ATTACH

ENE GY

ABSO BE

ONLY TO

DO SAL

D- ING

MAXIMUM ATTACHMENT DISTANCE

WITH HOOK WITHOUT HOOK

ACCEPTABLE DESIGNED ETAINE

DO NOT

ATTACH

ENE GY

ABSO BE

TO ANCHO

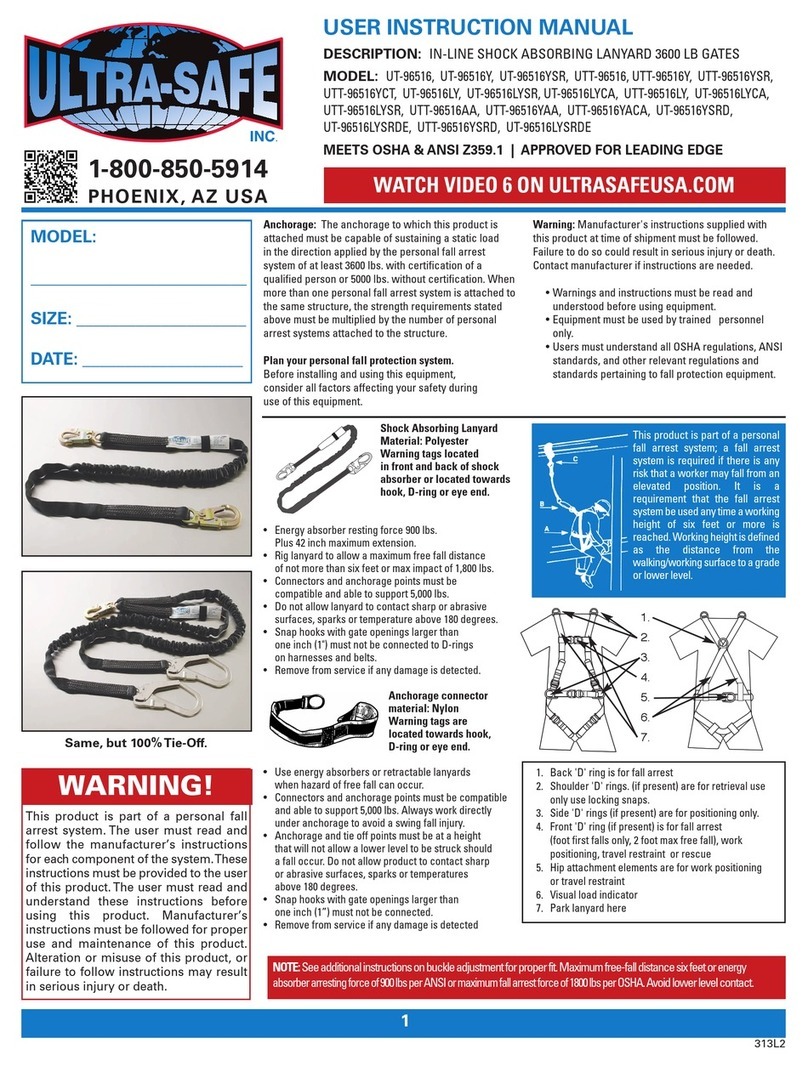

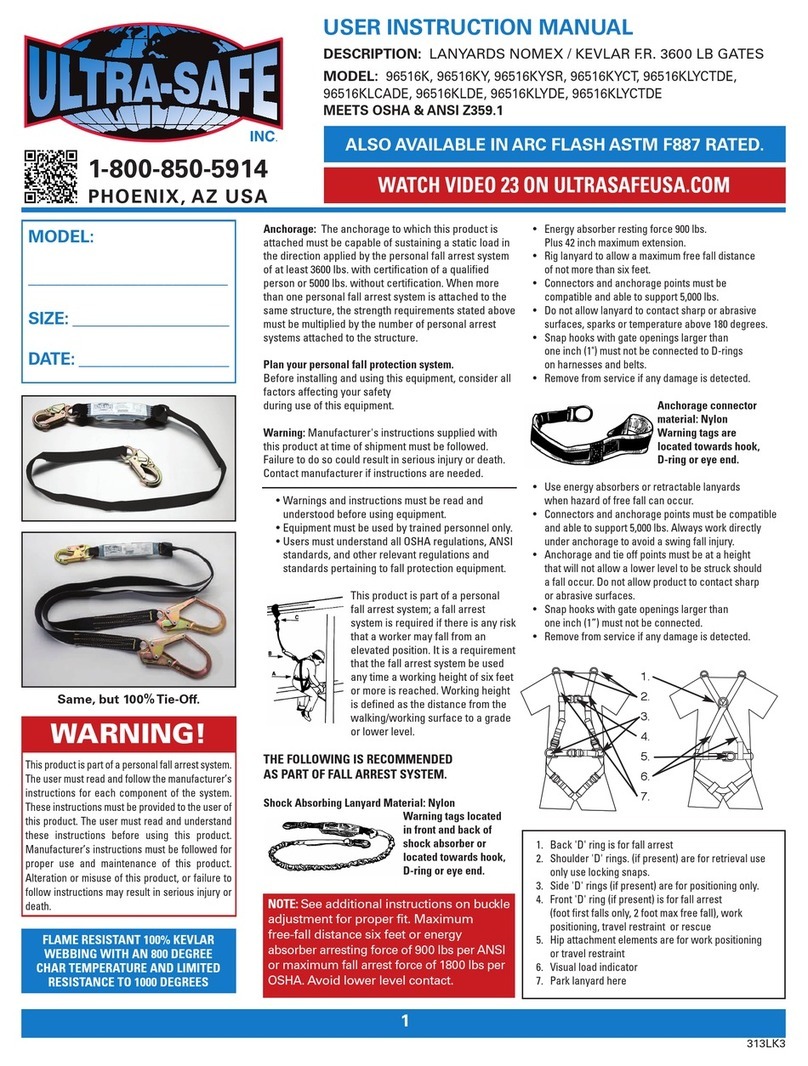

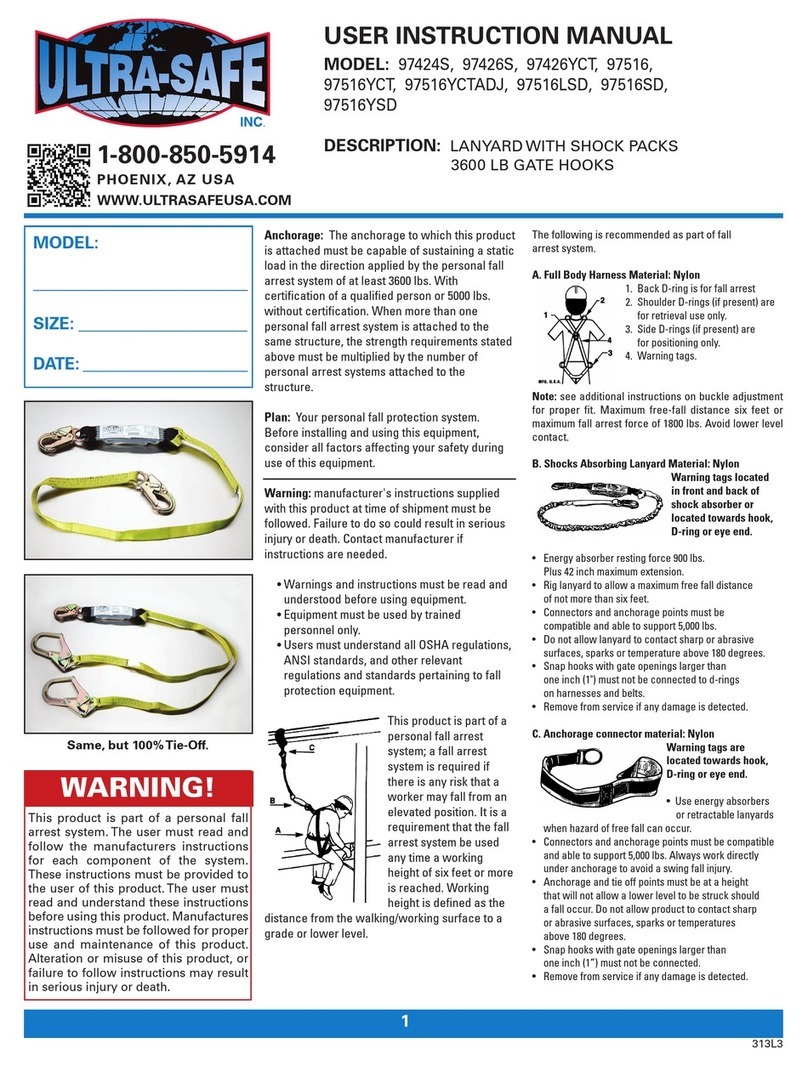

When using lanyards commonly referred to as "100% tie-

off”, "Y" type, "double" or "twin leg" shock absorbing

lanyards. This supplement provides additional information

on the use of these types of lanyards that are used with a

personal fall arrest systems. Practices that must be

followed in order to use a 100% tie-off lanyard safely.

1. The shock absorber pack portion of the lanyard

assembly MUST be connected to the back dorsal D-ring

NLY, by way of a double locking lanyard snap hook

(other connectors provided, consult ULTRA-SAFE, INC.)

connect shock absorber directly to the dorsal D-ring.

2. Do not connect shock absorber to the anchorage point

at any time.

3. Do not connect the unused leg of the lanyard assembly

to any portion of the full body harness, unless a

specifically designed lanyard snap hook loop retainer

is provided for this purpose.

4. When connecting from one anchorage point to the next

(traversing a vertical or horizontal structure) do not

connect to an anchorage point further apart than, the

length of the lanyard.

5. When using a 100% tie-off lanyard assembly, do not

allow any part of the lanyard to pass under arms or legs.

6. Connection of both lanyard legs to separate anchorage

points is acceptable, as long as anchorage points are

within the length of the lanyard.

MAINTENANCE, SE VICING, STO AGE:

Clean lanyard with water and a mild detergent solution. Wipe

off hardware with a clean, dry cloth, and hang to air dry. Do not

dry with heat source. Excessive buildup of dirt, paint, etc., may

occur and prevent the lanyard from working properly, and in

severe cases degrade the webbing or rope to a point where it

has become weakened and should be removed from service.

If you have any questions concerning the condition or cleaning

of your lanyard, doubts about putting it into service or require

more information, contact Ultra-Safe, Inc.

AFTE A FALL: Components which have been subjected to

the forces of arresting a fail must be removed from service

and destroyed.

ESCUE PLAN: When using this equipment, the employer

must have a rescue plan and the means at hand to implement

the rescue, as well as communicate that plan to users,

authorized persons, and rescuers.

COMPATIBILITY OF CONNECTO S:

IMP RTANT: Use only connectors that are suitable to each

application and are compatible with connecting elements.

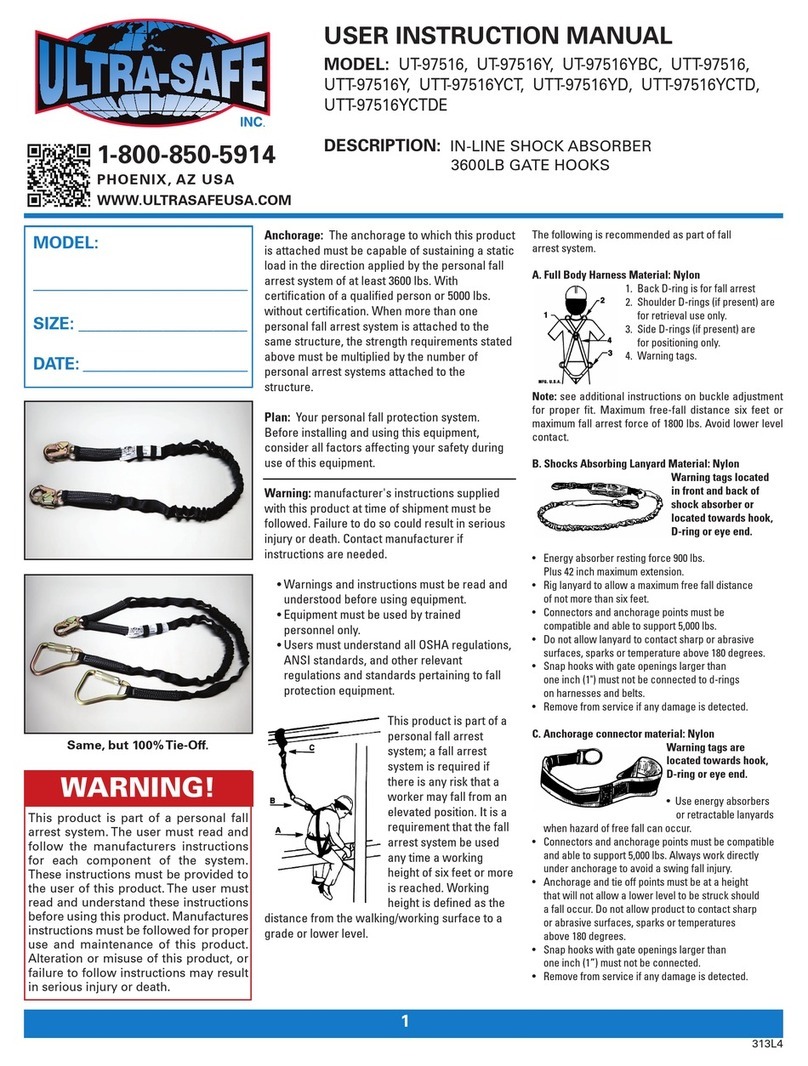

ATTACHING A TIE-BACK LANYA D: Place the tie-back

lanyard over the anchoring structure. Ensure the lanyard is not

twisted. Adjust the sliding D-ring or choke back hook so it

hangs below the anchoring structure. Attach the lanyard end

hook to the floating D-ring or choke back hook. Ensure the

lanyard is cinched tight around the anchorage during use or

choke back hook directly back to body of lanyard.

2

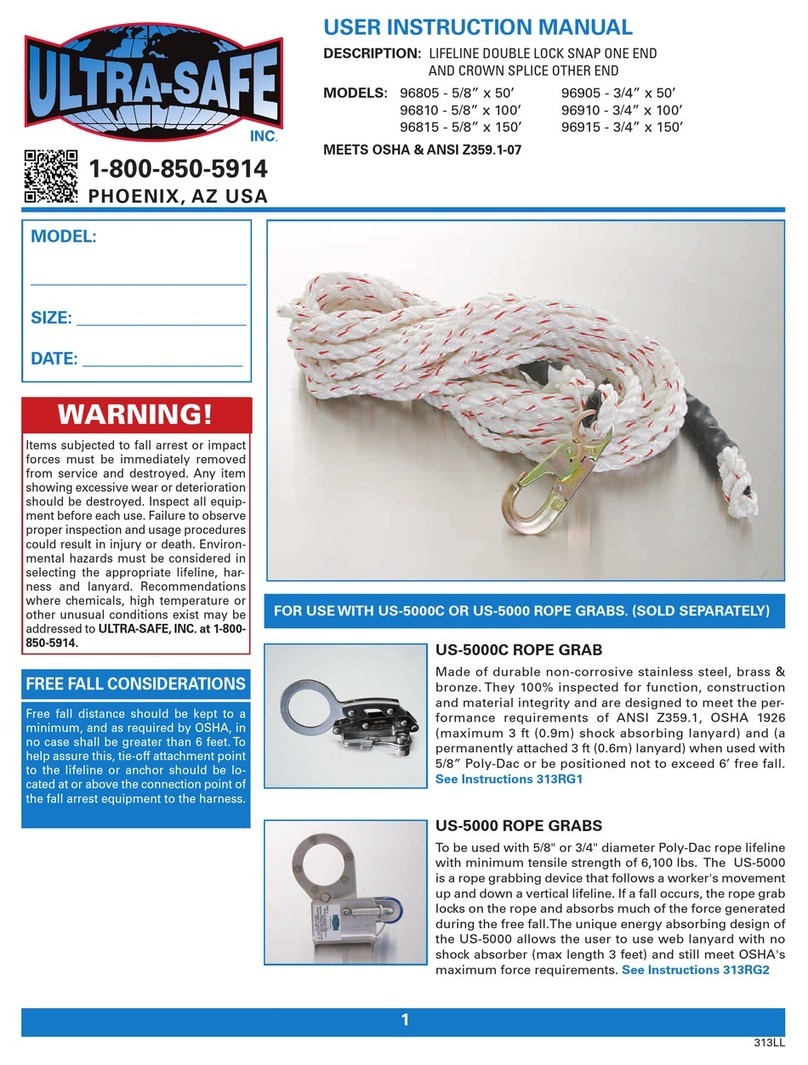

ANCHORAGE: Select a rigid anchorage point that

is capable of supporting the required loads. The

anchorage location must be carefully selected to

reduce possible free fall and swing fall hazards

and to avoid striking an object during a fall.

The anchorage should be generally level

(horizontal) to prevent the anchorage connector

from sliding down an incline when in use, which

could cause serious injury to the user.

CONNECTING TO ANCHORAGE OR ANCHORAGE

CONNECTOR: Always connect the energy

absorber end of the lanyard to the body support

(harness). Connect the lanyard end to the

anchorage or anchorage connector. Component

style energy absorbers should be connected to

the' body support first, then coupled to the rest of

the system. Some anchorage connector devices

may be supplied with permanently attached

energy absorber. Use of an additional energy

absorber or energy absorbing lanyard with these

types of subsystems is not recommended.

FREE FALL: Maximum free-fall distance six feet or

energy absorber arresting force of 900 lbs per ANSI or

maximum fall arrest force of 1800 lbs per SHA.

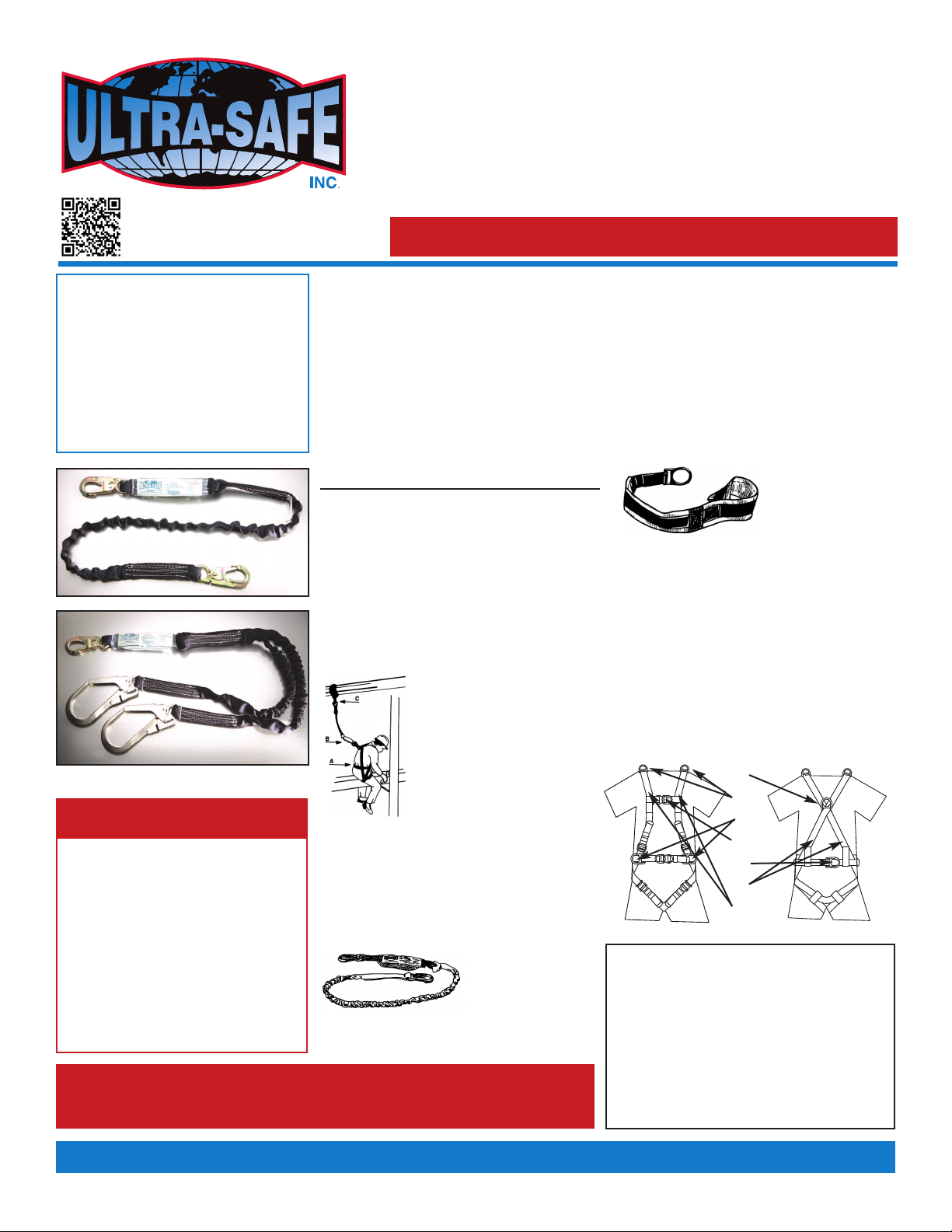

FALL CLEARANCE: Should a fall occur, there

must be sufficient clearance in the fall area to

arrest the fall before striking the ground or other

object. Energy absorbers can extend the fall

arrest distance by up to 52 inches. The

illustration to the right shows how to estimate fall

clearance distance when using an energy

absorbing lanyard or energy absorber

subsystem. ther factors may influence the

required clearance distances. For example,

using an energy absorbing lanyard or energy

absorber with a rope grab (fall arrestor) may

require additional clearance due to stretch in the

lifeline or sliding of the rope grab on the lifeline

during fall arrest. Some full body harness models

incorporate a sliding (positional) D-ring in the

back as the fall arrest attachment, movement of

this D-ring during fall arrest can increase the fall

clearance distance required. Use caution when

assembling system components that could act

to extend the fall arrest distance (and therefore

fall clearance required). Refer to manufacturer's

instructions for each part of the system for more

information on fall clearance.

CAUTION: When working near moving

machinery, make sure Ultra-Safe components

are free from entanglement.

Swing Fall

Hazard

Energy

Absorbing

Lanyard

Energy

Absorbing

Lanyard

Connecting

Subsystem

Anchorage

Connector

Anchorage

Connector

Anchorage

Connector

WARNING: Do not alter or intentionally misuse this equipment. Consult Ultra-Safe, Inc. when using this equipment In combination with components or subsystems other than those

described in this manual. Some subsystem and component combinations may interfere with the operation of this equipment. Use caution when using this equipment around moving

machinery, electrical hazards, chemical hazards, sharp edges, or overhead materials that may fall onto the lanyard. Do not loop the lanyard around small structural members.

Failure to heed this warning may result in equipment malfunction, serious injury, or death. Any repair must be performed by Ultra-Safe, Inc. or an authorized repair station only.

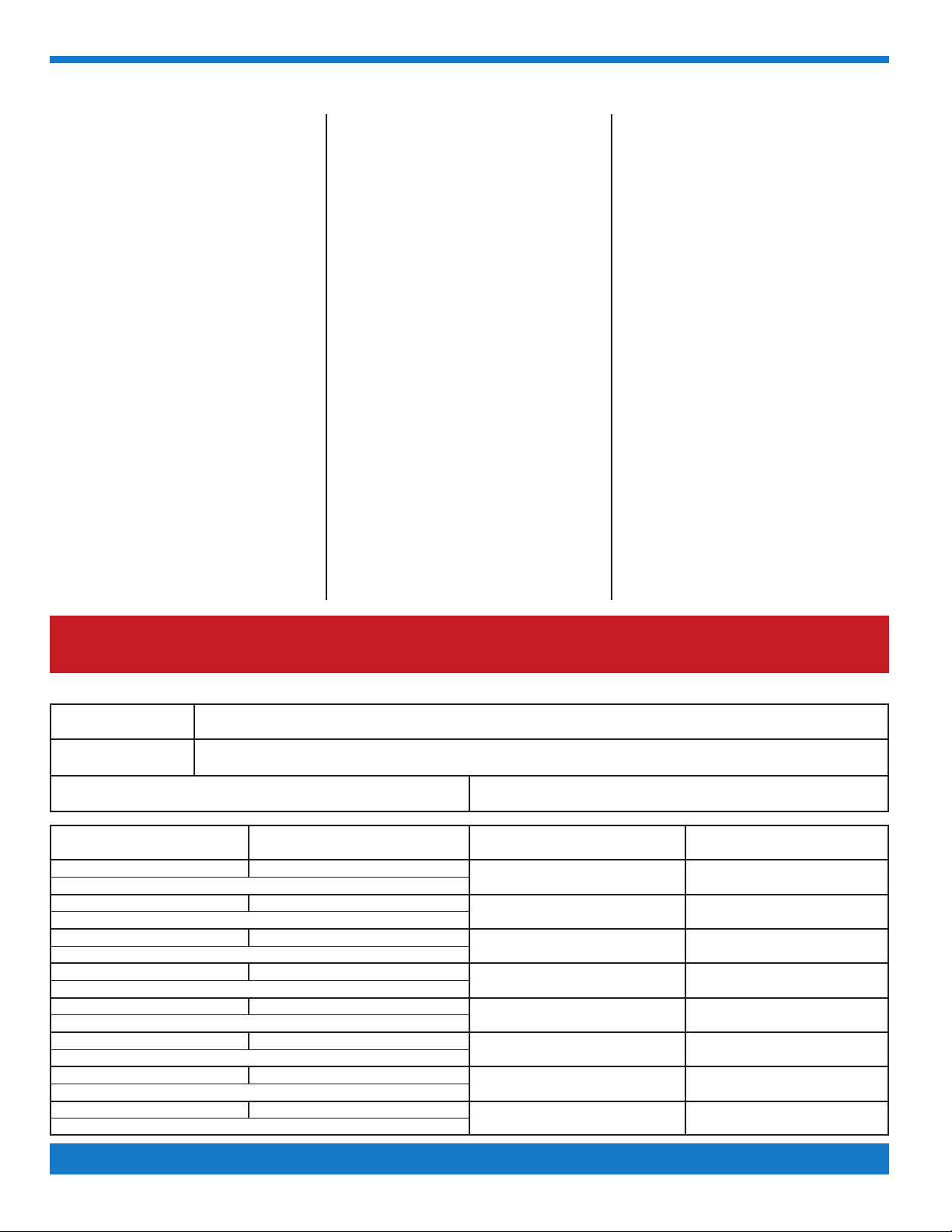

• Connectors must be compatible with the anchorage

or other system components.

• Connectors must be compatible in size, shape, and strength

• Non-compatible connectors may unintentionally disengage

Do not allow gate to

contact anchorage

member.

Tie-off point diameter should be

large enough so that hook does

not contact anchor point.

Corre t In orre t

Anchor

Point

Nearest

bstruction

(Lower Level)

NOTE:

Allow a minimum

of 17’ 10” from

anchor point to

lower level.

Clearance to bstruction

1 1/2ft (.5m) Min Allowed