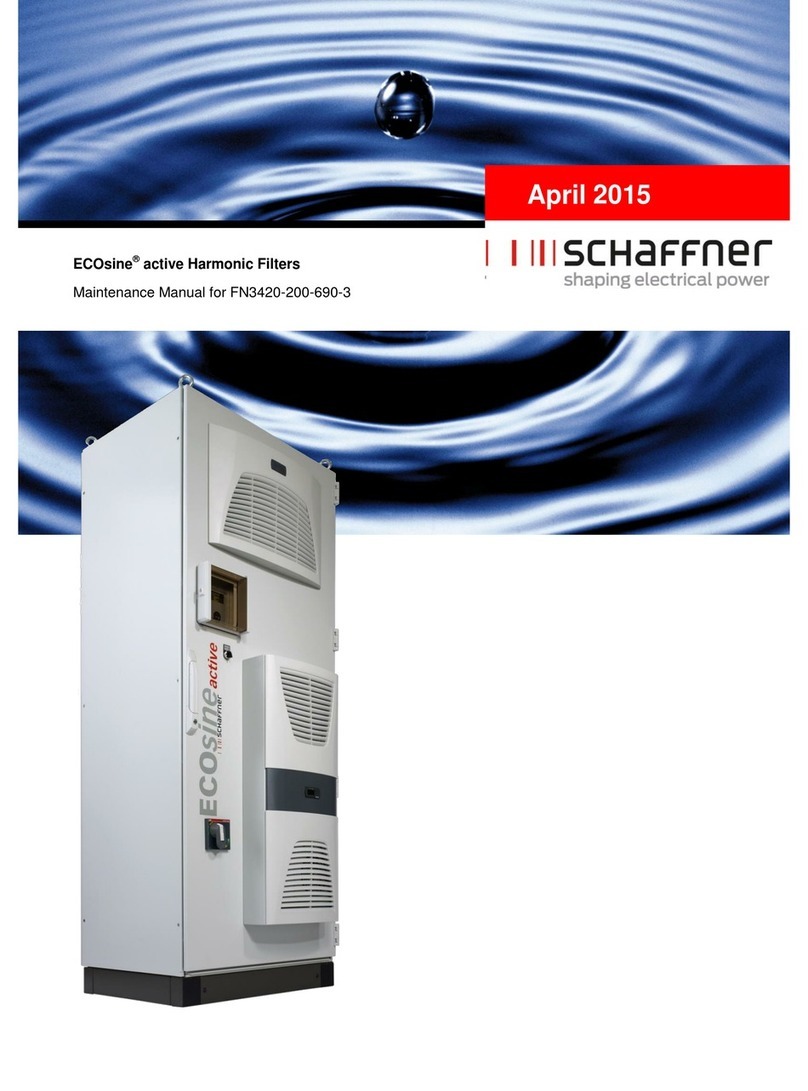

6 Ecosine®active Harmonic Filters – Maintenance Manual for FN35xx Cabinet

3 Environmental Conditions / Exclusion of warranty

This document classifies groups of environmental parameters and their severities to which

ecosine active harmonic filters are subjected when mounted for stationary use at weather

protected locations under use conditions, including periods of erection work, down time,

maintenance and repair. The lifetime of electronic equipment is depending on the

environmental conditions they are exposed to. Especially in harsh environments lifetime is

reduced due to the corrosiveness of the atmospheric environment. Generally corrosion in

micro or power electronics depends on several variants such as the package type, materials

involved, assembly processes, moisture, inorganic and organic contaminants, atmospheric

pollutants, temperature, thermal stress and electrical bias. To increase the lifetime Schaffner

provides all ecosine active filters with the ability to work within pollution degree 2 (PD2) and

does use coated PCB’s according to IEC61721-3-3. Schaffner standard PCB construction

complies with class 3C2. Please carefully read the provided information and check if your

application fulfills the required specifications as Schaffner expressly points out that the

manufacturer's warranty shall lapse with immediate effect if ecosine active sync harmonic

filters are transported, stored, installed or operated outside their published specifications.

Important

Ecosine active sync harmonic filters (AHF) listed below are IP20

or IP54 devices to be installed in an environment in compliance

with the requirements named in this document.

All AHF must be installed in a clean, dry location, e.g. in

sufficiently ventilated or air-conditioned electric cabinets or closed

electric rooms. Contaminants such as oils, liquids, corrosive

vapors, abrasive debris, dust and aggressive gases must be kept

out of the filter enclosure.

WARNING: Conductive dust may cause damage to ecosine

active sync harmonic filters. Ensure that installation site of

ecosine active sync is free of conductive dust.

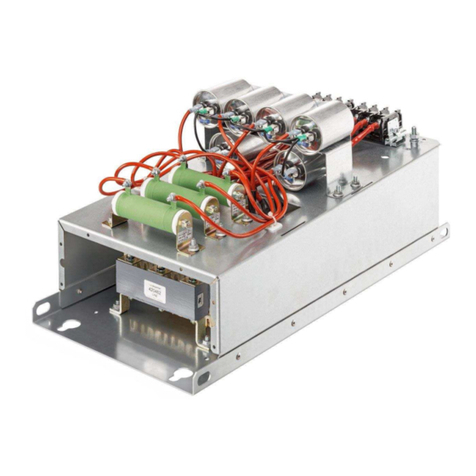

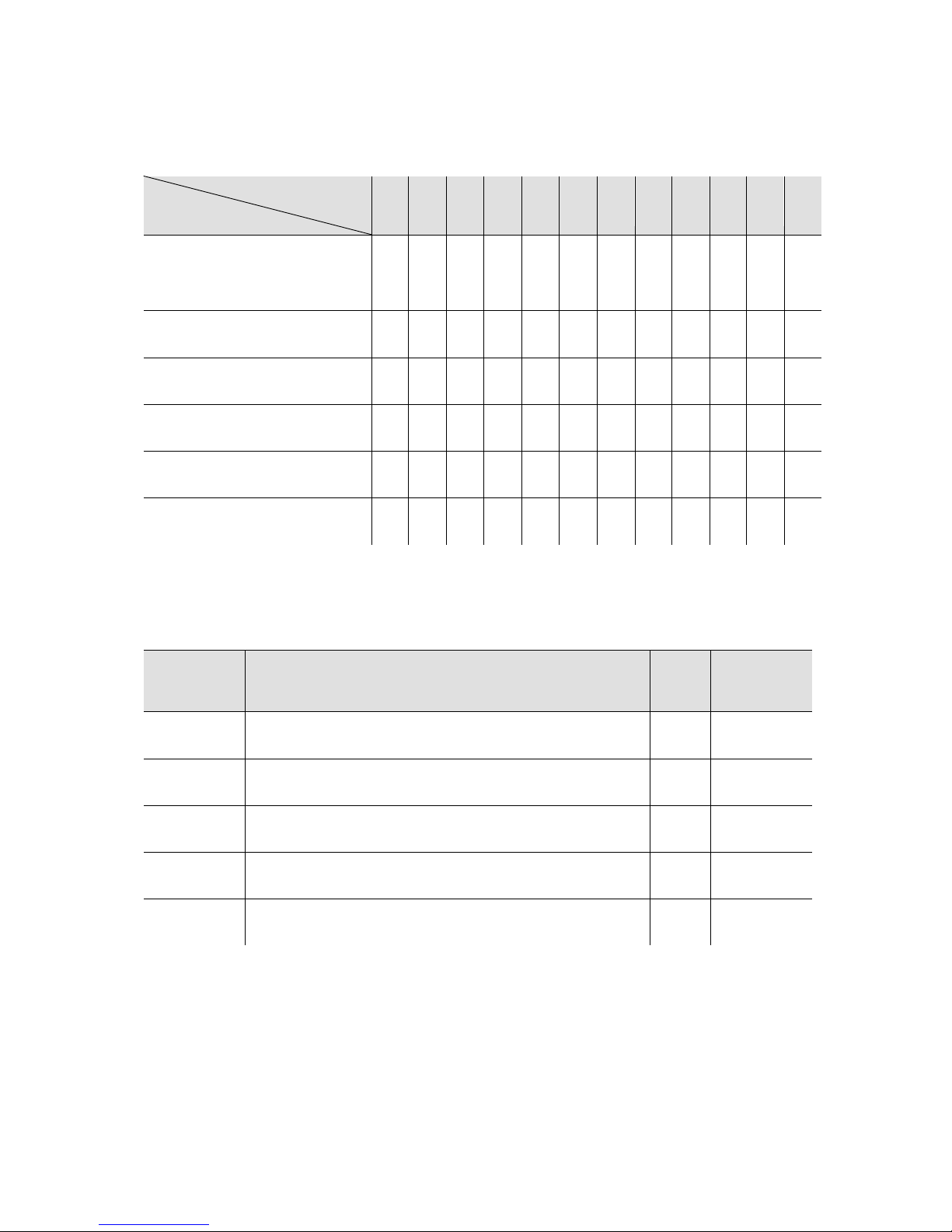

Products

FN3540/41 series, 3/4-wire filters, models 60A

FN3545 series, 3/4-wire filters, models 60…300A

Overvoltage class

(EN50178)

Ecosine active sync are designed according to EN 50178

overvoltage class III

Storage environmental

specifications

(IEC 60721-3-1, EN50178)

Climate conditions for storage class 1K3:

•Temperature range: -25°C to +55°C

•Relative humidity: < 95%, no condensation

•Atmospheric pressure: 70KPa to 106KPa

Transportation

environmental

specifications

(IEC 60721-3-2, EN50178)

Climate conditions for transport class 2K3:

•Temperature range: -25°C to +70°C

•Relative humidity: < 95%, no condensation

•Atmospheric pressure: 70KPa to 106KPa