4

1. Transport & Handling

1.1 Transport

The SCANTOOL belt grinding machine is packed in protective wrapping and

delivered on a pallet with the following measures: 120 x 80 x 120 cm

1.2 Handling

The machine can easily be transported on the pallet on which it is delivered.

1.3 Placing

Mounting of the belt grinder must take place on a firm and level ground. The

machine must be fastened to the ground by means of the four fittings (Ø10) which

are used to fasten the belt grinder to the pallet.

The machine is provided with no-volt release protection switch and connected for

the wanted voltage (V). The electrical connection must be performed by an

authorized electrician, and it is important to control that the motor (and ventilator)

has the correct direction or rotation (please see the arrow on the motor).

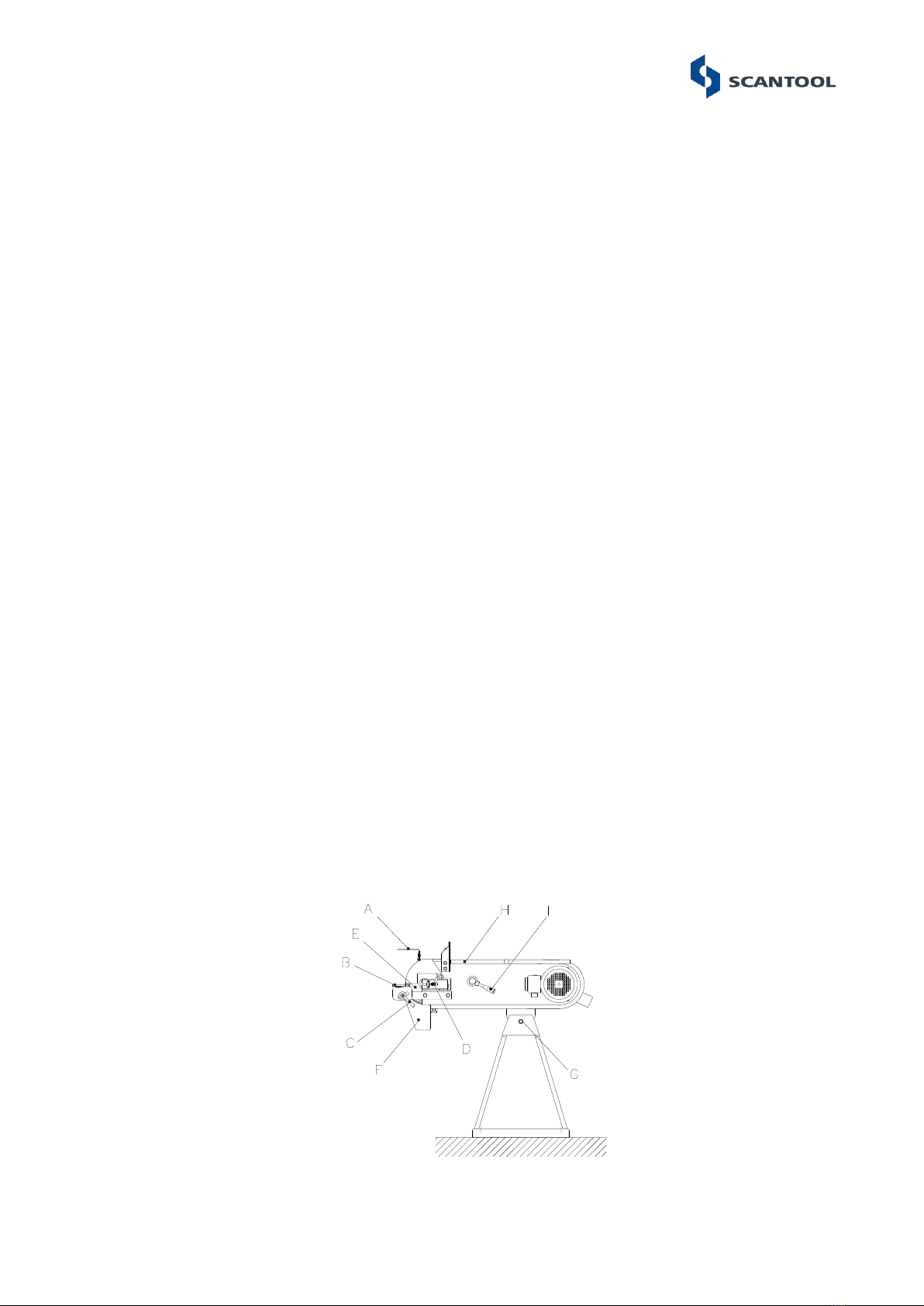

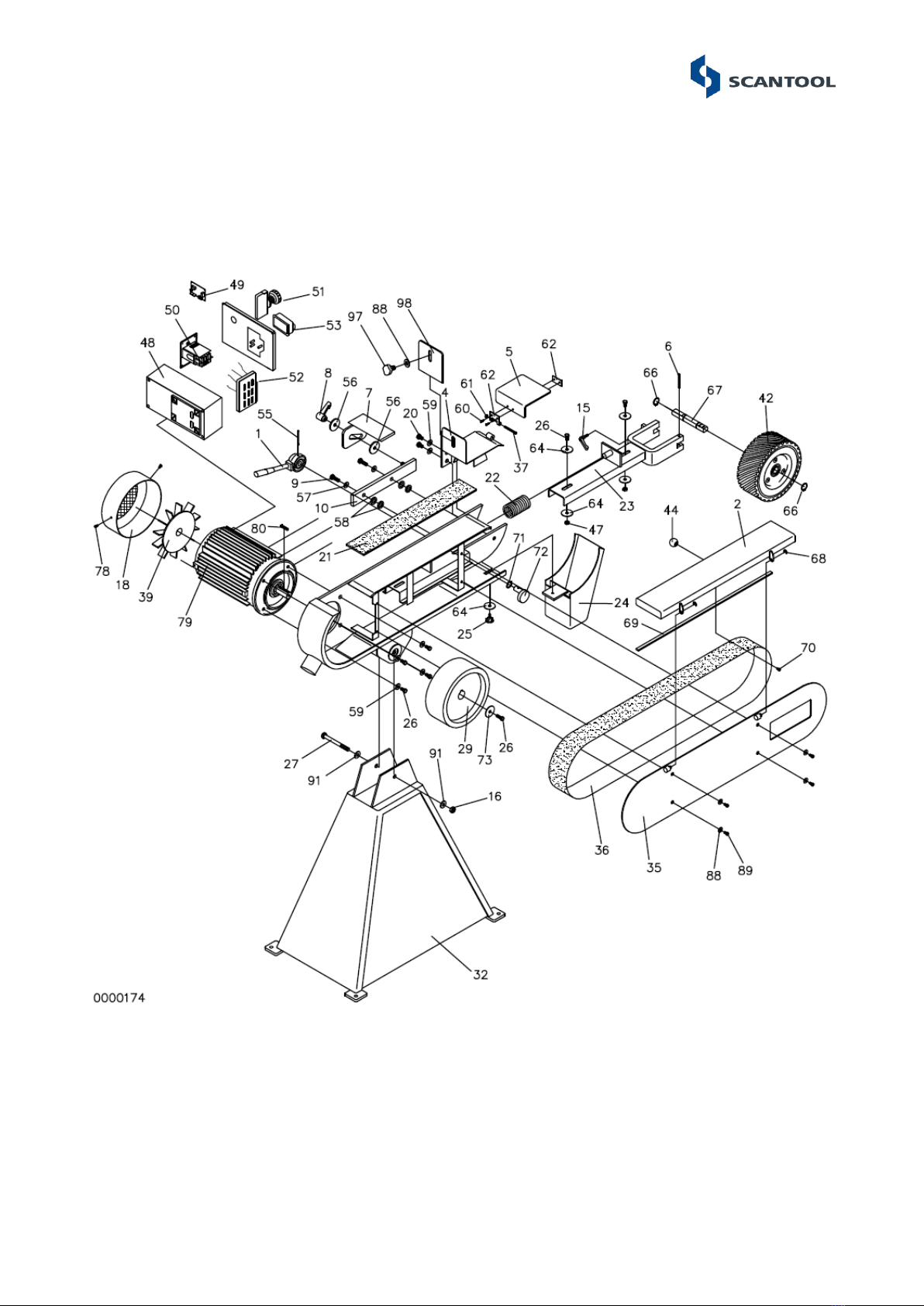

Eye shields, suction hose and perhaps dust bag must be mounted before use. The

clamps for mounting the suction hose are placed in the dust bag. The eye shields

(A) must be mounted into the eye shield fitting (see fig.: 1.1).

The tool rest (B) must be mounted at a distance of minimum 2 mm from the belt,

and the handle (C) must be fastened. Turn the contact wheel by your hand and

adjust the belt by means of the handle (D) until it runs just on the contact wheel

(E). It must be controlled that the spark box (F) is properly fastened. The wanted

working height is adjusted by bolt/locknut (G).

Fig.: 1.1