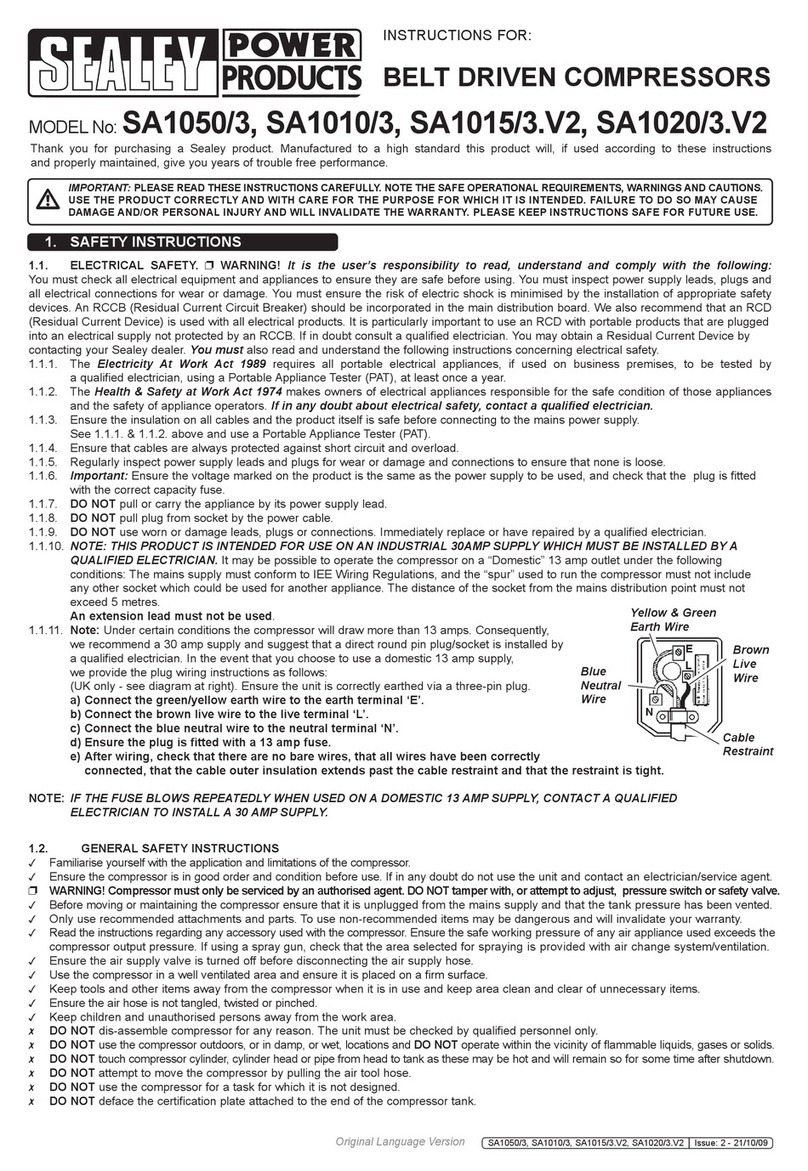

When completed, check that there are no bare wires,

that all wires have been connected correctly, that the

cable external insulation extends beyond the cable

restraint and that the restraint is tight. Never use the

earth connection instead of the neutral. The earth connection

must be achieved according to the EN 60204 industrial

safety standards.

1.1.12. THE IMPORTANCE OF THE EARTH CONNECTION

This compressor must be connected to earth to safeguard

the operator against electrical shocks whilst the machine is

in use. The electrical connection must be carried out only by

a qualified electrical engineer. The earth wire of the power

supply cable of the compressor must be connected only and

exclusively to the PE pin of the terminal board of the actual

compressor.

1.1.13. If it is necessary to replace a plug on the power supply cable

ensure that the earth wire is connected. All electrical repairs

must be carried out exclusively by a qualified electrical

engineer. Avoid all risks of electric shocks. Never use the

compressor with a damaged electrical mains supply cable.

Regularly check all electrical cables. Never use the

compressor in or near water or near a hazardous area where

electrical shocks may be encountered.

1.1.14. CHECK THE ROTATION DIRECTION

These 10hp compressors are equipped with a phase

sequence relay (KR) that, every start, checks the rotation

direction and, in case of wrong rotation direction, stops

the compressor (“AL3” error message on the electrical

board). Disconnect the compressor from the mains power,

reverse two phases of the power cable on the terminals for

connection of the cable line and restart the compressor.

1.2. SAFETY (INSTALLATION).

IMPORTANT! The compressor must be installed and

commissioned by qualified personnel.

7 DO NOT USE THE COMPRESSOR IF IT IS FAULTY. Ensure

that the compressor is in good order and condition before use.

If the compressor is noisy or vibrates excessively when

running, stop it immediately. If in any doubt do not use the unit

and contact an electrician/service agent.

3 OPERATE THE COMPRESSOR AT THE RATED VOLTAGE.

Operate the compressor at the voltage specified on the

electric data plate. You could damage or burn-out the motor

and other electric components if the compressor is operated at

a higher or lower voltage than its rated voltage.

3 USE THE COMPRESSOR CORRECTLY. Operate the

compressor in compliance with the instructions provided in this

manual. DO NOT allow children to use the compressor or

those who are not familiar with it.

1.3. SAFETY (OPERATIONAL AREA/ENVIRONMENTAL).

3 OPERATIONAL AREA. Keep the work area clean and remove

any tools or unnecessary items that are not required. Install

the compressor on a firm surface away from any heat sources.

3USE THE COMPRESSOR IN A WELL VENTILATED AREA.

Ensure there is adequate ventilation space all around the

compressor.

7DO NOT USE THE COMPRESSOR IN THE PRESENCE OF

FLAMMABLE LIQUIDS OR GAS. The compressor may

produce sparks while running. DO NOT use the compressor

where there may be paints, gasoline, chemical compounds,

glues or any other flammable or explosive material.

3KEEP UNAUTHORISED PERSONS AWAY FROM THE

WORKING AREA. All non-essential persons must be kept at a

safe distance from the operational area. Prevent children or

anyone else from touching the power supply cable of the

compressor.

7DO NOT USE THE COMPRESSOR OUTDOORS. DO NOT

install the compressor in damp or wet locations or in areas

where condensation may form.

7DO NOT COVER THE COMPRESSOR or restrict air flow

around the machine whilst operating.

3 IF THE COMPRESSOR IS USED FOR PAINTING JOBS.

a) DO NOT work in closed rooms or near naked flames.

b) Check that the area selected for spraying is provided with

an air change system or adequate ventilation.

c) Wear face and nose mask.

3 When the compressor is not in use, it should be switched

off, isolated from the mains supply and the air drained

from the tank.

3 STORE THE COMPRESSOR APPROPRIATELY. If the

compressor is not used immediately, it must be stored in a dry

place away from atmospheric agents until it is installed.

1.4. SAFETY (AIR/PRESSURE).

WARNING! THE AIR TANK IS A PRESSURE VESSEL AND

THE FOLLOWING SAFETY MEASURES APPLY:

7DO NOT tamper with the safety valve and DO NOT modify

or alter the tank in any way. DO NOT strap anything to the

tank.

7DO NOT subject the tank to impact, vibration or to heat

and DO NOT allow contact with abrasives or corrosives.

7 DO NOT drill, weld or deform the compressed air tank.

7 DO NOT UNSCREW THE OUTLET CONNECTION WHEN

THE TANK IS PRESSURISED. DO NOT unscrew the

connection for any reason whatsoever without first checking if

the tank is discharged.

3Ensure the air supply valve is turned off before disconnecting

the air supply hose.

3 PNEUMATIC CIRCUIT. Use recommended pneumatic hoses.

Read the instructions regarding any accessory used with the

compressor. Ensure the safe working pressure of any air

appliance used exceeds the compressor maximum pressure.

3Ensure the air hose is not tangled, twisted or pinched.

7DO NOT operate the compressor without an inlet air filter.

1.5. SAFETY (TRAINING/GOOD PRACTICE).

7DO NOT allow anyone to operate the compressor unless they

have received full instructions and adequate training.

3 KEEP THESE USE AND MAINTENANCE INSTRUCTIONS

for future reference and make then available to the compressor

operator. The operator must be familiar with all the controls and

compressor characteristics before starting to work with the

machine.

3 AVOID ACCIDENTAL START-UP. Ensure that the main switch

is turned OFF before connecting the compressor to the

electrical power supply. Never move the compressor while it is

connected to the electrical power supply or when the tank is

pressurised.

3 PRECAUTIONS FOR THE POWER SUPPLY CABLE. DO NOT

disconnect the power supply plug by pulling on the cable. Keep

the cable away from heat, oil and sharp edges. DO NOT stand

on the electrical cable or squash it under heavy weights.

3 LOOK AFTER THE COMPRESSOR WITH CARE. Follow the

maintenance instructions. Inspect the power supply cable on a

regular basis and if damaged it must be repaired or replaced

by an authorised service centre. Visually check the outside

appearance of the compressor, ensuring that there are no

visual anomalies. Contact your nearest Sealey dealer if

necessary.

3 CHECK FOR FAULTY PARTS OR AIR LEAKS. Before each

use, visually inspect the compressor. If a safety guard or other

parts are damaged, they must be checked carefully to evaluate

whether they continue to provide the intended protection.

Check the alignment of moving parts, hoses, gauges,

pressure reducers, pneumatic connections and every other part

that may be crucial for the normal operational efficiency of the

compressor. All damaged parts must be properly repaired or

replaced by an authorised service centre or replaced following

the instructions provided in instruction manual.

3 TURN THE COMPRESSOR OFF WHEN IT IS NOT IN USE.

When the compressor is not in use turn the main ON/OFF

switch to the OFF position (“0”).

7DO NOT DEFACE THE CERTIFICATION PLATE ATTACHED

TO THE END OF THE COMPRESSOR TANK.

1.6. SAFETY (PERSONAL/MECHANICAL).

7 DO NOT USE THE COMPRESSOR WITHOUT THE SAFETY

GUARDS FITTED. Never use the compressor without all the

safety guards properly fitted in their correct place (i.e.

panelling, belt guard, safety valve). If these parts are to be

removed for maintenance or servicing purposes, ensure that

they are correctly reinstalled before using the compressor

again.

Original Language Version SSC12710 & SSC12710D Issue: 3 - 23/02/12