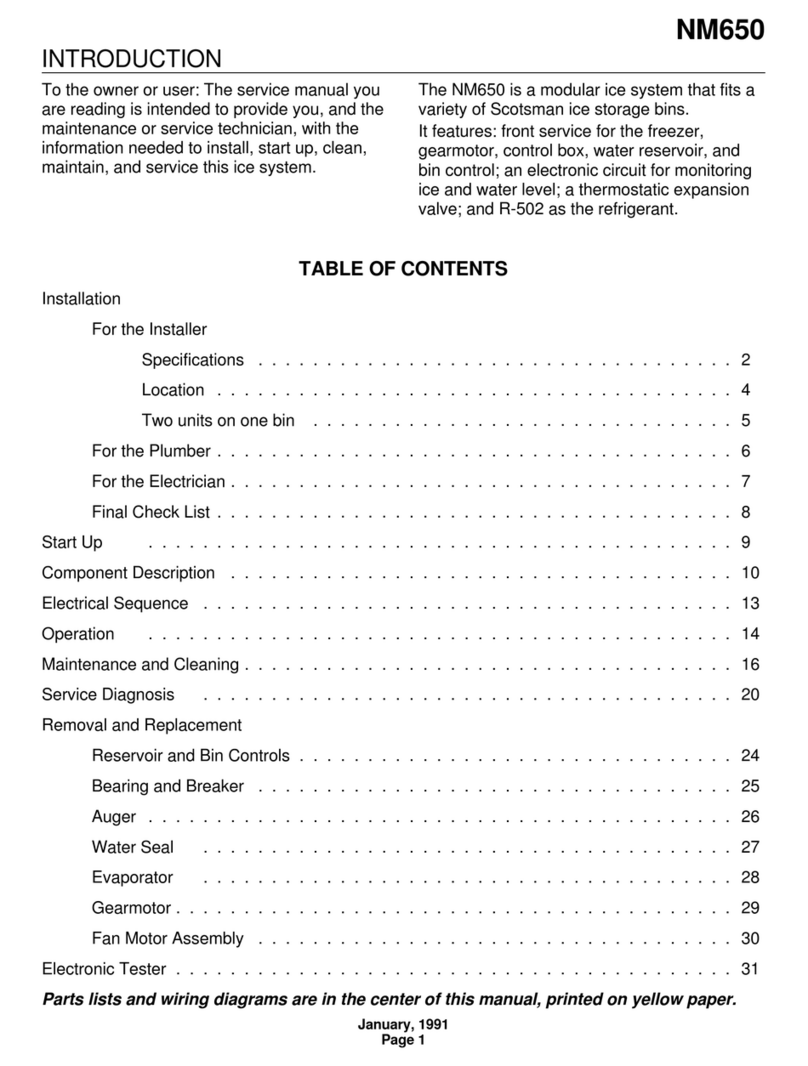

Create the System

Plan the installation. The system consists of four

parts: the ice making section, the compressor

package, the interconnecting tubing and the

remote condenser. Of these, the biggest variable is

the interconnecting tubing.

Tubing: The tubing consists of three pre-charged,

insulated and sealed soft copper tubes. They each

contain a small holding charge of R-404A. One

tube, the liquid line, is 3/8” OD. The vapor tube is

½” OD and the suction tube is ¾” OD. A site

inspection will determine what length of tubing is

required for the installation.

Excess tubing must be either shortened at the job

site (recovering the holding charge, purging with

nitrogen when brazing and evacuating to 50

microns) or coiled up inside the building.

Installations with greater than 20 feet of vertical lift

between ice machine and the compressor require

a suction line trap. The suction line requires careful

handling and large radius bends to prevent kinking.

Roof mounting: To make installation easier the

compressor and condenser are designed to be

assembled together on the roof. Some

installations will require the use of a hoist to lift the

components to the roof.

Pad mounting: The compressor and condenser

may be located below the ice making section, up to

a limit of 15 feet.

Distance from unit: Limited to the length of the

available pre-charged tubing.

Elevation: CP unit limited to 35 feet above the ice

making section.

Compressor package: Electrical power must be

supplied to the compressor package. The remote

condenser fan motor takes its power from the

compressor package.

Ice making section location and attachment:

The 115/60 Hz ice making section is cord

connected and requires an outlet within 6 feet of

the installation.

Interconnecting wires: An interconnecting wire

harness is included with the CP unit. One end

plugs into the ice making section and the other into

the compressor package. The system will NOT

operate without this harness.

Exposed tubing: Minimize the amount of tubing

exposed outdoors.

Confirm Component Availability:

·EH430

·C1410CP with ERC1086 or

·C1800CP with ERC2086 or

·C2000CP with ERC2086

·ERC required unless connecting to an approved

condenser coil.

Note: Only these condensers may be used. They

do NOT contain a headmaster valve. That valve is

in the Compressor Package. Do NOT use any

other Scotsman condenser. Do NOT use these

condensers on any other Scotsman remote

product.

·Interconnecting tubing kit

Note: Check tubing integrity before assembly by

attaching a refrigeration compound gauge onto

one of each tube’s schrader valves. If there is

pressure, the tube is OK, if not it should be

checked for damage and leaks.

·Bin or dispenser adapter

Prodigy Eclipseä1400, 1800, 2000

April 2006

Page 8