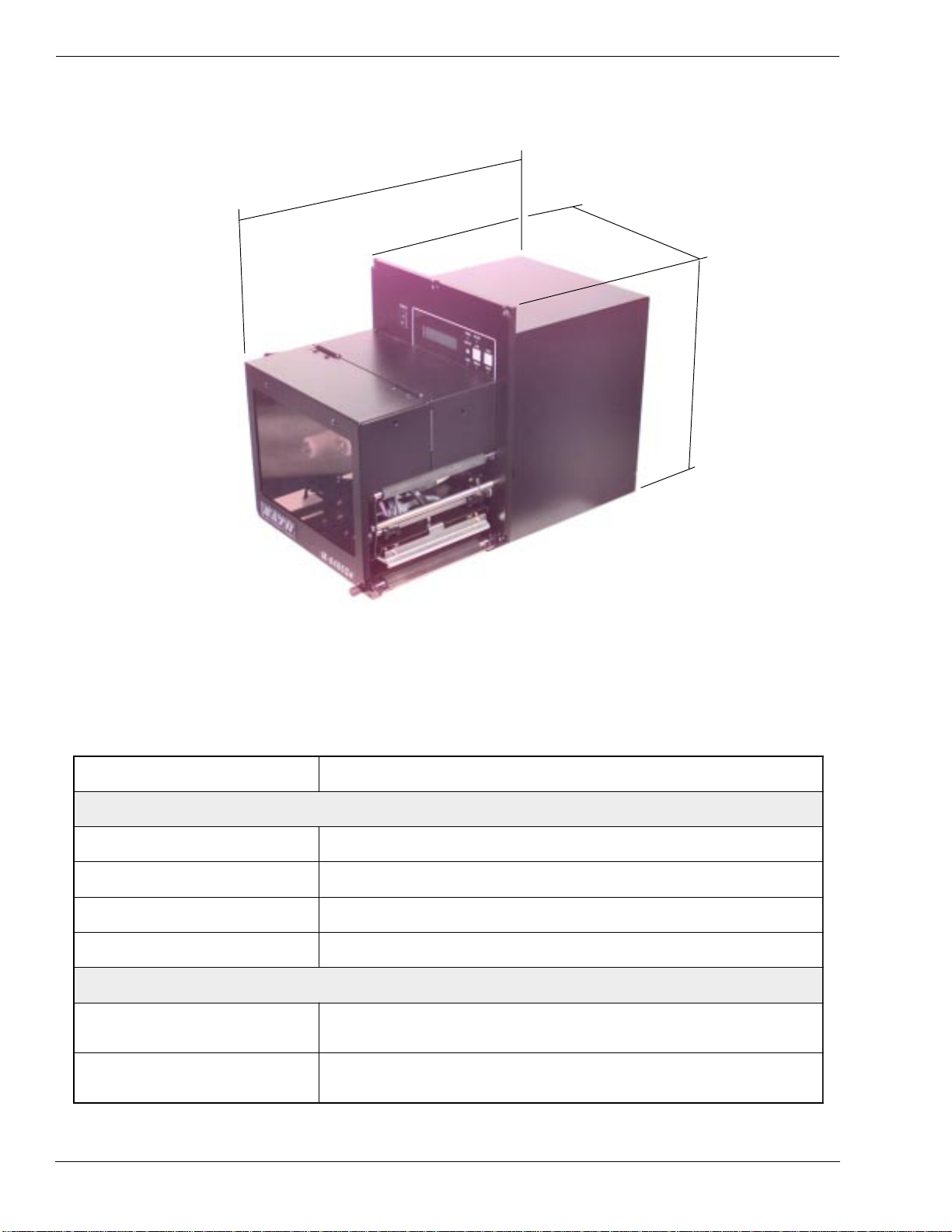

1.2 Dimensions and Power Requirements

WIDE

DEEP

HIGH

NOITACIFICEPS eS5848-M

SNOISNEMID

ediW )mm462(.ni4.01

peeD )mm014(.ni1.61

hgiH )mm003(.ni8.11

thgieW )gK43.11(sbl0.52

STNEMERIUQERREWOP

egatloV )%01-/+(V022-511 )%1-/+(zH06/05

noitpmusnoCrewoP eldIW05 gnitarepOW007

Page 1-3

Section 1. Overview and Specifications

PN 9001080

Rev. A SATO M-8485Se Standard Print Engine

Service Manual

DIP SWITCH

CONFIGURATION

TABLE

O

PERATION PANEL

LABEL EDGE GUIDE

M

EDIA OUT

R

IBBON UNWIND

R

IBBON REWIND

R

IBBON

HEAD PRESSURE

ADJUST

NIP ROLLER LATCH

HEAD LOCK

LEVER

P

LATEN ROLLER

M

EDIA HOLD DOWN

PEEL BAR

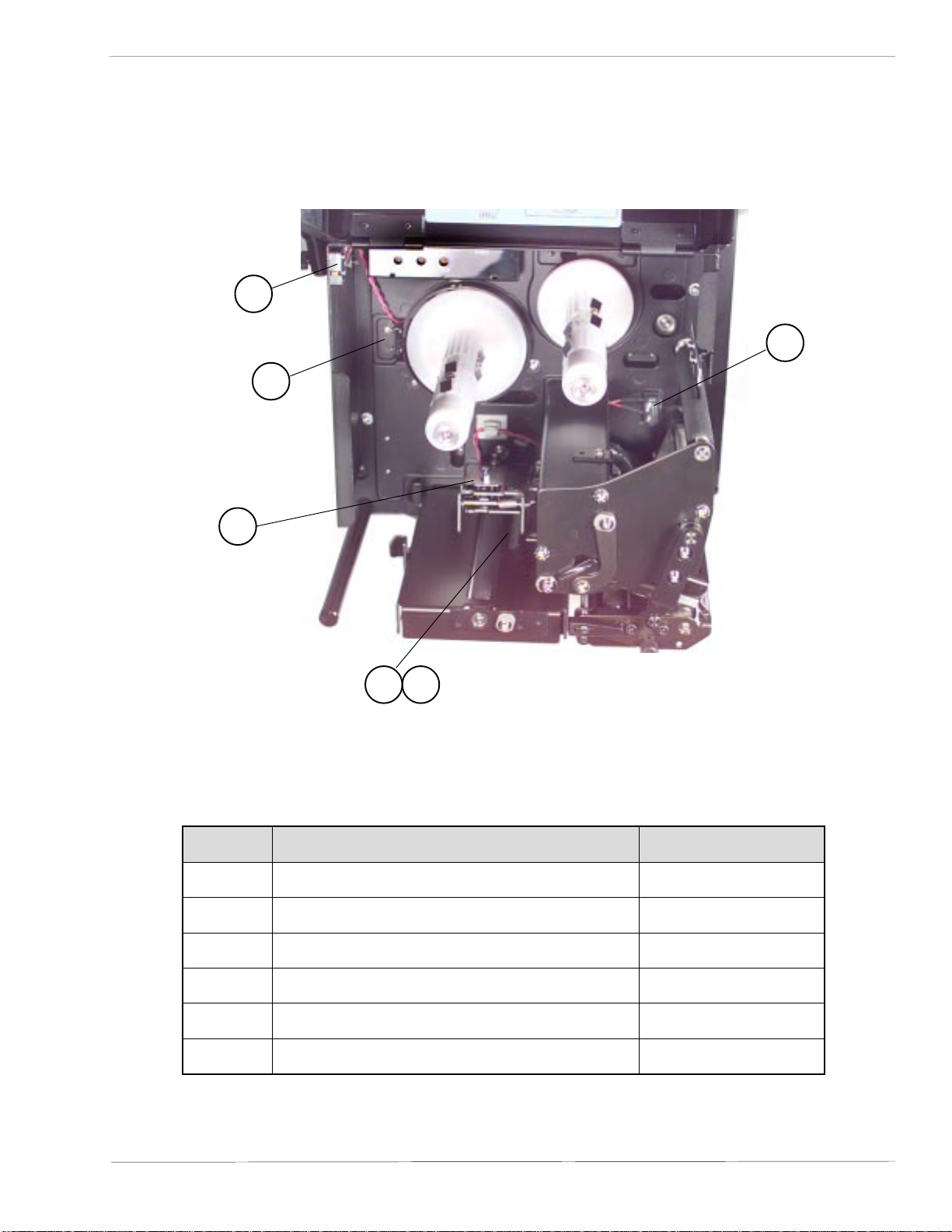

1.3 Components

DIP SWITCH PANEL

Page 1-4

Section 1. Overview and Specifications

SATO M-8485Se Standard Print Engine

Service Manual PN 9001080

Rev. A

PRINT HEAD

PEEL BARPLATEN

ROLLER

NIP ROLLER

ASSEMBLY (COVERS

THE REAR PLATEN)

Components

MAIN PC BOARD

MOTOR

FRONT COVER

POWER SUPPLY

DISPLAY PANEL

PC BOARD

PRINT HEAD

RIBBON

Page 1-5

Section 1. Overview and Specifications

PN 9001080

Rev. A SATO M-8485Se Standard Print Engine

Service Manual

1.4 Operation Panel

1.5 Dip Switch Panel

The DIP Switch panel is located under the front lid and contains two 8-position DIP

switches and three adjustment potentiometers. Adjustment procedures for these are listed

in Section 2, Configuration.

DSW1 is located on RS232C I/O Card if installed. DIP SWITCHES

POTENTIOMETERS

CONTROL KEYS &

INDICATORS

LCD DISPLAY

OPERATION PANEL

LCD Display 2 Line x 16 Character display

LABEL LED Illuminated when label is out

RIBBON LED Illuminated when ribbon is out

ERROR LED Illuminated when errors have occurred

ON-LINE LED Illuminated when printer is On-Line

LINE KEY Switches the printer On-Line or Off-Line. Can also be used

as a Pause function key to stop label during the printing

process.

FEED KEY Feeds one blank label

POWER ON/OFF

SWITCH

Page 1-6

Section 1. Overview and Specifications

SATO M-8485Se Standard Print Engine

Service Manual PN 9001080

Rev. A

1.6 Input/Output Connections (Rear Panel)

SERVICE BOARD

For electrical checks

and adjustments

EXT CONNECTOR

An external signal connector

for interfacing with the label

applicator system. Use the

cable provided.

COVERS OPTIONAL

MEMORY PCB BOARD

For PCMCIA Memory Card

INTERFACE SLOT

For Plug-In Interface

Modules

AC POWER CONNECTOR

To AC Line - Use the

power cable provided

AC FUSE

To protect the printer

from abnormal power

input

Type 15A/250V

Page 1-7

Section 1. Overview and Specifications

PN 9001080

Rev. A SATO M-8485Se Standard Print Engine

Service Manual

1.7 Switches and Sensors

METI NOITPIRCSED NOITCESREFER

1rosneSnoitoMnobbiR11-6noitceS

2hctiwSnepOrevoC21-6noitceS

3hctiwSnepOdaeH31-6noitceS

4srosneS"kraM-eyE"&)2/1toB(paGlebaL41-6noitceS

5)2/1poT(paGlebaL51-6noitceS

6rosneStuOlebaL71-6noitceS

1

2

3

5

(IN TOP LID)

4 6

Page 1-8

Section 1. Overview and Specifications

SATO M-8485Se Standard Print Engine

Service Manual PN 9001080

Rev. A

Switches and Sensors

12

3

4

56

Page 1-9

Section 1. Overview and Specifications

PN 9001080

Rev. A SATO M-8485Se Standard Print Engine

Service Manual

1.8 Adjusting the Label Sensor

RIBBON GUIDE

PLATE

LABEL GAP

SENSOR

ADJUST SLOT SENSOR POSITION

SCREWS

The label gap (transmissive) sensor can be positioned over a limited range. The movable

sensor assembly is mounted on the Label Hold Down and is held in position by two screws.

To adjust the position of the sensor, both screws must be loosened and the sensor moved to

the desired position in the slot and then the screws retightened. Adjustments to compensate

for different liner opacity are done with the LCD panel.

Page 1-10

Section 1. Overview and Specifications

SATO M-8485Se Standard Print Engine

Service Manual PN 9001080

Rev. A

Adjusting the Label Sensor

The M-8485Se printers can position labels using either a label gap (transmissive) or an " ye-

Mark" (reflective) sensor. The sensor used is selected by DSW2-2. The gap sensor position

can be adjusted over a limited range. In addition, the signals from the sensors can be

adjusted using the LCD panel to compensate for different liner opacities and/or " ye-Mark"

reflectance values.

eS5848-M

htdiWlebaLxaM )renilsedulcni( )mm431("72.5

htdiWtnirPxaM)mm821("0.5

rosneSpaG egnaRtnemtsujdA )mm86otmm41("76.2ot"5.0

aerAtnirP-noN)mm3("21.0

PRINT HEAD

INSIDE FRAME

INSIDE LABEL EDGE

MAXIMUM WIDTH

MAXIMUM PRINT WIDTH

GAP SENSOR

ADJUSTMENT

NON-PRINTABLE AREA

EYE-MARK ON BACK SIDE

OF LINER

MINIMUM WIDTH = 0.125" (3 mm)

MINIMUM LENGTH = 0.5" (12 mm)

Page 1-11

Section 1. Overview and Specifications

PN 9001080

Rev. A SATO M-8485Se Standard Print Engine

Service Manual

1.9 Ribbon

1.10 Installation Considerations

Use only SATO thermal transfer ribbons which were formulated expressly for use in all

SATO printers. Use of other than approved ribbons may result unsatisfactory print quality

and/or damage to the print head and may void your warranty.

Printer operation can be affected by the printer environment. The location of the printer

should be free from dust, humidity and sudden vibrations. To obtain optimum results from

the printer module, avoid locations influenced by:

Direct or bright sunlight since bright light will make the label sensor less responsive and

may cause the label to be sensed incorrectly.

xcessive warm or cold temperatures can cause electrical problems within the printer.

(See Section 3- Specifications).

Page 1-12

Section 1. Overview and Specifications

SATO M-8485Se Standard Print Engine

Service Manual PN 9001080

Rev. A

All specifications subject to change without notice.

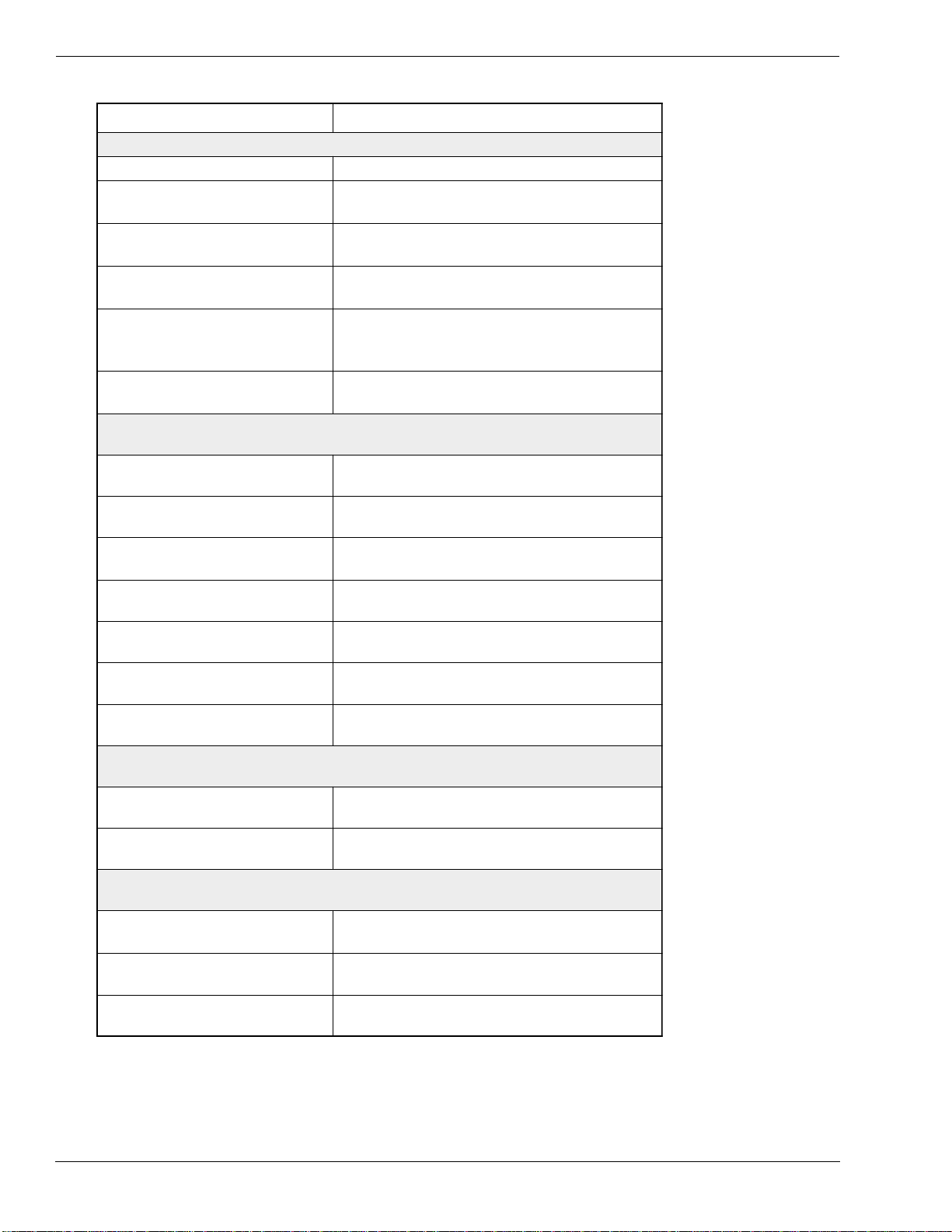

1.11 General Printer Specifications

NOITACIFICEPSeS5848-M

TNIRP dohteMrefsnarTlamrehTrotceriD

)elbatceleSresU(deepS spi21ot4 s/mm003ot001

)eziStoD(eludoMtnirP .ni9400. mm521.

noituloseR ipd302 mmpd8

htdiWtnirPmumixaM .ni0.5 mm821 stod4201

htgneLtnirPmumixaM .ni2.94 mm9421

AIDEM

htdiWmuminiM)mm52(.ni0.1

htgneLmuminiM)mm6(.ni52.

htdiWmumixaM ni52.5 mm431

epyT suounitnoCrodedloF-naF,slebaLtuCeiD

repilaCmumixaM)mm52.(.ni010.

euqroTdniwnUxaMslebalediw.ni5htiw)gK4(sbl8.8

noisneTdniweRrepaPgnikcaBsselrog004

GNISNESLEBAL

urhT-eeSevissimisnarTelbatsujdA

"kraM-eyE"evitcelfeRdexiF

NOBBIR

htdiWmumixaM ni52.5 mm431

htgneL)M006(tf8691

ssenkcihTdniWniecaF,norcim5.4

Page 1-13

Section 1. Overview and Specifications

PN 9001080

Rev. A SATO M-8485Se Standard Print Engine

Service Manual

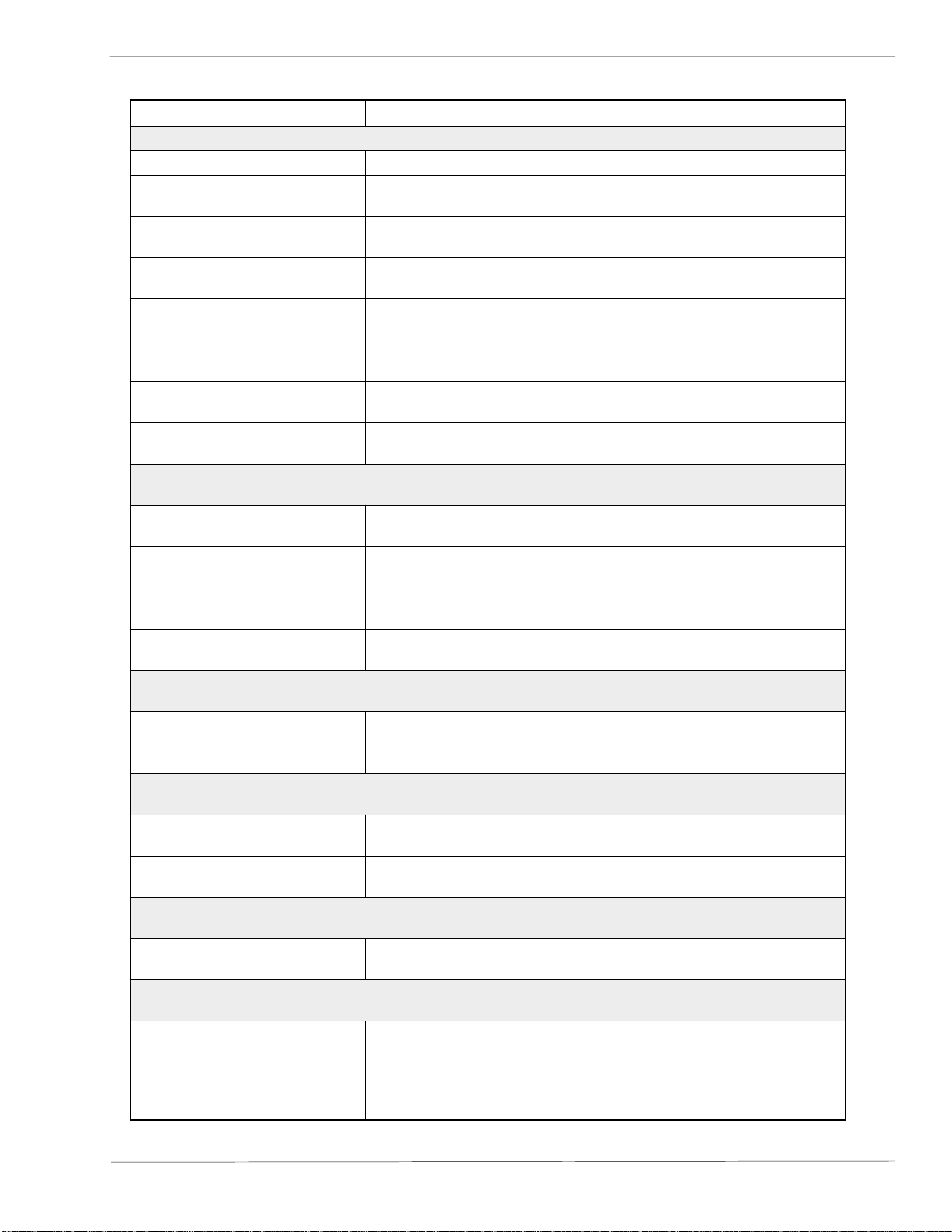

General Printer Specifications

NOITACIFICEPS eS5848-M

LATNEMNORIVNE

erutarepmeTgnitarepO14

0

401ot

0

5(F

0

04ot

0

)C

erutarepmeTegarotS0

0

401ot

0

02-(F

0

04ot

0

)C

ytidimuHgnitarepO gnisnednoc-non,HR%58-51

ytidimuHegarotS gnisnednoc-non,HR%09xaM

egrahcsiDcitatsortcelEVK8

SLAVORPPAYROTALUGER

ytefaS VUT,EC,ASC,LU

IME/IFR AssalCCCF

NOITARUGIFNOC

ottfeL dnaHthgiR deeFlebaLseY

otthgiR dnaHtfeL deeFlebaLseY

All specifications subject to change without notice.

Page 1-14

Section 1. Overview and Specifications

SATO M-8485Se Standard Print Engine

Service Manual PN 9001080

Rev. A

General Printer Specifications

NOITACIFICEPSeS5848-M

SLANGISDNASLORTNOC eniL-nODEL

rewoPDEL

lebaLDEL

nobbiRDEL

rorrEDEL

lenaPDCLretcarahC61xeniL2

hctiwSeniL-ffO/nOlenaPtnorF

hctiwSdeeFlebaLlenaPtnorF

hctiwSffO/nOrewoPlenaPtnorF

STNEMTSUJDARETEMOITNETOP

ssenkraDtnirPlenaPedisnI

hctiPlenaPedisnI

tesffOlenaPedisnI

yalpsiDlenaPtnorF

SNOITCENNOCECAFRETNI

)1(

lellaraP4821EEEI

laireS

locotorPlaireS

)spbK6.75ot0069(C232SR )spbK6.75ot0069(584/224SR

)ysuB/ydaeR(lortnoCwolFerawdraH )ffO-X/nO-X(lortnoCwolFerawtfoS lanoitcerid-iB

tenrehtETesaB001/01

suBlaireSlasrevinU1.1reVBSU

GNISSECORP

UPCCSIRtiB23

MORhsalFBM2

MARDSetyBM61

reffuBevieceRBM59.2

MORhsalFlanoitpOBM4

yromeMAICMCPlanoitpOMARSBM4rohsalFBM61

All specifications subject to change without notice.

(1) Plug-In Interface Modules

Page 1-15

Section 1. Overview and Specifications

PN 9001080

Rev. A SATO M-8485Se Standard Print Engine

Service Manual

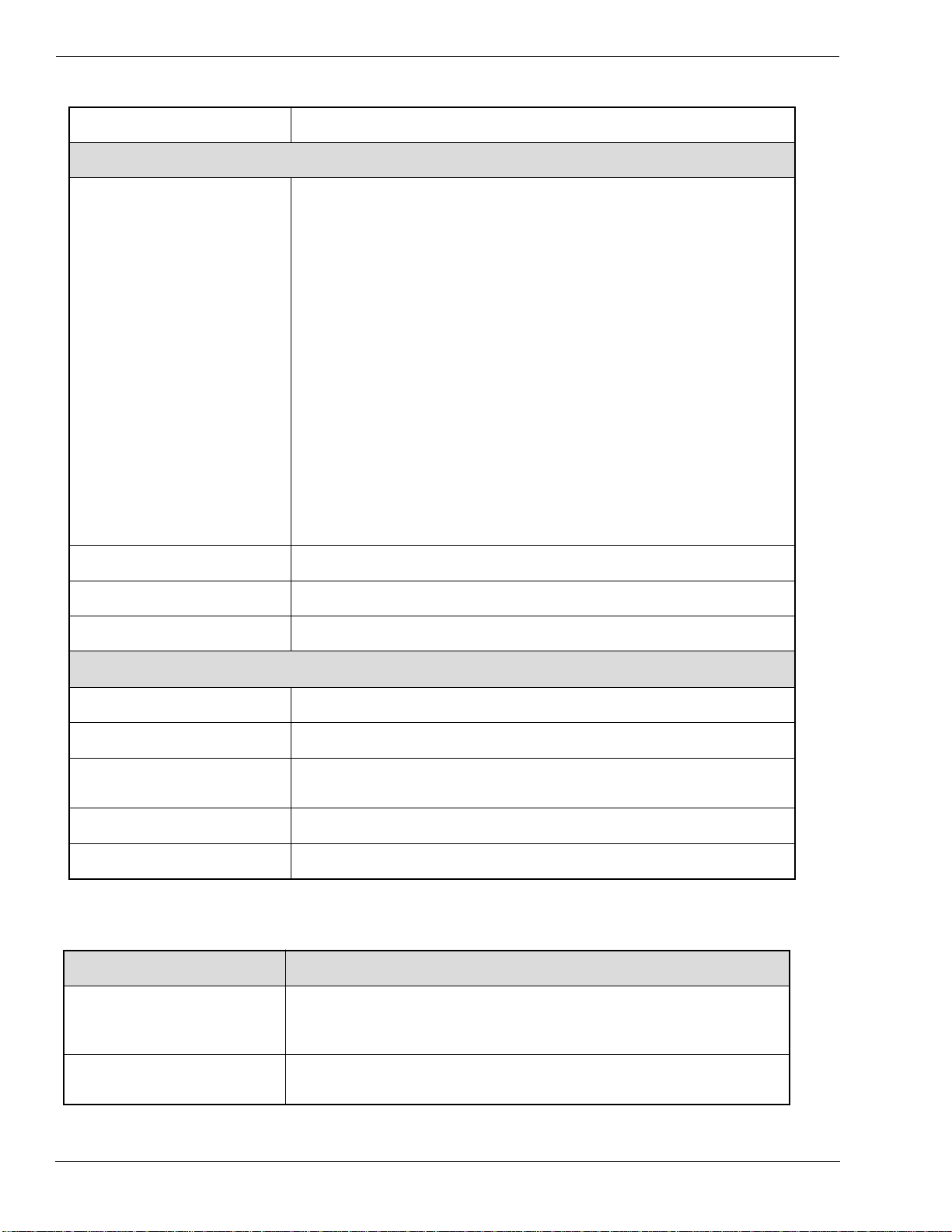

1.12 Character Fonts

NOITACIFICEPSeS5848-M

STNOFXIRTAM tnoFU )Hstod9xWstod5(

tnoFS )Hstod51xWstod8(

tnoFM )Hstod02xWstod31(

tnoFUX acitevleH)Hstod9xWstod5(

tnoFSX dloBdesnednoCsrevinU)Hstod71xWstod71(

tnoFMX dloBdesnednoCsrevinU)Hstod42xWstod42(

tnoFAO A-RCO)Hstod22xWstod51(

tnoFBO B-RCO)Hstod42xWstod02(

STNOFGNIHTOOMSOTUA

BW )Hstod03xWstod81(tnoFBW

LW )Hstod25xWstod82(tnoFLW

BX dloBdesnednoCsrevinU)Hstod84xWstod84(tnoFLX

LX fireSsnaS)Hstod84xWstod84(tnoFLX

TNOFROTCEV

gnicapSdexiFrolanoitroporP stod999x999otstod05x05eziStnoF snoitairaVtnoF01,acitevleH

STNOFRETSARAFGA

tnoFA tp27ot8,semiTGC

tnoFB tp27ot8,etarivmuirTGC

STNOFELBADAOLNWOD

margorPytilitUhtiwstnoFepyTeurT

LORTNOCRETCARAHC

setanidroocYroXehtrehtieniX21otpunoisnapxE lortnochctiPretcarahC lortnocecapSeniL ytilicaftnirPlanruoJ

0

0

09,

0

081,

0

072dna

0

noitatoR

All specifications subject to change without notice.

®

Page 1-16

Section 1. Overview and Specifications

SATO M-8485Se Standard Print Engine

Service Manual PN 9001080

Rev. A

All specifications subject to change without notice.

1.13 Bar Codes and Other Features

YROSSECCA eS5848-M

NOISNAPXEYROMEM BM8dna)MARSBM4rohsalFBM61otpu(sdraCyromeMAICMCP reffubtnirp,egarotseliFcihparGrofdesuebnaC.MORhsalF .stnofepyTeurTdedaolnwoddnaegarotstamrof,noisnapxe

ROSNESLEBALTUO-ECAF foecafehtnodetnirp"skraM-eyE"evitcelferrofrosnesdetnuom-poT .lebaleht

1.14 Optional Accessories

NOITACIFICEPSeS5848-M

SEIGOLOBMYS

latnemelppuSNAE/CPU(dnalkooB 31-NAE,8-NAE RABADOC 93edoC 39edoC 821edoC 5fo2devaelretnI 5fo2lairtsudnI 5fo2xirtaM ISM TENTSOP 821-NAE/CCU E-CPUdnaA-CPU xirtaMataD edocixaM 714FDP FDPorciM FDPdetacnurT edoCRQ

soitaR shtdiwrabelbanifedresU5:2,3:1,2:1

thgieHraB elbammargorpresU,stod006ot4

noitatoR0

0

09,

0

081,

0

072dna

0

SERUTAEFREHTO

gnirebmuNlaitneuqeS sedocrabdnasciremunhtobfognirebmunlaitneuqeS

sretcarahCmotsuC sretcarahclaicepsrofegarotsMAR

scihparG scihpargelbasserddatodlluF stamrofXCP.roPMB.,yraniB/xeHOTAS

yalrevOmroF stamrofxelpmocfognitidedeeps-hgihroyalrevomroF

kcolCemiTlaeR emittnirptaslebalgnipmatsrofkcolcemiT/etaD

Page 2-1

PN 9001080

Rev. A SATO M-8485Se Standard Print Engine

Service Manual

Configuration

2.1 Dip Switch Settings

2

Section

Two DIP switches (DSW2 & DSW3) are located inside the cover. These switches

can be used to set:

• Thermal transfer or direct thermal mode

• Head Check Mode

• Hex Dump Mode

• Label sensor enable/disable

• Single Job or Multi-Job Receive Buffer

• Operation Mode

In addition, a third DIP switch (DSW ) is located on the RS232 Serial Adapter

card and is used to set the RS232C transmit/receive parameters.

DSW1

Each switch is an eight section toggle switch. The On position is always to the

top. To set the switches, first power the unit Off, then position the DIP switches.

Finally after placing the switches in the desired positions, power the printer back

on. The switch settings are read by the printer electronics during the power-up

sequence. They will not become effective until the power is cycled.

DIP SWITCHES

Page 2-2

Section 2. Configuration

PN 9001080

Rev. A

SATO M-8485Se Standard Print Engine

Service Manual

DSW1

ON

OFF

1 2 3 45 6 7 8

DSW1

ON

OFF

1 2 3 45 6 7 8

DSW1

ON

OFF

1 2 3 45 6 7 8

DSW1

ON

OFF

1 2 3 45 6 7 8

DSW2

ON

OFF

1 2 3 45 6 7 8

DSW1-4 SETTING

Off 1 Stop Bit

On 2 Stop Bits

Parity Selection (DSW1-2, DSW1-3): These switches select the type of parity used

for error detection.

Stop Bit Selection (DSW1-4): Selects the number of stop bits to end each byte

transmission.

Baud Rate Selection (DSW1-5, DSW1-6): Selects the data rate (bps) for the RS232

port.

Dip Switch Settings

Data Bit Selection (DSW1-1): This switch sets the printer to receive either 7 or 8

data bits for each byte transmitted.

RS232 Transmit/Receive Setting (Located on RS232 I/F Module)

DSW1-1 SETTING

Off 8 data bits

On 7 data bits

Protocol Selection (DSW1-7, DSW1-8): Selects the flow control and status

reporting protocols.

(* Will select protocol for M-8400 if DSW2-8 is ON)

DSW1-2 DSW1-3 SETTING

Off Off Disabled

Off On Even

On Off Odd

On Off Not Used

DSW1-5 DSW1-6 SETTING

Off Off 9600

Off On 19200

On Off 38400

On On 57600

DSW1-7 DSW1-8 SETTING

Off Off Rdy/Bsy

Off On Xon/Xoff

On Off Bi-Com 3

On On Bi-Com 4

Other manuals for M-8485Se Series

5

Table of contents

Other SATO Printer manuals

Popular Printer manuals by other brands

IBM

IBM 102 user guide

Aisino

Aisino RCK-600 user guide

Konica Minolta

Konica Minolta Magicolor 3300 user guide

Epson

Epson Stylus Pro 4880 ColorBurst Edition - Stylus Pro 4880... user guide

Astro Machine

Astro Machine ASTROJET 2650P Operator's manual

Toshiba

Toshiba TEC B-850 Series Key Operation Specification