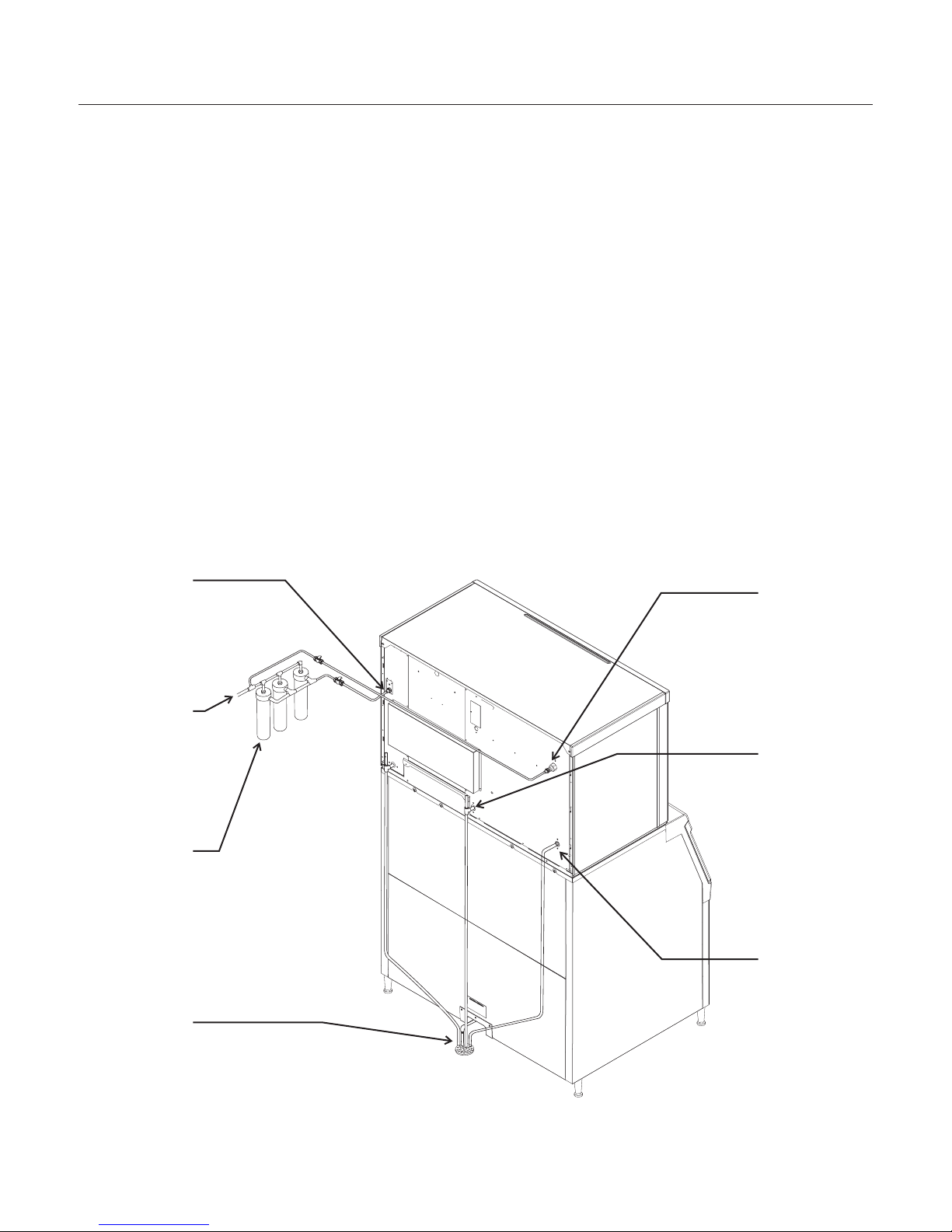

Water

The quality of the water supplied to the ice machine

will have an impact on the time between cleanings

and ultimately on the life of the product. There are

two ways water can contain impurities: in

suspension or in solution. Suspended solids can be

filtered out. In solution or dissolved solids cannot

be filtered, they must be diluted or treated. Water

filters are recommended to remove suspended

solids. Some filters have treatment in them for

suspended solids. Check with a water treatment

service for a recommendation.

Scotsman filters:

A triple head filter is recommended for the potable

water. Either the Scotsman SSM3 taste and odor

filter system, or the ADS-AP3 Aqua Patrol system.

RO water. This machine can be supplied with

Reverse Osmosis water, but the water conductivity

must be no less than 10 microSiemens/cm.

Condenser Water Supply - filtration not

recommended for this water supply

Potential for Airborne Contamination

Installing an ice machine near a source of yeast or

similar material can result in the need for more

frequent sanitation cleanings due to the tendency

of these materials to contaminate the machine.

Most water filters remove chlorine from the water

supply to the machine which contributes to this

situation. Testing has shown that using a filter that

does not remove chlorine, such as the Scotsman

Aqua Patrol, will greatly improve this situation,

while the ice making process itself will remove the

chlorine from the ice, resulting in no taste or odor

impact. Additionally, devices intended to enhance

ice machine sanitation, such as the Scotsman

Aqua Bullet, can be placed in the machine to keep

it cleaner between manual cleanings

Water Flush

Cube ice machines use more water than what ends

up in the bin as ice. While most water is used

during ice making, a portion is designed to be

drained out every cycle to reduce the amount of

hard water scale in the machine. That’s known as

water flush, and an effective flush can increase the

time between needed water system cleaning.

In addition, this product is designed to

automatically vary the amount of water flushed

based on the purity of the water supplied to it. The

water flush rate can also be set manually.

Adjustments of flush due to local water conditions

are not covered by warranty.

November 2006

Page 4

C1448, C1848, C2148W

Air and Water Cooled User Manual