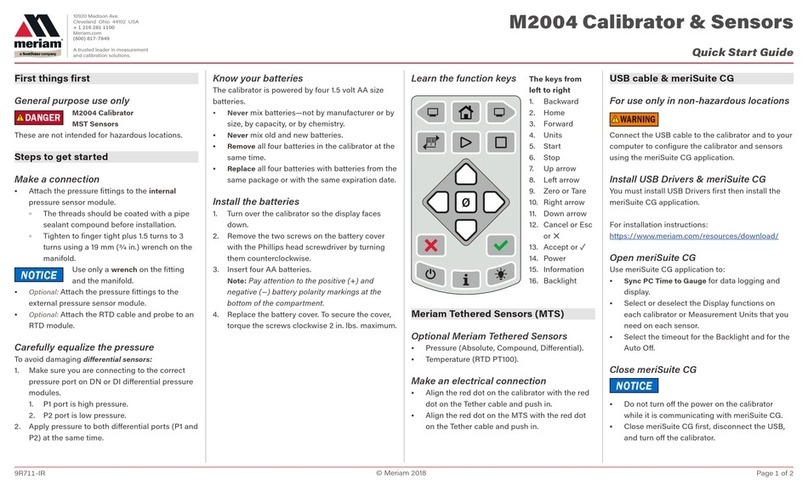

MFT 4000/4010/4020 OPERATING INSTRUCTIONS

TABLE OF CONTENTS

Subject Page

MFT 4000 Overview.................................................................................................................................. 1

Keypad Overview ...................................................................................................................................... 1

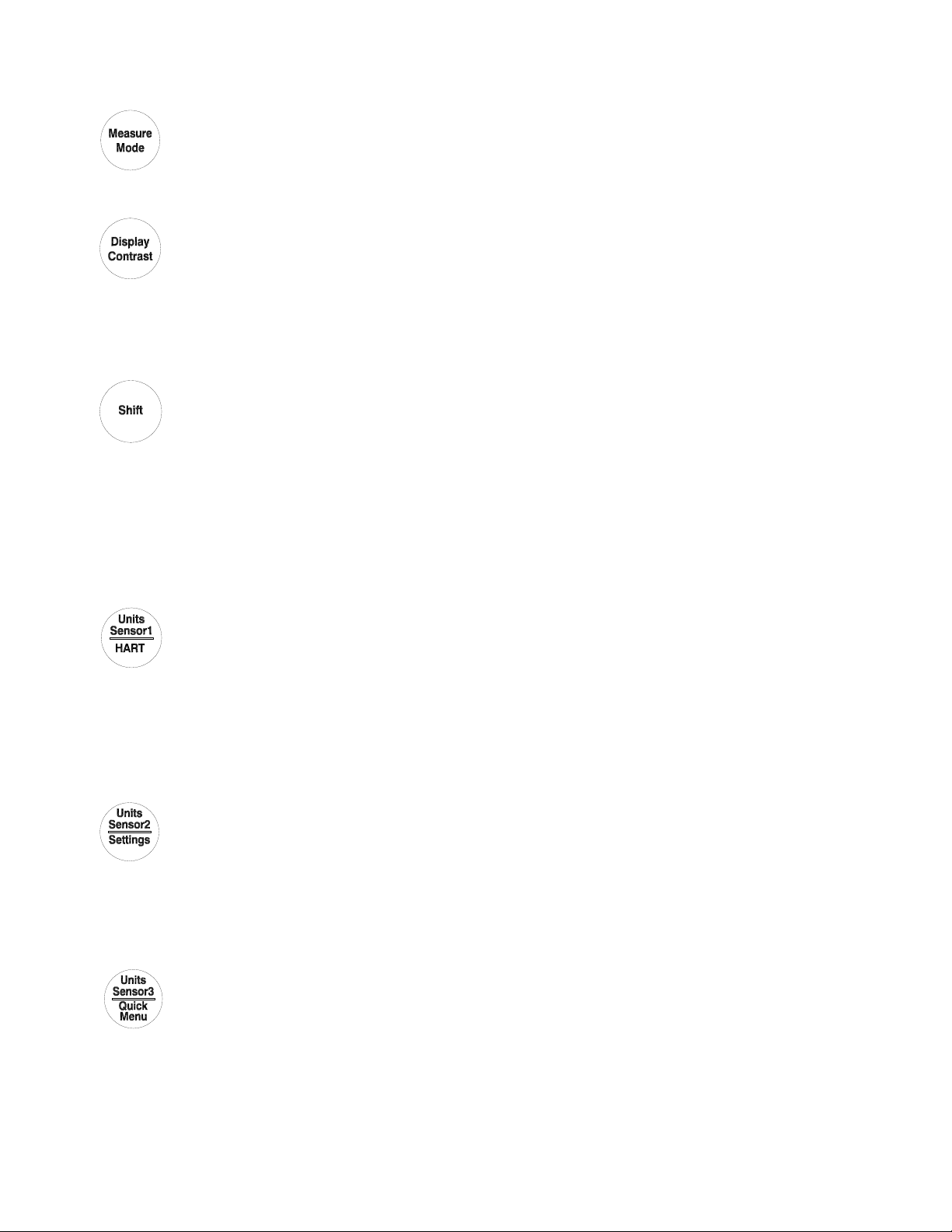

Single Function Keys............................................................................................................................ 1

Dual Function Keys .............................................................................................................................. 2

Soft Keys............................................................................................................................................... 3

Alphanumeric Data Entry ..................................................................................................................... 3

Measure Mode ........................................................................................................................................... 5

Header-line Symbols............................................................................................................................. 5

Display Screen ........................................................................................................................................... 5

Soft Key Options........................................................................................................................................ 5

Zero....................................................................................................................................................... 6

Mn/Max ................................................................................................................................................ 6

Damp..................................................................................................................................................... 6

More...................................................................................................................................................... 6

Hold ...................................................................................................................................................... 6

Sensr...................................................................................................................................................... 6

Rcal ....................................................................................................................................................... 7

Settings....................................................................................................................................................... 7

Lockout Features................................................................................................................................ 7

Lockout Code................................................................................................................................ 8

Disable Lockout ............................................................................................................................ 8

Change Lockout Code................................................................................................................... 8

Damp Rate ......................................................................................................................................... 8

Off Timer ........................................................................................................................................... 9

Clock Edit .......................................................................................................................................... 9

General Operation.................................................................................................................................... 10

Sensor Installation/Removal ............................................................................................................ 10

Change Units / Removing & Restoring Sensors on Display............................................................ 10

Sensor Module Engineering Units ................................................................................................... 11

Installation & Removal of Batteries – Standard MFTs.................................................................... 11

Install & Remove Batteries – Intrinsically Safe MFTs.................................................................... 11

Over pressurization – Pressure Modules.......................................................................................... 11

Media compatibility – Pressure Modules......................................................................................... 12

Applications ............................................................................................................................................. 12

Gauge Pressure Calibration.................................................................................................................. 12

Differential Pressure Calibration ......................................................................................................... 13

Additional DP Application Information .............................................................................................. 14

Vacuum and Absolute Pressure Calibration ........................................................................................ 14

Electrical Connections ............................................................................................................................. 15

Milliamp transmitters............................................................................................................................... 15

Voltage transducers.................................................................................................................................. 16

Field Recalibration.................................................................................................................................. 16

DB-9 Connection Port.............................................................................................................................. 19

Hazardous Area Use (Intrinsically Safe Option) ..................................................................................... 19

MFT 4000 Series - Model Specific Features ........................................................................................... 21