1Description

SGTP-CO is a portable single gas detector designed to detect the presence of CO gas in the ambient

environment. SGTP-CO has a replaceable gas sensor and battery, giving an unlimited lifetime of operation.

When activated, SGTP-CO continuously monitors ambient air for the presence of carbon monoxide (CO)

and alerts the user to potentially unsafe exposure with LED, vibrating, and audible alarms in the event that

gas concentration exceeds alarm set points.

The SGTP-CO is designed for use in hazardous areas and offers reliable and durable monitoring in a

compact, lightweight package. It is also designed to withstand the harshest industrial working conditions

and is simple to operate.

2Warning

Any unauthorized attempt to repair or modify the product, or any other cause of damage beyond the

range of the intended use, including damage by fire, lightening, or other hazard, voids liability of the

manufacturer

Activate this product only if sensor, visual, detection, and audible cover are clear from contaminants

such as dirt and debris that could block the area where gas is to be detected.

Do not clean and rub the LCD screen of the products with a dry cloth or hands in hazardous

environment to prevent the static electricity.

Perform cleaning and maintenance of the products in fresh air that is free of hazardous gases.

Test the response of a sensor regularly by the gas concentration exceeding alarm set point

Test LED, audio and vibration manually.

Gas concentration measurements by the sensor can vary based on the environment (temperature,

pressure and humidity). Therefore, calibration of SGT-P should be performed in the same (or similar)

environment of the device’s actual use.

If the temperature changes sharply during use of the device (e.g., indoors vs outdoors), the value

of the measured gas concentration can suddenly change. Please use the SGT-CO after the gas

concentration value has stabilized.

Severe vibration or shock to the device may cause a sudden reading change. Please use SGT

CO after the value of gas concentration has stabilized. Excessive shock to SGT-P can cause

the device and/or sensor to malfunction

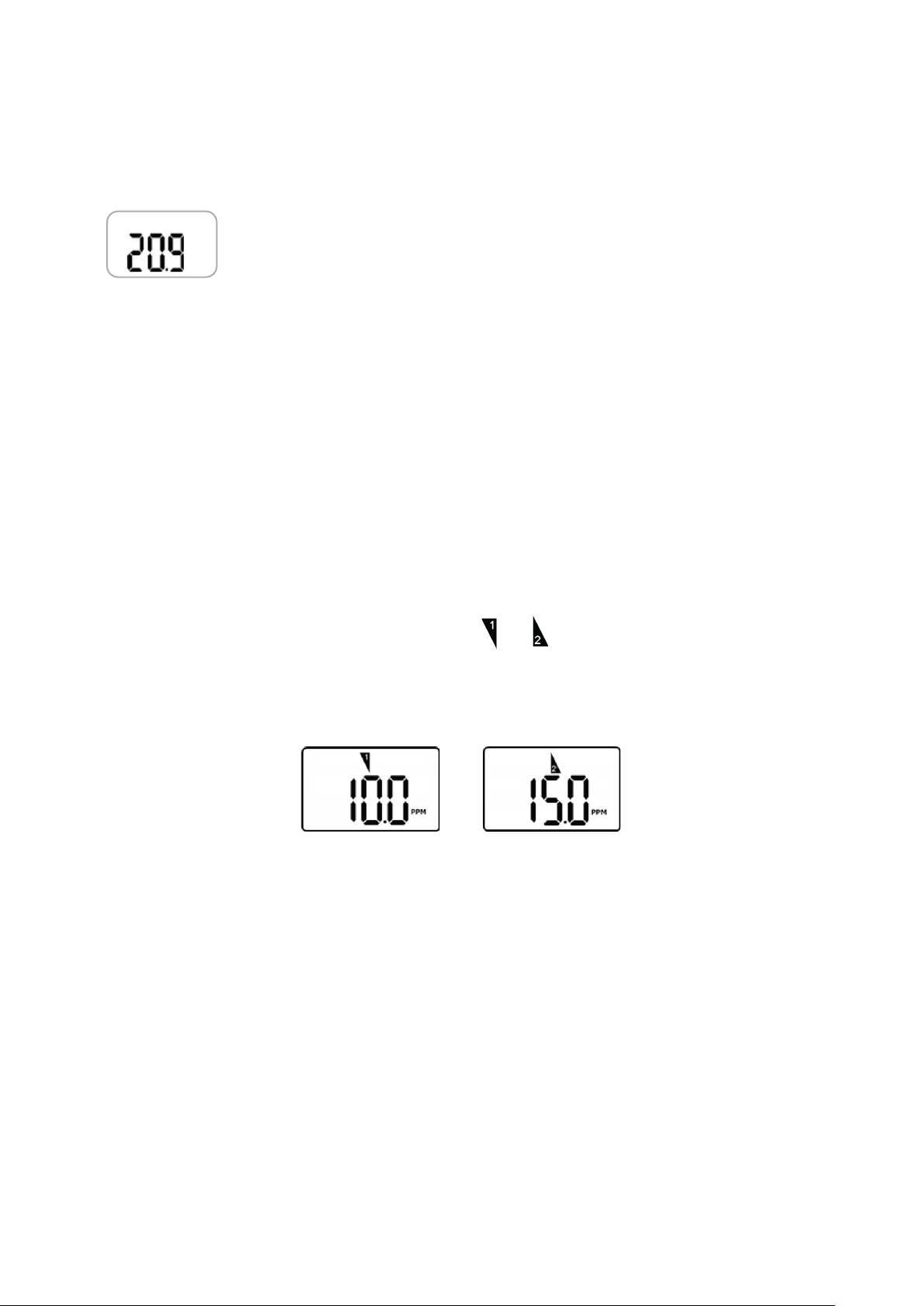

All alarm value is set based on the alarm standard that is required by international standard. Therefore,

alarm values should be changed only under the responsibility and approval of the administration of the

work site where the instrument is used.

Use IR communications in the safety zone which is free of hazardous gases.

Replace the battery and sensor in clean environment, which is free of hazardous gas.