INSTRUCTIONS FOR:

BELT DRIVEN COMPRESSORS

Models: SA1015/3 & SA1020/3

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

SA1015/3 & SA1020/3 - 1069 - (2) - 050601

1. SAFETY INSTRUCTIONS

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

1.1. ELECTRICAL SAFETY. p WARNING! It is the users responsibility to read, understand and comply with the following:

You must check all electrical equipment and appliances to ensure they are safe before using. You must inspect power supply leads, plugs and

all electrical connections for wear or damage. You must ensure the risk of electric shock is minimised by the installation of appropriate safety

devices. An RCCB (Residual Current Circuit Breaker) should be incorporated in the main distribution board. We also recommend that an RCD

(Residual Current Device) is used with all electrical products. It is particularly important to use an RCD with portable products that are plugged

into an electrical supply not protected by an RCCB. If in doubt consult a qualified electrician. You may obtain a Residual Current Device by

contacting your Sealey dealer. You must also read and understand the following instructions concerning electrical safety.

1.1.1. The Electricity At Work Act 1989 requires all portable electrical appliances, if used on business premises, to be tested by

a qualified electrician, using a Portable Appliance Tester (PAT), at least once a year.

1.1.2. The Health & Safety at Work Act 1974 makes owners of electrical appliances responsible for the safe condition of those appliances

and the safety of appliance operators. If in any doubt about electrical safety, contact a qualified electrician.

1.1.3. Ensure the insulation on all cables and the product itself is safe before connecting to the mains power supply.

See 1.1.1. & 1.1.2. above and use a Portable Appliance Tester (PAT).

1.1.4. Ensure that cables are always protected against short circuit and overload.

1.1.5. Regularly inspect power supply leads and plugs for wear or damage and connections to ensure that none is loose.

1.1.6. Important: Ensure the voltage marked on the product is the same as the power supply to be used, and check that the plug is fitted with the

correct capacity fuse.

1.1.7. DO NOT pull or carry the appliance by its power supply lead.

1.1.8. DO NOT pull plug from socket by the power cable.

1.1.9. DO NOT use worn or damage leads, plugs or connections. Immediately replace or have repaired by a qualified electrician.

1.1.10. NOTE: THIS PRODUCT IS INTENDED FOR USE ON AN INDUSTRIAL 30AMP SUPPLYWHICH MUST BE INSTALLED BY A QUALIFIED

ELECTRICIAN. It may be possible to operate the compressor on a Domestic 13 amp outlet under the following conditions: The mains supply

must conform to IEE Wiring Regulations, and the spur used to run the compressor must not include any other socket which could be used for

another appliance. The distance of the socket from the mains distribution point must not exceed 5 metres.

An extension lead must not be used.

1.1.11. Note: Under certain conditions the compressor will draw more than 13 amps. Consequently,

we recommend a 30 amp supply and suggest that a direct round pin plug/socket is installed by

a qualified electrician. In the event that you choose to use a domestic 13 amp supply,

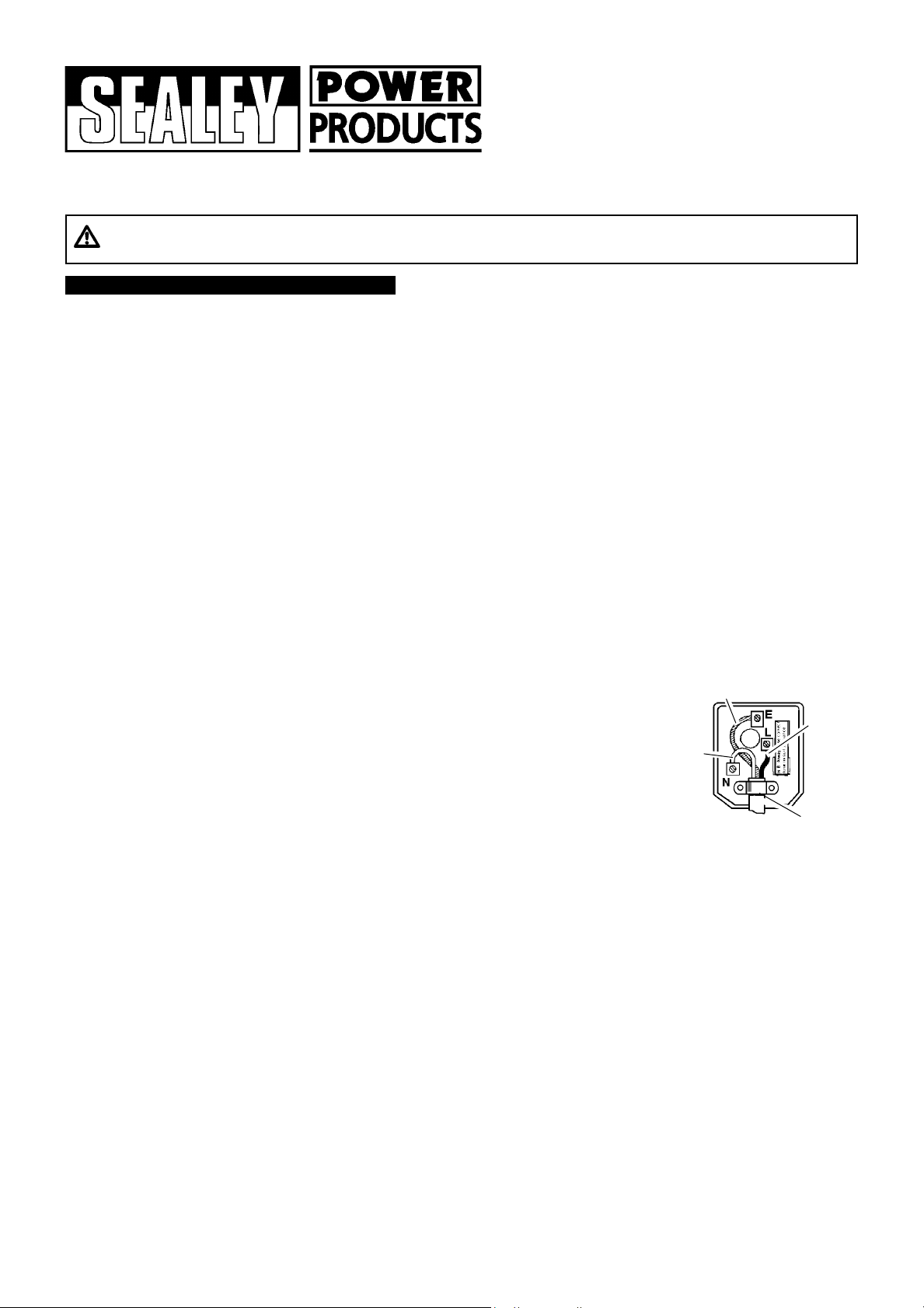

we provide the plug wiring instructions as follows:

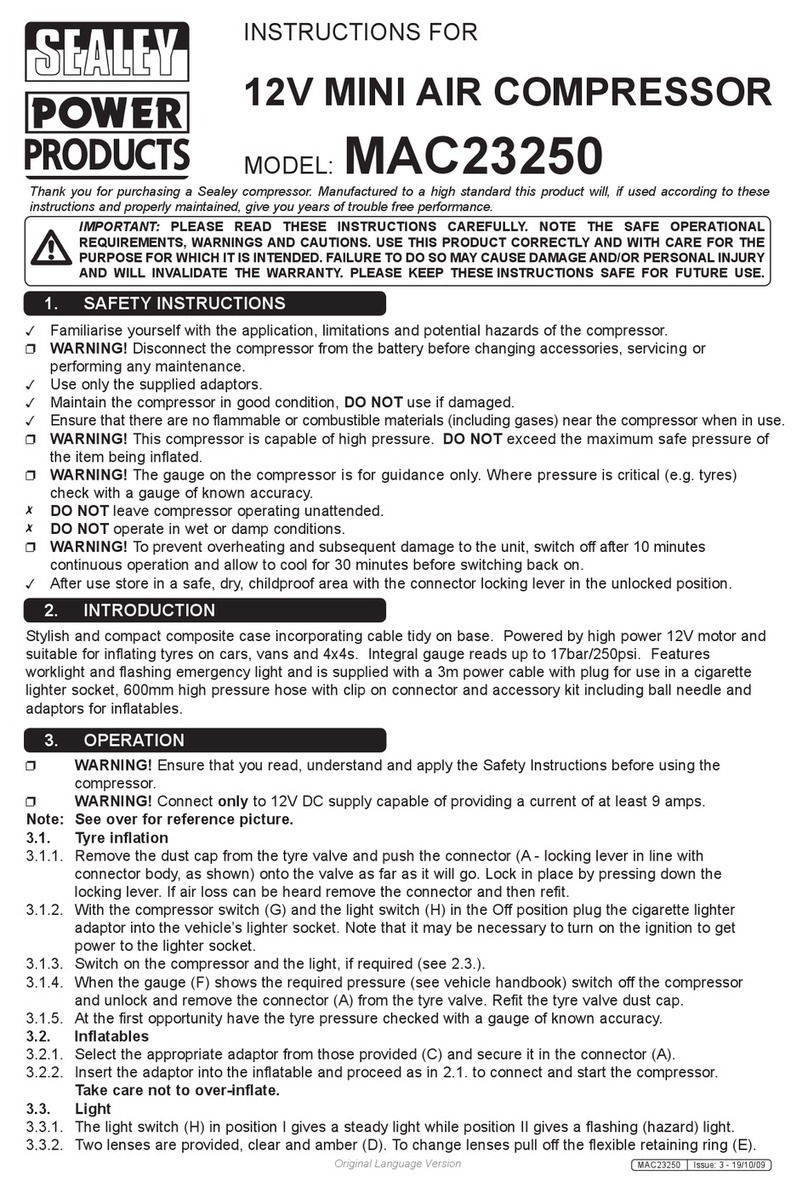

(UK only - see diagram at right). Ensure the unit is correctly earthed via a three-pin plug.

a) Connect the green/yellow earth wire to the earth terminal E.

b) Connect the brown live wire to the live terminal L.

c) Connect the blue neutral wire to the neutral terminal N.

d) Ensure the plug is fitted with a 13 amp fuse.

e) After wiring, check that there are no bare wires, that all wires have been correctly

connected, that the cable outer insulation extends past the cable restraint and that the restraint is tight.

NOTE: IF THE FUSE BLOWS REPEATEDLY WHEN USED ON A DOMESTIC 13 AMP SUPPLY, CONTACT A QUALIFIED

ELECTRICIAN TO INSTALL A 30 AMP SUPPLY.

Blue

Neutral

Wire

Yellow & Green

Earth Wire

Cable

Restraint

Brown

Live

Wire

1.2. GENERAL SAFETY INSTRUCTIONS

3Familiarise yourself with the application and limitations of the compressor.

3Ensure the compressor is in good order and condition before use. If in any doubt do not use the unit and contact an electrician/service agent.

pWARNING! Compressor must only be serviced by an authorised agent. DO NOT tamper with, or attempt to adjust, pressure switch or safety valve.

3Before moving or maintaining the compressor ensure that it is unplugged from the mains supply and that the tank pressure has been vented.

3Only use recommended attachments and parts. To use non-recommended items may be dangerous and will invalidate your warranty.

3Read the instructions regarding any accessory used with the compressor. Ensure the safe working pressure of any air appliance used exceeds the

compressor output pressure. If using a spray gun, check that the area selected for spraying is provided with air change system/ventilation.

3Ensure the air supply valve is turned off before disconnecting the air supply hose.

3Use the compressor in a well ventilated area and ensure it is placed on a firm surface.

3Keep tools and other items away from the compressor when it is in use and keep area clean and clear of unnecessary items.

3Ensure the air hose is not tangled, twisted or pinched.

3Keep children and unauthorised persons away from the work area.

7DO NOT dis-assemble compressor for any reason. The unit must be checked by qualified personnel only.

7DO NOT use the compressor outdoors, or in damp, or wet, locations and DO NOT operate within the vicinity of flammable liquids, gases or solids.

7DO NOT touch compressor cylinder, cylinder head or pipe from head to tank as these may be hot and will remain so for some time after shutdown.

7DO NOT attempt to move the compressor by pulling the air tool hose.

7DO NOT use the compressor for a task for which it is not designed.

7DO NOT deface the certification plate attached to the end of the compressor tank.