3000KG AIR OPERATED COIL SPRING

COMPRESSOR

MODEL NO: RE3000

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLYAND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURYAND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

1.1. GENERAL SAFETY.

WARNING! Ensure Health & Safety, local authority, and general workshop practice regulations are adhered to when using this equipment.

WARNING! Wear approved safety hand and eye protection (standard spectacles are not adequate).

WARNING! TRAPPING DANGER – Keep hands and fingers away from the spring and compressing jaws in use.

9Keep the work area clean, uncluttered and ensure there is adequate lighting.

9Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

9Remove ill-fitting clothes. Remove ties, watches, rings, other loose jewellery. Contain and/or tie back long hair.

9Wear appropriate protective clothing.

9Familiarise yourself with the applications, limitations and potential hazards of the spring compressor.

8DO NOT use the spring compressor for a task it was not designed to perform.

8DO NOT allow untrained persons to use the spring compressor.

1.2. PRE-OPERATIONAL SAFETY.

8DO NOT operate compressor if parts are damaged or missing as this may cause failure and/or personal injury.

9Before commencing compression, make a visual inspection of machine to ensure pins are securely positioned and that there is no sign

of wear or fatigue – if found, DO NOT use and refer to your local Sealey stockist for advice and replacement parts.

9Ensure jaw locating pins are properly positioned and safety clips are attached correctly.

9Before commencing compression of spring, ensure coils of the spring are seated securely in the yokes of the compressor and cannot slide out

during compression.

9ALWAYS ensure that the safety guard locks in place.

1.3. OPERATIONAL SAFETY.

9When applying compression to the spring, always stand to one side of the compressor.

▲DANGER! Stop compressing the spring before the coils touch / bind.

▲DANGER! Before attempting to remove top cap nut, always use a tool or similar to test if the compression has been relieved, DO NOT

use your hands / fingers.

9We recommend the use of purpose made strut tools to remove the top-nut from the shock piston.

9Once compressed, and the strut removed, we recommend releasing the tension on the spring. DO NOT leave the spring under

compression in the machine unattended and DO NOT leave in compression for prolonged periods, i.e. overnight.

9Before releasing the compression ensure that the top strut-nut is securely tightened to the manufacturer’s tolerance.

9Release the compression slowly keeping your hands and fingers away from the spring assembly.

9Be sure that the tension on the spring is fully controlled by the strut assembly before removing it from the yokes of the compressor.

1.4. POST OPERATIONAL SAFETY.

9When not in use, clean and store the spring compressor in a safe, dry, childproof location.

9Maintain the spring compressor in good condition. Replace or repair damaged parts. Use genuine parts only.

9Unauthorised parts may be dangerous and will invalidate the warranty.

2. INTRODUCTION

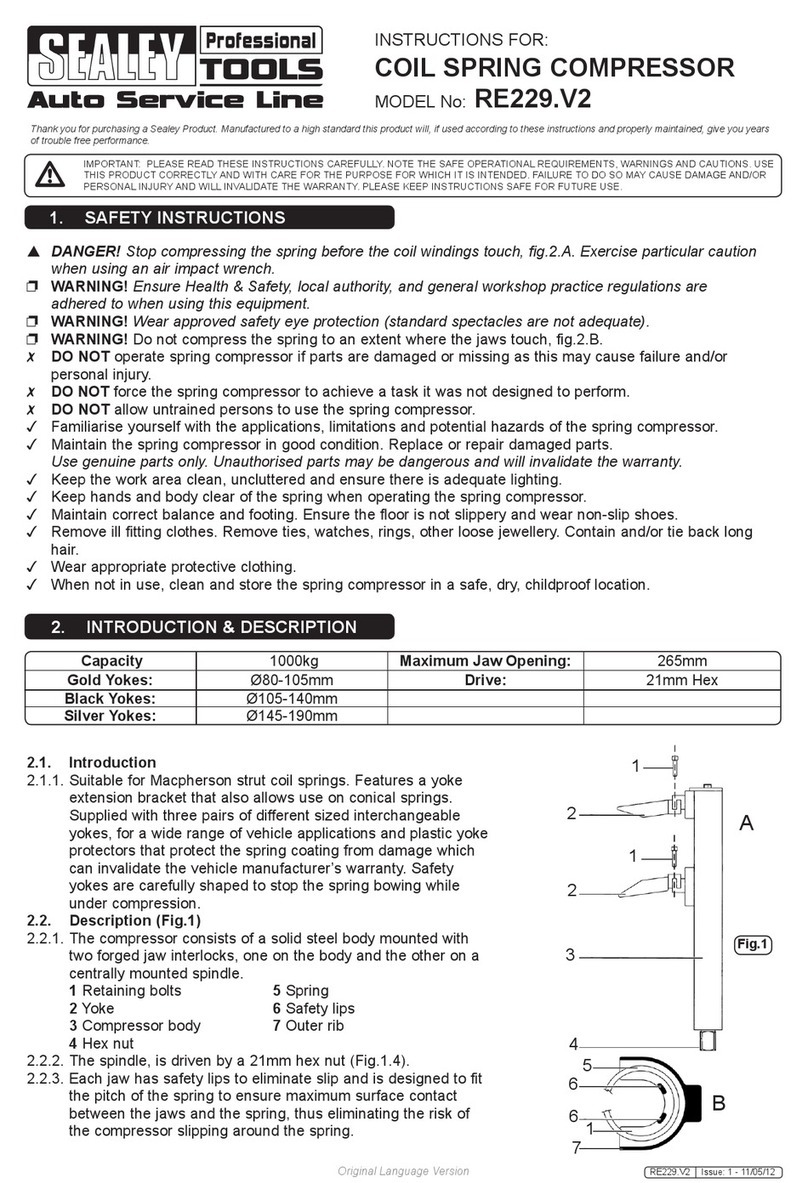

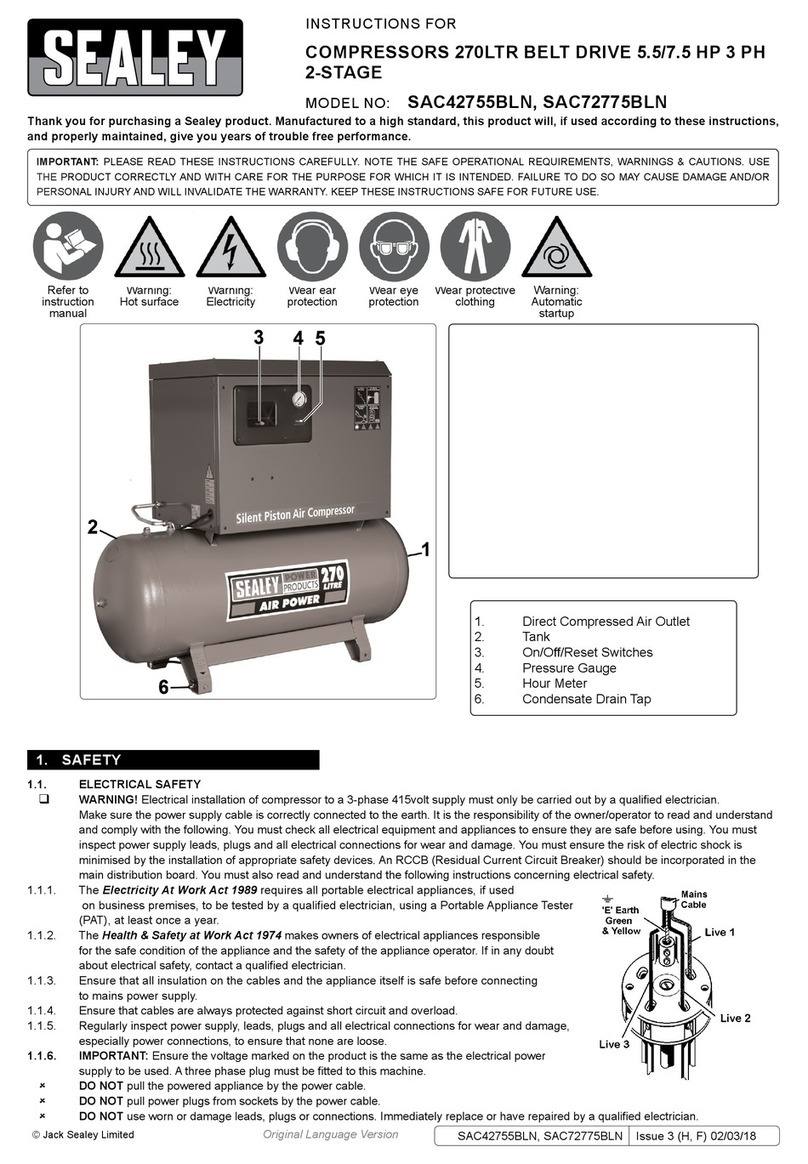

Fast and safe compression of suspension coil springs. 3000kg Air-operated unit with safety locking guard.

Adjustable swivel upper arm clamps. Also includes a suspension strut clamp. Fits a wide range of left and right-handed coil spring

congurations and diameters

3. SPECIFICATION

Model no.:.................................................................RE3000

Maximum Load: ......................................................... 3000kg

Upper Arm Travel:......................................................330mm

Actuation:..............................................................Foot Pedal

Maximum Air pressure: ...................................145psi (10bar)

Refer to

instructions Wear eye

protection Wear protective

gloves Beware

coil binding

RE3000 Issue 1 31/07/23

Original Language Version

© Jack Sealey Limited

Wear safety

footwear Warning:

Keep bystanders

away

Warning:

Crushing of

hands

General

Warning

Accessories (Not Included)……….RE01 - Right Handed Yoke Small

RE02 - Right Handed Yoke

RE03 - Left Handed Yoke

RE04 - Upper Coil Spring Bracket