2

Operating instructions

Safety switch AZ 200 T

EN

1.6 Warning about misuse

In case of improper use or manipulation of the safety switch-

gear, personal hazards or damages to machinery or plant

components cannot be excluded. The relevant requirements

of the standard EN 1088 must be observed.

1.7 Exclusion of liability

We shall accept no liability for damages and malfunctions resulting from

defective mounting or failure to comply with this operating instructions

manual. The manufacturer shall accept no liability for damages

resulting from the use of unauthorised spare parts or accessories.

For safety reasons, invasive work on the device as well as arbitrary

repairs, conversions and modifications to the device are strictly

forbidden; the manufacturer shall accept no liability for damages

resulting from such invasive work, arbitrary repairs, conversions and/or

modifications to the device.

2. Product description

2.1 Ordering code

This operating instructions manual applies to the following types:

AZ 200➀-T-➁

No. Option Description

➀

SK Screw connection

CC Cage clamps

ST1 M23 x 1 connector (8+1) pole

ST2 M12 x 1 connector, 8 pole

➁

Outputs

1P2P 1 p-type diagnostic output and

2 p-type safety outputs

3P2P 3 p-type diagnostic output and

2 p-type safety outputs

SD2P serial diagnostic output and

2 p-type safety outputs

Only if the information described in this operating instructions

manual are realised correctly, the safety function and therefore

the compliance with the Machinery Directive is maintained.

2.2 Special versions

For special versions, which are not listed in the order code below 2.1,

these specifications apply accordingly, provided that they correspond to

the standard version.

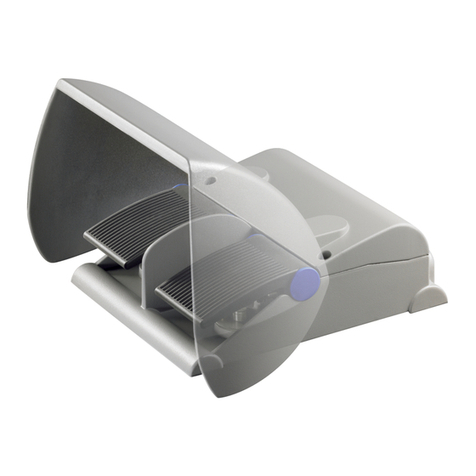

2.3 Purpose

The AZ 200 with non-contact electronic safety sensors is designed for

application in safety circuits and is used for monitoring the position of

movable safety guards. The integrated door detection sensor monitors

the closed condition of the safety guard, the sensor of the actuator

monitors the actuator position. The safety function consists of safely

switching off the safety outputs when the safety guard is opened and

maintaining the safe switched off condition of the safety outputs for as

long as the safety guard is open. The opening of the safety guard is

detected by the safety sensors.

LED functions

The safety switchgear signals the operational state as well as errors

through three coloured LED’s installed on the front side of the device.

green supply voltage on

red: Error (see flash codes)

Yellow operating condition

2.4 Technical data

Standards: IEC 60947-5-3, EN ISO 13849-1,

IEC 61508

Material of the enclosure: glass-fibre reinforced thermoplastic,

self-extinguishing

Mechanical life: ≥ 1 million operations

Latching force: 30 N

Protection class: IP67 to IEC/EN 60529

Insulation protection class: II,

X

Overvoltage category: III

Degree of pollution: 3

Realisation of the electrical connection: Screw terminals or cage

clamps, M12 or M23 connector

Cable section: min. 0.25 mm², max. 1.5 mm²

(including conductor ferrules)

Tightening torque for the cover screws: 0.7 ... 1 Nm (TorxT10)

Cable entry: M20 x 1.5

Series-wiring: max. 31 devices (not applicable

for ordering suffix -3P2P)

Cable length: max. 200 m (Cable length and

cable section alter the voltage drop

depending on the output current)

Switching distances to IEC 60947-5-3:

Rated operating distance Sn:6.5 mm

Assured switching distance sao:4.0 mm

Assured switch-off distance sar:30 mm

Hysteresis: max: 1.5 mm

Repeat accuracy: < 0.5 mm

Ambient conditions:

Ambient temperature: −25 °C ... +70 °C

Storage and transport temperature: −25 °C ... +85 °C

Resistance to vibration: 10 ... 55 Hz, amplitude 1 mm

Resistance to shock: 30 g / 11 ms

Switching frequency: 1 Hz

Response time: < 60 ms

Duration of risk: < 120 ms

Time to readiness: < 4000 ms

Max. actuating speed: ≤ 0.2 ms

Electrical data:

Rated operating voltage Ue:24 VDC -15% / +10%

(stabilised PELV)

Rated operating current Ie:0.7 A

No-load current Io:max. 0.1 A

Rated impulse withstand voltage Uimp:0.8 kV

Rated insulation voltage Ui:32 VDC

Device insulation: internal short-circuit proof

Screw terminals or cage clamps: ≤ 4 A when used to UL 508

- Connector M12: ≤ 2 A

- Connector M23: ≤ 4 A

EMC rating: to EN 61000-6-2

Safety inputs: X1 and X2 (-1P2P and -SD2P)

Rated operating voltage Ue3:- 3 V ... 5 V (Low)

15 V ... 30 V ( High)

Rated operating current Ie3:typically 2 mA at 24 V

Safety outputs Y1 and Y2: p-type, short-circuit proof

Rated operating voltage Ue1:0 V ... 4 V under Ue

Rated operating current Ie1:max. 0.25 A each

Utilisation category: DC-13

Leakage current Ir: ≤ 0.5 mA

Diagnostic output OUT / OUT2 / OUT3: short-circuit proof, p-type

Rated operating voltage Ue2:0 V ... 4 V under Ue

Rated operating current Ie2:(lout + lout2 + lout3 ≤ le2)

-1P2P: max. 0.05 A

-3P2P: max. 0.1 A

Utilisation category: DC-13

Wiring capacitance for serial diagnostics: max. 50 nF

cULus: Use isolated power supply only

For use in NFPA 79 Applications only Adapters

providing field wiring means are available from

the manufacturer. Refer to manufacturers information.