5

1.5 NOISE

The Noise level for this machine is strictly under 70 db.

1.6 DANGER ZONES

The roiling area of the machine is the most dangerous area as it' cannot be guarded.

Only the user himself is responsible for his safety. Even the danger here is not very

significant and avoidable following points must be done in case of any emergency.

-Never remove any guards before completely stopping the machine.

1.7 Working Area

The user must be careful for third persons entering the operation area of the machine.

Material should be fed only from the front of the machine.

No material should be fed if the machine is running.

1.8 PERSONNEL

Personnel under age of 16 years to operate the machine are strictly forbidden.

The Operator of the machine should carefully read this manual and understand the dangers

he might be in if he misuses or abuses the machine. In case any part of this manual is

unreadable or illegible please contact the dealer and manufacturer.

The owner of the machine should be responsible for operating the machine with qualified

personnel.

1.9 PERSONNEL Protection

No special protection equipment is needed during the normal operation of the machine, only

hand gloves are recommended to avoid minor cuts in the hand which may be caused by the

material.

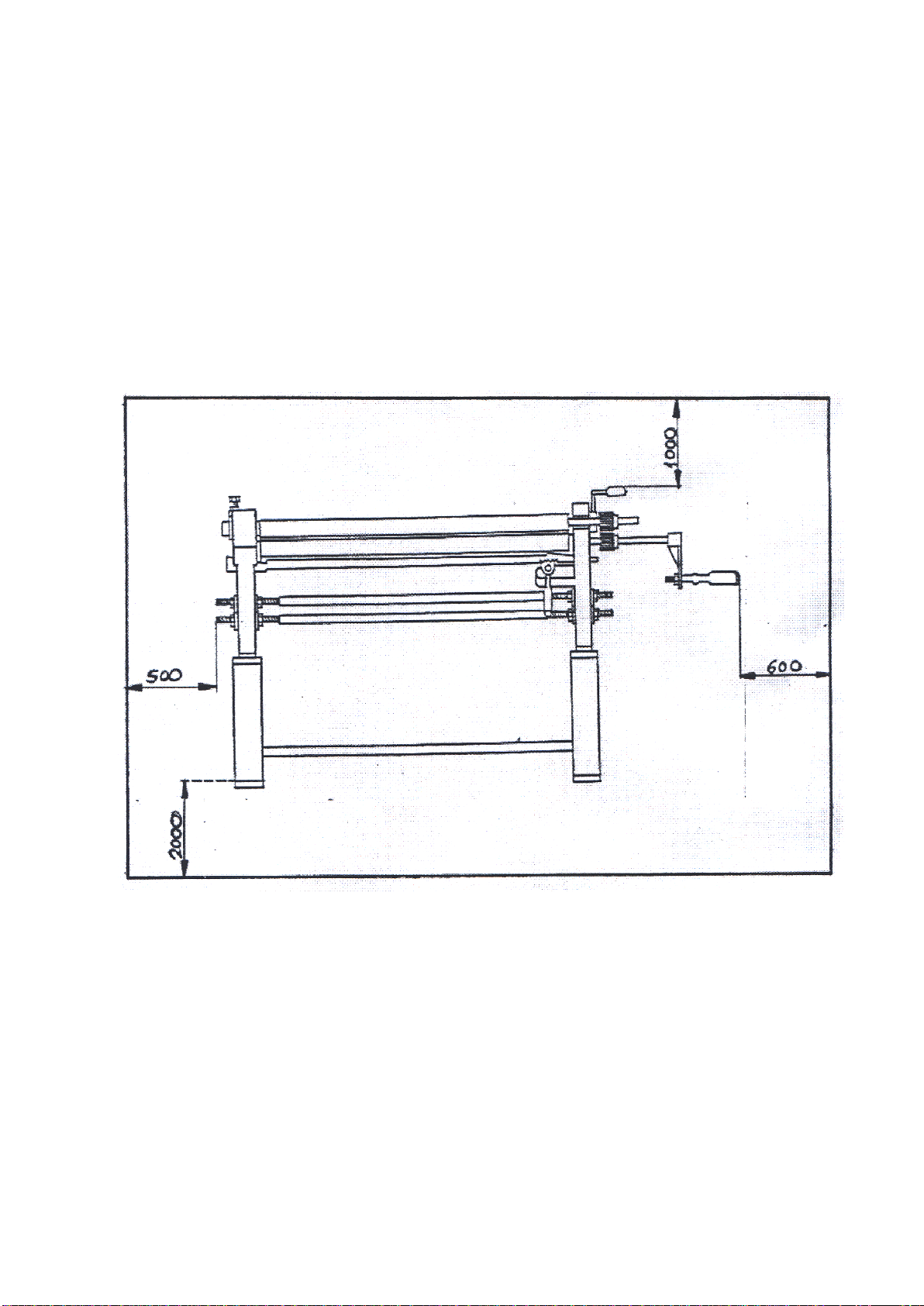

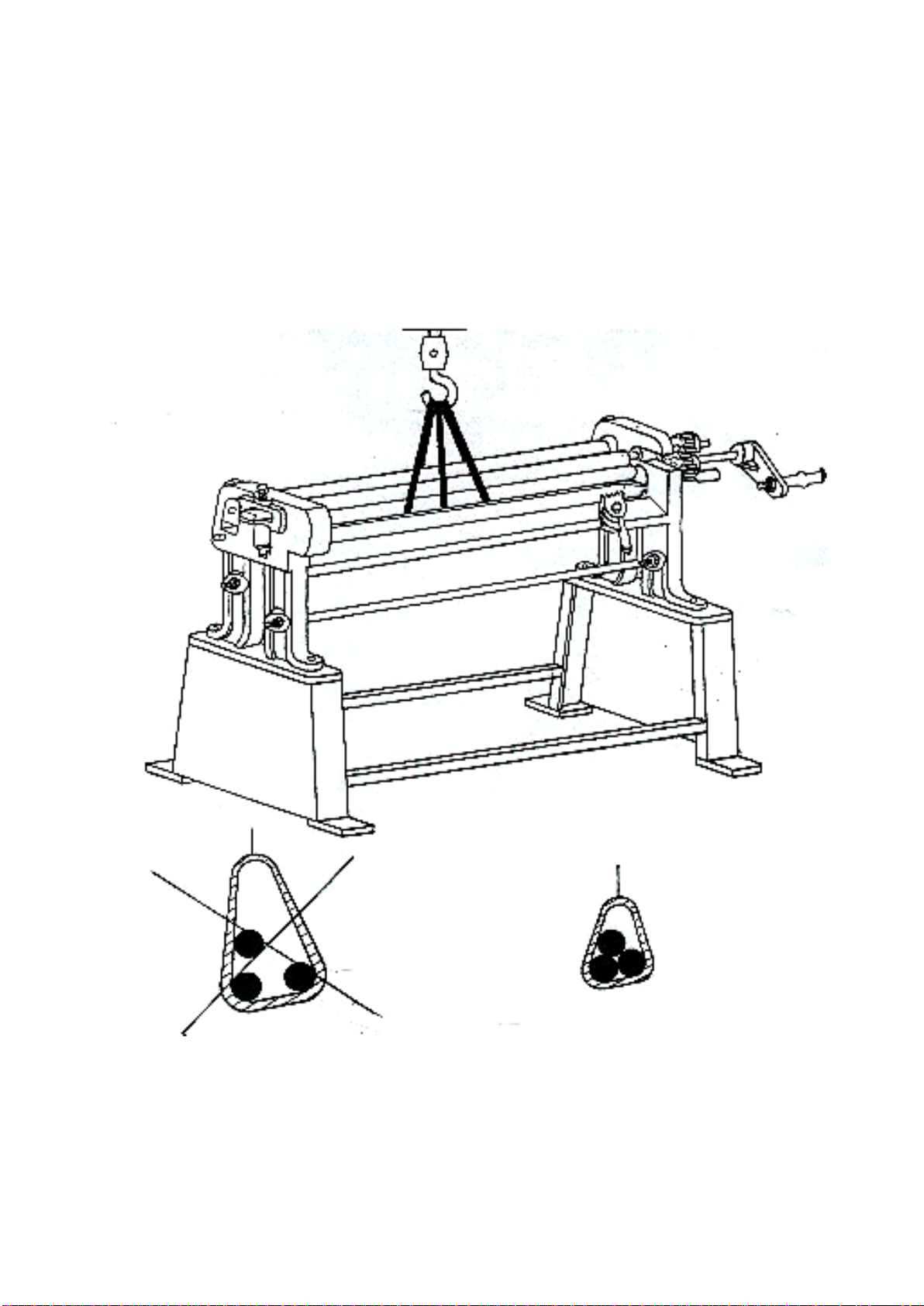

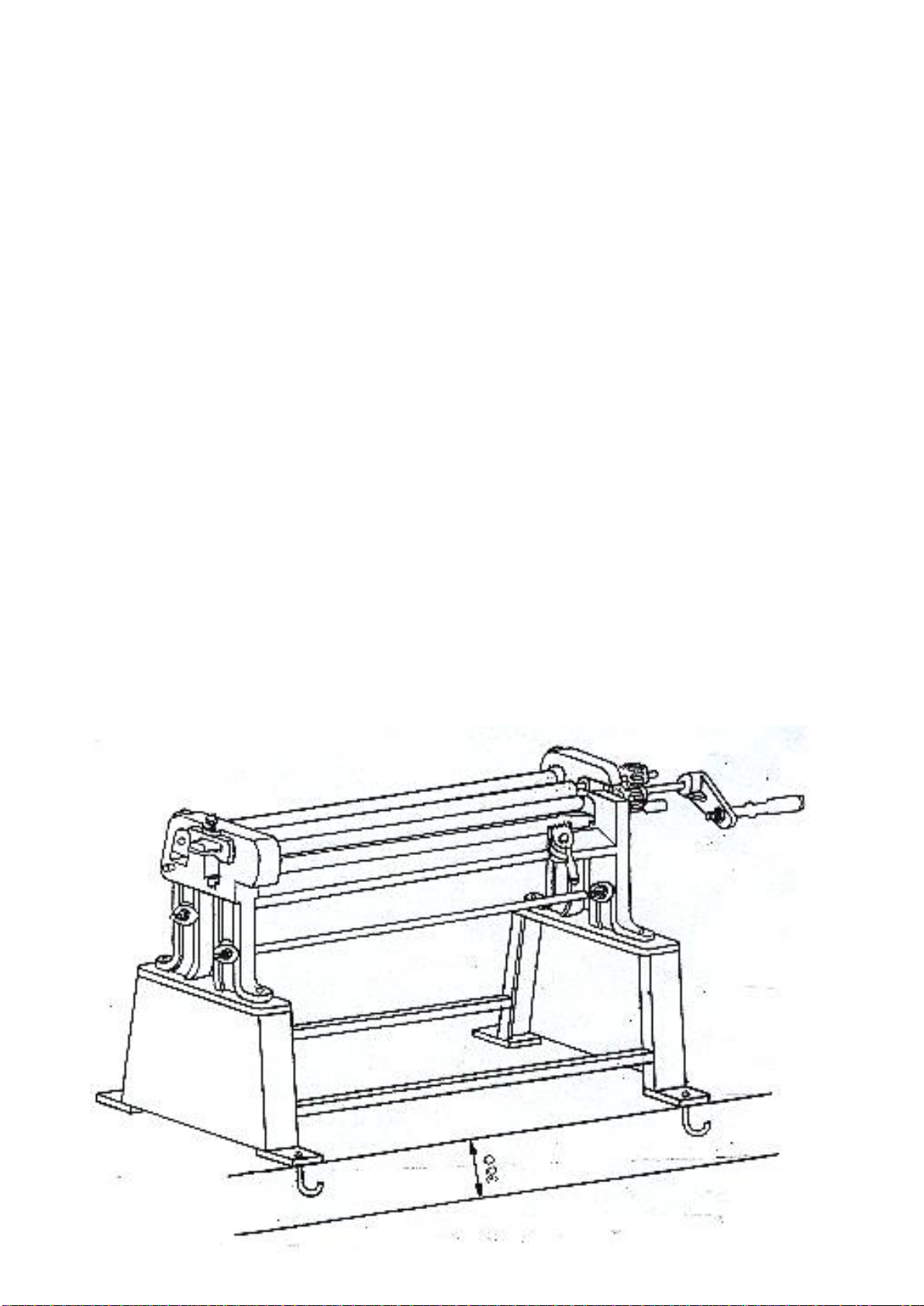

1.10 Protection ON SETUP (LOOK FOUNOATION PIAN)

The machine must be firmly and rigidly bolted to the ground. Unsteady machines have the

risk of over-dropping and may cause serious personnel injury and can even be fatal. Also

while setting up the machine you must place it so that all caution signs on the machine is

visible and readable. All emergency stops must be easily accessible.