Sea-Bird Scientific SBE 39plus User manual

User manual

SBE 39plus-IM temperature

recorder

Document No. SBE39IM

Release Date: 2023-03-21

Version: A

425-643-9866

seabird.com

Table of Contents

Section 1 Safety information............................................................................................................ 3

1.1 Hazard information....................................................................................................................... 3

1.2 Equipment labels.......................................................................................................................... 4

Section 2 SBE 39plus IM quick start guide................................................................................... 5

Section 3 Specifications.................................................................................................................... 7

3.1 Mechanical................................................................................................................................... 7

3.1.1 Dimensions..........................................................................................................................7

3.2 Electrical ..................................................................................................................................... 8

3.3 Communication........................................................................................................................... 8

3.4 Analytical .................................................................................................................................... 8

Section 4 Overview............................................................................................................................. 9

4.1 Battery life.................................................................................................................................... 9

Section 5 Set up sensor and verify operation............................................................................ 11

5.1 Inductive modems...................................................................................................................... 11

5.1.1 Set up IMM........................................................................................................................ 11

5.1.2 Set up SIM.........................................................................................................................12

5.2 Install software and test sensor.................................................................................................. 14

5.2.1 Software menu items.........................................................................................................14

5.3 Set up sensor ID and test IMM................................................................................................... 15

5.4 Set up sensor ID and test SIM................................................................................................... 16

5.5 Set up and test USB communication......................................................................................... 18

5.6 Set up and test RS232 communication...................................................................................... 19

5.7 Mooring cable and wiring........................................................................................................... 20

Section 6 Deployment and recovery.............................................................................................23

6.1 Set up sensor............................................................................................................................. 23

6.2 Set up software.......................................................................................................................... 25

6.3 Configure software..................................................................................................................... 25

6.3.1 Timeout description........................................................................................................... 26

6.4 Data collection modes................................................................................................................ 26

6.4.1 Autonomous mode............................................................................................................ 26

6.4.2 Controlled (polled) mode................................................................................................... 27

6.4.3 Combination mode............................................................................................................ 27

6.4.4 Averaging mode................................................................................................................ 27

6.5 Default output format ................................................................................................................. 27

6.6 Recover sensor from deployment.............................................................................................. 28

Section 7 Transmit and convert data........................................................................................... 29

7.1 Transmit data to a PC................................................................................................................ 29

7.1.1 Use the IM telemetry to transmit data............................................................................... 30

7.2 Convert data............................................................................................................................... 31

Section 8 Maintenance..................................................................................................................... 33

8.1 Replace batteries and desiccant................................................................................................ 33

8.2 Clean pressure sensor............................................................................................................... 34

8.2.1 Calculate pressure correction............................................................................................35

8.3 Examine O-rings........................................................................................................................ 35

8.4 Clean bulkhead connectors........................................................................................................ 36

8.5 Calibration.................................................................................................................................. 37

8.5.1 Temperature...................................................................................................................... 37

8.5.2 Pressure............................................................................................................................ 37

8.6 Spare parts and accessories...................................................................................................... 38

1

Section 9 Reference: command descriptions............................................................................ 39

9.1 Integrated IMM........................................................................................................................... 39

9.2 SIM commands.......................................................................................................................... 40

9.3 Acquisition micro-controller ....................................................................................................... 40

9.3.1 Status................................................................................................................................ 41

9.3.2 General setup.................................................................................................................... 43

9.3.3 Memory setup....................................................................................................................43

9.3.4 Output format setup...........................................................................................................43

9.3.4.1 Diagnostic data format ............................................................................................ 44

9.3.4.2 XML data format....................................................................................................... 44

9.3.5 Autonomous operation with data storage.......................................................................... 45

9.3.6 Controlled ("polled") data collection.................................................................................. 46

9.3.7 Coefficients........................................................................................................................46

9.3.8 Data upload....................................................................................................................... 46

Section 10 General information..................................................................................................... 49

10.1 Warranty................................................................................................................................... 49

10.2 Service and support................................................................................................................. 49

10.3 China RoHS disclosure table................................................................................................... 49

Table of Contents

2

Section 1 Safety information

Please read this entire manual before this equipment is unpacked, set up, or operated.

Pay attention to all danger, warning, and caution statements. Failure to do so could result

in serious injury to the operator or damage to the equipment.

DANGER

Indicates a potentially or imminently hazardous situation which, if not avoided, will result in death

or serious injury.

WARNING

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in minor or moderate injury.

NOTICE

Indicates a situation which, if not avoided, may cause damage to equipment. Information that

requires special emphasis.

1.1 Hazard information

WARNING

If the user thinks that the lithium batteries have leaks, pressure may have built up inside

of the pressure housing. Follow ESD protocols to release internal pressure. Put on

safety glasses and protective gloves and make sure that the sensor is pointed away

from the body and other people. In a well ventilated very SLOWLY loosen the bulkhead

connector to release the pressure. Keep away from heat, sparks, flame, and other

sources of ignition. Do not smoke.

CAUTION

The pressure housing contains Electrostatic Discharge (ESD) sensitive parts and

assemblies that are susceptible to damage from ESD. Follow ESD protocols:

• Put on protective eye wear before you open the pressure housing.

• Any electrostatic charge on the body of the human operator must be released

before the pressure housing is opened: put a hand on a grounded surface, or

better, wear a grounded antistatic wrist strap.

• At a minimum, wear short-sleeved antistatic clothing, such as cotton, or better,

wear an antistatic smock for this service activity. Do not wear a sweater, fleece or

polyester-based clothing.

• At a minimum, use a workstation with a wood or metal tabletop, or better, a

tabletop that dissipates static. Do not use a workstation with a synthetic or

polymeric-based tabletop.

NOTICE

The manufacturer is not responsible for any damages due to misapplication of misuse of this

product including, without limitation, direct, incidental and consequential damages, and disclaims

such damages to the full extent permitted under applicable law. The user is solely responsible to

identify critical application risks and install appropriate mechanisms to protect process during a

possible equipment malfunction.

3

1.2 Equipment labels

Read all labels and tags attached to the equipment. Personal injury or damage to the

equipment could occur if not observed. A symbol on the equipment is referenced in the

manual with a precautionary statement.

Electrical equipment marked with this symbol may not be disposed of in European domestic or public disposal

systems. Return old or end-of-life equipment to the manufacturer at no charge to the user.

EFUP: Hazardous material exists over the threshold of GB/T 26572.2011. The number in the center of

the symbol is the Environmentally Friendly Use Period as specified by SJ/T 11364-2014, China's

marking for the Restriction of the Use of Hazardous Substances in Electrical and Electronic Products.

This product should be recycled after its environmentally friendly use period.

Safety information

4

Section 2 SBE 39plus IM quick start guide

This quick start guide gives the steps necessary to make sure that the SBE 39plus IM

sensor operates correctly and collects data before it is deployed.

This quick start guide and user manual applies to those SBE 39 models that are equipped

with an Inductive Modem Module (IMM) or Surface Inductive Modem (SIM).

What's in the box:

• SBE 39plus, with four Saft LS 14500 AA lithium cells installed.

• CD—has software, calibration files, documentation

• Spare parts kit

• I/O cable for internal USB connector to connect the sensor to a PC

• Optional Inductive Modem Module

• Optional SIM circuit board and I/O cable

• Optional Inductive Cable Coupler (ICC)

1. Install the manufacturer-supplied software on a PC. Refer to Install software and test

sensor on page 14 for details.

2. If necessary, install new batteries and desiccant. Refer to Replace batteries and

desiccant on page 33 for details.

The manufacturer ships new sensors with 4 AA lithium cells installed.

3. Set up the IMM if so equipped. Refer to Set up IMM on page 11 for details. Set up

and test the sensor with the IMM. Refer to Set up sensor ID and test IMM

on page 15 for details.

4. Set up the SIM if so equipped. Refer to Set up SIM on page 12 for details. Set up

and test the sensor with the SIM. Refer to Set up sensor ID and test SIM on page 16

for details.

5. Connect the sensor to the PC and double-click on SeaTermV2.exe to start the

software.

6. Set up the sensor for deployment. Refer to Set up sensor on page 23 for details.

a. If necessary, make sure that all data stored in the sensor is transmitted to a PC.

b. Set the date and time (#iiDateTime)

c. Configure the data collection settings.

d. Send the #iiDS and #iiDC commands to verify the setup.

7. Immediately after the sensor is recovered from a deployment:

a. Use the software to turn off the sensor.

b. Rinse the sensor with fresh water.

c. Keep the sensor out of direct sunlight between deployments.

8. Transmit data from the sensor to a PC.

9. To store the sensor:

a. Rinse the sensor thoroughly, then dry.

b. Leave the batteries in the sensor for storage up to a year.

5

SBE 39plus IM quick start guide

6

Section 3 Specifications

3.1 Mechanical

Plastic Titanium

Depth rating 600 m 10500 m

Optional strain-gauge pressure sensor 20, 100, 350, 600, 1000, 2000, 3500, 7000 m

Weight in air, water, with embedded thermistor 0.6 kg, 0.25 kg 1.2 kg, 0.7 kg

3.1.1 Dimensions

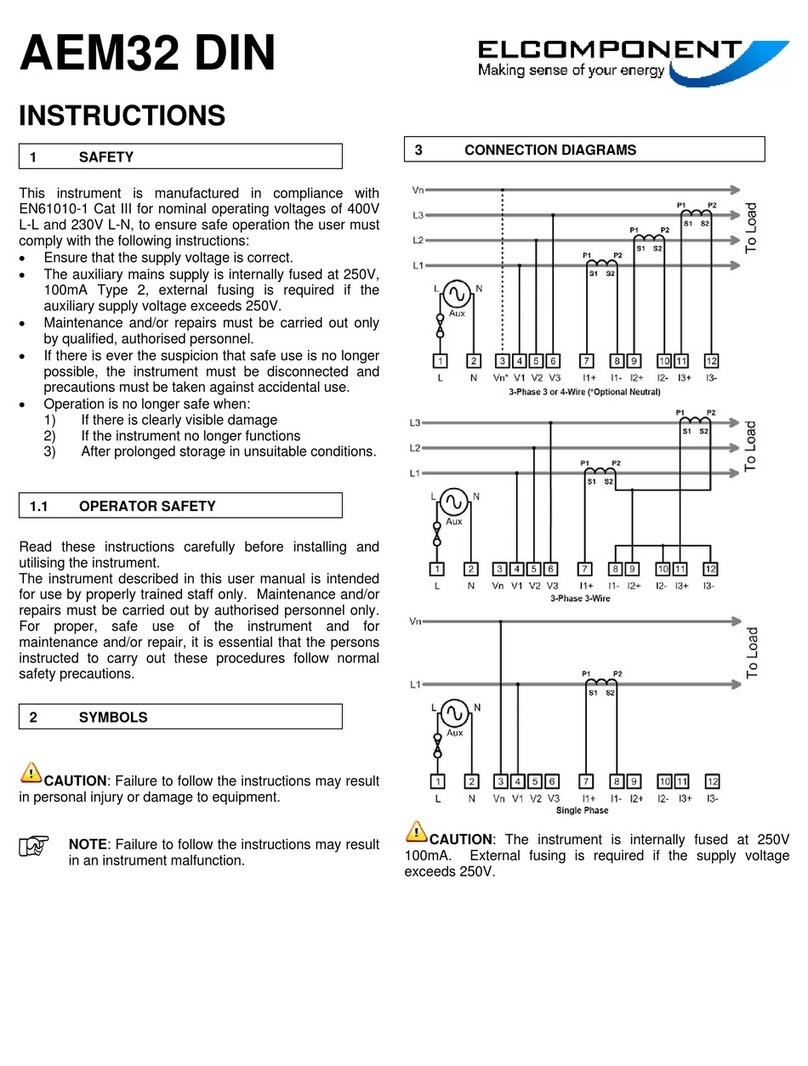

Figure 1 SBE 39plus-IM lengths

Figure 2 SBE 39plus fairing

7

3.2 Electrical

Temperature Temperature and pressure

Internal batteries 4 Saft LS 14500 AA lithium cells, 7.2 V, 5.2 Ah

Input 9-30 VDC

Current draw (2.5 mA, 280 mseconds): 0.00070 A-sec (3 mA, 280 mseconds): 0.00084 A-sec

Current draw, low power 25 µA

3.3 Communication

Temperature Temperature and pressure

Communication interface IMM, SIM, or USB

Data collection interval 5 seconds to 6 hours, user-programmable

Data collection time 0.28 sec

Data collection transmit time, low power 0.022 mA-sec/character

Data collection transmit time, full power 0.032 mA-sec/character

Memory 64MB

Data storage 9,500,000 samples

(12-sec interval, 2 years)

5,500,000 samples

(7-sec interval, 2 years)

3.4 Analytical

Parameter Range Accuracy Stability Resolution

Temperature -5–45 °C ±0.002 °C (-5–35 °C)

±0.01 °C (35–45 °C)

0.0002 °C/mo 0.0001 °C

Pressure not more than the SBE

39 rated depth

±0.1% 0.05% full scale range/yr 0.002% full scale range

Specifications

8

Section 4 Overview

The SBE 39plus-IM is a high-accuracy temperature recorder. The sensor is designed for

moorings and other long-term, fixed-site deployments.

Optional equipment:

• Pressure sensor, strain gauge

• Fairing ("net fender") to protect from fishing lines and nets.

The SBE 39plus-IM is equipped with an internal battery pack and uses an Inductive

Modem (IM) to transmit data and get commands over a plastic-covered steel mooring

cable. The cable uses Differential-Phase-Shift-Keyed (DPSK) telemetry. No electrical

cables or connectors are required.

Two models are available:

• Embedded thermistor, with a time constant of approximately 25 seconds.

• External thermistor, with a time constant of approximately 0.5 seconds.

Communication with the SBE 39plus-IM requires an Inductive Modem Module (IMM) or

Surface Inductive Modem (SIM), for a serial interface between a PC or other controller

and up to 100 SBE 39plus-IM sensors. Communication is through a full-duplex RS232,

with commands and data transmitted half-duplex between the IMM or SIM and the SBE

39plus-IM.

The user can operate the sensor in one of several modes:

Autonomous operation—interval

• Operates at user-selected intervals (5–second to 6-hours).

• Operation sequence:

1. The sensor makes one measurement

2. The data is stored internally

3. The sensor goes into a low power mode until the next sample is collected.

Controlled (polled) operation

• Controlled data collection is useful when the sensor is integrated with satellite, radio,

or wire telemetry equipment.

• Operation sequence:

1. The sensor makes one measurement

2. The sensor sends the data to the controller

3. The sensor goes into a low power mode until the next command to operate.

Combo operation

The sensor operates autonomously and transmits the last stored data to the IMM or SIM.

Average operation

The sensor operates autonomously and transmits the average of the data collected since

the last transmission to the IMM or SIM.

4.1 Battery life

The battery pack is 4 size AA cells in series of 3 parallel strings. The battery holder has a

yellow cover plate. It is NOT compatible with the older battery holder that has a red cover

plate. The manufacturer recommends the user uses a conservative capacity value of

4.0 amp-hours, even though the nominal capacity is calculated at 5.2 amp-hours.

Battery life depends on the type of deployment, but in general, the limit is the memory

capacity, not the battery capacity. The 39plus-IM is shipped with the Deployment

Endurance Calculator software to calculate the maximum deployment time. Examples of

a manual calculations are shown below.

9

Example 1: Ten 39plus-IMs with pressure sensors are set up to take a sample every 5 seconds, or 720 samples/hour.

Sensors are set to full power transmit (SetEnableFullPwrTX=Y), with an average transmitted to a PC every hour. Setting is

#iiOutputFormat=1, approximately 80 characters per sample. How long can it be deployed?

Communications current draw = 0.84 mA-s/sample = 0.00084 A-s/sample.

720 × 0.00084 = 0.6048 A-s/hour

Transmit current draw/sample = 0.032 mA-s/character = 0.000032 A-s/character

0.000032 A × 80 characters = 0.00256 A-s/sample

In 1 hour, 1 × 0.00256 a-s/sample = 0.00256 A-s/hour

Standby current draw = 800 µA = 0.8 mA = 0.0008 A.

Current draw per query = 0.0008 A × 1 sec/IM × 9 other IMs on mooring = 0.0072 A-s/query

1 query/hour × 0.0072 A-s/query = 0.0072 A-sec/hour

Low power current draw = 60 µA = 0.06 mA = 0.00006 A

In one hour, 0.00006 A × (3600 seconds/hour - 720 × 0.28 sec/sample - 9 seconds standby) = 0.2034 A-s/hour

Power consumed/hour = 0.6048 + 0.00256 + 0.0072 + 0.2034 = 0.8180 A-s/hour

Battery capacity = (4.0 aH × 3600 seconds/hour) ÷ 0.0.8180 A-s/hour = 17603 hours = 733 days = 2.0 years

Number of samples = 17603 hours × 720 samples/hour = 12,674,000 samples

The memory capacity is approximately 5,500,00 samples. The 39plus-IM will continue to collect and transmit data

after the memory is full, but will not overwrite the data stored in memory.

Example 2: A 39plus-IM without pressure is deployed on a mooring set up to take a polled sample every minute, or

60 samples/hour. Sensor is set to full power transmit (SetEnableFullPwrTX=Y). Setting is #iiOutputFormat=1, approximately

80 characters per sample. The PwrOff command is sent immediately after each sample. How long can it be deployed?

Polled data collection current draw = 1.9 mA-sec/sample = 0.0019 A-s/sample. In 1 hour, 60 samples × 0.0019 A-s/sample =

0.1140 A-s/hour

Transmit current draw/sample = 0.032 mA-s/character = 0.000032 A-s/character

0.000032 A × 80 characters = 0.00256 A-s/sample

In 1 hour, 60 queries/hour × 0.00256 A-s/sample = 0.1536 A-s/hour

Standby current draw = 800 µA = 0.8 mA = 0.0008 A.

Current draw per query = 0.0008 A × 1 sec/IM = 0.0008 A-s/query

1 query/hour × 0.008 A-s/query = 0.0008 A-sec/hour

Low power current draw = 60 µA = 0.06 mA = 0.00006 A

***** one 39-IM or 9? see p. 14 of legacy manual.

In one hour, 0.00006 A × (3600 seconds/hour - 60 × 0.28 sec/sample) = 0.0595 A-s/hour

Power consumed/hour = 0.1140 + 0.1536 + 0.0008 + 0.0595 = 0.3279 A-s/hour

Battery capacity = (4.0 aH × 3600 seconds/hour) ÷ 0.3279 A-s/hour = xxx hours = xxx = xx years

Number of samples = xx hours × xx samples/hour = xxx samples

The memory capacity is approximately 5,500,00 samples. The 39plus-IM will continue to collect and transmit data

after the memory is full, but will not overwrite the data stored in memory.

Battery life is also affected by deployment orientation. The manufacturer recommends

that the 39plus is deployed vertically, with the thermistor pointed down, or horizontally. If

the 39plus is deployed with the thermistor pointed up, the battery life may be reduced by

up to 40%. This will not affect most deployments because even with a 40% reduction, the

SBE 39plus could still collect approximately 7.4 million samples, more than the memory

can store.

Overview

10

Section 5 Set up sensor and verify operation

Set up the hardware and install the software for the sensor to make sure that it functions

correctly before deployment.

• Install the manufacturer-supplied software.

• Verify operation.

IMPORTANT:all commands are pre-pended with #ii. Do not use #ii for RS232 and

SDI-12 protocols. For example, the "Stop" command is ii#Stop for IMM and SIM and

Stop for RS-232.

5.1 Inductive modems

An Inductive Modem Module (IMM) or Surface Inductive Modem (SIM) is required to

communicate with the SBE-39plus. The communication between the modem and

MicroCAT is half-duplex, and the modems operate at 1200 baud.

• IMM: available data rates are 1200, 2400, 4800, 9600, 19200, or 38400 baud.

• SIM: available data rates are 1200, 2400, 4800, or 9600 baud.

5.1.1 Set up IMM

Verify that the sensor and modem operate correctly before deployment. Operation notes:

• Supply the IMM with 7–24 V.

• The maximum current for operation is approximately 15 mA.

• The manufacturer recommends a minimum of 20 ohms impedance to reduce noise

during operational tests.

1. Make a loop of insulated test wire through the modem coupling and put the other end

of the loop through the IMM test coupler or ICC.

2. Connect the wire ends from the test coupler or ICC to J1 on the IMM.

3. Connect the IMM to the serial port of the PC.

4. Set up the IMM for either option A or B. Make sure to add a script that has one of

these setups to the buoy controller so the IMM can be re-set if it gets corrupted.

a. Option: Full use of IMM

*Init

*Init (send twice to set IMM to default state)

11

SetConfigType=2

SetEnableAutoIMFlag=0

SetEnableBackSpace=1

SetEnableBinaryData=0

SetEnableEcho=1

SetEnableHostFlagConfirm=0

SetEnableHostFlagTerm=0

SetEnableHostFlagWakeup=0

SetEnableHostPromptConfirm=0

SetEnableHostServeOnPwrUp=1

SetEnablePrompt=1

SetEnableHostWakeupCR=0

SetEnableSignalDetector=0

SetTermFromHost=36

SetTermToHost=13

b. Option: IMM emulates the SIM

*Init

*Init (send twice to set IMM to default state)

SetConfigType=1

SetEnableBinaryData=0

5. Send the GetCD command to verify that the IMM is set up correctly

5.1.2 Set up SIM

Verify that the sensor and modem operate correctly before deployment. Setup notes:

• Supply the SIM with 7–25 V.

• The maximum current for operation is approximately 30 mA.

• The manufacturer recommends a minimum of 20 ohms impedance to reduce noise

during operational tests.

Configure the SIM to operate in one of two modes:

Normal power (default)—the SIM operates when power is supplied. SIM setup:

• Connect "Power Common" to JP1 pin 1.

• Connect 7–25 VDC to JP1 pin 2.

• Verify there is no connection to JP1 pin 3.

• Verify the jumper is across J3.

Logic-level controlled power—this switches power to the SIM. SIM setup:

• Connect "Power Common" to JP1 pin 1.

• Connect 7–25 VDC to JP1 pin 2. If "VCNTL" is < 1 V, SIM is off. If "VCNTL" is > 2V,

SIM is on.

• Remove the jumper across J3.

1. Make a loop of insulated test wire through the modem coupling and connect the test

wire ends to the SIM cable terminals at JP4.

Set up sensor and verify operation

12

2. Remove the J5 jumper from the SIM.

This puts a 1K resistor in series with the inductive loop and reduces signal amplitude,

so that any other MicroCATS that are close to the connected sensor do not respond

to commands.

3. Connect the SIM to the serial port of the PC.

4. Interface connection: verify that the SIM is configured for RS232:

a. The jumper is on J1 pins 2 and 3.

b. The jumper is on J2 pins 2 and 3.

c. Remove the jumper on J4.

Set up sensor and verify operation

13

5. Connect wires to JP2:

a. Pin 2 is RS232 transmit from SIM to PC.

b. Pin 3 is RS232 transmit from PC to SIM.

c. Pin 5 is power common.

6. Inductive mooring cable:

• If the Inductive Cable Coupler (ICC) is installed, connect wires from the ICC to

JP4.

• If the ICC is not installed, connect wires from the mooring cable and seawater

ground to JP4 on SIM-direct.

Note that ICC v4 may have three wires. If the ICC has a pigtail termination, solder the

white and white-black wires together and attach to one terminal of JP4. Attach the

white-red wire to the other terminal.

7. For normal deployment, make sure that the jumper is installed on J5.

5.2 Install software and test sensor

Make sure that the sensor is connected to the PC through the serial connector on the

supplied cable. Most PCs no longer have serial ports, and a serial-to-USB adapter is

necessary. Make sure that the USB driver software is installed on the PC so that there is

communication between the sensor and the PC.

1. Install the Seasoft V2 software from the manufacturer-supplied CD.

2. Double-click on SeatermV2.exe to start the launcher. If this is the first time the

software is opened, a Serial Port Configuration window opens. The software

automatically connects at the default baud rate of 19200 but will try others if

necessary. The software automatically looks for the serial port number of the

connected sensor.

3. At the Instruments menu item, select SBE 39plus-IM.

4. Push OK to close this window.

The main window opens. The area on the left shows available commands. The large

area on the right shows commands and the responses from the sensor to those

commands.

5.2.1 Software menu items

Note that the sensor will "time out" if it does not receive a command for two minutes. To

start the sensor again, select Connect in the software Communications menu or push

Enter.

Set up sensor and verify operation

14

Menu item Description

File Load command file opens the selected .xml command file in the "Send Commands" area.

Unload command file closes the file and removes the commands from the "Send Commands" area.

Exit closes the program.

Communications Connect connects to the COM port. Disconnect disconnects from the COM port.

Configure establishes COM port and baud rates.

Disconnect and reconnect turns communications off then on. Useful if a sensor is non-responsive.

Command Abort stops the sensor. (The Esc key is equivalent.)

Send 5-second break is used with Serial Line Sync Mode.

Send stop command stops sensor operation.

Set local time/Set UTC time sets the clock in the sensor. (This is disabled if the baud rate is set at

115200 because the software cannot set the time at that rate.)

Capture Capture sensor responses to save real-time data or for diagnostics. Select Capture again to turn it off.

Capture status shows in the "Status" bar.

Upload Upload data from the sensor to a PC. Data is in an .xml format and is automatically converted to a .hex

and .xmlcon file for the Data Conversion software module.

Tools Diagnostics log saves diagnostic data.

Use Convert .xml data file to manually convert data if the automatic Upload does not convert the data.

Send script sends the same setup information to a number of MicroCAT sensors.

Options Select (default) or deselect the option to Prompt to launch data conversion after data upload.

5.3 Set up sensor ID and test IMM

1. From the Instrument menu, select SBE 39plus IM.

SeatermIM starts.

2. For IMM: after the first use, the software will send DS to automatically try to connect.

If there is no response to DS, the software continues to communicate with the IMM.

a. The software sends GetHD and GetCD to get the status of the IMM.

b. If ConfigType=1, the software sends PwrOn to all connected IMM sensors.

c. If ConfigType=2, the software sends ForceCaptureLine to reserve the IM line and

then sends SendWakeupTone to all connected IMM sensors.

d. The next try for connection depends on the ID configuration in the software from

the last time it was used.

• If the software is set to "Automatically get instrument ID" it sends id? and

waits for the sensor to communicate. The software then sends !iiGetHD and

#iiGetHD to the ID sent by the sensor.

• If the software is set to "Use fixed ID" it sends !iiGetHD and #iiGetCD to the

lD that was set the last time the user used the software.

e. The software shows the list of available commands in the Send Commands

window.

3. Do the steps below if the sensor does not respond to ID, !iiGetHD, #iiGetHD to

troubleshoot the problem.

a. In the Communications menu, select Configure. In the Configure

Communications window, select the COM port and baud rate for

communication. The manufacturer-set baud rate is on the Configuration page that

ships with the sensor.

If the ID is fixed, make sure that the ID is the correct one for that sensor.

b. Push OK.

c. In the Communications menu, select Connect.

Set up sensor and verify operation

15

• If Connect is not available, select Disconnect and reconnect. The software

will try to connect at the specified baud rate, but will try all other available

baud rates to try to connect.

d. If there is still no communication, check the cable and connections with the SIM

or IMM, the sensor, and the PC.

e. If there is still no communication, do step 1 with a different COM port or different

fixed ID and try to connect again.

4. In the software, enter #iiDS, then push Enter.

The output for the "Display Settings" command:

SBE39plus-IM V4.4.0 SERIAL NO. 03907844 23 Mar 2016 08:43:31

battery voltage = 7.16, back-up voltage = 3.34

not logging: initialized

sample interval = 30 seconds

samplenumber = 0, free = 5592405

configuration = temperature and pressure

data format = converted engineering

output temperature, Celsius

output pressure, Decibar

output sample number

temperature = 23.16 deg C

5. To collect a sample, enter #iiTS (where ii is the sensor ID), then push Enter.

The output for the "Take Sample" command, that shows output from an installed

pressure sensor and #iiOutputFormat=1:

07844, 23.1801, 0.106, 17 Apr 2018, 09:01:44

where

• 07844 = 39plus SN

• 23.1801 = temperature, °C (defined by #iiSetTempUnits=)

• 0.106 = pressure, decibars (defined by #iiSetPressUnits=)

• 17 Apr 2018 = date

• 09:01:44 = time

6. Each sensor on a mooring must have a unique ID so that it can communicate with the

IM and PC. Make sure that only one 39plus is online at a time to set the ID.

a. Enter *ID-ii to set the ID for the 39plus. (ii=user-assigned ID), then push Enter.

b. Enter the *ID=ii again, then push Enter to verify the information.

c. Record the ID.

d. Go to Communications menu, then Configure. Select Use fixed ID, then enter

the new ID and push OK.

The software now has the correct ID information to send commands.

7. Send additional commands as necessary.

8. Enter PwrOff, then push Enter to put the sensor in a low power mode.

The sensor is ready for application-specific setup and deployment.

5.4 Set up sensor ID and test SIM

1. From the Instrument menu, select SBE 39plus IM.

SeatermIM starts.

2. For SIM: after the first use, the software will send DS to automatically try to connect

to the SIM.

Set up sensor and verify operation

16

• If the software is set to "Automatically get instrument ID" it sends id? and waits

for the sensor to communicate. The software then sends !iiGetHD and #iiGetHD

to the ID sent by the sensor.

• If the software is set to "Use fixed ID" it sends !iiGetHD and #iiGetCD to the lD

that was set the last time the user used the software.

The software shows the list of available commands in the Send Commands window.

3. Do the steps below if the sensor does not respond to ID, !iiGetHD, #iiGetHD to

troubleshoot the problem.

a. In the Communications menu, select Configure. In the Configure

Communications window, select the COM port and baud rate for

communication. The manufacturer-set baud rate is on the Configuration page that

ships with the sensor.

If the ID is fixed, make sure that the ID is the correct one for that sensor.

b. Push OK.

c. In the Communications menu, select Connect.

• If Connect is not available, select Disconnect and reconnect. The software

will try to connect at the specified baud rate, but will try all other available

baud rates to try to connect.

d. If there is still no communication, check the cable and connections with the SIM

or IMM, the sensor, and the PC.

e. If there is still no communication, do step 1 with a different COM port or different

fixed ID and try to connect again.

4. In the software, enter #iiDS, then push Enter.

The output for the "Display Settings" command:

SBE39plus-IM V4.4.0 SERIAL NO. 03907844 23 Mar 2016 08:43:31

battery voltage = 7.16, back-up voltage = 3.34

not logging: initialized

sample interval = 30 seconds

samplenumber = 0, free = 5592405

configuration = temperature and pressure

data format = converted engineering

output temperature, Celsius

output pressure, Decibar

output sample number

temperature = 23.16 deg C

5. To collect a sample, enter #iiTS (where ii is the sensor ID), then push Enter.

The output for the "Take Sample" command, that shows output from an installed

pressure sensor and #iiOutputFormat=1:

07844, 23.1801, 0.106, 17 Apr 2018, 09:01:44

where

• 07844 = 39plus SN

• 23.1801 = temperature, °C (defined by #iiSetTempUnits=)

• 0.106 = pressure, decibars (defined by #iiSetPressUnits=)

• 17 Apr 2018 = date

• 09:01:44 = time

6. Each sensor on a mooring must have a unique ID so that it can communicate with the

IM and PC. Make sure that only one 39plus is online at a time to set the ID.

a. Enter *ID-ii to set the ID for the 39plus. (ii=user-assigned ID), then push Enter.

b. Enter the *ID=ii again, then push Enter to verify the information.

Set up sensor and verify operation

17

c. Record the ID.

d. Go to Communications menu, then Configure. Select Use fixed ID, then enter

the new ID and push OK.

The software now has the correct ID information to send commands.

7. Send additional commands as necessary.

8. Enter PwrOff, then push Enter to put the sensor in a low power mode.

The sensor is ready for application-specific setup and deployment.

9. IMPORTANT: Install the J5 jumper on the SIM circuit board again.

This jumper must be installed for normal deployment operation.

5.5 Set up and test USB communication

You must remove the end flange to connect to the internal USB connector.

1. Set up the USB connection:

a. Make sure the outside of the sensor is dry.

b. Use a wrench on the wrench flats of the end flange to unscrew the end flange.

c. Pull the end flange and the attached electronics out of the pressure housing.

d. Use a lint-free cloth or tissue to remove any water from the O-rings and surfaces

inside the housing.

e. Connect the USB cable to the USB connector near the battery pack.

f. Connect the USB cable to the USB port on the PC.

2. Start Seaterm V2.

3. From the Instruments menu, select SBE 39plus IM USB.

SeatermUSB-SBE39plus-IM opens. If there is only one USB device connected the

software should automatically connect to it (it may be necessary to select Refresh). If

there is more than one device connected, select the one you want, then Refresh.

Table 1 Toolbar menu buttons

Refresh the connection to the sensor Capture sensor setup to a .cap file

Cancel the current command Terminal opens SeatermUSB Terminal, to send Acquisition

Microcontroller commands to the sensor

Upload selected data from the sensor Convert XML Data converts uploaded xml data to a .asc

or .cnv file, to plot data

Upload All the data from all USB-connected sensors Diagnostics output for troubleshooting

Table 2 Software window areas

Connected Devices Lists each sensor connected to the PC.

Current Configuration Shows current setup from GetSD, GetHD, GETCD, GetCC, and GetEC commands

SBE 39plus IM

Configuration Options

Lets the user change common setup parameters such as set time, clear memory, clear event

counter, set action when USB is disconnected, set interval for autonomous data collection.

Status bar Shows status of a command, such as data upload progress.

4. Make sure all of the data from the sensor is uploaded to the PC.

5. Change any settings in the SBE 39plus Configurations area.

6. Unplug the USB cable from the 39plus-IM.

7. Install new desiccant.

Refer to Replace batteries and desiccant on page 33 for details.

8. Attach the end flange:

a. Make sure that there is no water on surfaces or O-rings.

Set up sensor and verify operation

18

Table of contents

Other Sea-Bird Scientific Measuring Instrument manuals

Sea-Bird Scientific

Sea-Bird Scientific SBE 11plus V2 User manual

Sea-Bird Scientific

Sea-Bird Scientific SBE 37 MicroCAT Quick manual

Sea-Bird Scientific

Sea-Bird Scientific WQM-a User manual

Sea-Bird Scientific

Sea-Bird Scientific SBE 39plus-IM User manual

Sea-Bird Scientific

Sea-Bird Scientific ECO-FLNTUS User manual

Sea-Bird Scientific

Sea-Bird Scientific OCR-504 User manual

Sea-Bird Scientific

Sea-Bird Scientific SUNA V2 User manual

Sea-Bird Scientific

Sea-Bird Scientific SUNA V2 User manual