OPERATION

Loading the clamp

1. When placing the clamp onto the material, the clamp should be in the

“locked open” or open position with the gripping cam(s) out of the jaw

opening. This helps to prevent damage to the gripping teeth during

loading.

2. Center the clamp so the load is balanced when lifted. When using

more than one clamp, make sure the clamps are positioned to share

equal loads.

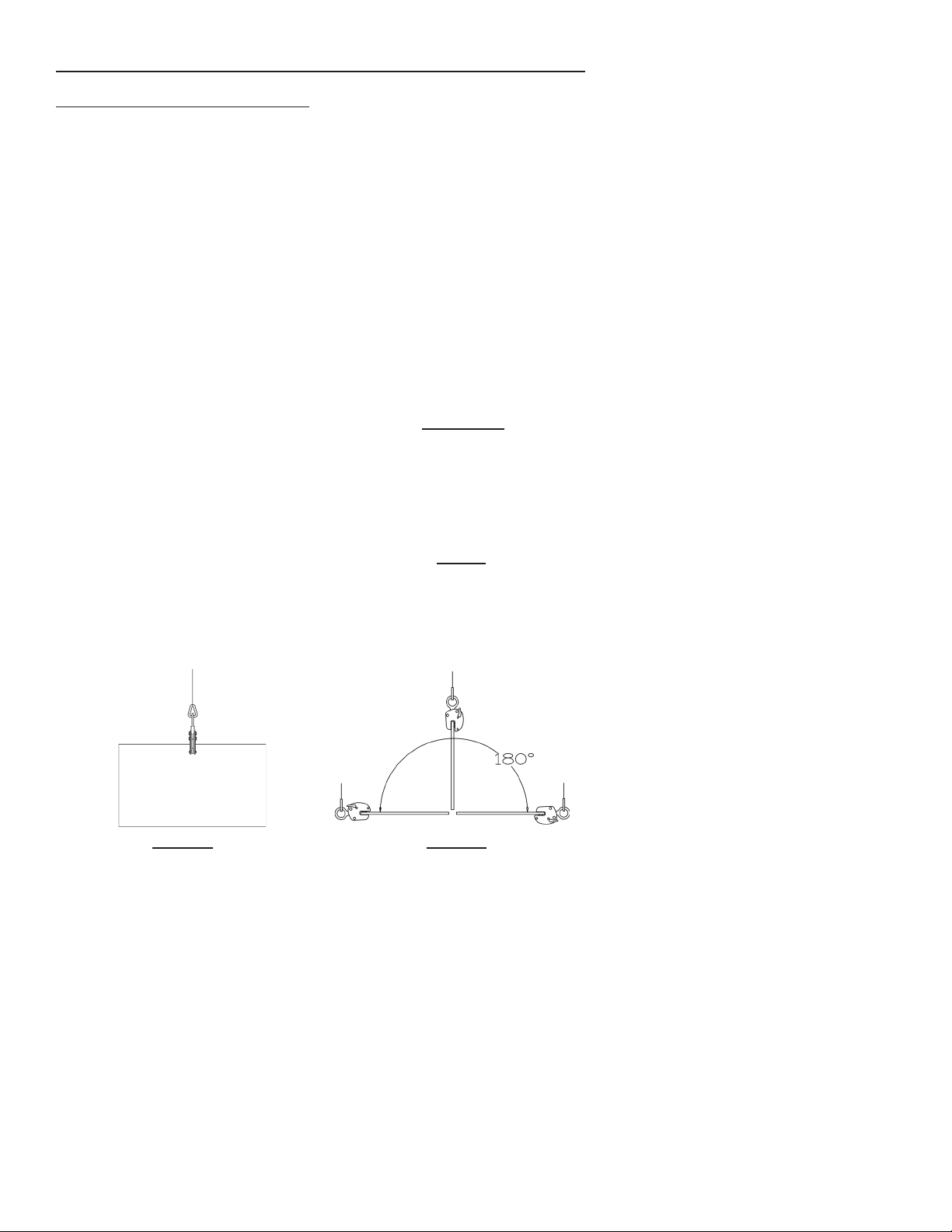

3 For a clamp with a standard lifting shackle (SC-10), make sure the

clamp is positioned so the direction of force applied by the crane is in

line with the lifting shackle (Fig. 3).

WARNING: Never exceed 10° side loading with a VL series clamp

with a standard Lifting Shackle (Fig. 3).

4. Place the jaw of the clamp around the material to be lifted. Make sure

the clamp is positioned so the edge of the material is 1/8” to 1/4” from

the back of jaw opening and the gripping surfaces are in full contact

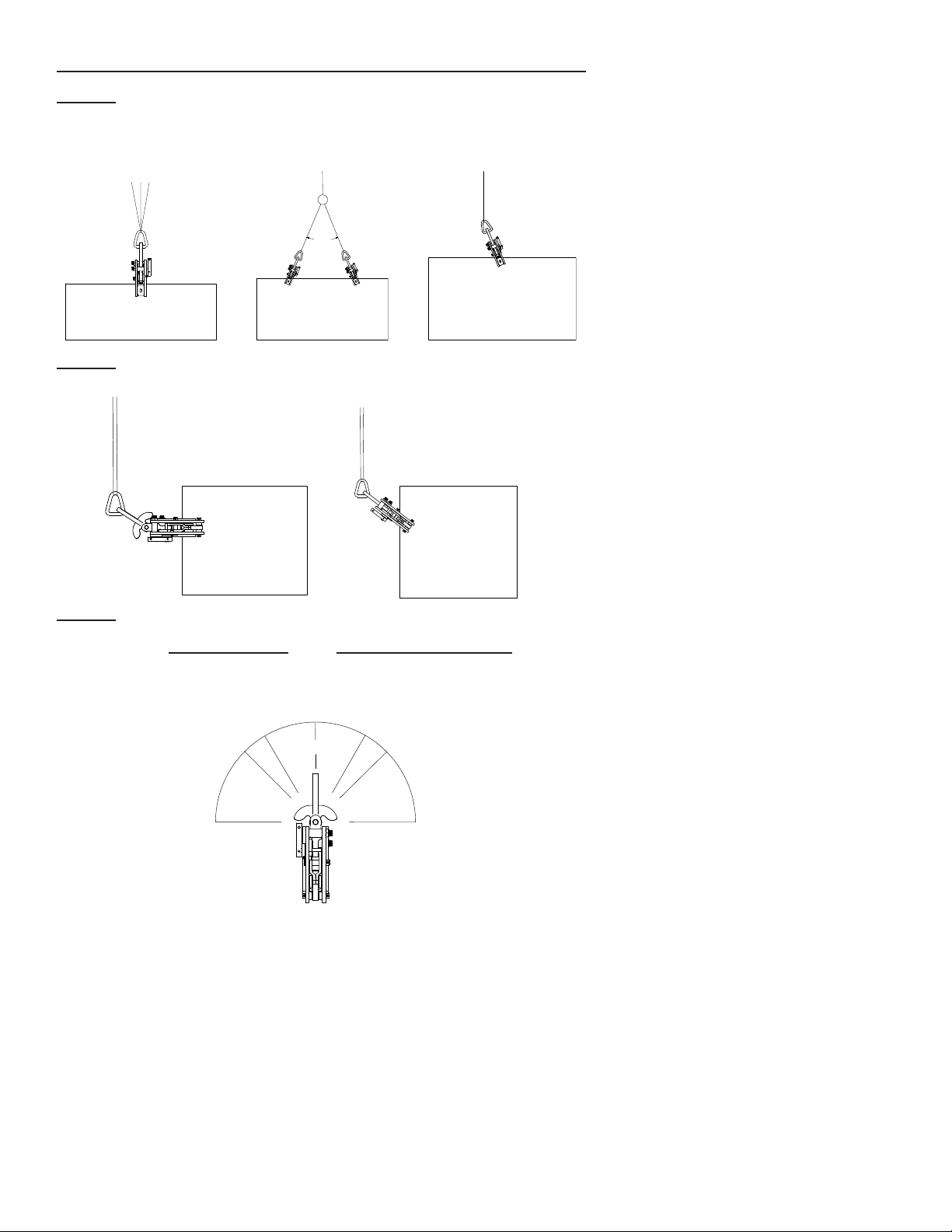

with the material. When lifting from a horizontal position, our unique

design allows the operator to load the clamp with the gripping pad

(D, Fig. 7) below the plate or on top of the plate.

5. Secure the clamp in the “locked closed” position. Do this by seating

the clamp on the material with the gripping pad (D, Fig. 6) against the

material and rotating the lock handle (A, Fig. 7) until the lock inside

the body is positioned against the stop (B, Fig. 7). The gripping cam(s)

(C, Fig. 7) will rotate into the jaw and engage the material at the point

where they will bite into the material once the lift is started.

Note: When using a clamp with the auxiliary push-button lock handle,

ensure the auxiliary lock is fully engaged and the spring-loaded push

button on the handle is flush with the push-button retainer ring.

WARNING: Not properly seating the clamp may cause the clamp

to slide on the material once the lift begins. Always ensure the

grippers are seated properly. Check this by pushing away on the

clamp body as you pull back on the lifting shackle (E, Fig. 7) and

look to ensure the gripping cam(s) and gripping pad are engaging

the material.

6. Once the clamp is properly locked closed onto the material, the clamp

is now ready to make a lift.

WARNING: The operator and all other personnel should be fully

clear of the lifting area.

Safety Clamps, Inc. VL Series Clamps

6