SCIFIT PRO1 Sport Operating and safety instructions

Other SCIFIT Fitness Equipment manuals

SCIFIT

SCIFIT Intelli-fit Troubleshooting guide

SCIFIT

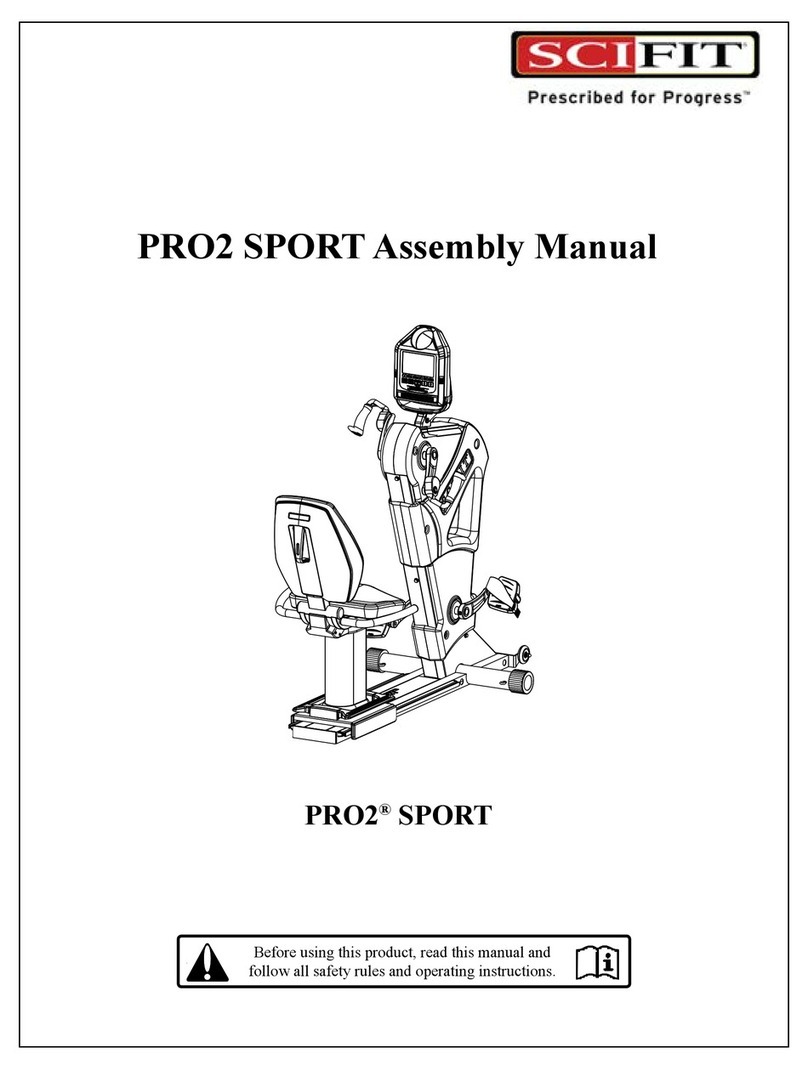

SCIFIT PRO2 Mounting instructions

SCIFIT

SCIFIT PRO2-INT Series User manual

SCIFIT

SCIFIT PRO1 Sport Instructions for use

SCIFIT

SCIFIT TC1000 Series Instructions for use

SCIFIT

SCIFIT PRO1XX-DOMHUR User manual

SCIFIT

SCIFIT STANDARD User manual

SCIFIT

SCIFIT PRO1 Sport User manual

SCIFIT

SCIFIT SXT7000 Parts list manual

SCIFIT

SCIFIT PRO2 User manual

SCIFIT

SCIFIT PRO1030-INT User manual

SCIFIT

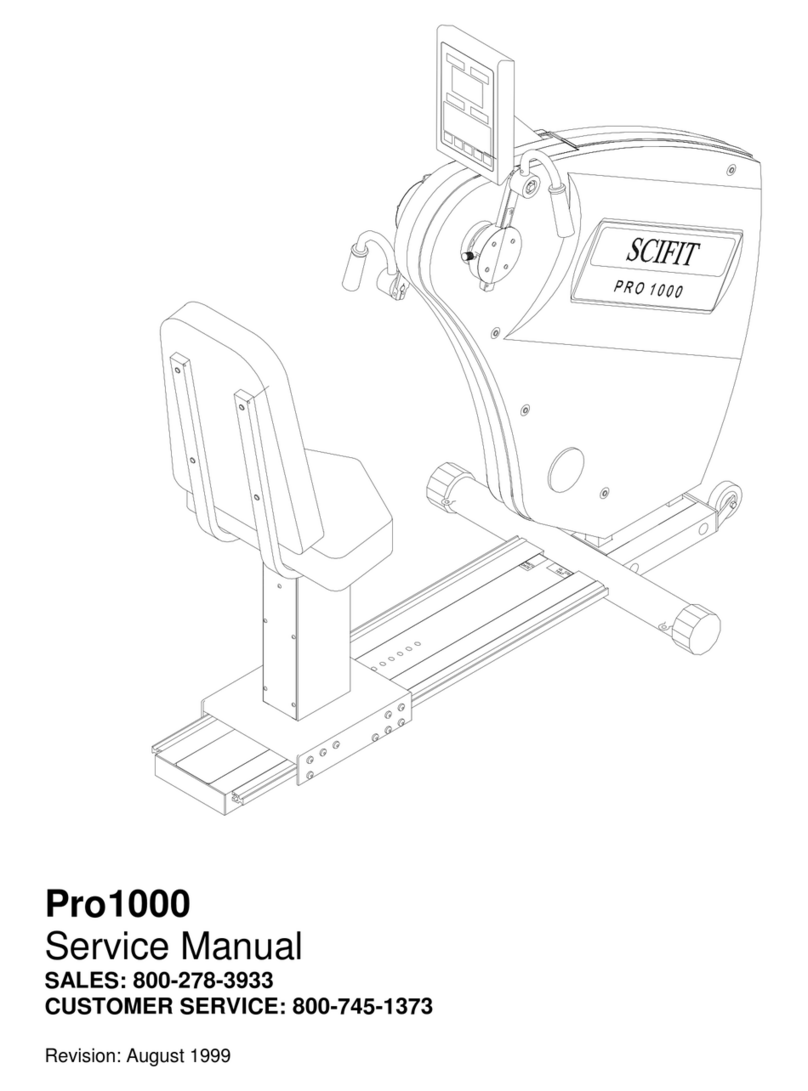

SCIFIT PRO1000 Sport User manual

SCIFIT

SCIFIT PRO2 User manual

SCIFIT

SCIFIT SXT7000 User manual

SCIFIT

SCIFIT PRO1000 Sport User manual

SCIFIT

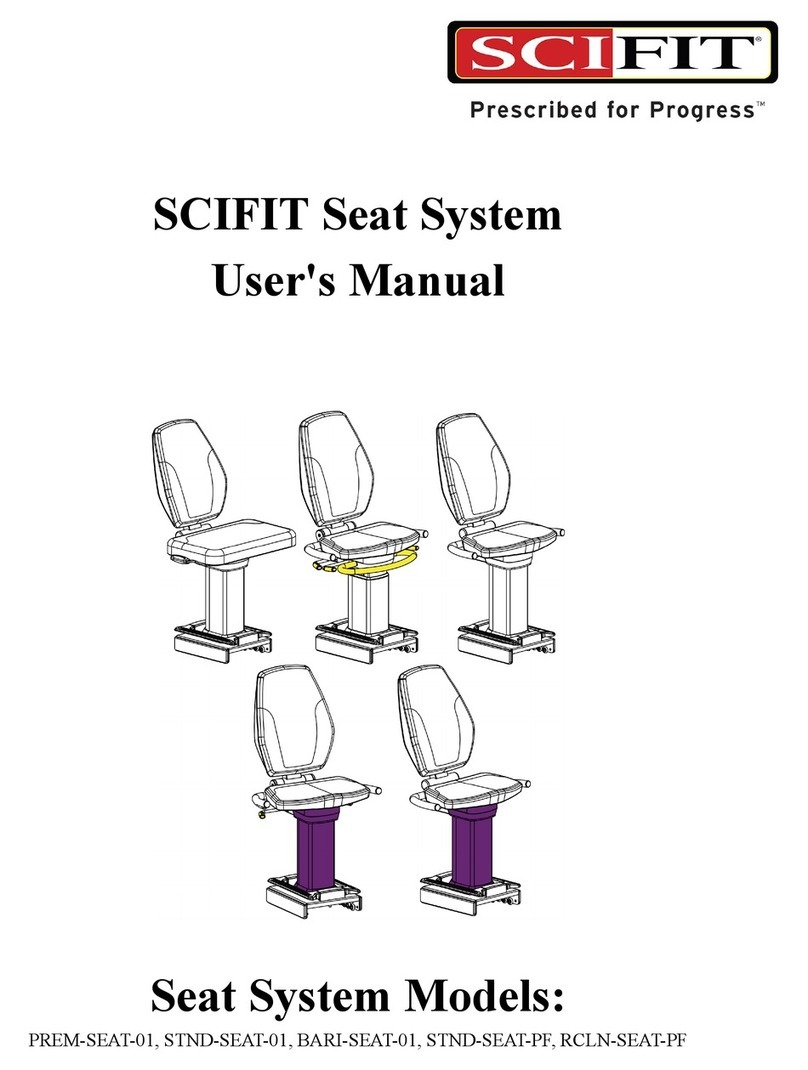

SCIFIT PREM-SEAT-01 User manual

SCIFIT

SCIFIT PRO2 User manual

SCIFIT

SCIFIT PRO1 Sport User manual

SCIFIT

SCIFIT SONE Series User manual

SCIFIT

SCIFIT PRO2 Instructions for use

Popular Fitness Equipment manuals by other brands

G-FITNESS

G-FITNESS AIR ROWER user manual

CAPITAL SPORTS

CAPITAL SPORTS Dominate Edition 10028796 manual

Martin System

Martin System TT4FK user guide

CIRCLE FITNESS

CIRCLE FITNESS E7 owner's manual

G-FITNESS

G-FITNESS TZ-6017 user manual

Accelerated Care Plus

Accelerated Care Plus OMNISTIM FX2 CYCLE/WALK user manual