Sea Recovery SRC Aqua Matic 450-1 User manual

Aqua Matic

Model 450-1800

Owner’s Manual

Rev. A - 29 October 2008

Manual PN B651120002A

Sea Recovery Corp.

19610 S. Rancho Way

Rancho Dominguez, Ca 90220

www.searecovery.com • sales@searecovery.com

SRC Aqua Matic 450-1

SRC Aqua Matic 700-1

SRC Aqua Matic 900-1

SRC Aqua Matic 900-2

SRC Aqua Matic 1400-2

SRC Aqua Matic 1800-2

FOR SYSTEM V3.00-MAY 2007

Aqua Matic 450-1800 Rev. A

TABLE OF CONTENTS

SECTION CONTENTS PAGE

Table of Contents i - iv

Copyright v

Terms and Conditions v

Patent Notification v

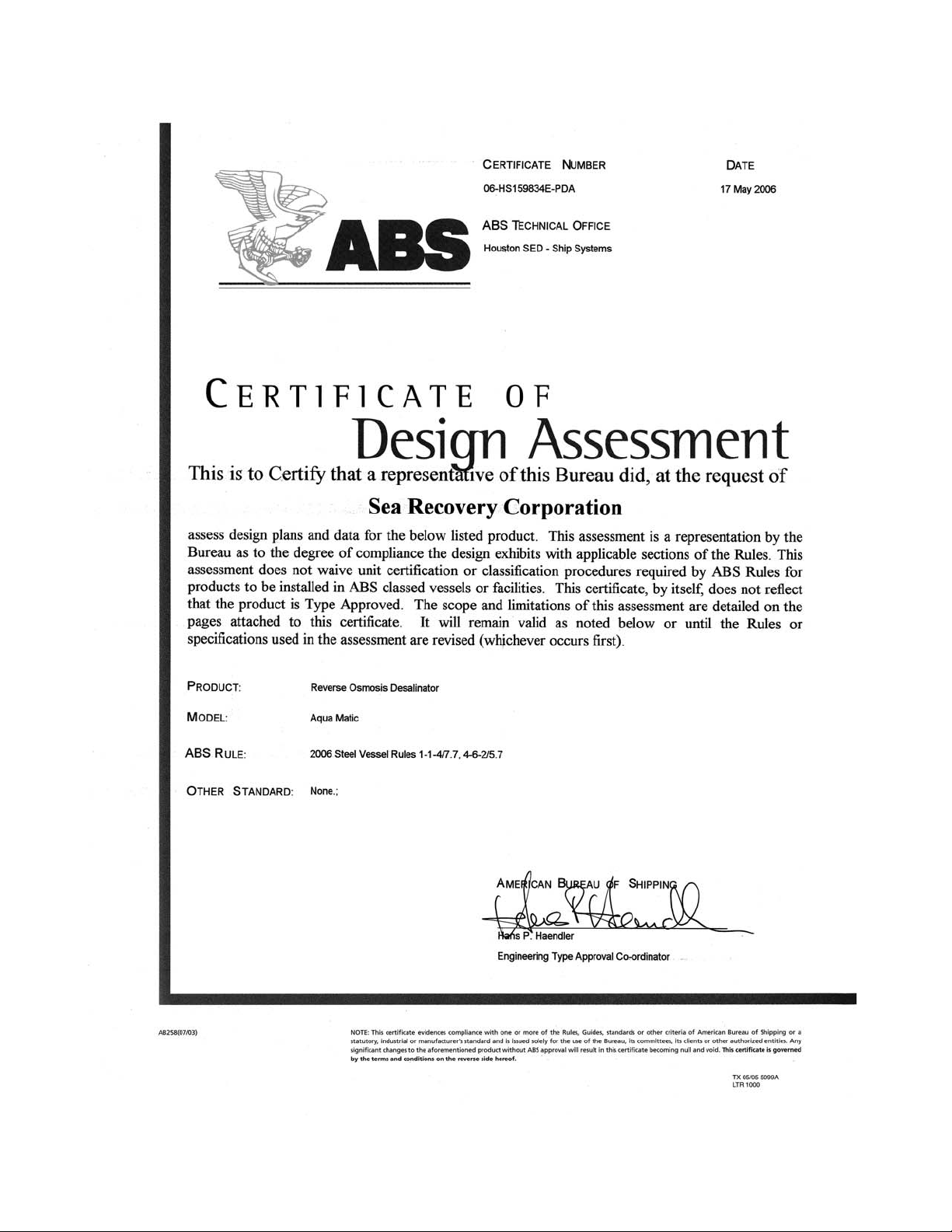

Approvals vi - ix

American Bureau of Shipping Type Acceptance vi - vii

Federal Communications Commission Compliance viii

Conformité Européne CE Compliance viii

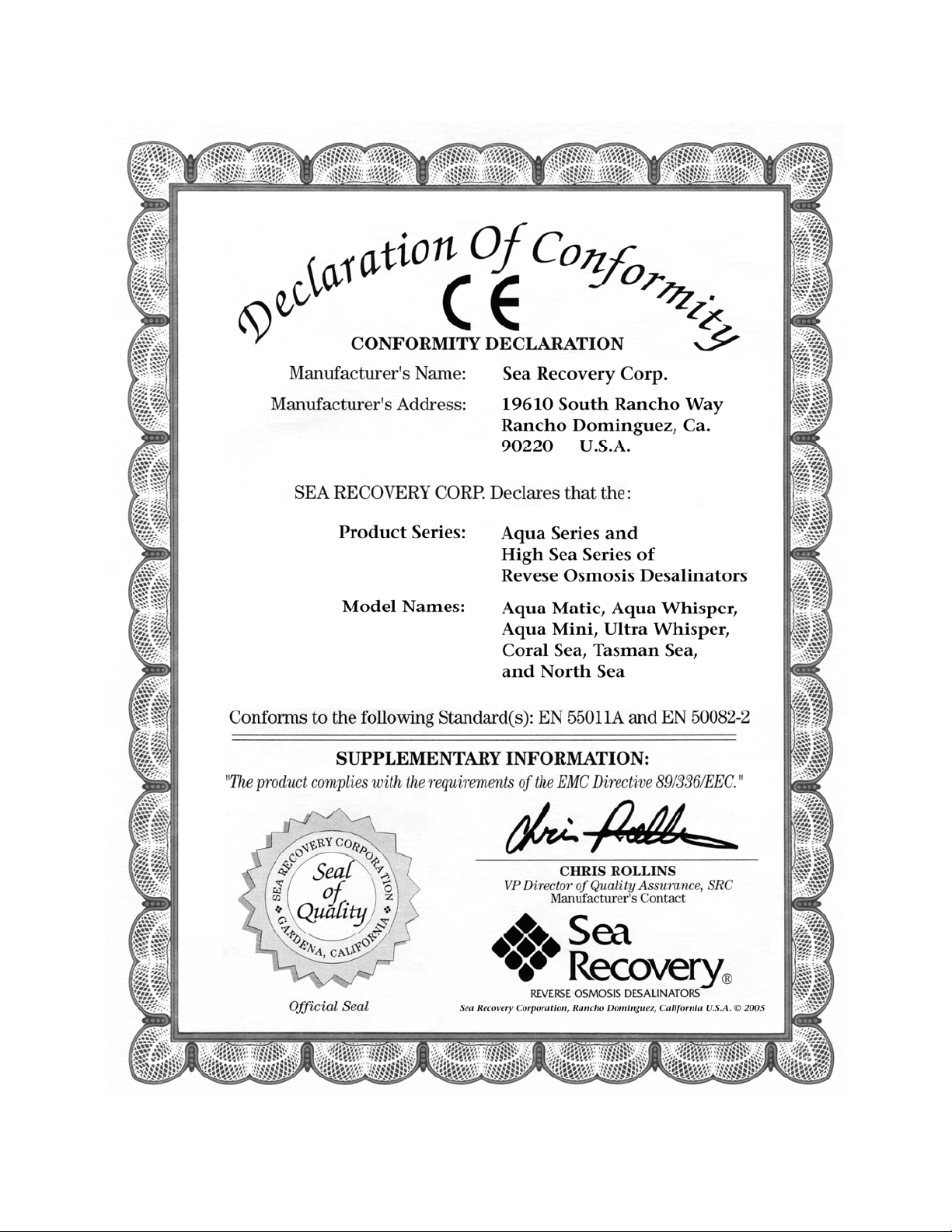

CE Declaration of Conformity ix

Limited Warranty x

Warranty Registration Form xi - xii

System Identification Information Form xiii

Preface xiv

System Information Screen xv

Specifications xvi - xviii

1 Section 1

INTRODUCTION, COMPONENT IDENTIFICATION & EXPLANATION 1 - 20

Sea Recovery’s Approach to Desalination 3

Osmosis & Reverse Osmosis 3

Spiral Wound Reverse Osmosis Membrane Element 3

Anatomy of a Reverse Osmosis Membrane Element 4

Introduction to the System & Component Descriptions 5

Component Identification Piping and Interconnect Diagram (P&ID) 6

Component Location Illustration, Aqua Matic Compact Style 7

Component Location Illustration, Aqua Matic Modular Style 8

Component Descriptions 9 - 19

Helpful Terms 20

2 Section 2

PRE-INSTALLATION R.O. MEMBRANE CARE, SYSTEM INSTALLATION, and LAND INSTALLATION

Installation of the Aqua Matic and Membrane Care prior to installation 1 - 56

System Storage and Installation Precautions and Information 3

Storage Prior to Uncrating 3

Reverse Osmosis Membrane Element Susceptibility to Chemical Attack 3

Installation Competency 3

Installation Cautions 3

Special Considerations 4 - 5

Installation Cautions 4

Connection Line Cautions 4

Accessibility Cautions 4

Electrical Power Requirements 5

Distance Between Components 5

Tools Required For Installation 5

Components Supplied by Installer or Owner 5 - 6

Visual Packing List Aqua Matic Compact Style 7

Visual Packing List Aqua Matic Modular Style 8

Visual Packing List Aqua Matic Optional Accessories 9

Dimensions Aqua Matic Compact Style 10

Dimensions Aqua Matic Modular Style 11

Dimensions Aqua Matic Modular Optional Accessories 12

Piping and Interconnect Diagrams 13 - 17

i

Aqua Matic 450-1800 Rev. A

Prefiltration Interconnect Diagrams 18 - 19

Explanation of Pressure Transducers 20

Prefiltration Configurations 21 - 25

Reverse Osmosis Membrane Element Note 25

Installation of and specific to Aqua Matic Compact Style 26 - 37

Placement and securing the main system frame 27

Component mounting 27 - 33

Tubing and Hose precautions 34

Interconnecting components with supplied hose 35 - 36

Customer supplied fresh water tank high and low level switches, and alarm 36 - 37

Remote Control installation 37

Electrical connection notes and cautions 37

Installation of and specific to Aqua Matic Modular Style 38 - 53

Component mounting 38 - 47

Tubing and Hose precautions 48

Interconnecting components with supplied hose 49 - 51

Customer supplied fresh water tank high and low level switches, and alarm 51 - 52

Remote Control installation 52

Electrical connection notes and cautions 53

Land Installation Illustrations 54 - 55

3 Section 3

AQUA MATIC FEATURES SET-UP, PROGRAMMING THE SYSTEM, CALIBRATIONS, and FUNCTION

TESTS

Features Set Up of the Aqua Matic System (user programming) 1 - 12

Features Set-Up and Programming the Control Logic explanation 3

Programming the Aqua Matic computer logic 4 - 10

Screen Contrast 4

U.S. Standard or metric standard measurements 4

Diversion valve set point 4

Model setup 5

Fresh water flush option setup 6 - 7

Differential Pressure Transducer 8

Salinity Calibration 8

Brine Water and Product Water Flow Meter Calibration 8

Detect Remote 9

Function Tests of Electric Components 10

• Booster Pump Electric Motor

• High Pressure Pump Electric Motor

• Diversion Valve energize solenoid

• Fresh Water Flush Valve

• Back Pressure Regulator Electric Motor Actuator

• U.V. Sterilizer Ballast and Lamp

System Information Screen 11

4 Section 4

NEW SYSTEM COMMISSIONING

Commissioning of a New Aqua Matic System 1 - 16

System Commissioning Notes 3

Installation Check 3

Reverse Osmosis Membrane Element notes 3 - 4

ii

Aqua Matic 450-1800 Rev. A

Commissioning and Start-Up Procedure of a New System 4 - 14

New System Initial Readings Log 15 - 16

5 Section 5

SYSTEM OPERATION

Operating the Aqua Matic 1 - 18

Notes Regarding the Automated Operational Sequence 3

Reverse Osmosis Membrane Element Warning 4

Automatic Mode WITHOUT the Fresh Water Flush option 5 - 7

Automatic Mode WITH the Fresh Water Flush option 8 - 10

Manual Mode 11 - 14

Daily System Readings Logs 15 - 18

6 Section 6

SYSTEM STORAGE AND R.O. MEMBRANE ELEMENT CLEANING

Aqua Matic Storage and Membrane Care 1 - 18

R.O. Membrane Element Handling & System Storage Cautions 3

Once Through Rinse and Closed Loop Configuration Illustrations 4

Once Through Rinse and Closed Loop Configuration Simplified Illustrations 5

Once Through Rinse preparation 6

Closed Loop preparation 6

Short Term Shutdown 7 - 8

Long Term Shutdown 9 - 11

R.O. Membrane Element Cleaning 12 - 18

7 Section 7

TROUBLE SHOOTING ABNORMALITIES

System and Component Troubleshooting 1 - 42

Troubleshooting notes and Cautions 3

System Information Screen 4

Troubleshooting Fault Screens 5 - 8

Troubleshooting Error Screens 9

Troubleshooting by Component ID Numbers 10 - 32

Control Sequence and Process 33 - 37

Electrical and Electronic Troubleshooting 38 - 42

8 Section 8

MAINTENANCE & REPAIR

System and Component Maintenance and Repair 1 - 30

System Information Screen 3

Maintenance & Repair Notes 4

Operator Maintenance Intervals 5

Individual Component Maintenance & Repair 6 - 30

Listed in order of I.D. number

9 Section 9

ELECTRICAL DIAGRAMS & INFORMATION AND TOUCH SCREEN SHOTS

Electrical Information 1 - 36

Electrical Requirements & Information 3

Electrical Motor Power Specifications 4

Recommended Circuit Breaker Amperage Rating 4

Recommended Wire Sizes 4 - 5

Wire insertion into terminal strips 5

Wire Size Cross Reference American Wire Gauge (AWG) vs Metric Wire Sizes 6

iii

Aqua Matic 450-1800 Rev. A

Aqua Matic COMPACT Style System Electrical 7 - 21

Aqua Matic Compact Style Electrical Wire Routing & Connection Illustrations 8 - 12

Strain Relief Identification 9

Connecting Optional Differential Pressure Transducer 10

Connecting Fresh Water Flush 10

Connecting U.V. Sterilizer 11

Connecting Remote Touch Screen 12

Aqua Matic Compact Style Electrical Line Drawings 13 - 17

Electric Motor Windings and Wiring Diagrams 14 - 15

Three Phase Power Transformer 16

Logic Controller Board 17

Aqua Matic Compact Style Wiring Diagrams 18 - 21

Single Phase without Soft Motor Starter 19

Single Phase with Soft Motor Starter 20

Three Phase 21

Aqua Matic MODULAR Style System Electrical 22 - 35

Aqua Matic Modular Control Panel Strain Relief Identification 23

Connecting Low Pressure and Optional Differential Pressure Transducers 24

Connecting Fresh Water Flush 25

Aqua Matic Compact Style Electrical Line Drawings 26 - 31

Electric Motor Windings and Wiring Diagrams 27 - 28

Three Phase Power Transformer 29

Logic Controller Board 30

Electrical Chassis Component Identification 31

Aqua Matic Compact Style Wiring Diagrams 32 - 35

Single Phase without Soft Motor Starter 33

Single Phase with Soft Motor Starter 34

Three Phase 35

10 Section 10

EXPLODED PARTS VIEWS & PART NUMBERS

Exploded Parts Views with Part Numbers, Descriptions and Technical Notations 1 - 82

System Information Screen 3

Common to both the Compact and Modular Style 3 - 26

Specific only for the Compact Style 27 - 56

Specific only for the Modular Style 57 - 82

11 Section 11

CONVERSION CHARTS

Conversion Charts & Cross Reference Information 1-10

Micron / Inch / Mesh Comparison Measurements 3

Temperature Celsius vs Fahrenheit Conversion Chart 3

Temperature Effect Comparison Chart 4

Seawater Temperature & Pressure Effects Chart 5

Water Comparison Chart Gallons / Volume / Weight 6

PPM (Parts Per Million) Conversion Chart 7

Pressure Comparison 8

Metric / U.S. Customary Unit Equivalents 8

Wire Size Cross Reference Chart 9

iv

Aqua Matic 450-1800 Rev. A

© COPYRIGHT NOTIFICATION

© 2005 Sea Recovery Corporation. AQM System V3 May 2007. Revision October 2008.

The name “Sea Recovery®” is a U.S. Registered Trademark and belongs to Sea Recovery Corporation with all rights

reserved.

The Sea Recovery®logo mark is a U.S. Registered Trademark and belongs to Sea Recovery Corporation with all rights

reserved.

All content included within this Owner’s Manual, such as text, graphics, logos, and images, is the property of Sea

Recovery Corporation and protected by U.S. and international copyright laws. The compilation (meaning the

preparation, collection, arrangement, and assembly) of all content within this Owner’s Manual is the exclusive property

of Sea Recovery Corporation and protected by U.S. and international copyright laws. All software used in the design

and manufacture of the Sea Recovery Reverse Osmosis Desalination System is the property of Sea Recovery

Corporation and protected by U.S. and international copyright laws. All computer and logic programming used in the

design and manufacture of the Sea Recovery Reverse Osmosis Desalination System the property of Sea Recovery

Corporation and protected by U.S. and international copyright laws. All touch screen images used in the design and

manufacture of the Sea Recovery Osmosis Desalination System is the property of Sea Recovery Corporation and

protected by U.S. and international copyright laws.

The content of this Owner’s Manual and the software, programming, and touch screen graphic designs used in the

design and manufacture of the Sea Recovery Reverse Osmosis Desalination System is for the purpose of operation,

maintaining, and repair of the Sea Recovery Reverse Osmosis Desalination System. Any other use, including the

reproduction, modification, distribution, transmission, republication, display, or performance, of the content within this

Owner’s Manual is strictly prohibited.

Terms and Conditions

Your use of this Owner’s Manual acknowledges acceptance of the terms and conditions provided herewith and your

agreement to comply with all applicable laws and regulations pertaining to the use of this Owner’s Manual.

In addition, you agree not to use Sea Recovery’s trademarked name or Sea Recovery’s trademarked logo mark in any

form or manner except with Sea Recovery Corporation’s written permission. Sea Recovery Corporation holds all rights

to its copyrights and trademarks, and to the material contained in this Owner’s Manual. Any use of such requires the

written permission from Sea Recovery Corporation.

PATENT NOTIFICATION

Certain aspects of the Sea Recovery Aqua Matic Reverse Osmosis Desalination System are protected by U.S. Patent

Laws. Sea Recovery has applied for a Patent relating to aspects of the Sea Recovery Aqua Matic Reverse Osmosis

Desalination System.

v

Aqua Matic 450-1800 Rev. A

Sea Recovery’s Reverse Osmosis Desalination Systems

are Type Accepted by the American Bureau of Shipping, ABS.

ABS

American Bureau of Shipping.

Safety, Service, Solutions

These three goals define the activities of ABS. They are the bedrock upon which the American Bureau of

Shipping’s commitment to set standards of excellence as one of the world’s leading ship classification societies is

founded.

From its inception in 1862, setting safety standards for the marine industry has been the core commitment of ABS.

This is achieved through the establishment and application of technical standards, known as Rules, for the design,

construction and operational maintenance of ships and other marine structures. Classification is a process that

certifies adherence to these Rules.

The core competencies of this worldwide network of ABS professionals lie in the fields of survey, engineering and

auditing. Backing these field representatives is an unequivocal commitment to research and development.

The ABS Type Approval Program

The ABS Type Approval program has existed in some form since 1983. Today it is formalized in the Rules. Two

basic processes and certificates establish the validity of a product and all other certificates that may be issued in the

program. The format imitates the format of the European Marine Equipment Directive (MED).

•Satisfactory evaluation of a product to a set of Rules or standards is recorded in the issue of a “Product

Design Assessment (PDA)” certificate. The process is the same as would be followed for an ABS Design

Review Letter. It imitates the Module B category of the MED.

•Satisfactory evaluation of the manufacturing (Works) facility to confirm their ability to consistently

manufacture the product in accordance with the PDA is recorded in the issue of a “Manufacturing

Assessment (MA)” certificate. This was previously known in ABS as the MMEC program. This imitates the

modules D and E of the MED.

The IACS Ad-Hoc Committee for the Certification of Materials and Components have consensus that Type

Approval requires; 1) an evaluation of the product including prototype tests (if necessary), 2) a witness of the

manufacture of the product (type test), and 3) an assessment of the manufacturer’s ability to consistently

manufacture the product in accordance with the approved specifications. There are a multitude of derivations of

this process; following is an abbreviated outline of the basic certificates:

A Type Approved Product has satisfied the processes of:

1. An Engineer's evaluation of a design to determine conformance with specifications. The manufacturer

should submit sufficient information to allow ABS to determine if the product meets specification. This results

in a Product Design Assessment Certificate (PDA).

2. Witnessing manufacture and testing of a type of the product to determine compliance with the specification

3. A Surveyor's evaluation of the manufacturing arrangements to confirm that the product can be consistently

produced in accordance with the specification. This results in the issue of a Manufacturing Assessment

Certificate

vi

Aqua Matic 450-1800 Rev. A

vii

Aqua Matic 450-1800 Rev. A

Sea Recovery’s Reverse Osmosis Desalination Systems

comply with FCC FCC § 15.105

United States Federal Communications Commission Compliance

FCC § 15.105

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

__________________________________________________________________

Sea Recovery’s Reverse Osmosis Desalination Systems

have been independently tested and determined to be in compliance

with European CE (Conformité Européne)

The CE Mark ('Trade Passport to Europe') is a visible declaration by the manufacturer (or his representative,

importer, etc.) that the equipment which is marked complies with all the

requirements of all the applicable directives. This mark allows manufacturers and exporters to circulate products freely

within the 15 European Union (EU) members. Having ensured that the equipment does indeed meet all these

requirements (including all the administrative requirements involved in being able to demonstrate compliance), the CE

Mark may then be affixed and the product released.

The letters, "CE", indicate that the manufacturer has undertaken all assessment procedures required for the product.

The CE mark indicates conformity to the legal requirements of the EU Directives.

The "CE" mark is now mandatory for regulated products sold in the European Union.

viii

Aqua Matic 450-1800 Rev. A

ix

Aqua Matic 450-1800 Rev. A

Sea Recovery Aqua Matic 450 - 1800 LIMITED WARRANTY

Sea Recovery warrants that the Sea Recovery Desalination System performs according to specifications for a period of twelve (12) months from the

date of shipment. Sea Recovery’s liability under this warranty is limited to repair or replacement of the Aqua Matic Desalination System at Sea

Recovery’s discretion. Under no circumstances is Sea Recovery liable for consequential damages arising out of or in any way connected with the

failure of the system to perform as set forth herein. This limited warranty is in lieu of all other expressed or implied warranties, including those of

merchantability and fitness for a particular purpose.

Warranty Period starts from the date of original shipment by Sea Recovery, or with proof of purchase from the date of sale to

the original retail purchaser:

1. System and accessories: 1 (one) year

2. Repairs made by Sea Recovery after the original warranty period has expired: 3 (three) months

Normal reoccurring user maintenance listed below is not covered by this or any Sea Recovery limited warranty:

1. Sea Strainer Element 3. Fuses 5. Instrument Calibration

2. Cartridge Filter Elements 4. Centrifugal Pump Seal Assemblies

This or any Sea Recovery limited warranty does not cover installation components not supplied by Sea Recovery.

Improper installation resulting in the Sea Recovery System or component failure or decline in performance is not covered by this or any Sea Recovery

limited warranty.

The Sea Recovery Reverse Osmosis Membrane Element is guaranteed to be cleanable for a minimum of one year from date of shipment, providing

cleaning periods are adhered to, and fouling is acid soluble metal hydroxides and calcium carbonates or alkaline soluble organic, inorganic substances

and microbiological slimes. The Sea Recovery R.O. Membrane Element is not guaranteed against iron fouling (rust), chemical or petroleum products

attack, extreme temperatures (over 120°F/under 32°F), drying out, or extreme pressures (over 1000 psig).

In the event of a defect, a malfunction, or failure specifically covered by this warranty and during the warranty period, Sea Recovery will repair or

replace, at its option, the product or component therein which upon examination by Sea Recovery appears to be defective.

To obtain warranty service, the defective product or part must be returned to an authorized Sea Recovery Service Center or direct to Sea Recovery.

An updated listing of Sea Recovery Factory Service Centers can be found on the Sea Recovery web site at http://www.searecovery.com. The purchaser

must pay any transportation or labor expenses incurred in removing and returning the product to the service center or to Sea Recovery.

The limited warranty does not extend to any system or system component which has been subjected to alteration, misuse, neglect, accident, improper

installation, inadequate or improper repair or maintenance or subject to use in violation of instructions furnished by Sea Recovery, nor does the

warranty extend to components on which the serial number has been removed, defaced, or changed.

Sea Recovery reserves the right to make changes or improvements in its product, during subsequent production, without incurring the obligation to

incorporate such changes or improvements on previously manufactured equipment.

The implied warranties, which the law imposes on the sale of this product, are expressly LIMITED in duration to the time period above. Sea

Recovery shall not be liable for damages, consequential or otherwise, resulting from the installation, use, and/or operation of this product or from the

breach of this LIMITED WARRANTY.

CAUTION: Use of non Sea Recovery supplied parts and accessories, including but not limited to, maintenance parts, pre-filter elements, cleaning and

storage chemical, spare parts, replacement parts, system components, installation components and/or system accessories, shall void all warranty

expressed or implied.

Sea Recovery Corporation

P.O. Box 5288

Carson, California 90745-5288 U.S.A.

Tel: 1-310-637-3400 • Fax: 1-310-637-3430

x

Aqua Matic 450-1800 Rev. A

Sea Recovery®

Aqua Matic™450 - 1800

System Warranty Registration

INSTRUCTIONS: At the time of purchase of the Sea Recovery Reverse Osmosis water maker, please complete

the warranty information listed below. After completing this form, please make a copy, and mail it to the

address provided at the bottom of this form.

System Information: Aqua Matic 450 - 1800

Model Number:

Aqua Matic _____450-1; _____700-1, _____900-1; _____900-2; _____1400-2; _____1800-2

Model Style: _____ Compact; _____ Vertical; _____ Modular

Serial Number: __________________________

Operating Voltage:

Single Phase: ___ 110/115 VAC or ___ 220/230 VAC Cycles: ___50 Hz or ___ 60 Hz

Three Phase: ___ 220 VAC; ___ 380 VAC; ___ 415 VAC; or ___ 460 VAC Cycles: ___50 Hz or ___ 60 Hz

Date Purchased: _____________________________

Date Commissioned: _________________________ (First tested or operated)

Dealer Information:

Dealer's Name: _______________________________________________________________

Address: _____________________________________________________________________

City: _______________________________ State: _____________________________

Country: ____________________________ Postal Code: _______________________

Dealer's Invoice Number: _________________________

Customer Information:

Customer’s Name: ___________________________________________________________

Address: _____________________________________________________________________

City: _______________________________ State: _________________________

Country: ____________________________ Postal Code: __________________

Telephone Number: ________________________ E-Mail Address: ________________

If Vessel Installation:

Boat’s Manufacture: ___________________________

Boat’s Model: __________________________, Length: ______ Feet or ______ Meters.

Boat’s Name: ________________________________________________________________

Mail a copy to:

Sea Recovery Corporation

P.O. Box 5288

Carson, California 90745-5288 U.S.A.

Attention: Warranty Registration

Tel: 1-310-637-3400 • Fax: 1-310-637-3430

xi

Aqua Matic 450-1800 Rev. A

Customer’s comments: ____________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

Mail a copy to:

Sea Recovery Corporation

P.O. Box 5288

Carson, California 90745-5288 U.S.A.

Attention: Warranty Registration

xii

Aqua Matic 450-1800 Rev. A

Sea Recovery®

Aqua Matic™450 - 1800

System Identification Information

INSTRUCTIONS: It is important that this form is completely filled in by the owner at the time of purchase of

the Sea Recovery Reverse Osmosis Desalinator. This information will be requested by our Service

Department and Parts Order Desk whenever contacting Sea Recovery for technical assistance or by the Sales

Department whenever ordering parts.

System Information: Aqua Matic 450 - 1800

Model Number:

Aqua Matic _____450-1; _____700-1, _____900-1; _____900-2; _____1400-2; _____1800-2

Model Style: _____ Compact; _____ Vertical; _____ Modular

Serial Number: __________________________

Operating Voltage:

Single Phase: ___ 110/115 VAC or ___ 220/230 VAC Cycles: ___50 Hz or ___ 60 Hz

Three Phase: ___ 220 VAC; ___ 380 VAC; ___ 415 VAC; or ___ 460 VAC Cycles: ___50 Hz or ___ 60 Hz

Date Purchased: _____________________________

Date Commissioned: _________________________ (First tested or operated)

Dealer Information:

Dealer's Name: _______________________________________________________________

Address: _____________________________________________________________________

______________________________________________________________________________

City: _______________________________ State: _____________________________

Country: ____________________________ Postal Code: _______________________

Telephone Number: ___________________________________________________________

Dealer's Invoice Number: _________________________

Sea Recovery Corporation

P.O. Box 5288

Carson, California 90745-5288 U.S.A.

Tel: 1-310-637-3400 • Fax: 1-310-637-3430

xiii

Aqua Matic 450-1800 Rev. A

PREFACE

Thank you for your purchase of a Sea Recovery Aqua Matic Reverse Osmosis Desalination System.

This manual contains instructions for the installation, operation, maintenance, and repair of the Sea

Recovery Desalination System. This information is provided to ensure extended life and safe

operation of your Sea Recovery system.

Please read this manual thoroughly before installation or operation, and keep it for future reference.

A better understanding of the system ensures optimum performance and longer service life.

Sea Recovery’s Reverse Osmosis Desalination Systems are designed and engineered to function as a

complete working unit. Generally speaking, the performance of each component within the System

is dependent on the component prior to it and governs the performance of all components after it.

Proper performance of the system is thus dependent upon proper operation of every single

component within the system.

The intent of this manual is to allow the operator to become familiar with each component within

the Sea Recovery system. By understanding the function, importance, and normal operation of

each component within each subsystem of the unit, the operator can readily diagnose minor

problems, which if detected early are usually easily corrected. However, if left unattended, a

problem in one component eventually affects the rest of the system and leads to further repairs.

The manual is divided into sections that address different subject matter. Each section should be

reviewed before operating the Reverse Osmosis Desalination system.

The major documented cause of failures and problems are from the use of third party, non Sea

Recovery, parts, from improper installation, and from improper operation:

The use of third party, non Sea Recovery, consumables, spares, and assemblies have, can, and

will damage the Sea Recovery system and/or specific components within the system. Do not use

parts, components, consumables, or assemblies from any source other than Sea Recovery. Use of

third party, non Sea Recovery, components, consumables, or assemblies will void any and all

warranty of the system and/or the effected component within the system.

Sea Recovery maintains inventory for immediate shipment and our Service Dealers throughout

the world maintain stock of Sea Recovery parts. Always insist on Sea Recovery supplied parts

for your system in order to avoid failures, eliminate problems, and maintain your Sea Recovery

Warranty.

Follow the Installation Instructions within this Owner’s Manual.

Follow the Operation Instructions within this Owner’s Manual.

xiv

Aqua Matic 450-1800 Rev. A

From time to time, Sea Recovery may make programming changes to the Control Logic (CONTROL VER), Display

Logic (DISPLAY VER), and the Display Operating System (DISPLAY OS).

Other physical production changes may also be made from time to time and are tracked by Sea Recovery through the

System Serial Number.

Troubleshooting and repair methods and results can vary depending on the information that is displayed at the

SYSTEM INFORMATION screen.

When requesting assistance from Sea Recovery or one of Sea Recovery’s service dealers,

ALWAYS PROVIDE ALL INFORMATION DISPLAYED AT THE SYSTEM INFORMATION SCREEN.

1st Screen007 2

nd Screen044 3

rd Screen008 4

th Screen024

Touch the Logo Touch MENU Touch INFORMATION

SYSTEM INFO

SERIAL NUMBER helps us to determine the latest physical version and configuration of your system which is necessary

to ensure that we provide you with the correct information or parts.

SIZE tells us the production capacity of your system which gives us a bench mark in diagnosing product water flow and

pressure concerns.

FWF tells us if you have installed and are utilizing the Fresh Water Flush feature.

TOTAL TIME assists us in diagnosing abnormalities that can occur at given operational time intervals such as required

pump maintenance, or R.O. Membrane Element condition.

DV Set Point helps us to determine if the R.O. Membrane Element is losing its rejection capabilities or if the 3-Way

Product Water Diversion Solenoid Valve Set Point is simply adjusted too high or too low.

CONTROL VER allows us to determine the specific sequential operation of the system based on the version of the

programmed control logic.

DISPLAY VER and DISPLAY OS assists us in diagnosing problems associated with the Main and Remote Touch

Screen(s).

Notes: __________________________________________________________________________________________

___________________________________________________________________________________________________

___________________________________________________________________________________________________

___________________________________________________________________________________________________

___________________________________________________________________________________________________

___________________________________________________________________________________________________

xv

Aqua Matic 450-1800 Rev. A

SPECIFICATIONS

PERFORMANCE:

PRODUCT WATER PRODUCED PER HOUR AND PER DAY OF OPERATION:

( +-15% at 850 psig / 56 BAR, 77°F / 25°C & 35,000 PPM TDS Feed Water Salinity )

Model Number per 1 hour of operation: per 24 hours of operation:

U.S. Gallons / Liters U.S. Gallons / Liters

SRC Aqua Matic 450-1 18.8 71 450 1703

SRC Aqua Matic 700-1 29.2 110.4 700 2650

SRC Aqua Matic 900-1 37.5 142 900 3407

SRC Aqua Matic 900-2 37.5 142 900 3407

SRC Aqua Matic 1400-2 58.3 220.8 1400 5300

SRC Aqua Matic 1800-2 75 283.9 1800 6814

SALT REJECTION (CHLORIDE ION): 99.4%

PRODUCT WATER TEMPERATURE: Ambient to feed water temperature

SPECIFICATIONS:

SALINITY MONITORING: Automatic computer controlled electronic monitoring. The salinity monitoring

components of the system give a continuous readout in micromhos per cubic centimeter, are temperature

compensated and of a fail-safe design.

SALINITY RANGE OF FEED WATER:

Seawater up to 50,000 PPM TDS (NaCl) (typical seawater salinity is 35,000 PPM)

TEMPERATURE RANGE: Max. 122°F / 50°C, Min. 33°F / .5°C

SYSTEM FEED WATER:

Alternating Current 50 Hz Alternating Current 60 Hz

Feed Water Flow Per Hour: 225 U.S. Gallons / 852 Liters 270 U.S. Gallons / 1,022 Liters

REVERSE OSMOSIS MEMBRANE:

TYPE: Specifically selected High Rejection / High Yield aromatic tri-polyamide, thin film composite, spiral wound,

single pass reverse osmosis membrane element.

CHLORINE TOLERANCE: 0.1 PPM.

pH RANGE: 3-11 (typical seawater pH is 8)

SYSTEM PRESSURE:

FEED WATER: Minimum 6 psi / .42 Kg/cm2. / 41.4 kPa Maximum 40 psi / 2.8 Kg/cm2/ 275.8 kPa

OPERATION: Seawater @ 35,000 PPM & 77°F / 25 C: Nominal 800 psi / / 56.25 Kg/cm2/ 5516 kPa

EXTERNAL INSTALLATION WATER CONNECTIONS:

Pipe sizes to be supplied by the installer for connection of the Sea Recovery supplied components

Aqua Matic

Feed Inlet: 3/4” MNPT Male National Pipe Thread U.S. Standard

Brine Discharge 3/4” MNPT Male National Pipe Thread U.S. Standard

Product 1/2” FNPT Female National Pipe Thread U.S. Standard

xvi

Aqua Matic 450-1800 Rev. A

WEIGHT:

MODEL

Compact Style Vertical Style Modular Style

Aqua Matic 450-1 159 lbs / 72 kg 164 lbs / 74 kg 149 lbs / 67 kg

Aqua Matic 700-1 162 lbs / 73 kg 167 lbs / 75 kg 152 lbs / 68 kg

Aqua Matic 900-1 171 lbs / 77 kg 176 lbs / 79 kg 161 lbs / 73 kg

Aqua Matic 900-2 171 lbs / 77 kg 176 lbs / 79 kg 161 lbs / 73 kg

Aqua Matic 1400-2 177 lbs / 80 kg 182 lbs / 82 kg 167 lbs / 75 kg

Aqua Matic 1800-2 182 lbs / 82 kg 187 lbs / 84 kg 172 lbs / 78 kg

ELECTRICAL MOTOR SPECIFICATIONS:

(H.P. = Horse Power; RPM = Revolutions Per Minute; FLA = Full Load Amperes; LRA = Locked Rotor Amperes @

Start Up)

ALTERNATING CURRENT SYSTEMS:

Single Phase Alternating Current:

High Pressure Pump Motor Booster Pump Motor

VAC Hz H.P RPM FLA LRA H.P RPM FLA LRA

110 50 3 2850 23 89 .5 2850 7.4 20

220 50 3 2850 11.5 44 .5 2850 3.7 10

115 60 3 3450 25.4 86 .5 3450 9.4 20

230 60 3 3450 12.7 43 .5 3450 4.7 10

Three Phase Alternating Current:

High Pressure Pump Motor Booster Pump Motor

VAC Hz H.P RPM FLA LRA H.P RPM FLA LRA

220 50 2.5 2850 7.9 24.9 .5 2850 2.5 8.2

380 50 2.5 2850 4.6 14.4 .5 2850 1.5 4.7

230 60 3 3450 7.6 23.8 .5 3450 2.4 7.9

460 60 3 3450 3.8 11.9 .5 3450 1.2 3.9

RECOMMENDED CIRCUIT BREAKER SUPPLYING POWER TO SYSTEM AMPERAGE RATING:

Operating Recommended

AC Voltage Phase Circuit Breaker

110 - 115 VAC Single 50 Ampere

220 - 230 VAC Single 25 Ampere

220 VAC Three 15 Ampere

380 VAC Three 10 Ampere

460 VAC Three 10 Ampere

RECOMMENDED POWER WIRE SIZE TO Aqua Matic SYSTEM:

Operating Phase Maximum Recommended Minimum Wire Size for Length of run

Voltage Load

10 Ft / 3 meter 25 Ft / 8 meter 50 Ft / 15 meter

110-115 VAC Single 34.8 Ampere 10 AWG / 6 mm28 AWG / 10 mm28 AWG / 10 mm2

220-230 VAC Single 17.4 Ampere 12 AWG / 4 mm212 AWG / 4 mm212 AWG / 4 mm2

220-230 VAC Three 10.4 Ampere 14 AWG / 2.5 mm214 AWG / 2.5 mm214 AWG / 2.5 mm2

380 VAC Three 6.1 Ampere 14 AWG / 2.5 mm214 AWG / 2.5 mm214 AWG / 2.5 mm2

460 VAC Three 5 Ampere 14 AWG / 2.5 mm214 AWG / 2.5 mm214 AWG / 2.5 mm2

xvii

Aqua Matic 450-1800 Rev. A

xviii

RECOMMENDED POWER WIRE SIZE TO Aqua Matic BOOSTER PUMP:

Operating Phase Maximum Recommended Minimum Wire Size for Length of run

Voltage Load

10 Ft / 3 meter 25 Ft / 8 meter 50 Ft / 15 meter

110-115 VAC Single 9.4 Ampere 14 AWG / 2.5 mm214 AWG / 2.5 mm214 AWG / 2.5 mm2

220-230 VAC Single 4.7 Ampere 14 AWG / 2.5 mm214 AWG / 2.5 mm214 AWG / 2.5 mm2

220-230 VAC Three 2.5 Ampere 16 AWG / 1.5 mm216 AWG / 1.5 mm216 AWG / 1.5 mm2

380 VAC Three 1.5 Ampere 16 AWG / 1.5 mm216 AWG / 1.5 mm216 AWG / 1.5 mm2

460 VAC Three 1.2 Ampere 16 AWG / 1.5 mm216 AWG / 1.5 mm216 AWG / 1.5 mm2

RECOMMENDED POWER WIRE SIZE TO Aqua Matic HIGH PRESSURE PUMP:

Operating Phase Maximum Recommended Minimum Wire Size for Length of run

Voltage Load

10 Ft / 3 meter 25 Ft / 8 meter 50 Ft / 15 meter

110-115 VAC Single 25.5 Ampere 12 AWG / 4 mm210 AWG / 6 mm210 AWG / 6 mm2

220-230 VAC Single 12.7 Ampere 14 AWG / 2.5 mm212 AWG / 4 mm212 AWG / 4 mm2

220-230 VAC Three 7.9 Ampere 14 AWG / 2.5 mm214 AWG / 2.5 mm214 AWG / 2.5 mm2

380 VAC Three 4.6 Ampere 14 AWG / 2.5 mm214 AWG / 2.5 mm214 AWG / 2.5 mm2

460 VAC Three 3.8 Ampere 14 AWG / 2.5 mm214 AWG / 2.5 mm214 AWG / 2.5 mm2

Other manuals for SRC Aqua Matic 450-1

1

This manual suits for next models

5

Table of contents

Other Sea Recovery Marine Equipment manuals