User and installation manual LCL Filters 2/22

i. LCL Filters

Product characteristics and field of application

The LCL family FN6840 has been designed for AFE (Active Front End) drives. In addition, the LCL filter

can also be applied in combination with other AIC (Active Infeed Converter) applications in case the

specification does fit their requirements.

An LCL filter belongs as a functional part to the AFE or AIC. As a functional part it provides an impedance

between grid and drive, which is necessary to connect the AFE to the grid and to control the input

current. Depending on the grid impedance and drive settings, the LCL filter can limit the ripple current

generated by the AFE/AIC to a level of <5%.

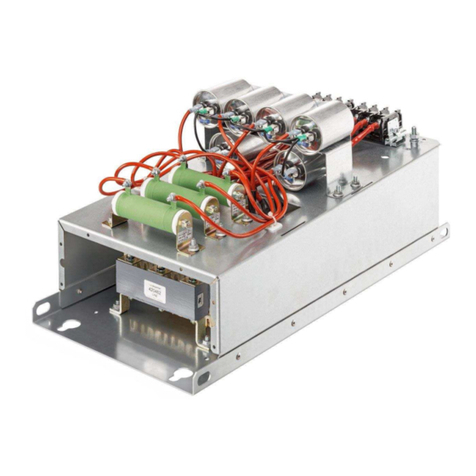

The ready-to-be-connected compact enclosed filter includes all the necessary LCL components in one

package.

Please note that some information in this document relate to filter sizes and

versions that might not be available at the time of reading. Please consult

Schaffner sales to get the latest information about our offering.

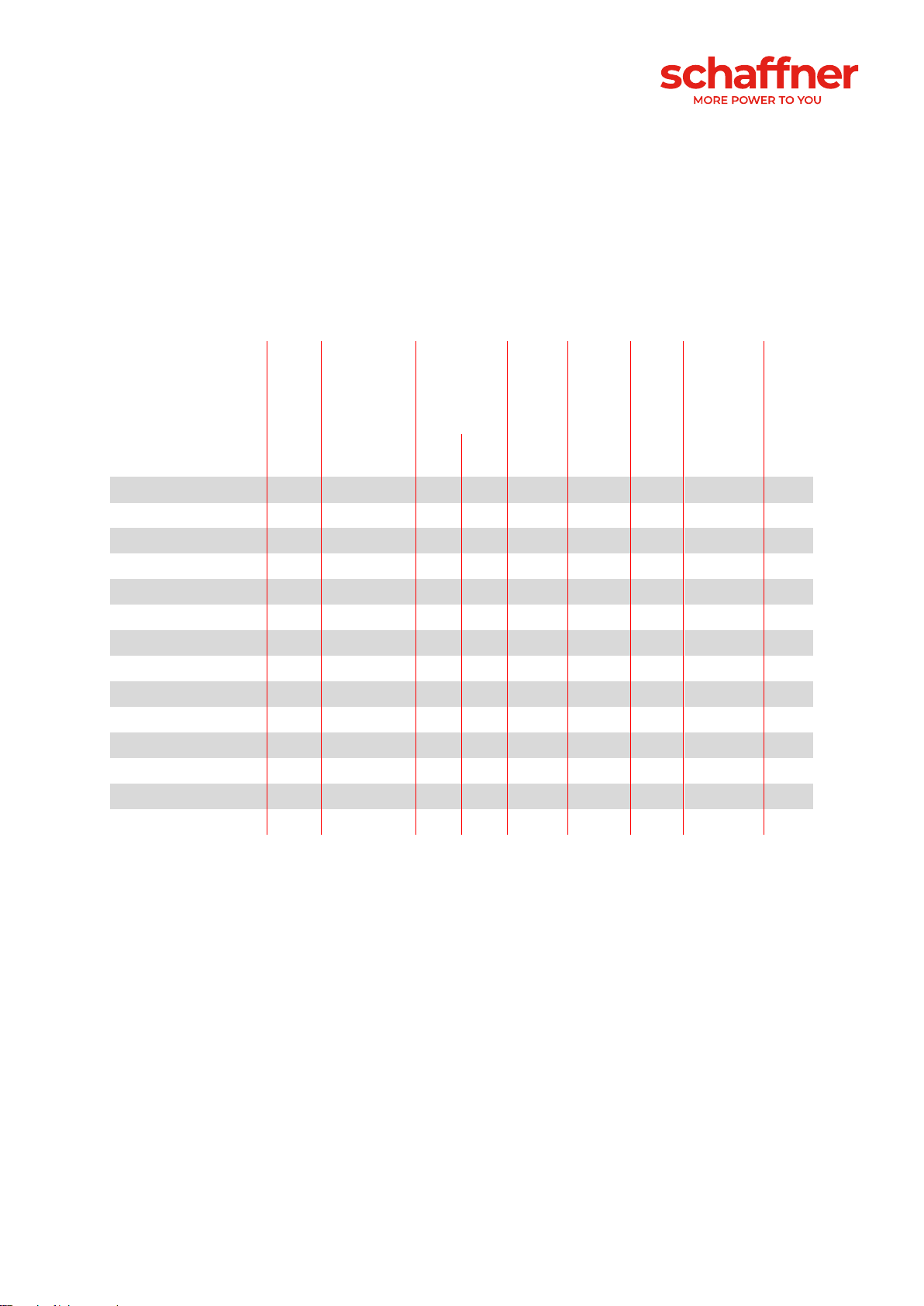

The standard FN6840 LCL filter series from Schaffner has the following key features:

▪Current and voltage range of 25 A … 380 A @ 50°C, up to 480 VAC 50/60Hz

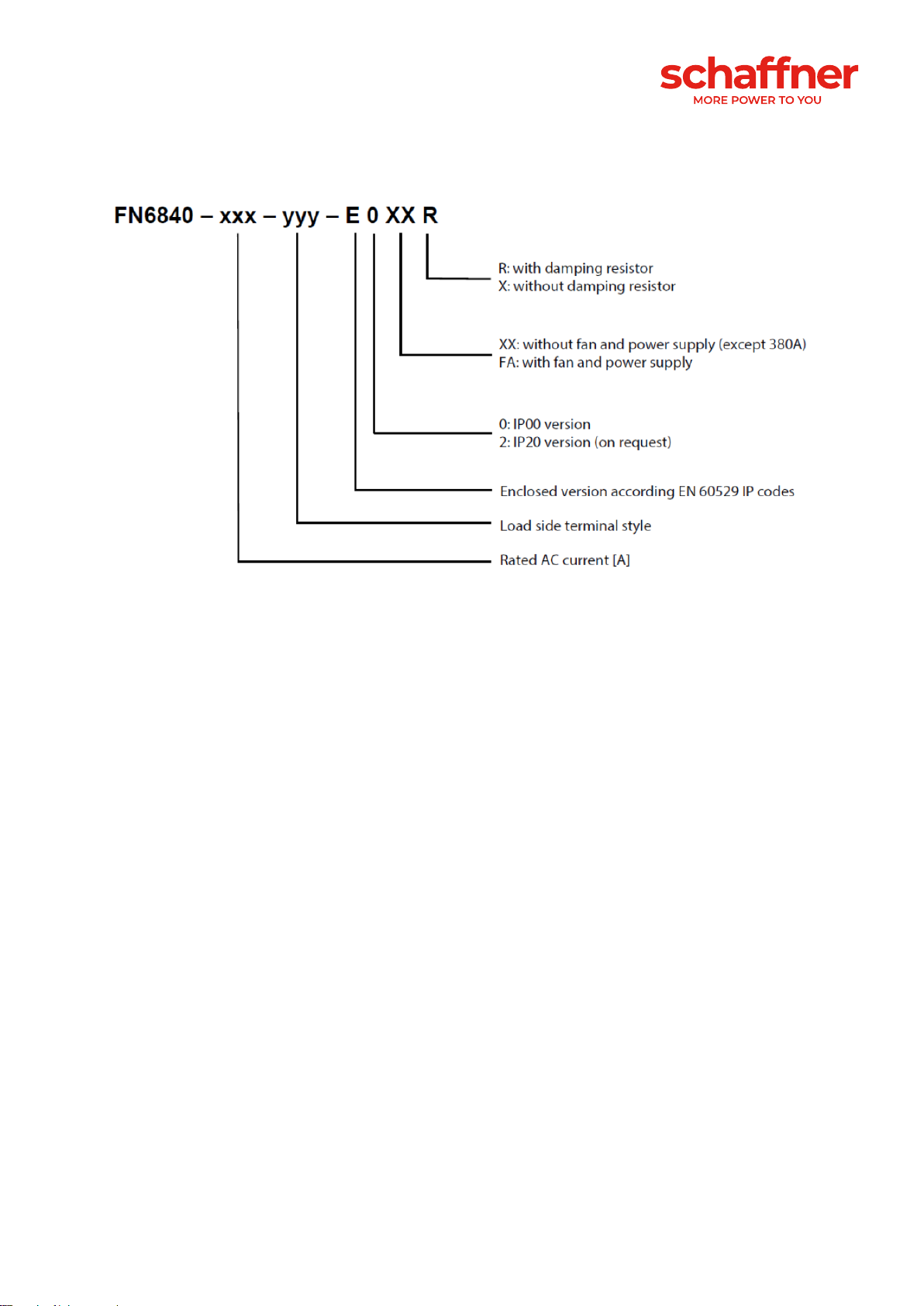

▪Versions with or without resonance damping

▪Versions without cooling fan and without power supply (up to 250A)

▪Versions with cooling fan and with power supply (380A only)

▪Versions in IP00

▪Custom specific adaptations to fulfil dedicated requirements

Typical examples of regenerative motor drives applications:

▪Elevator, hoists and cranes, transportation systems

▪Machine tools, machines with frequent breaking cycles

▪Centrifuges, flywheels (when switched off)

▪Winder / Unwinder, rolling mills run-out tables

▪Press feeders

▪Test stands

Typical examples of other AIC applications:

▪Renewable energy, e.g. Wind generator or Photovoltaic inverter

▪Energy storage or battery charging systems

To fulfill customized application requirements please contact our local sales and support organization.

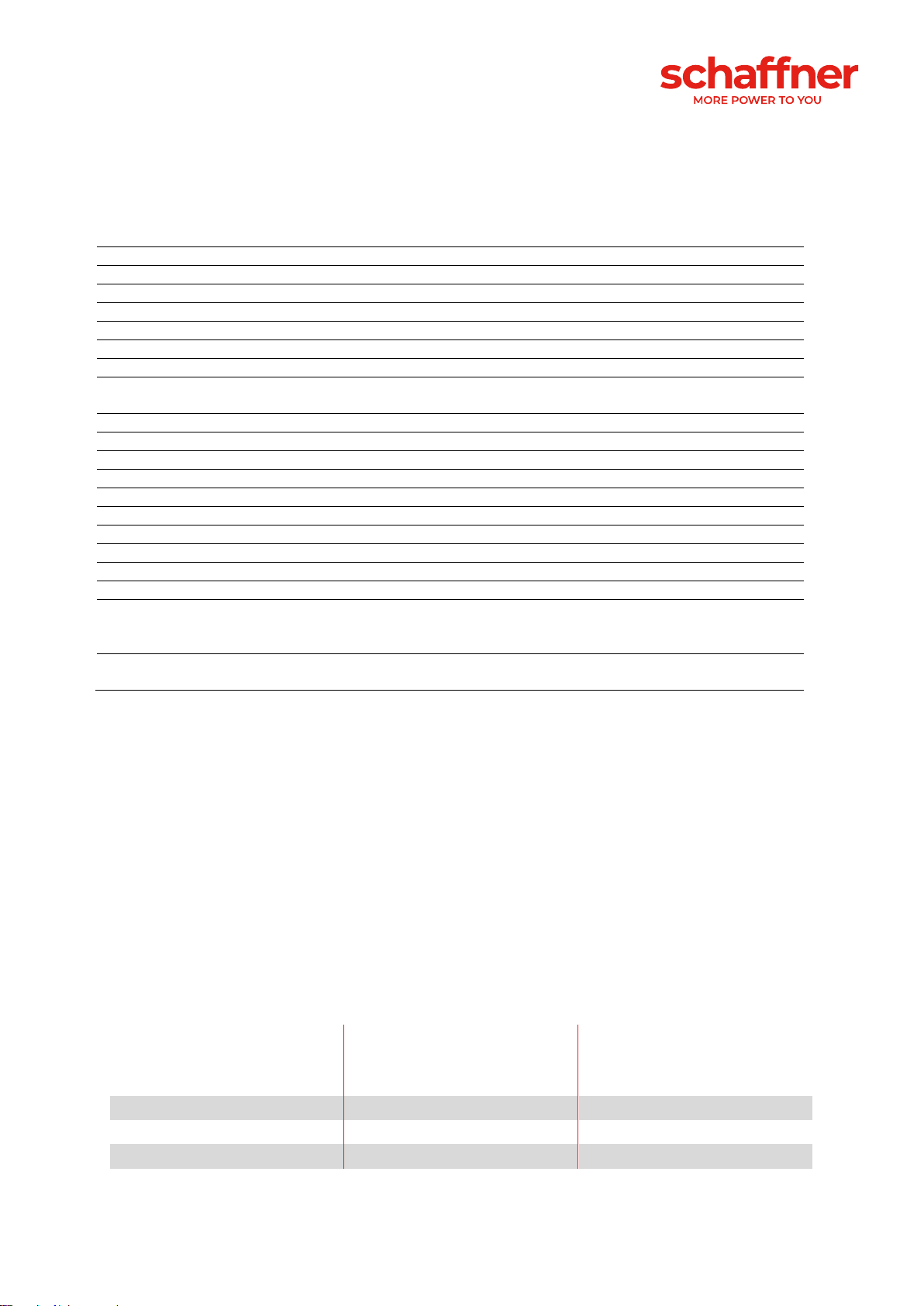

The LCL filter from Schaffner can be configured in different ways (with/without resonance damping,

with/without cooling fan).

This user manual is intended to support designers, installers, and application engineers with filter

selection, installation, application, and maintenance.

For additional support, please feel free to contact your local Schaffner sales and support organization.

ii. Important user notice

Schaffner LCL Filters are designed for the operation on the input (grid) side of power electronic

equipment with AFE (Active Front End) or AIC (Active Infeed Converter) in balanced three-phase power

systems, like typically used for AC motor drives and other converter systems. Filter suitability for a given

application must be determined by the user on a case-by-case basis. Schaffner will not assume liability