P:\INSTALLATI N INST\ACCESS RIES\INST-EH SERIES.vsd REV C 10-14 Page 3

DR

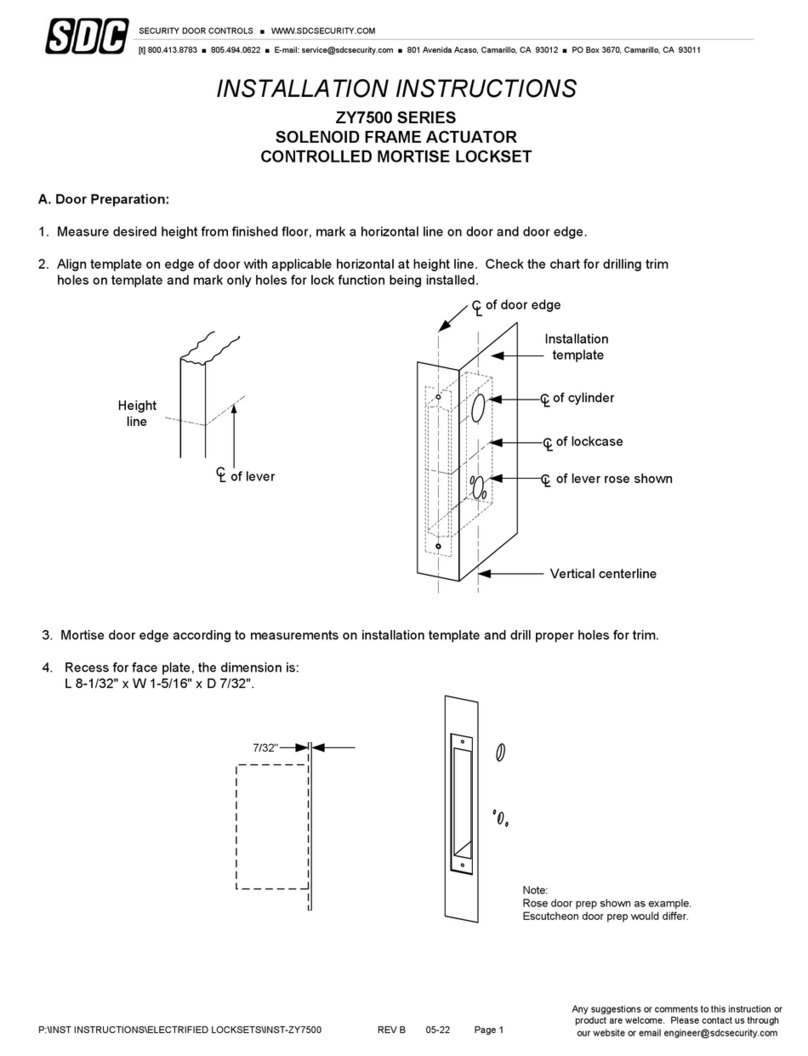

STEP 6:

pening door will reveal

mounting template. Apply

final pressure to insure

template does not fall off

while assembly takes place.

STEP 7:

Insert alignment template into

center of mounting template.

Use tab to rotate to fine

adjustment. While holding

alignment template with one

hand, remove adhesive

backing of tab, then push flat

against door.

STEP 8 A:

If not using door assembly

drill fixture, center punch

points indicated on

alignment template for either

horizontal or vertical

mounting. For best results,

drill 1/8” pilot holes first, then

follow with 5/16” dia drill.

STEP 8C:

If mounting catch plate assembly directly to door, drill

1/8”dia. pilot hole approximately 1 to 1-1/2” deep,

being careful not to go through door.

CATCH PLATE EXTENSION ROD

ASSEM LY:

DR

1/8”

5/16”

M

U

N

T

I

N

G

T

E

M

P

LA

T

E

R

E

AD

I

N

S

T

R

C

U

T

I

N

S

D R

STEP 9:

For either style of mounting (thru door/direct) remove

ONLY alignment template, then place swivel in center.

Align holes, then insert screws and tighten assembly

fully. Lastly, remove mounting template.

D R

D R

STEP 8 :

If using door assembly drill fixture,

alignment template is not required.

Locate drill bushing end into mounting

template, holding firmly flat against door,

then tighten slightly. Make sure fixture is

flat against edge of door, tighten fully and

drill through using 5/16” dia. drill.