1

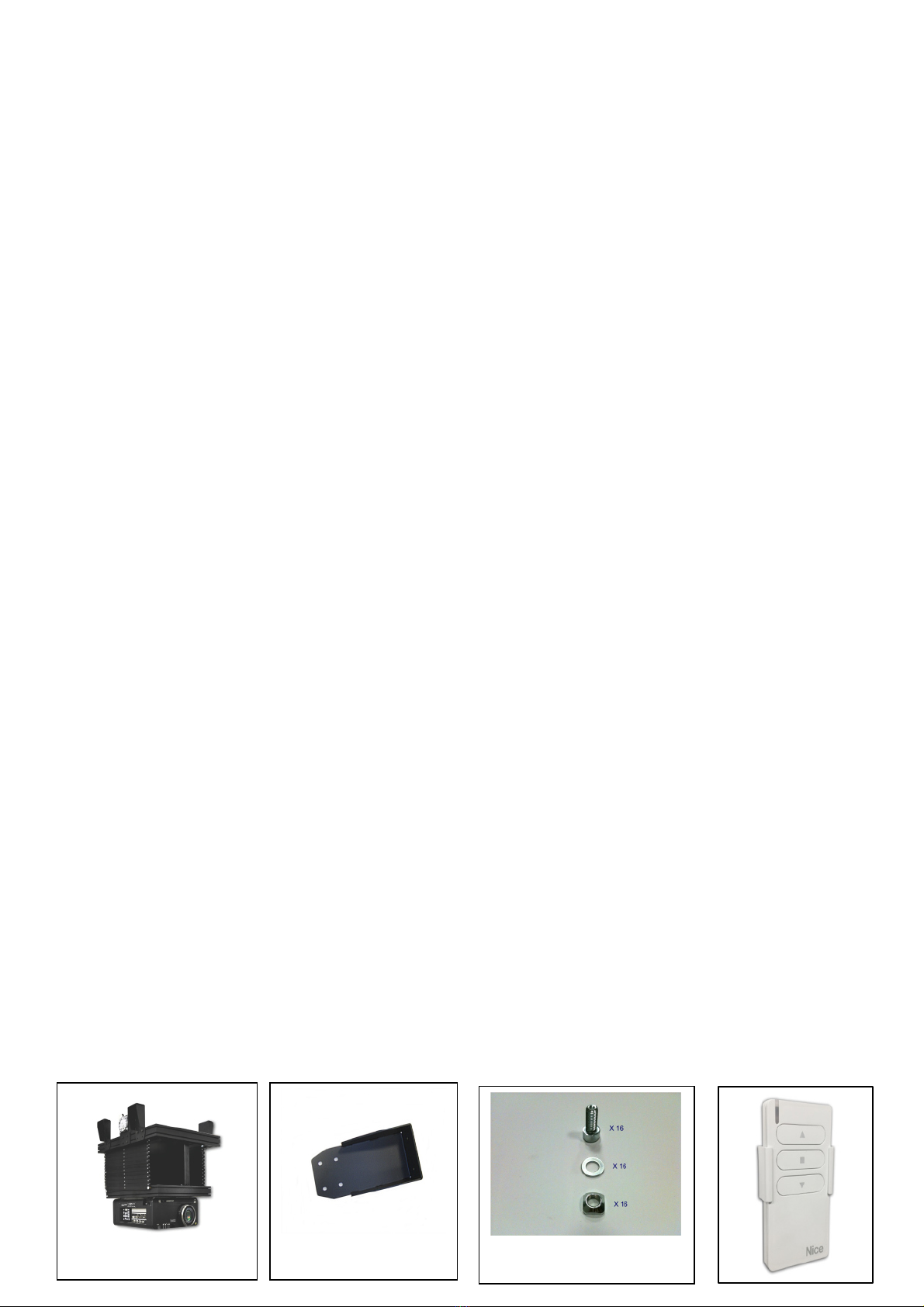

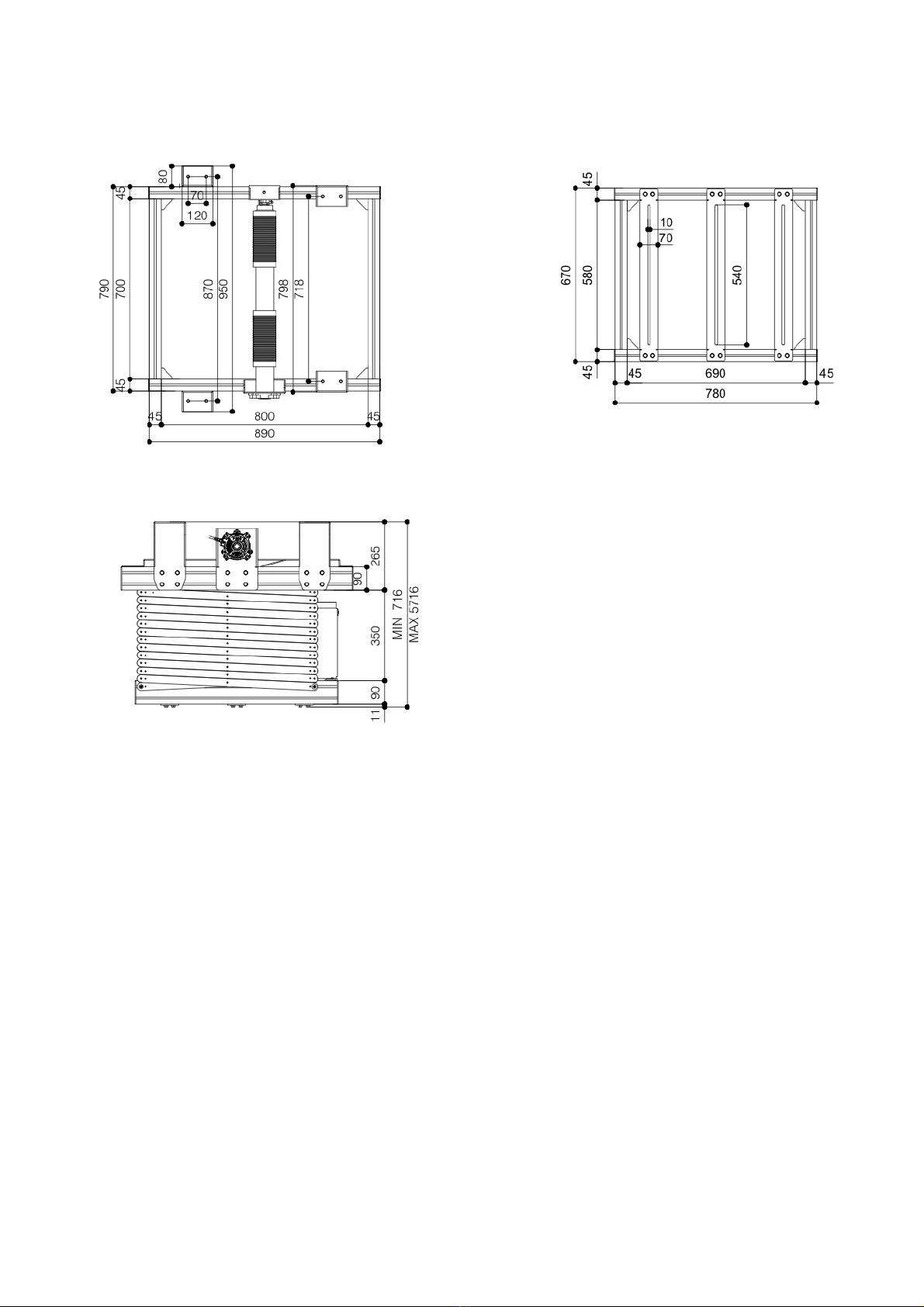

MOTORIZED PROJECTOR LIFT

MOD. SI-H XL 500 (version OCT-2021)

INSTALLATION MANUAL

Thank you for purchasing the new SI-H XL 500 Projector Lift.

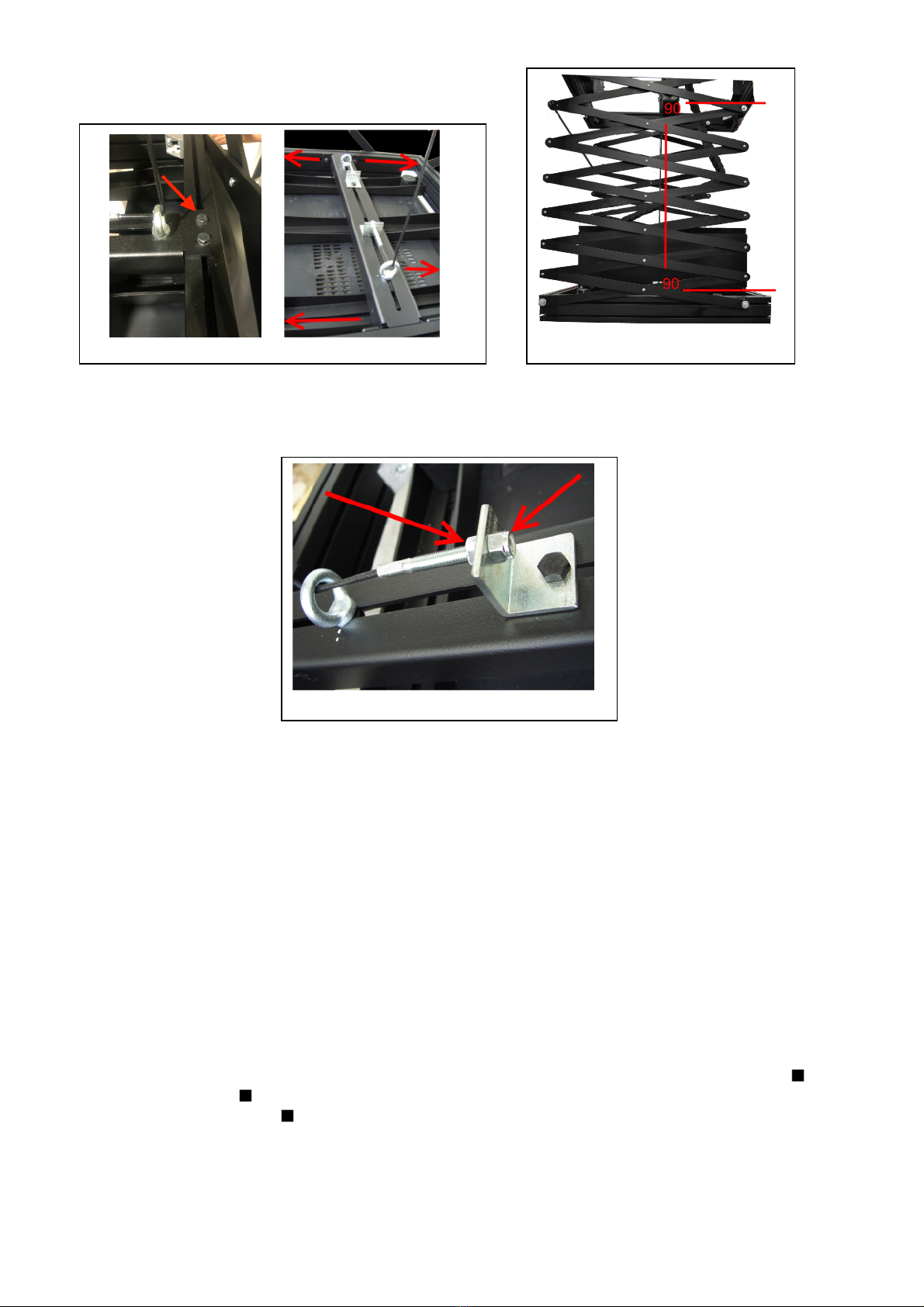

The SI-H XL 500 is supplied with a set of components and accessories that make it suitable for installation for

the majority of standard AV applications, but note must be made of the restrictions that apply to the weight

capability of this unit and not exceeded.

BEFORE INSTALLING THE LIFT, PLEASE READ THE FOLLOWING INSTRUCTIONS CAREFULLY. Please, always

keep these instructions so that anyone can read them when needed.

THE MANUFACTURER DOES NOT TAKE RESPONSIBILITY FOR ANY DAMAGE TO PROPERTY OR PERSONAL

INJURY IF THE PROJECTOR LIFT IS USED OUTSIDE OF RECOMMENDED SPECIFICATIONS OR IN CASE OF

INCORRECT INSTALLATION.

Before installing the projector lift, please read the following instructions carefully:

•The projector lift must be used INDOORS ONLY.

INSTALLATION OF SI-H XL 500 PROJECTOR LIFT HAS TO BE CARRIED OUT FROM

QUALIFIED PERSONNEL ONLY.

•IT IS FORBIDDEN TO STAY UNDER THE LIFT AND WITHIN A RANGE OF 3 MT. FROM THE

LIFT.

•NEVER CONNECT MORE THAN ONE MOTOR TO THE SAME SWITCHER. USE THE

SUPPLIED REMOTE CONTROL ONLY.

•IN CASE OF MAINTENANCE, UNPLUG THE POWER SUPPLY.

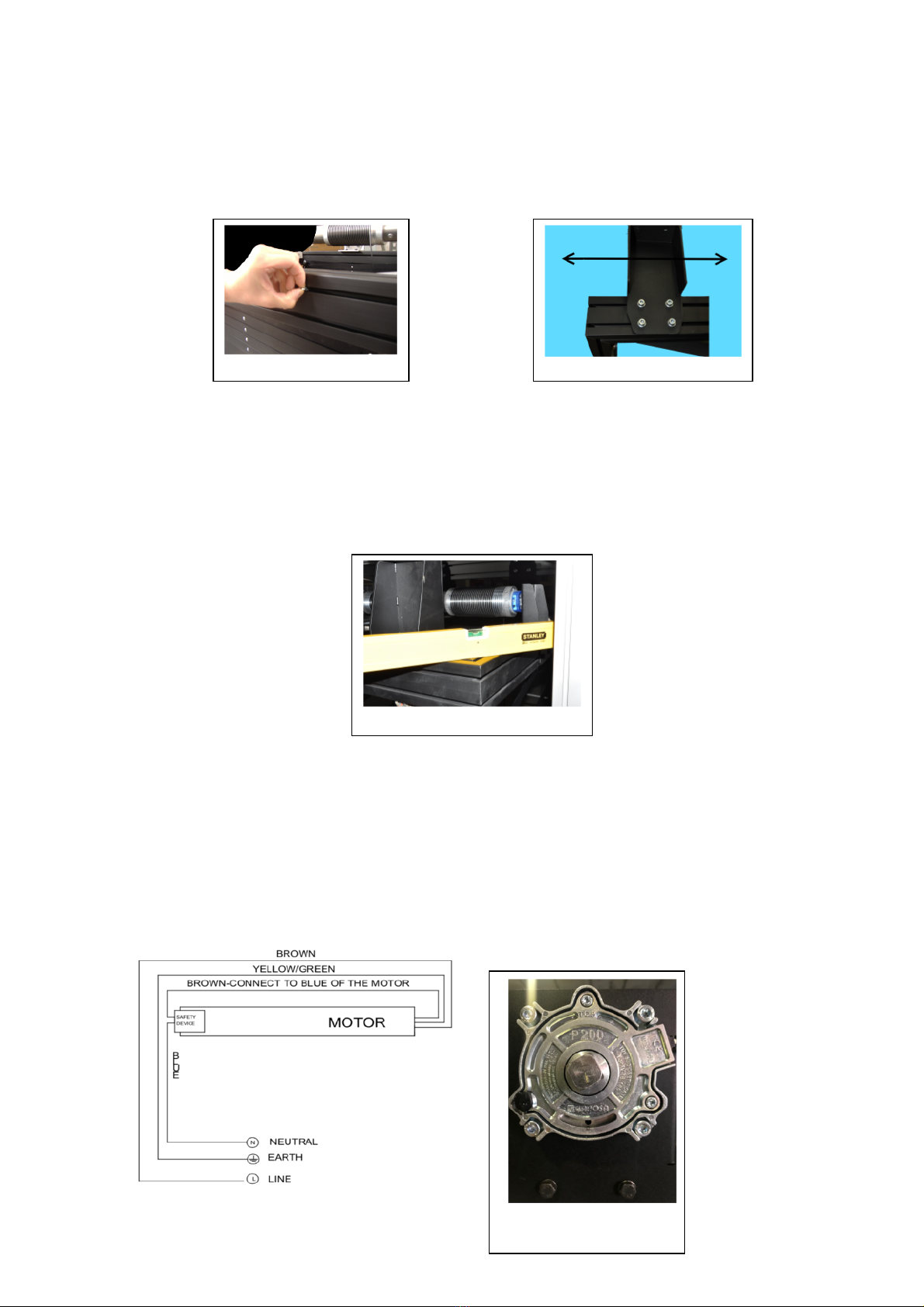

•Please conrm that your projected image width will t your screen from your proposed

mounting location prior to installation.

•Incorrect use of the lift, including exceeding the maximum lifting weight, will be

dangerous. The manufacturer does not take responsibility for any damage o property or

personal injury if the lift is used outside of recommended specications.

•Incorrect use of the projector lift, including exceeding the maximum lifting weight of 95

kg., would be dangerous and invalidates the warranty.

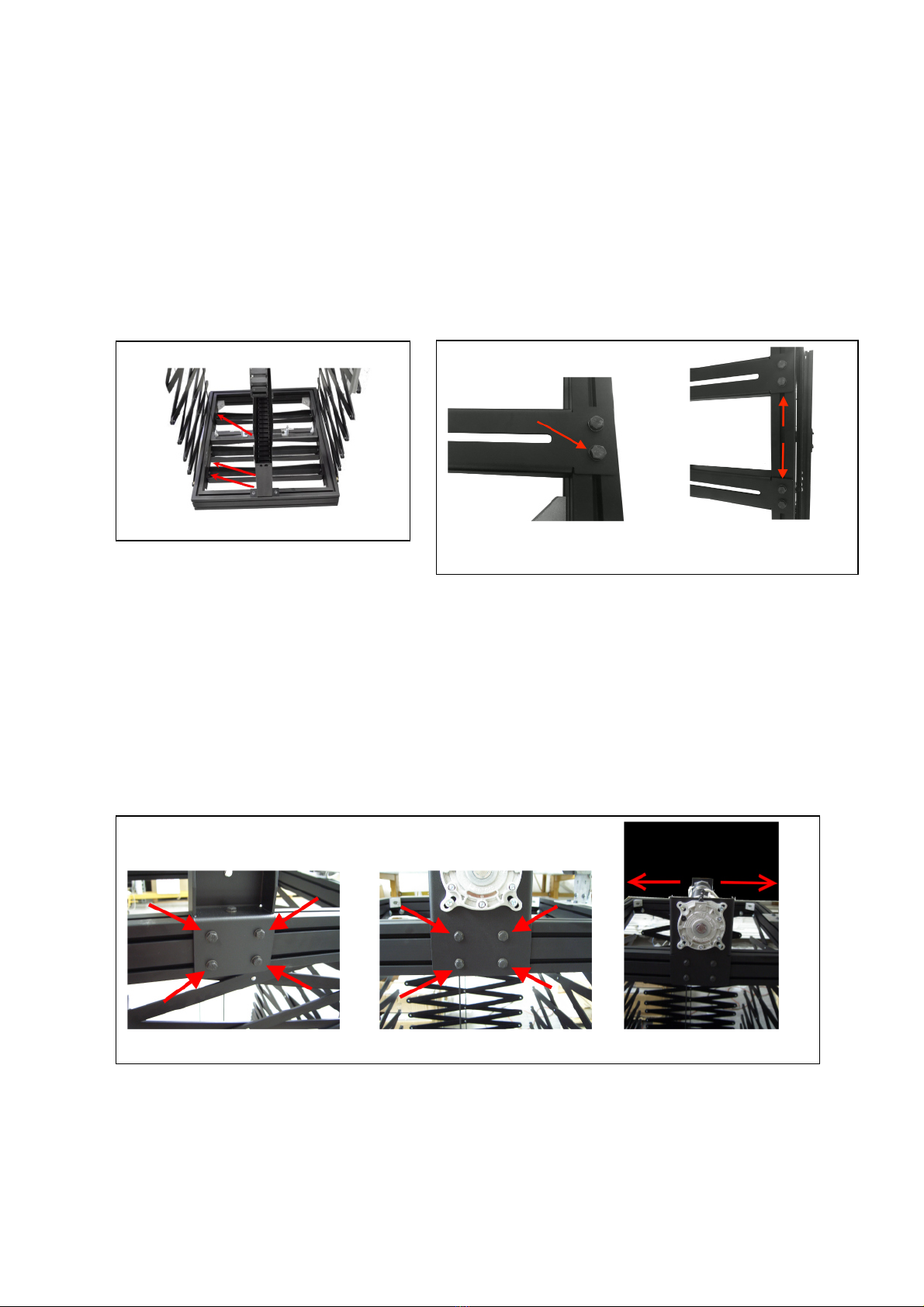

•This product uses a 230V AC Motor. DO NOT attempt to service the motor. Incorrect

servicing could lead to risk of electric shock.

•For any repairing, please contact directly the dealer you purchased the unit from.

•DO NOT try to disassemble the lift or to paint the structure, as these operations will

invalidate the warranty.

•Half-yearly and yearly the screen winch system has to be checked. Please see check

register at page 8 of this document.

•In addition to manufacturer inspection guidelines, we recommend you check your

countries own legal obligations for checking and testing of lifting equipment.

The manufacturer and his agents do not take responsibility for any damage to property

or personal injury if the winch is installed/used outside of recommended

specications.

This product uses a 230 V AC motor. DO NOT attempt to carry out repairs to

the motor, there are no user serviceable parts.

Incorrect servicing could lead to risk of electric shock. In the event of a

fault, please contact the dealer /supplier you purchased the lift from.

Warranty is 24 months Return To Base.

The projector lift SI-H XL 500 is certied.