Schier Products FS-DUO User manual

Part #: 8070-011-02

Find these instructions online at: schierproducts.com/fs-duo

Contents

Special Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Getting to Know the FS-DUO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Buried Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

On the Floor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

On the Floor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

INSTALLATION GUIDE

FS-DUO Wastewater Sampling Port

© Copyright 2020 Schier, 04/24/2020

page 2 of 8

FS-DUO Installation Guide

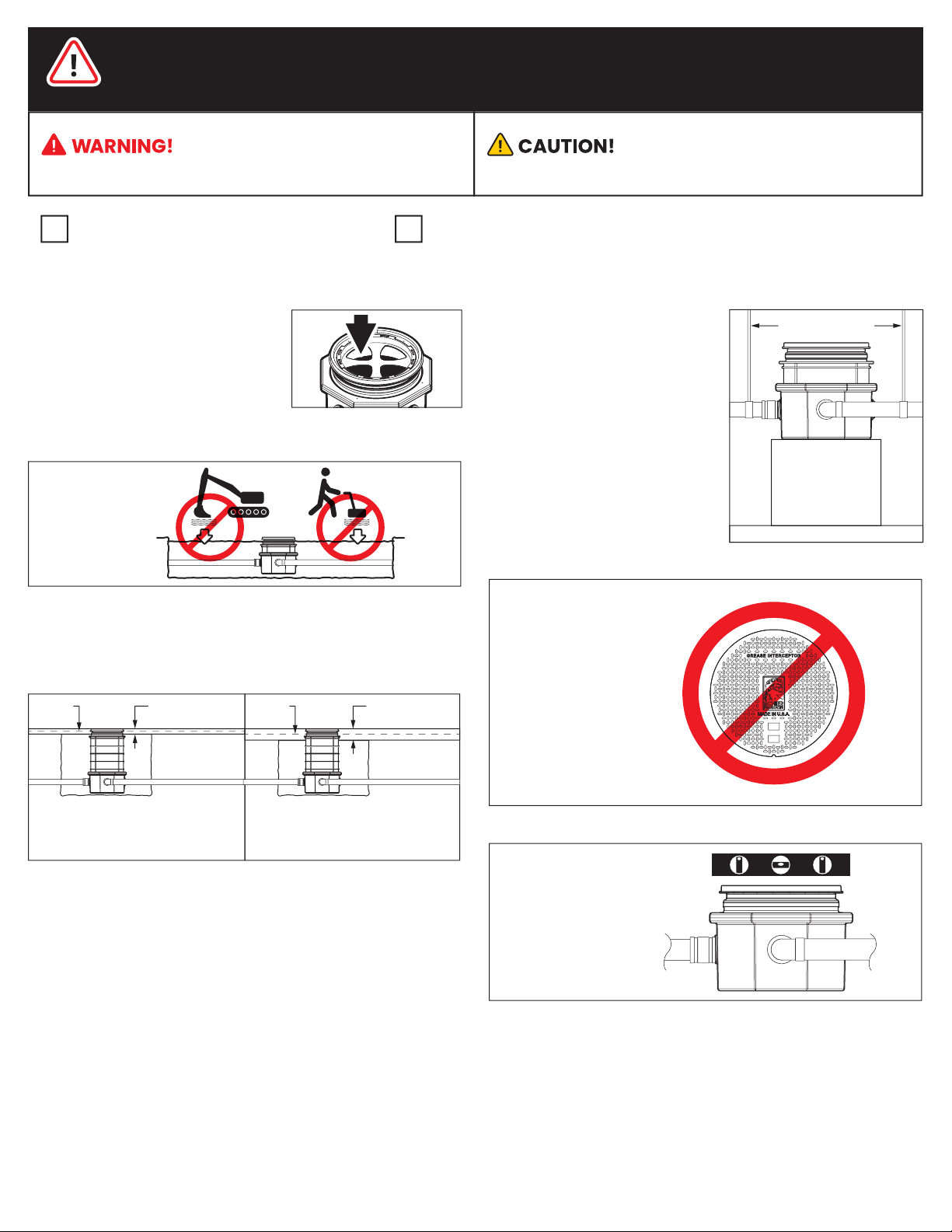

SPECIAL PRECAUTIONS

Do not install this unit in any manner

except as described in these instructions.

Doing so may result in property damage, personal injury or death.

DO NOT AIR TEST UNIT OR RISER SYSTEM!

For Schier SV24 Sampling Port Installations - Failure to follow this

guidance voids your warranty

Read all instructions before installation Install in conformance with all local codes

Installation Instructions

Installation instructions and additional

components are included with the

sampling port. Read all instructions

prior to installation. This sampling

port is intended to be installed by a

licensed plumber in conformance

with all local codes.

DO NOT

COMPACT

BACKFILL

A concrete slab to finished grade with rebar is required when

installing interceptor below grade.

Below Grade Installation Slab Requirements

Pedestrian Traffic or

Greenspace Areas Vehicular Traffic Areas

Rebar

4" min. slab 8" min. slabRebar

To prevent connection failure or

damage to fittings, ensure heavy

inlet and outlet piping (such as

cast iron or long runs) is properly

supported or suspended during

entire installation process.

Above grade installations must be

supported by a platform or trapeze

(not included) that contacts the

entire footprint of the unit.

Composite cover C24H2 is

recommended for use in above

grade installations.

Above Grade Installation Additional Support

pipe supports

DO NOT USE CAST

IRON COVERS IN

ABOVE GRADE

OR INDOOR

INSTALLATIONS

THE FS-DUO MUST

BE INSTALLED LEVEL

TO FUNCTION

PROPERLY

Support

Structure

(by others)

GETTING TO KNOW THE FS-DUO

1. Pickable Cast Iron Cover (standard)

2. Cover Gasket

3. Safety Star

4. Safety Star Tether

5. Cover Adapter

6. Cover Adapter Gasket

Assembly(x2) with Upper and

Lower Stainless Steel Band Clamps

7. Flow Distributor Body

8. Bulkhead Connection Retaining Nut

9. Bulkhead Connection Gasket

10. Outlet Bulkhead Connection

4" FPT (x2)

11. 4" Plain End Fitting (x3)

12. Inlet Diffuser

13. Inlet Diffuser Retaining Nut

14. Inlet Bulkhead Connection 4" FPT

15. Composite Cover Bolts

and Washers (x4)

16. Bolted Composite Cover (optional)

17. 7/16" Nut Driver Bit

3

4

5

6

7

8

9

10

11

17

15

16

2

11

10

9

8

12

13

9

8

14

11

page 3 of 8

FS-DUO Installation Guide

1

2

Special Precautions

BURIED INSTALLATION

Install flow distributor as close as possible to and

upstream from interceptors being served

1

Provide at least 16"

clearance above unit for

routine maintenance.

2

16" min.

3 Risers

(94") Max

4

Max Water Level

Risers are

not designed

to retain water

5

3ODOR ALERT!

Interceptor is not a sewer gas

trap. All upstream fixtures must

be trapped

page 4 of 8

FS-DUO Installation Guide

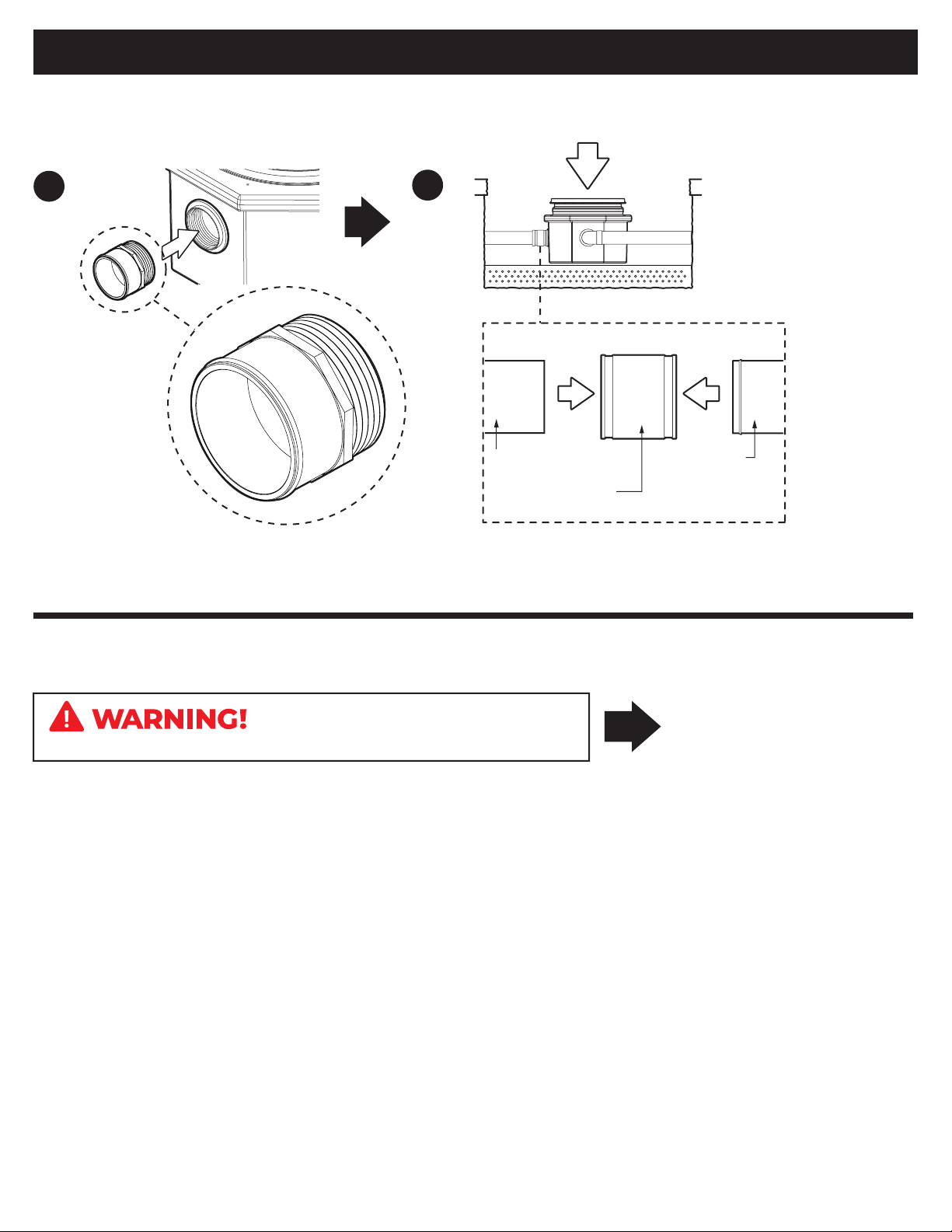

Excavate hole at least 12" larger than sampling port

on all sides and 6" deeper than port bottom.

Lay a level bed of well-packed, crushed aggregate

(approximately 3/4" size rock or sand, with no fines)

in the base of hole.

1a 1b

6" or more

12" 12"

6"

1 Excavate Burial Pit

Screw plain end

fittings (included)

into bulkhead

fittings using

pipe thread

sealant or tape

approved for use

with plastics. 6"

connection types

come pre-installed

from the factory.

2a

4" Plain End

4" FPT

DETAIL

BURIED INSTALLATION

3 Wet or Air Test Piping Per Local Code

Doing so may result in property damage, personal injury or death.

DO NOT AIR TEST UNIT OR RISER SYSTEM! Have a Leak? Call customer

care at 913-951-3300

Hours 8am-5pm CST, M-F

2b

2 Connect Piping

Lower unit into pit and

set level. Mechanically

couple inlet and outlet

drainage lines to unit.

Do not solvent weld.

Vent per local code.

DETAIL

Flexible PVC Coupling

Plain End

Fitting

Drain line

page 5 of 8

FS-DUO Installation Guide

BURIED INSTALLATION

4 Bring Cover Flush-to-Grade

The FS-DUO is ready for burial depth of 22" from finished grade to bottom of unit (or 13-1/2" to centerline of inlet).

Deeper burials will require extending the Cover Adapter and possibly adding risers.

Measure dimension X to determine riser height needed.

4a

Install riser(s) if required

(see instructions included with FCR2).

4b

Riser Height Risers

Needed Required

0" - 4" None (use adapter)

>4" - 34" FCR2 (x1)

>34" - 64" FCR2 (x2)

>64" - 94" FCR2 (x3)

If required, Cover Adapter

may now be tilted up to

10º in any direction using

gasket flexibility.

4f

Adjust Cover Adapter

height as needed.

Maintain a minimum

2-1/2" insertion depth.

2-1

/

2" minimum

4d

Loosen the

Cover Adapter Upper

Band Clamp using 7/16"

Nut Driver Bit.

4c

Tighten Upper

Band Clamp to 5 -8 ft.

lbs. of torque using 7/16"

Nut Driver Bit.

4e

5 Backfill and Finished Grade

TOP VIEW 18"

min

45º

18"

min

18"

min

18"

min

Concrete Slab

Rebar

Pour concrete slab to finished grade.

5b

Vehicular Traffic Areas:

Minimum 8" thick concrete slab with rebar required. Thickness of

concrete around covers to be determined by specifying engineer. If

traffic loading is required the concrete slab dimensions shown are for

guideline purposes only. Concrete to be 28 day compressive strength

to 4,000 PSI. Use No. 4 rebar (ø 1/2") grade 60 steel per ASTM A615:

connected with tie wire. Rebar to be 2-1/2" from edge of concrete and

spaced in a 12" grid with 4" spacing around access openings.

Pedestrian Traffic or Greenspace Areas:

Minimum 4" thick concrete slab with rebar required.

5b1

Rebar

5a

Backfill evenly around tank using crushed aggregate

(approximately 3/4" size rock or sand with no fines) or

flowable fill. Do not compact backfill around unit.

page 6 of 8

FS-DUO Installation Guide

Special Precautions

Install flow distributor as close as

possible to and upstream from

interceptors being served

1

Use composite cover C24H2 only for

above grade installations

2

Above grade installations must be

supported by a platform or trapeze

(not included) that contacts the

entire footprint of the unit.

3

ON THE FLOOR INSTALLATION

Screw plain end

fittings (included)

into bulkhead

fittings using

pipe thread

sealant or tape

approved for use

with plastics. 6"

connection types

come pre-installed

from the factory.

1a

4" Plain End

4" FPT

DETAIL

ODOR ALERT!

Sampling port is not a sewer gas trap. All

upstream fixtures must be trapped

4

1 Connect Piping FLOOR BELOW INSTALLATION DETAIL

Mechanically

couple inlet and

outlet drainage

lines to unit. Do not

solvent weld.

Ensure all upstream

fixtures are trapped.

Vent per local code.

1b

vent per

local code

DETAIL

Flexible PVC Coupling

Plain End

Fitting

Drain line

2 Wet or Air Test Piping Per Local Code

Doing so may result in property damage, personal injury or death.

DO NOT AIR TEST UNIT OR RISER SYSTEM! Leak? Call customer care at

913-951-3300

8a – 5p M – F CST

Provide at least 16"

clearance above unit for

routine maintenance.

16" min.

5

page 7 of 8

FS-DUO Installation Guide

composite cover C24H2

support platform (by others)

INSTALLATION DETAILS

page 8 of 8

FS-DUO Installation Guide

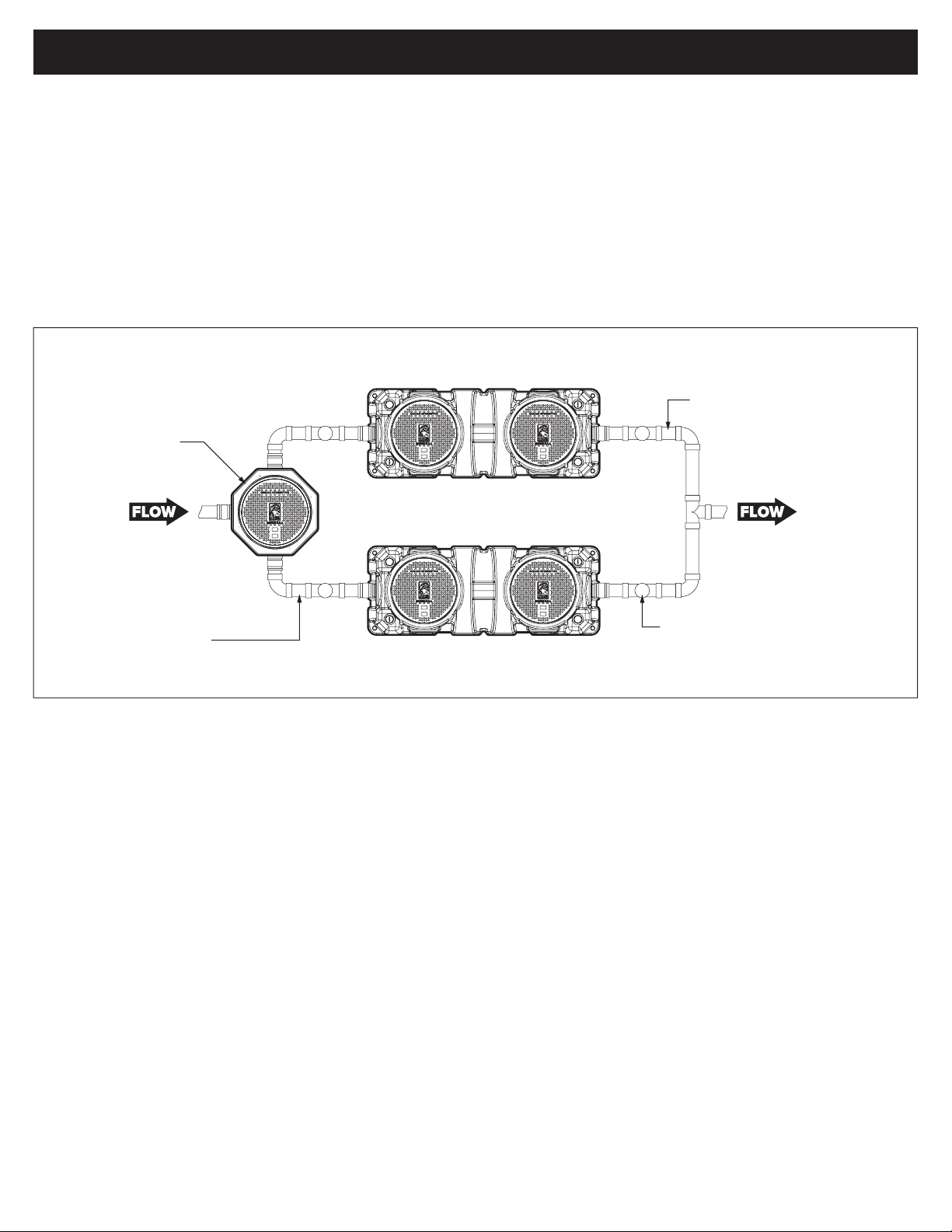

1 Parallel Installations

For flow rates above 100 GPM and higher grease storage requirements the FS-DUO flow distributor must be piped

in parallel with two grease interceptors as shown to ensure the system works properly as designed. Units must be

equally spaced to ensure equal euent flow distribution.

For below grade installations, all units must be level in the excavation pit. It is recommended to install a two-way

cleanout tee extended to finished grade before and after each unit for line cleaning purposes.

All manifolds, piping between units and two-way cleanout tees by others.

TOP VIEW OF 2 GB-250 UNITS PIPED IN PARALLEL

Inlet Manifold

Outlet Manifold

Two-way cleanout tee

extended to grade

(provided by others)

FS-DUO

Table of contents

Popular Laboratory Equipment manuals by other brands

Viso Systems

Viso Systems LabRail user manual

NoiseKen

NoiseKen ESS-2000AX instruction manual

Amsco

Amsco Century Operator's manual

Thermo Scientific

Thermo Scientific Thermo Scientific HyPerforma quick start guide

3D Histech

3D Histech Pannoramic MIDI user manual

NuAire

NuAire LabGard ES NU-565-400 Operation & maintenance manual

Thermo Scientific

Thermo Scientific AI 3000 operating manual

cytiva

cytiva Amersham ImageQuant 500 operating instructions

Noztek

Noztek fusionX user manual

BD

BD CARV II Installation and user guide

BASENHURT

BASENHURT Tebas-Economic EFka300 pH/Chlor Installation and maintenance instructions

PVD Products

PVD Products PLD 3000 user guide