SDT International LUBExpert User manual

SDT International sa-nv • Bd de l’Humanité 415 • B-1190 Brussels (Belgium) • Tel: +32(0)2 332 32 25 • email: i[email protected]

SDT North America • 1532 Ontario Street, Cobourg, ON • Phone: 1-800-667-5325 | 1-905-377-1313 •email: info@sdthearmore.com

www.sdtultrasound.com

MAN.LUBExpert.EN--01--SDT-Lubexpertuser-manual-EN.DOCX

Copyright 2017 by SDT International, sa/nv All Rights Reserved

2/27

Table of Contents

1. Before You Begin ................................................................................................................. - 3 -

1.1. Good to Know ......................................................................................................................................... - 3 -

1.2. Recommended Calibration Intervals....................................................................................................... - 3 -

1.3. Declaration of conformity....................................................................................................................... - 3 -

1.4. Warranty ................................................................................................................................................. - 4 -

1.5. Responsibility limits ................................................................................................................................ - 4 -

1.6. Destruction and recycling of waste equipment ...................................................................................... - 4 -

1.7. Copyright................................................................................................................................................. - 5 -

2. Welcome Message .............................................................................................................. - 6 -

Introduction.........................................................................................................................- 7 -

3.1. What is LUBExpert?................................................................................................................................. - 7 -

4. Description........................................................................................................................... - 7 -

4.1. LUBExpert is available in two forms........................................................................................................ - 7 -

4.2. LUBExpert Kit .......................................................................................................................................... - 7 -

4.3. LUBExpert Base Kit Contents................................................................................................................... - 8 -

4.4. LUBExpert Upgrade for SDT270SU or SDT270DU (MK2 Only) ................................................................ - 9 -

4.5. Upgrade Kit Contents.............................................................................................................................. - 9 -

4.6. Charging the Battery ............................................................................................................................. - 10 -

4.7. Turning the LUBExpert “ON” and “OFF” ............................................................................................... - 10 -

Getting Started..........................................................................................................................- 11 -

4.8. Have you Installed UAS? ....................................................................................................................... - 11 -

4.9. Are UAS and LUBExpert up-to-date?..................................................................................................... - 11 -

5. System Settings Edits.........................................................................................................- 12 -

5.1. Grease Gun Management..................................................................................................................... - 12 -

5.2. Sensor Options –LUBExpert Mode....................................................................................................... - 13 -

6. LUBExpert databases in UAS .............................................................................................- 13 -

6.1. Managing Databases............................................................................................................................. - 13 -

6.2. Modifying a Database ........................................................................................................................... - 14 -

7. Working with Surveys........................................................................................................- 17 -

7.1. Create a new Survey ............................................................................................................................. - 17 -

7.2. Transfer Survey to LUBExpert ............................................................................................................... - 18 -

8. In the Field.........................................................................................................................- 19 -

8.1. Connecting LUBEsense.......................................................................................................................... - 19 -

8.2. Planned Survey Mode ........................................................................................................................... - 19 -

8.3. Lubrication Steps................................................................................................................................... - 20 -

9. Transfer Results to PC........................................................................................................- 22 -

10. View Results in UAS...........................................................................................................- 23 -

10.1. Selecting, Viewing Trends, FFT, and Measurement Details .................................................................. - 23 -

11. Reports ..............................................................................................................................- 24 -

11.1. Overall lubricant consumption.............................................................................................................. - 24 -

11.2. Lube consumption comparison............................................................................................................. - 25 -

MAN.LUBExpert.EN--01--SDT-Lubexpertuser-manual-EN.DOCX

Copyright 2017 by SDT International, sa/nv All Rights Reserved

3/27

1.Before You Begin

1.1. Good to Know

Due to typical self-discharging characteristics of NiMH batteries, it is recommended to charge

the LUBExpert battery at least every 3 months, even if the equipment is not used.

This manual contains instructions specific to LUBExpert App Firmware and its interface to

Ultranalysis Suite Software (UAS). References to UAS usage in the manual are intentionally

“LITE”. For instructions using UAS, refer to the UAS user’s manual.

LUBExpert App runs on an SDT270SU or SDT270DU. If you are using the LUBExpert App on one

of these devices and need device specific instructions, refer to your SDT270 User Manual.

1.2. Recommended Calibration Intervals

SDT recommends annual recalibration of SDT instruments and annual verification of sensors. The one-

year interval is consistent with the observed long-term stability of SDT electronic equipment’s.

For new equipment leaving the factory, however, the initial period is extended to 15 months. This

accounts for the lapse of time from delivery from factory floor to end users.

SDT recognizes that each customer may have their own Quality Assurance Standards and internal

requirements. If a customer has established a Quality Assurance Program that includes a documented

procedure for measurement deviations, and if an instrument and the relevant sensor show acceptable

deviations and do not show signs of physical damage, then calibration periodicity could be extended to

two years.

Third party organizations having more authority (Class, or State Administrations) may have defined their

own regulations for example 6 months, or 2 years calibration interval: by evidence, local legally

applicable regulations supersede SDT rules.

For these reasons, SDT Calibration Certificates no longer mention a “calibration due date”. Instead, SDT

codes each instrument with the “last calibration date”.

For user convenience, you can view the date of the last calibration of an SDT200, SDT270, or LUBExpert

instrument on the System Info menu screen.

This text refers to SDT document DC.QUAL.0051, part of SDT’s quality management system (ISO-9001).

1.3. Declaration of conformity

SDT International n.v. s.a. Boulevard de l’Humanité 415, B - 1190 BRUSSELS, BELGIUM

declares that LUBExpert, the object of this declaration, is built in conformity with the applicable

European Directives:

Electrical equipment for measurement IEC EN 61010-1

EMC Directive 2004/108/CE

Low voltage Directive 2006/95/CE.

The equipment hence displays the EC logo of being compliant to the current EC regulations.

To be able to operate by state of the art rules, as stipulated in the directive, it has been designed by the

following rules:

MAN.LUBExpert.EN--01--SDT-Lubexpertuser-manual-EN.DOCX

Copyright 2017 by SDT International, sa/nv All Rights Reserved

4/27

The SDT270 does not radiate electromagnetic waves (EMC)

The SDT270 is immunized against external electromagnetic radiation (EMI)

The SDT270 is protected against electrostatic discharges (ESD).

Note: the owner is obliged to preserve the present user’s manual with the obligation to pass it on to

future users or owners.

Brussels, January 2017

The Manager

1.4. Warranty

SDT International guarantees the LUBExpert unit against manufacturing faults for a period of 2 (two)

years, with the exception of the battery and accessories (charger, headphones, sensors, etc.) which are

guaranteed for a period of 6 (six) months. The warranty covers all material supplied and implies the free

replacement of all parts that contain a manufacturing fault.

Warranty does not include shipping, handling and importation.

The warranty applies to general and acceptable use. The warranty does not apply to normal wear and

tear, is void if misused, or accident damages the product, if the product is altered in any way, if an

unauthorized party attempts repair, or the unit is opened without written authorization of SDT

International.

SDT reserves the right to accept or deny warranty claims based on final inspection in our workshop.

In the event of a defect, contact your local SDT representative or SDT International.

1.5. Responsibility limits

Neither the company SDT International, nor any related company, will in any circumstances be liable for

any damages, including, without limitation, damages for loss of business, business interruption, loss of

information, defect of the SDT270 unit or its accessories, bodily harm, loss of time, financial or material

loss or any other indirect or consequential loss arising out of the use, or inability to use this product,

even when it has been warned of possible damages.

1.6. Destruction and recycling of waste equipment

In conformance with European Union (EU) Directives and in particular with Directive 2006/66/EU

"Batteries" and Directive 2012/19/EU "WEEE –Waste Electrical and Electronic Equipment", SDT

International is organizing the management of waste equipment. However local legal regulations have

precedence.

Thus, SDT Customers may

Either transfer a waste apparatus to a local company that will recycle it in accordance with

applicable local laws

Or return the waste apparatus to SDT International or to a SDT Dealer

For an apparatus that contains a battery, SDT International will transfer the battery to a local company

that will recycle it in accordance with EU "Batteries" Directive and Belgian laws.

SDT International will transfer the rest of the apparatus to a local company that will recycle it in

accordance with EU "WEEE" Directive and Belgian laws.

MAN.LUBExpert.EN--01--SDT-Lubexpertuser-manual-EN.DOCX

Copyright 2017 by SDT International, sa/nv All Rights Reserved

5/27

1.7. Copyright

© 2017 SDT International n.v. s.a. All rights reserved.

No one is permitted to reproduce or duplicate, in any form, the whole or part of this document without

the written permission of SDT International n.v. s.a.

The information herein is believed to be accurate to the best of our knowledge.

Due to continued research and development, specifications of this product can change without prior

notice. The most recent version of this manual is available at sdtultrasound.com in the downloads

section.

MAN.LUBExpert.EN--01--SDT-Lubexpertuser-manual-EN.DOCX

Copyright 2017 by SDT International, sa/nv All Rights Reserved

6/27

2.Welcome Message

Congratulations and thank you for your purchase of LUBExpert. Get ready to explore the world of

ultrasound assisted machinery lubrication. Whether you grease bearings on a time-based or calendar

based schedule, LUBExpert’s onboard lubrication and greasing assistant is ready to guide you to a

perfect and precise result every time.

Major bearing manufacturers claim that as much as 40% of all bearing related failures result from poor

lubrication practices. “Poor Lubrication Practices” include, but are not limited to, bearings receiving too

much grease, not enough grease, or even the wrong type of grease.

LUBExpert helps you Grease Bearings Right. That means delivering grease to the right location, using the

right grease type, dispensing the right quantity, at the right intervals, while receiving the right indication

about the condition of the lubrication.

If you’re ready to optimize your machinery lubrication practices, then let’s get started. The following

detailed and illustrated instructions will help you get the most from your LUBExpert/UAS investment.

MAN.LUBExpert.EN--01--SDT-Lubexpertuser-manual-EN.DOCX

Copyright 2017 by SDT International, sa/nv All Rights Reserved

7/27

Introduction

3.1. What is LUBExpert?

LUBExpert is an ultrasound solution dedicated to acoustic bearing lubrication.

LUBExpert combines SDT’s strong measurement capabilities and clever user interface to create an

onboard lubrication & greasing assistant. Intelligent algorithms guide lube-techs before, during, and

after re-greasing resulting in optimal lubrication parameters on all assets.

Given only a few machine parameters, LUBExpert monitors each stroke of grease and its effect on

bearing friction and temperature. Before and after bearing conditions are reported with a “GOOD”,

“BAD”, or “SUSPECT” status report.

4.Description

4.1. LUBExpert is available in two forms.

1. LUBExpert Kit –A complete standalone ultrasound instrument with dedicated firmware and

software for precision guided lubrication of bearings.

2. LUBExpert Upgrade –An upgrade kit that adds LUBExpert functionality to any SDT270SU and

SDT270DU ultrasound instrument. Please note that LUBExpert upgrade is only for SDT270 (MK2)

instruments with serial number beginning with “280”. If your serial number begins with “270”,

please contact your local SDT representative.

4.2. LUBExpert Kit

LUBExpert Base Kit Hardware

LUBExpert Ultrasound Data Collector equipped with the following features and functions:

•Static measurements with four condition indicators (4CI)

-Ultrasound –structure borne (LUBEsense Innovative Sensor Technology)

•Temperature –non-contact spot radiometer (°F/C)

•Onboard Assistant provides real-time stroke-by-stroke guidance

•Integration to UAS for user-defined planned survey mode

•Non-contact laser guided temperature measurement

•New and innovative LUBEsense ultrasound sensor

•Lube consumption report

•Before and After report

•“Good” “Bad” “Suspect” report

•Embedded algorithm constantly calculates bearing friction

•Four condition indicators

•Support for 6 languages plus icon commands

•2 stage backlit LCD

•IP addressable USB interface to PC (upload/download)

•12 button keypad and one-handed operation

•Aluminum extruded housing with rubber protective bumpers

MAN.LUBExpert.EN--01--SDT-Lubexpertuser-manual-EN.DOCX

Copyright 2017 by SDT International, sa/nv All Rights Reserved

8/27

LUBExpert Data Management Software

•Ultranalysis Suite™ Static LUBExpert License includes 1 licensed installation

•Tree structured database with dedicated “LUBExpert Mode”, multiple survey creation, trend

graphs, asset image mapping, customizable alarming, sensor and data collector serial number

recording for accountability.

Sensors & Accessories

•LUBEsense contact sensor, flat & curved magnetic bases, acoustic lube adaptor, sensor cable

•Custom swivel cradle mounts LUBExpert to any standard grease gun

•Headphones with 130dB noise attenuation (neckband style)

•Universal voltage battery charger (110-240V AC 50/60Hz)

•Manuals and applicable software on memory flash drive or downloadable

•Belt attachment and shoulder Strap

4.3. LUBExpert Base Kit Contents

Article Code

Description

FS.LBX.001 (.002 or .003)

LUBExpert Base Kit

FASFTWUASS01

Ultranalysis Suite Single LUBExpert License, Static

FU.LBX.001

LUBExpert Standard Device w/Battery

FAUPGRKEY270T

Key Activation, Temperature

FUBATTR270-01

Battery, SDT270/200/LUBExpert

FUHDPH-1

Headphone, Neckband

FUPWSPUN-01

SDT Universal Battery Charger w/o Cord

LUBExpert Accessory Pack Includes:

FAHOLSAC-01

Shoulder Strap

FAHOLSAC-02

Leather Belt Holder w/ Clip

SICABUSBAUSBBM

USB Cable

FUCABLPWRC7EU-01

EU Power Cord for Universal Battery Charger (.002)

FUCABLPWRC7US-01

US Power Cord for Universal Battery Charger (.001)

DMSDTNAUSB

SDT USB Memory Drive

Case:

FUSUITEPC-T6-01

LUBExpert Custom Carrying Case

Additional Components Include:

FU.SEN.LUBE.001

LUBEsense Contact Sensor, Threaded, w/o Cable

FUCABLSPLE7LE7-3

Cable for Contact Sensor, LEMO to LEMO, Coiled

FUSEACMAG-01

Magnetic Base, Flat Surface

FUSEACMAG-02

Magnetic Base, Multi Surface

FUSEACLUBE-03

Acoustic Lube Adaptor

FU.LBX.DVC.001

Grease Gun Mounting Cradle

MAN.LUBExpert.EN--01--SDT-Lubexpertuser-manual-EN.DOCX

Copyright 2017 by SDT International, sa/nv All Rights Reserved

9/27

4.4. LUBExpert Upgrade for SDT270SU or SDT270DU (MK2 Only)

LUBExpert Firmware Features

•Static measurements with four condition indicators (4CI)

-Ultrasound –structure borne (LUBEsense Innovative Sensor Technology)

•Onboard Assistant provides real-time stroke-by-stroke guidance

•Integration to UAS for user-defined planned survey mode

•New and innovative LUBEsense ultrasound sensor

•Lube consumption report

•Before and After report

•“Good” “Bad” “Suspect” report

•Embedded algorithm constantly calculates bearing friction

LUBExpert Upgrade Criteria for SDT270

•Different scenarios exist to add the LUBExpert Key to your SDT270. Some things to consider

prior to purchasing the LUBExpert Upgrade:

•Only SDT270 device serial numbers beginning with “280 xxx xxx” are eligible for upgrade. If the

SDT270 device serial number begins with “270 xxx xxx” the device must be exchanged. Contact

your local SDT Representative for details.

•Do you have a license of UAS (STATIC or DYNAMIC)? LUBExpert requires it.

•What is the platform of your SDT270 device?

-LUBExpert only functions on an SDT270SU or SDT270DU

-All other devices must be upgraded first

Sensors & Accessories Included in LUBExpert Upgrade Kit

•LUBEsense threaded contact ultrasound sensor

•Flat and curved magnetic bases

•Acoustic lube adaptor

•Sensor cable

•Custom swivel cradle mounts LUBExpert to any standard grease gun

4.5. Upgrade Kit Contents

Article Code

Description

FA.UKIT.R270.LBX

LUBExpert Upgrade Kit for SDT270SU/DU

FAUPGRKEY270L

Key Activation, LUBExpert

DMSDTNAUSB

SDT USB Memory Drive (manuals, drivers, software)

FU.SEN.LUBE.001

LUBEsense Contact Sensor, Threaded, w/o Cable

FUCABLSPLE7LE7-3

Cable for Contact Sensor, LEMO to LEMO, Coiled

FUSEACMAG-01

Magnetic Base, Flat Surface

FUSEACMAG-02

Magnetic Base, Multi Surface

FUSEACLUBE-03

Acoustic Lube Adaptor

FU.LBX.DVC.001

Grease Gun Mounting Cradle

MAN.LUBExpert.EN--01--SDT-Lubexpertuser-manual-EN.DOCX

Copyright 2017 by SDT International, sa/nv All Rights Reserved

10/27

4.6. Charging the Battery

The LUBExpert uses an internal NiMH battery. The battery charger connects to a socket on the bottom

side of the Instrument, near the headphone jack.

The charging time is typically 6 hours. When the LED of the charger is continuously green, the LUBExpert

battery is completely charged.

Like most batteries, leaving the LUBExpert charging after the charger says it is charged does not hurt the

battery –in fact it very slowly tops the charge up a little more.

Expect up to 8 hours of continuous use from your LUBExpert when the battery is fully charged. This will

vary depending on your need to use the backlight and the TEMP1 internal temperature sensor. Use the

function settings in the main menu to adjust the auto power down and the delay to automatically switch

off the backlight.

4.7. Turning the LUBExpert “ON” and “OFF”

To Turn On

Press the Power Button ①on the bottom right of the keypad. The status

LED ②will shine dark blue. Then, a few seconds later the SDT logo and a

“loading” message appears on the screen. If you do not see this message

your battery may be flat (see above for battery charging instructions).

To Turn Off

Push the Power Button ①on the bottom right of the keypad. The following

confirmation displays, asking to confirm that you indeed want to switch off

the unit, and to avoid accidently powering down LUBExpert. Confirm the

device shut down by pressing the Enter Button③.

①

②

③

MAN.LUBExpert.EN--01--SDT-Lubexpertuser-manual-EN.DOCX

Copyright 2017 by SDT International, sa/nv All Rights Reserved

11/27

Getting Started

4.8. Have you Installed UAS?

On-condition machinery lubrication starts with creating logical and manageable asset databases from

which routine greasing surveys evolve. Your LUBExpert kit includes a single installation license of SDT’s

highly acclaimed Ultranalysis Suite (UAS) software. If you have not already installed UAS and the SDT

device driver on your PC you’ll need to do that first. Everything you need resides on the USB drive

delivered with your LUBExpert kit. The installation process is simple enough however should you require

installation assistance contact your SDT authorized representative.

4.9. Are UAS and LUBExpert up-to-date?

Before we get started, let’s make sure your working with the latest tools. SDT takes customer feedback

seriously and we continuously improve UAS and LUBExpert to ensure the best experience possible. It is

therefore a good idea, from time to time, to check for firmware and software updates. While connected

to the Internet, you can confirm that both your software and your hardware are at the current update

by clicking the “?” Tab in UAS.

1. Launch UAS from the desktop icon or your program start menu.

2. UAS checks your software version and advises you if new updates are

available.

3. Now let’s check the firmware on your LUBExpert. Power up LUBExpert first, then connect it to

your PC with the supplied USB cable. UAS queries the device version and advises you if updates

are available.

4. Follow the simple and intuitive prompts and don’t hesitate to contact us if you experience

difficulties

MAN.LUBExpert.EN--01--SDT-Lubexpertuser-manual-EN.DOCX

Copyright 2017 by SDT International, sa/nv All Rights Reserved

12/27

5.System Settings Edits

UAS is a multi-functional software platform designed for all sorts of ultrasound condition monitoring

tasks. Before we create your first lubrication database and survey, there are a few setup tasks to attend

to. The onboard assistant needs some basic information about your lubrication processes.

If you haven’t already launched UAS software, do so now. Then select “Options” from the main menu

and then “System Settings”.

The System Settings dialogue box appears with several selector tabs oriented horizontally across the

top. The active window is bold and the rest appear lighter grey. Click on the “Grease Gun” tab located at

the right of the window.

5.1. Grease Gun Management

UAS and LUBExpert want to ensure you always use the right grease and the right amount. To do that you

need to specify the quantity of grease dispensed by a full stroke of your grease gun. If you don’t know

the dispensing capacity of your grease gun contact the manufacturer or better yet, measure it yourself.

A list of all the lubricants used in your greasing program are maintained in UAS using the simple

add/edit/delete tool here. Later you can assign the correct grease name to each asset bearing in your

plant.

Once you’re finished here, click Save to exit the System Settings dialogue window.

MAN.LUBExpert.EN--01--SDT-Lubexpertuser-manual-EN.DOCX

Copyright 2017 by SDT International, sa/nv All Rights Reserved

13/27

5.2. Sensor Options –LUBExpert Mode

SDT offers versatile solutions for so many applications; so, there are lots of sensors available. But for

LUBExpert, there are only two (LUBEsense and TEMP2). To help eliminate confusion we created

“LUBExpert Mode” in UAS to hide all the sensors that do not apply to LUBExpert. To enter LUBExpert

Mode, select “Options” from the main menu and then “System Settings”. The System Settings dialogue

box appears with several selector tabs oriented horizontally across the top. The active window is bold

and the rest appear lighter grey. Click on Sensors tab and then click the LUBExpert Mode check box and

then click LUBEsense and TEMP2 check boxes. All other sensor options will be hidden from view during

LUBExpert operation.

Once you’re finished, click Save to keep your selections and exit the System Settings dialogue window.

6.LUBExpert databases in UAS

6.1. Managing Databases

To create a new Tree Structure or a new Data Folder, click on the Create New button ⑤. From the new

window, type in the Data Folder field ⑧the desired name for creating a new Data Folder. In the Tree

Structure field, type the desired name for creating a new Tree Structure. Click on Save when done;

To select an existing Data Folder, click the arrow ②of the drop down menu then click on the desired

Data Folder;

To open an existing Tree Structure, select it from the list and click on Open ④;

To rename an existing Tree Structure, select it from the list and click on Edit ⑥;

To rename an existing Data Folder, click on the Edit button ②and then from the new window, type its

new name and click on Save;

To delete a Tree Structure, select it from the list and click on Delete ⑦. This action will delete the delete

the database. This operation is not reversible and cannot be undone. A warning message asks first for a

confirmation;

To Delete a Data Folder, click on the Delete button ③. This action will delete the delete the Data Folder

and all its associated databases. This operation is not reversible and cannot be undone. A warning

message asks first for a confirmation.

MAN.LUBExpert.EN--01--SDT-Lubexpertuser-manual-EN.DOCX

Copyright 2017 by SDT International, sa/nv All Rights Reserved

14/27

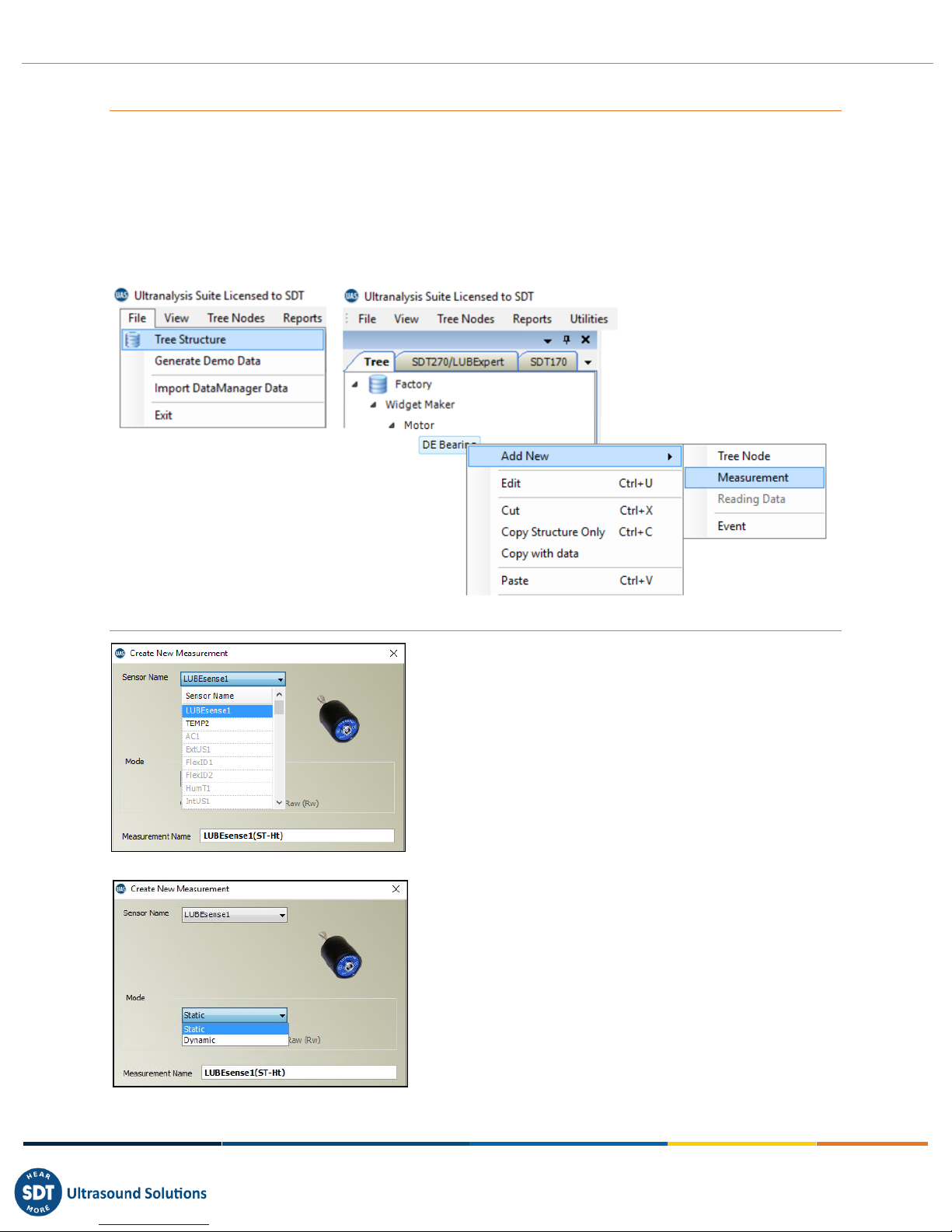

6.2. Modifying a Database

Add Descriptive Tree Nodes

You may choose to add a descriptive node or a

measurement node. Descriptive nodes serve to

describe the location of the physical asset.

Right click your mouse on any node in the open

database tree and select “Add New > Tree Node”

from the short-cut menu. This action opens the

“Create New Tree Node” dialogue box. Type the

name of the new Node and then click save. The new

node is added as a lower level sub-Node of the

database or Node level you selected.

②

①

③

④

⑤

⑥

⑦

⑧

⑨

MAN.LUBExpert.EN--01--SDT-Lubexpertuser-manual-EN.DOCX

Copyright 2017 by SDT International, sa/nv All Rights Reserved

15/27

Add Measurement Tree Nodes

The last node in the tree (up to seven) is always used as the measurement node. Measurement nodes

describe the type of measurement data collected from the asset. UAS will only allow you to assign

Measurement Nodes in the correct place on the tree structure. If “Measurement” option is inactive then

you have chosen the wrong section of the tree to add a measurement.

Adding LUBExpert measurements to your data tree is no different than adding other measurements. The

only difference is that for a LUBExpert measurement, you only have two sensor choices (LUBEsense and

TEMP2).

Assigning LUBExpert Sensors

If you followed the instructions to go into LUBExpert Mode,

the list of available sensors should only be two (LUBEsense

and TEMP2). The other sensors are still visible but inactive.

Choose LUBEsense to create an ultrasound measurement

node and TEMP2 to create a temperature measurement

node as required.

For ultrasound measurements, UAS gives you the option to

choose either Static or Dynamic and for temperature

measurements you can set the measurement interval and

the emissivity. Your LUBExpert will not measure Dynamic

data so it doesn’t really matter what you choose here. If

you choose Dynamic, LUBExpert and SDT270SU will only

record the 4 Static Condition Indicators (4CI).

If you are using an SDT270DU, choosing Dynamic here will

instruct your SDT270DU to collect both Dynamic and Static

data simultaneously.

MAN.LUBExpert.EN--01--SDT-Lubexpertuser-manual-EN.DOCX

Copyright 2017 by SDT International, sa/nv All Rights Reserved

16/27

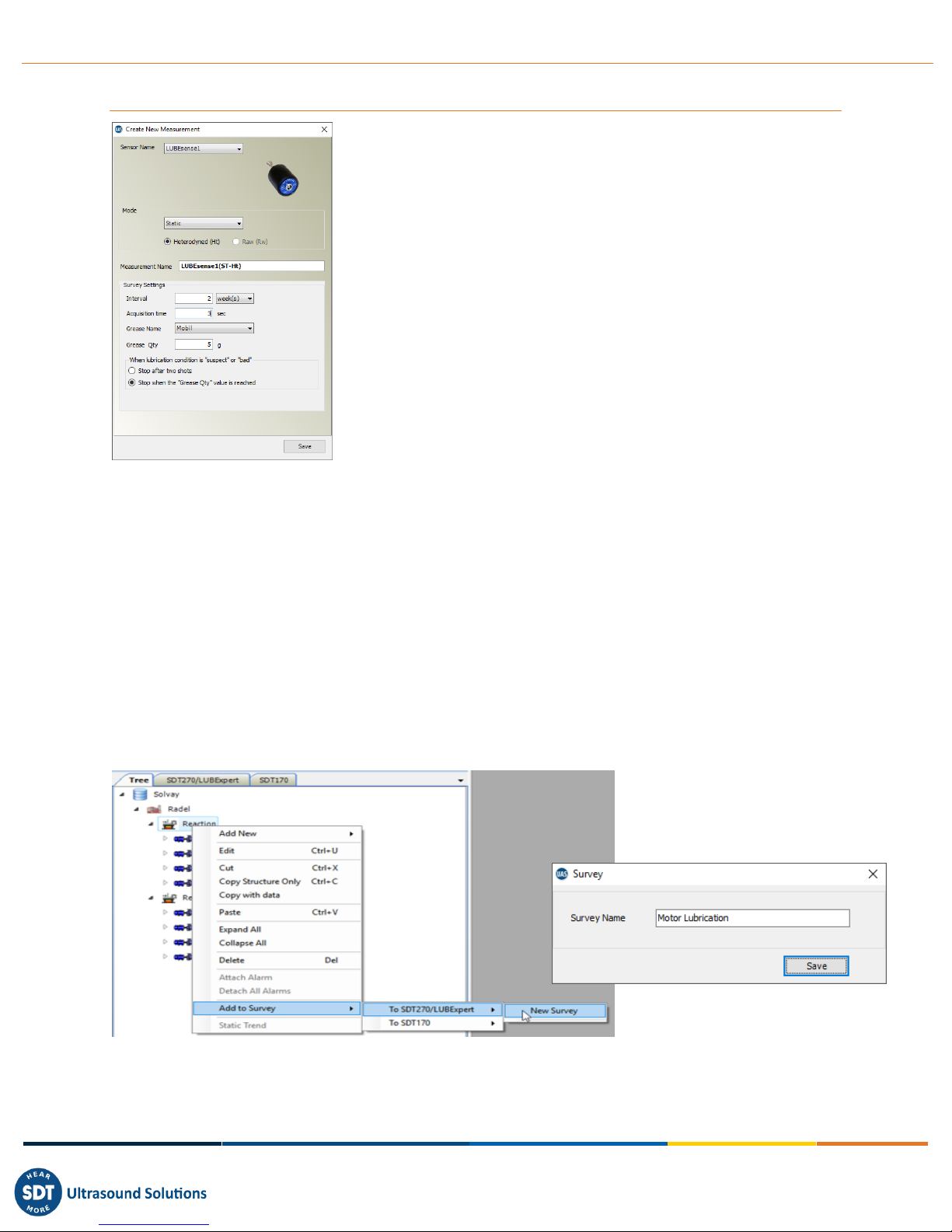

Setting Data collection Interval, Acquisition Time, and Temperature Emissivity

For both LUBEsense and TEMP2 measurements, the choice to

set your preferred data collection interval time ①in months,

weeks, days, or hours ②is made here. For TEMP2

measurements the additional choice to set emissivity exists

here. The default emissivity is 1.0.

Acquisition Time ③refers to the length of time you commit

your SDT instrument to sample data. Longer time for slow

speed applications and less time for normal and high speed.

The goal is to set the acquisition time long enough to capture

at a minimum, 2 to 3 full shaft rotations.

The default acquisition

time is one second. Enter

the desired value in the

Acquisition Time field of

the Create New

Measurement dialogue

box.

Setting Grease Type

Earlier we described how to set up a list of all the lubricant types

used in your plant under “Grease Gun Management”. With the

“Create New Measurement” dialogue box open, here you select the

grease type for this bearing using the drop down box ①beside

Grease Type.

Now locate the field named “Grease Qty” ②. Here you enter the

theoretical grease quantity when re-lubricating this bearing. This field

is important. It empowers LUBExpert to warn, in-the-field, if an

operator is about to dispense more grease to the bearing than it

should theoretically receive, thus preventing over-lubrication for

Suspect and Bad lubrication conditions.

If you don’t know the maximum lubricant capacity for your bearing,

this information is readily available from your bearing manufacturer,

or through a web search. Otherwise, you may leave this field blank.

Then LUBExpert will stop the lubrication process after two shots when the lubrication condition is

Suspect or Bad.

①

②

③

①

②

MAN.LUBExpert.EN--01--SDT-Lubexpertuser-manual-EN.DOCX

Copyright 2017 by SDT International, sa/nv All Rights Reserved

17/27

Stop on Status or Max Grease Capacity

LUBExpert returns three status conditions to signal the completion of

the lubrication task.

•GOOD

•SUSPECT

•BAD

In the event of a “SUSPECT” or “BAD” assessment, LUBExpert allows

you to perform one of two operations.

1. Stop greasing after 2 shots;

2. Stop greasing when the max grease quantity is reached.

From the “Create New Measurement” dialogue box, choose either

Option 1 (stop greasing after 2 shots) or Option 2 (Stop when the

"Grease Qty" value is reached). Save your selection and exit the

dialogue box.

7.Working with Surveys

Working with surveys in UAS for LUBExpert should be familiar to UAS users. For more detailed

explanations, reference your UAS user manual.

7.1. Create a new Survey

To create a new lubrication survey, right click on any asset in the data tree to access the shortcut menu.

From the shortcut menu select “Add to Survey” and then “To SDT270/LUBExpert” and then “New

Survey”. A dialogue box appears asking for the name of the new survey. Type it and click Save. The asset

is added to the New Survey.

Operator’s may choose to add assets one at a time, or a bulk addition is possible.

It is also possible to perform this action from the “Tree Nodes” menu.

MAN.LUBExpert.EN--01--SDT-Lubexpertuser-manual-EN.DOCX

Copyright 2017 by SDT International, sa/nv All Rights Reserved

18/27

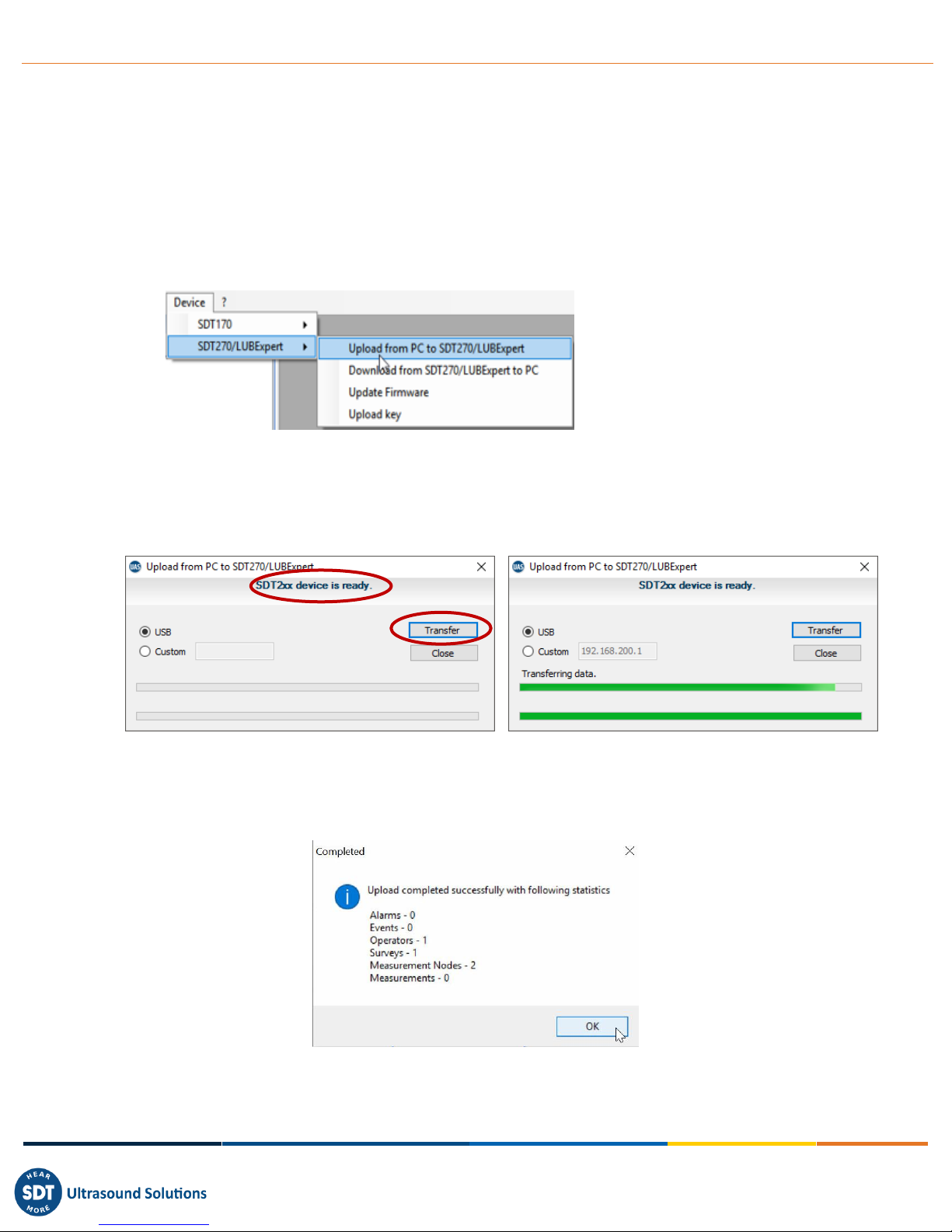

7.2. Transfer Survey to LUBExpert

To transfer lube surveys from UAS to LUBExpert or SDT270SU/DU:

•Connect LUBExpert or SDT270 instrument to PC using the USB transfer cable supplied (article

code SICABUSBAUSBBM).

-The device driver is found on the supplied USB Flash Drive.

•From the “Device” menu in UAS select “SDT270/LUBExpert” and then “Upload from PC to

SDT270/LUBExpert

•Wait for message “SDT2xx device is ready” and select “Transfer”

-If the message doesn’t appear, there is no connection between PC and device

Is the device switched on?

Is the correct driver installed?

•Wait for transfer progress to complete

•After a successful transfer a status report provides relevant transfer statistics

•Click OK. You’re ready to go!

MAN.LUBExpert.EN--01--SDT-Lubexpertuser-manual-EN.DOCX

Copyright 2017 by SDT International, sa/nv All Rights Reserved

19/27

8.In the Field

8.1. Connecting LUBEsense

LUBEsense is the only ultrasound sensor that works with LUBExpert or LUBExpert Mode on an

SDT270SU/DU. Connect sensor to instrument with the coiled LEMO to LEMO cable (Article Code:

FUCABLSPLE7LE7-3) supplied by SDT.

Carefully line up the red dots on the cable connector

with the Black input on the instrument. It is important to

line up the red dots to avoid damaging the cable’s

connector pins. Gently push the connector into the input.

The LUBEsense probe is identified as “LUBEsense1” on

the top left of the display when a successful connection

is made.

LUBEsense is delivered with both a Magnetic Mount (Article Code FUSEACMAG-01 and FUSEACMAG-02)

and the SDT Acoustic Grease Gun Adaptor (Article Code: FUSEACLUBE-03). Choose the interface you

want and screw it to the base of the LUBEsense.

8.2. Planned Survey Mode

You are now ready to begin a lubrication survey.

Press the Center Button (Enter) on the LUBExpert or SDT270SU/DU device to access the Main Menu.

Using the Down Arrow, highlight Planned Survey and press Enter. A list of available surveys appears.

Highlight the one you want using the Up/Down Arrows and press Enter.

LUBExpert displays the first asset point in the survey. Be sure that this is the machine you actually want

to lubricate, and press Enter to begin.

For your confirmation, and reminder, LUBExpert displays the lubricant designated for this bearing, the

maximum quantity of lubricant (bearing capacity) before the bearing is over-greased, and the number of

shots that value represents with the calibrated grease gun. Press Enter to begin lubrication.

MAN.LUBExpert.EN--01--SDT-Lubexpertuser-manual-EN.DOCX

Copyright 2017 by SDT International, sa/nv All Rights Reserved

20/27

8.3. Lubrication Steps

Set Amplification

Connect the SDT headphones to the LUBExpert or SDT270 instrument and place them over your ears.

Using the Right/Left arrows on the keypad, adjust the listening volume in the headset to a comfortable

level. This adjustment has no bearing on the measurement accuracy and repeatability.

Attach LUBEsense either to the grease fitting (if using the Lube Adaptor) or as close to the bearing as

possible with the magnetic mount.

Using the Up/Down arrows on the keypad, adjust the

amplification (gain A=XX) to the correct level. A

correct amplification level is attained only after both

Up and Down arrow indicators disappear from the

display.

Press the Enter button on the keypad and then F3 button to save the initial

condition data for the bearing.

Adding Grease

Follow the intuitive on-screen instructions to add grease to the bearing. Add one full shot of grease and

press Enter once the grease is delivered.

The bearing and lubricant are now in the churning phase.

LUBExpert enters a stabilization period of 10 seconds (default value) to allow the grease to churn into

the bearing.

Changing Stabilization Time

For larger bearings and extreme weather/temperature environments, it may

be necessary to increase the stabilization time to allow for a longer churning

phase.

To adjust the stabilization time press F2 (middle function button). This screen

appears. Press F2 to decrease and F3 to increase the stabilization time. Press

F1 to return to previous menu.

Status Report

Once the stabilization time counts down to zero LUBExpert will either give a

status report or ask for another shot of grease. You may:

•Add another shot of grease and press Enter to begin stabilization time

countdown for churning phase

•Press F3 to end the task

LUBExpert returns one of three results:

Other manuals for LUBExpert

1

Table of contents

Other SDT International Measuring Instrument manuals