NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

Sole UK Distributor, Sealey Group.

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk.

IP32 7AR

www.sealey.co.uk

sales@sealey.co.uk

01284 757500

01284 703534

Web

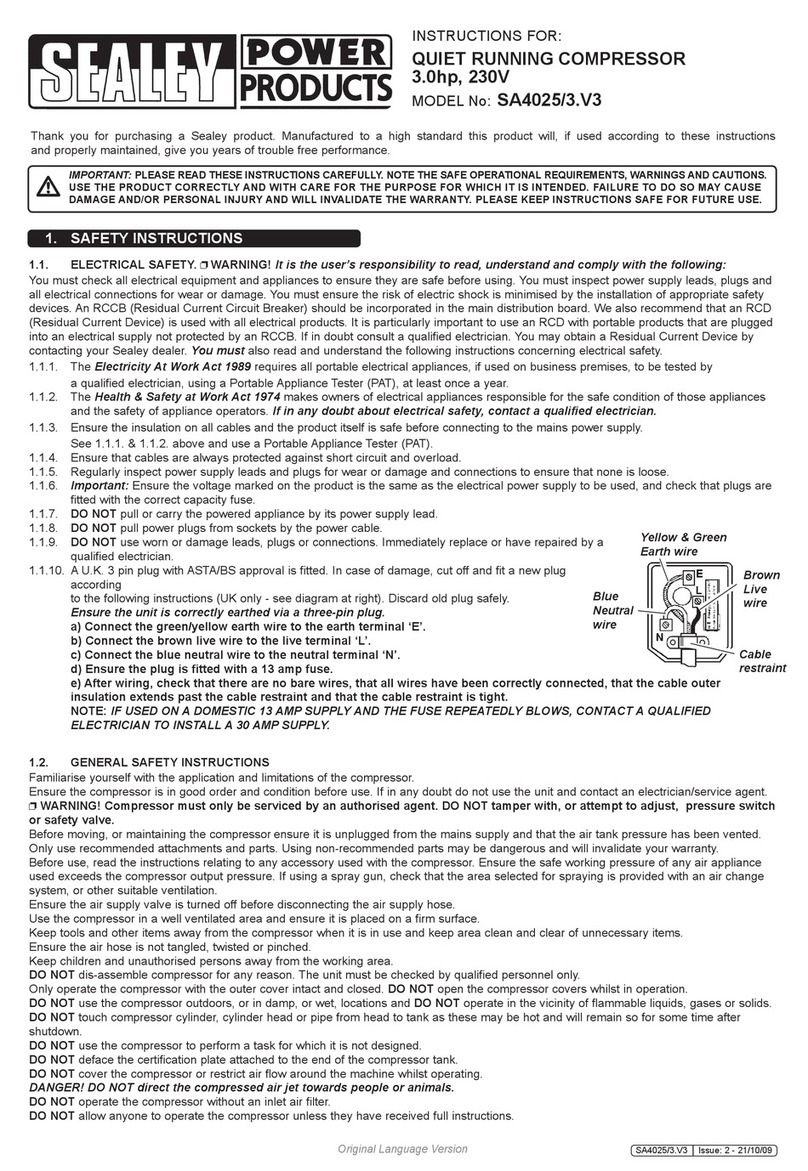

fig.2.

5. OPERATION

WARNING! Measure the outer diameter of the spring to be compressed and select the correct set of

jaws.

▲DANGER! DO NOT compress the spring to an extent where the coilwindingstouch.(seefig.2-A)

9Ensure that the centre line of the spring remains parallel to the compressor body at all times.

This applies to both straight springs and conical springs. The spring should not be touching the piston

orbodyofthecompressor.(seefig.2-B)

9Secure the strut with a clamp, vice or other adequate holding device.

9Before use check compressor assembly for signs of damage and particularly ensure jaws are in

good condition and securely mounted.

5.1. To Compress a Strut Removed From a Vehicle.

5.1.1. Screw the selected jaws onto the ram body and the piston respectively. Ensure that the recessed

sides of the jaws are facing each other.

5.1.2. Slacken the breather plug to allow the cylinder to breathe on the low pressure side of the piston.

5.1.3. Operatethepumphandle(seefig.1)todrivethejawstogether to the approximate length of the

spring and to allow compression of as many windings as possible.

5.2. Place the spring strut compressor onto the spring, ensuring the spring seats correctly into both

the upper and the lower jawsandcannotslideoutduringcompression.(seefig.2-D&E)

5.2.1. Ensurethatthecentrelinesofthespringandcompressorbodyareparallel.(seefig.2).

5.2.2. Operate the pump handle (seefig.1)and compress the spring until the upper support bearing is free

and the spring will rotate.

5.3. To Decompress a Strut Removed From a Vehicle.

5.3.1. Todecompressthespring,openthevalveslowlytoopenthejaws(fig.1).

5.3.2. Tighten the breather plug after use to avoid accidental oil leakage in transit.

6. MAINTENANCE

6.1. Before each use check the compressor to ensure it is not damaged or worn. If suspect do not use

the unit, but contact your local Sealey Dealer who will be able to advise you.

6.2. After use, release the hydraulic pressure and grease the piston rod using LM grease.

6.3. Keep the compressor clean, and when not in use store in a safe, dry, childproof location.

fig.2

Environmental Protection

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be

sorted, taken to a recycling centre and disposed of in a manner which is compatible with the environment.

When the product becomes completely unserviceable and requires disposal, drain off any fluids (if applicable)

into approved containers and dispose of the product and the fluids according to local regulations.

VS7011.V3| Issue 6 06/02/17

Original Language Version

© Jack Sealey Limited

Parts support is available for this product. To obtain a parts listing and/or diagram,

please log on to www.sealey.co.uk, email sales@sealey.co.uk or telephone 01284 757500.