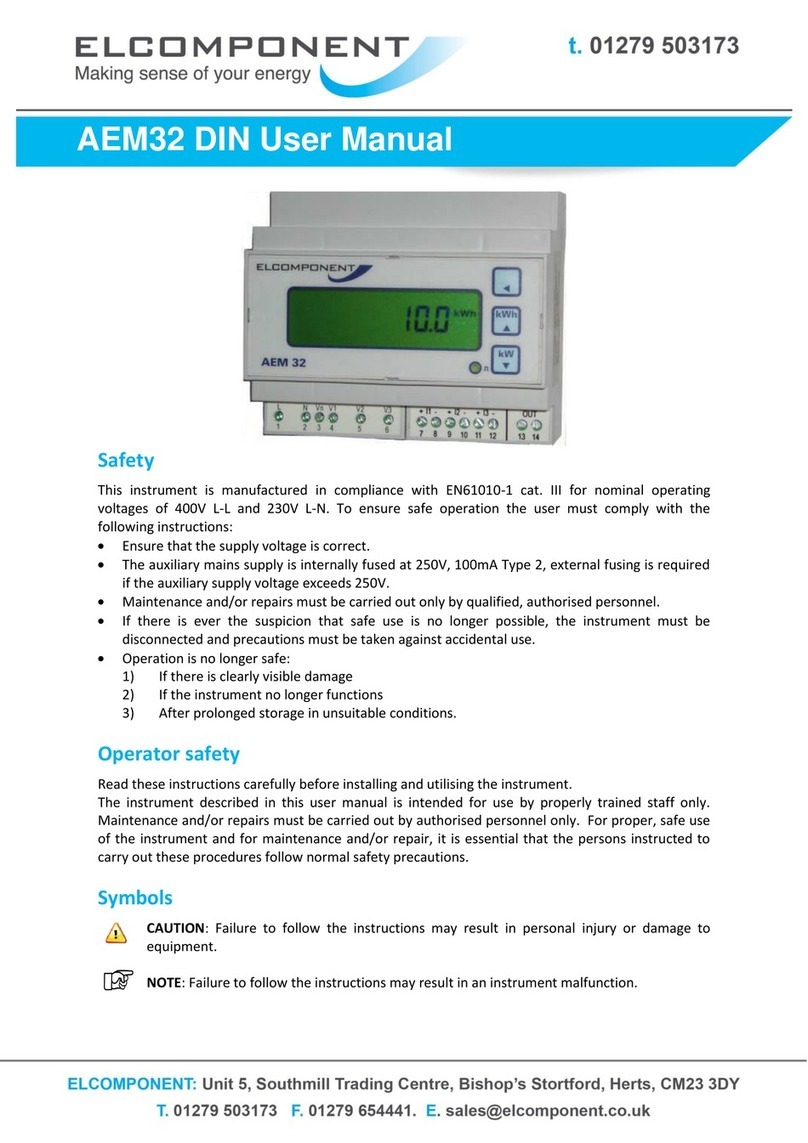

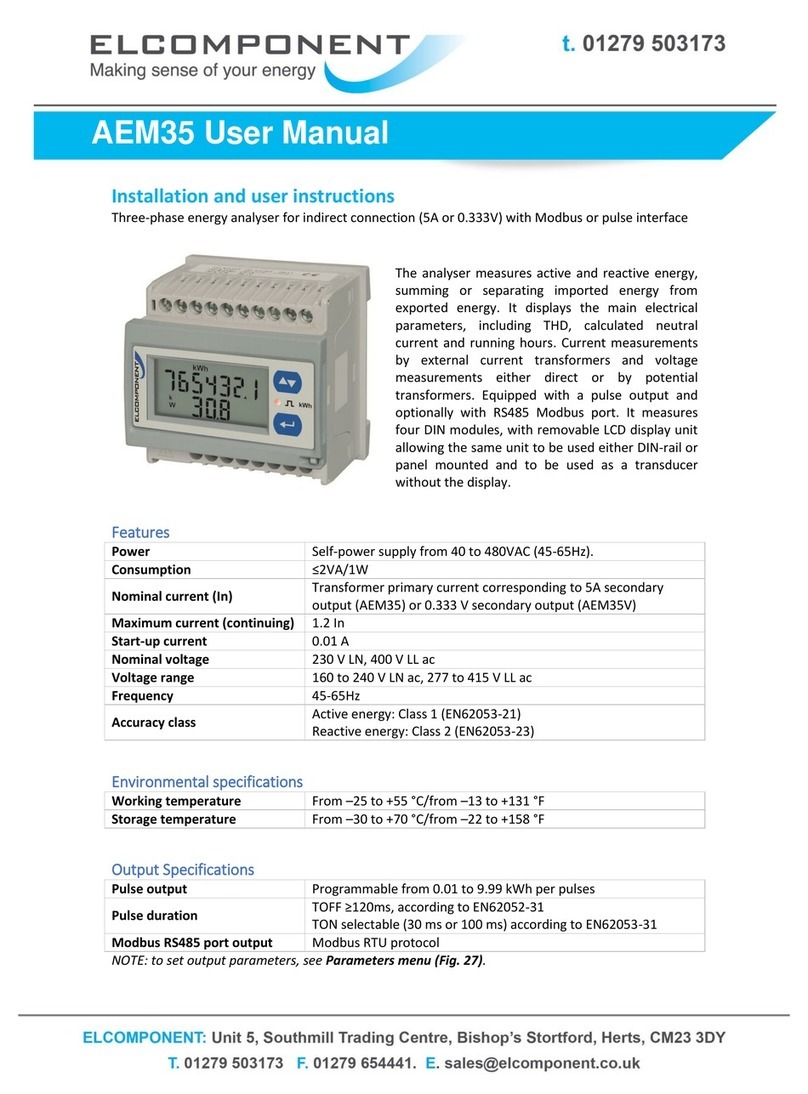

The AEM32 is suitable for use with current transformers

(CTs) with 5A secondary output. Metering quality CTs of

Class 1 accuracy with a minimum rating of 2.5VA are

recommended.

Connections should be made according to the diagrams

above.

CAUTION:

The pulse output contacts are rated at 100mA AC/DC,

100V max. Under no circumstances should this rating be

exceeded.

The output has a telltale l.e.d. on the front panel which

flashes ‘on’ to indicate a pulse being generated.

The pulse connections are as follows:

Terminals 13 & 14

The contacts are volt free and therefore an external power

supply must be provided.

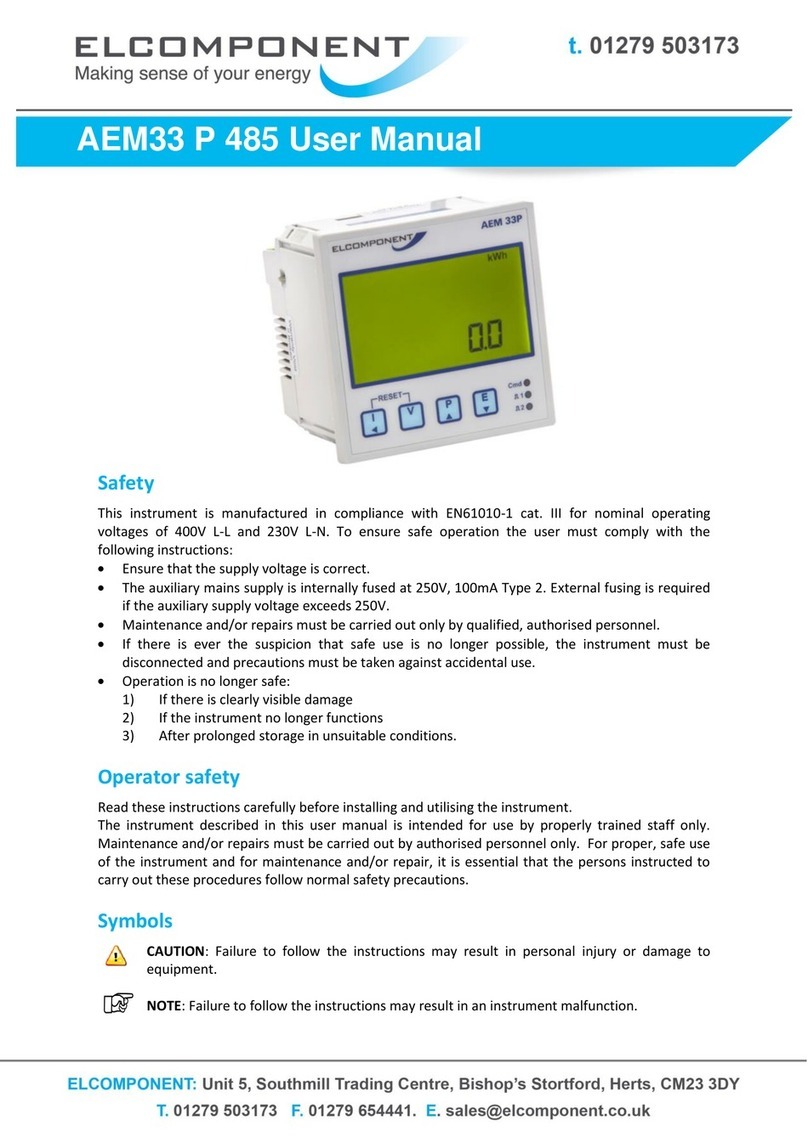

When the instrument is powered up, the display will initially

show the internal software version, then after a few

seconds will start displaying measured values. The three

buttons allow the user to scroll through the available

measurements.

ENERGY DISPLAYS

Press the button to select Total kWh or kWh Count

display pages. The kWh Count display remains visible for

1 minute before the unit reverts to Total kWh mode.

Press and together and hold for 5 seconds to

reset the kWh Count register to zero. Scaling of the

energy registers is set by the nominal input currents and

voltages and remains constant during operation of the

meter. Energy registers will accumulate from zero to

99,999,999 then restart from zero.

INSTANTANEOUS kW DISPLAY

3.1 CONNECTION OF THE CURRENT INPUT

Press to select the following display:

The instantaneous power display may show negative values

indicating export power or incorrectly wired inputs. REV CT

will also be show indicating that the most likely cause of the

negative reading is one or more current transformers fitted the

wrong way round on the primary conductor.

3.2 PULSE OUTPUT CONNECTIONS

5 PROGRAMMING

CT SET-UP

The instrument must be set up for the CTs to which it is

connected. This need only be done once, after which the

setting is maintained in memory for the life of the unit

regardless of whether it is powered up or not.

To enter programming mode press and

simultaneously for 5 seconds. The unit shows the CT primary

settings screen.

The CT primary value may then be set from the following

nominal values (secondary value must be 5A):

4 INSTRUMENT OPERATION

5, 10, 15, 20, 30, 40, 50, 60, 80, 100, 150, 200, 250, 300, 400,

500, 600, 800, 1000, 1200, 1250, 1500, 1600, 2000, 2400,

3000, 2500, 4000, 4500, 5000, 5500, 6000, 6500, 7000, 7500,

8000, 8500, 9000, 9500, 10000, 10500, 11000, 11500, 12000,

12500, 13000, 13500, 14000, 14500, 15000, 15500, 16000,

16500, 17000, 17500, 18000, 18500, 19000, 19500, 2000,

205000, 21000, 21500, 22500, 23000, 23500, 24000, 24500,

25000

Press the Sor Tkey until the desired current is displayed. If

the desired CT value is not present in the above list, the ratio

may be ‘fine adjusted’ as follows: Press and hold the Wand S

buttons simultaneously for 2 seconds to enter ‘Fine Adjust

Mode’. This is indicated by the display showing “CtF”, this

enables the CT primary value to be changed in 10A steps until

the desired ratio is displayed. Press the Wkey to store the

value and continue to the next parameter.

VT SET-UP

The default voltage setting is 400V and this value should not

be altered. Press the Wkey to continue to the next parameter.