The Work at Height Regulations places duties

upon employers and other duty holders

concerned with managing or carrying out work

at height.

Employers should establish a regime for the

inspection of equipment. It is essential that a

competent person is given the authority to

make objective decisions and take appropriate

action, even if this means rejecting a

component-at the cost of delaying a work task.

The inspection regime should include

•The equipment to be inspected

•User training

•Safe keeping, updating and access of User

record cards

•Frequency and type of inspection relevant

to each component

•Action to be taken if a defective component

is found.

There are also requirements in BS EN 865:2002 and BS

8437 which contain both general and specific

information on periodic inspection of fall protection

equipment.

Scissorsafe system and kit components carry

obsolescence dates and any component that has

reached this date and which has not been rejected for

other reasons, should be withdrawn from service and

not used again.

Good record keeping is essential to establish the age and

conditions of use for products.

Scissorsafe components carry unique serial numbers

that allow the history of the component to be recorded.

If the serial number is lost or becomes illegible, or if

Record cards are lost, please send a request to

Scissorsafe Ltd. and a replacement will be made

available to you.

These can be requested by email at

info@scissorsafe.co.uk.

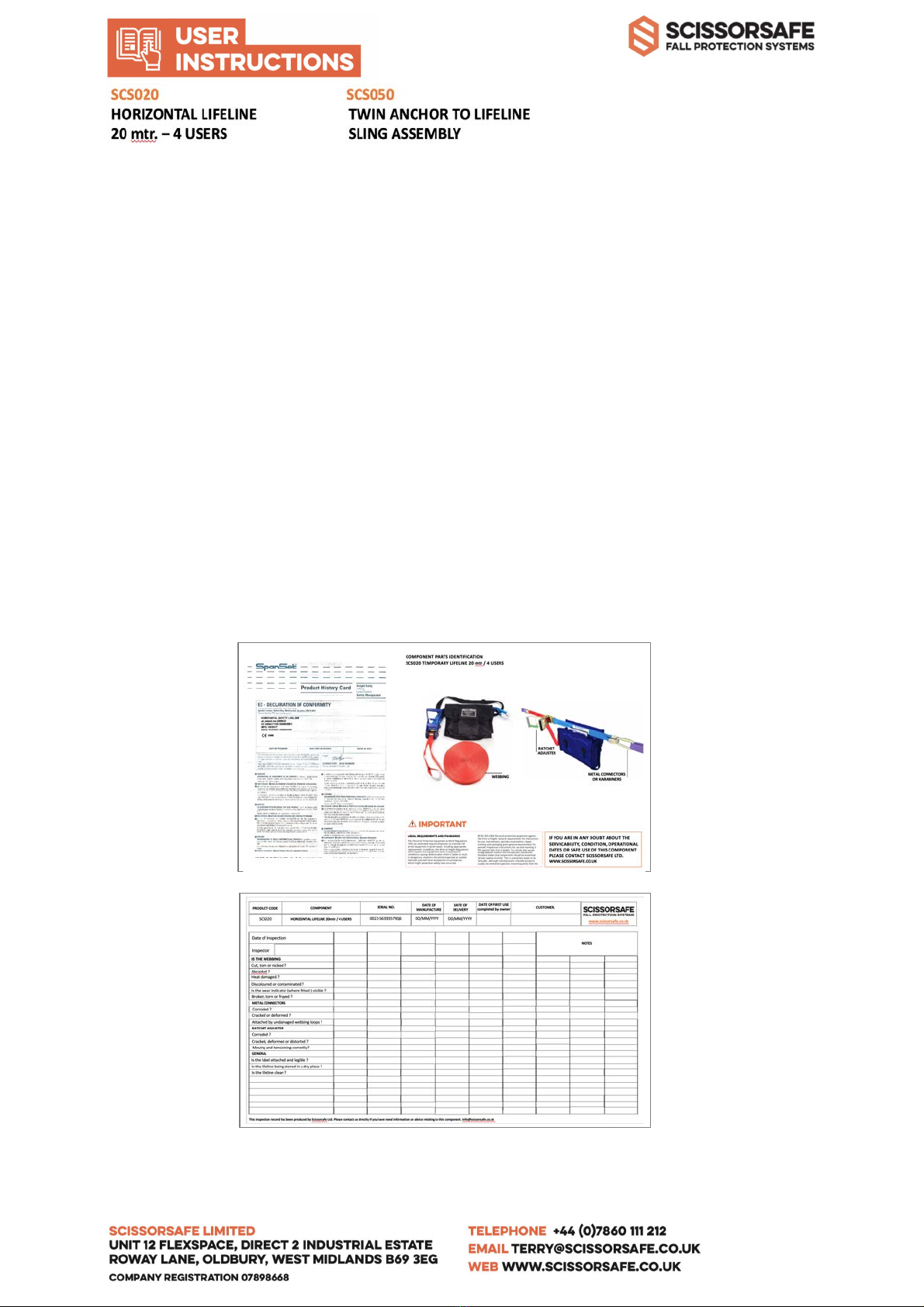

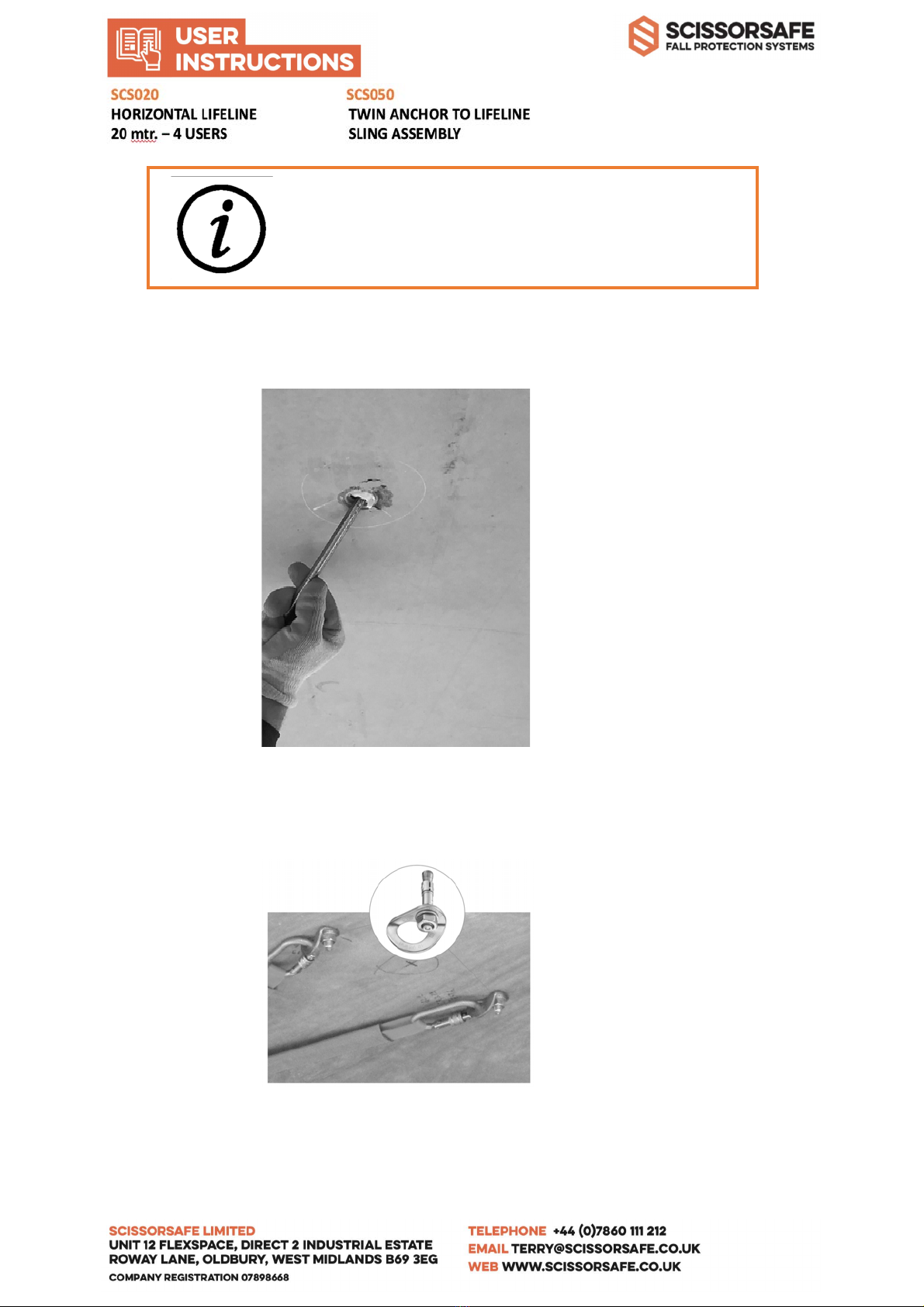

This component is intended for use as personal

safety device serving to protect the user in

conjunction with a Safety Harness compliant to

EN 361.

Please refer to the Routine Inspection Checklist

provided with this component before using it to

ensure that it is in a serviceable condition and

is operating correctly.

Users of this Anchorage Device must be trained

in its use and pre-inspection requirements.

Ensure that the Anchor Device is not used outside its

limitations, or for any purpose other than that which it is

intended and that the user has been trained to do.

This component should not be used by anyone that has a

medical condition which could affect their safety when

using it.

Do not make any alterations, additions or repairs to the

Anchorage Device and withdraw it from use immediately

should any doubt arise about its condition.

Ensure the compatibility of other components intended

for use with this Anchorage Device in a Work Restraint

System and always refer to their specific instructions prior

to using them.

Ensure that a rescue plan is in operation, taking into

account all possible rescue scenarios during the work

Important points to consider before using this component

SCS003

SCISSORSAFE ANCHORAGE TOOL