4. TOOL SELECTION

IMPORTANT: Take care when selecting tools for use with

the compressor. Air tool manufacturers normally express

the volume of air required to operate a tool in cubic feet

per minute (cfm). This refers to free air delivered by the

compressor (‘air out’) which varies according to the

pressure setting. Do not confuse this with the

compressor displacement which is the air taken in by

the compressor (‘air in’). ‘Air out’ is always less than ‘air

in’ - due to losses within the compressor - and so it is

important that, before choosing equipment, you study

the ‘Free Air Delivery’ figures shown in the Specification

Chart.

5. OPERATION

WARNING! ENSURE THAT YOU HAVE READ,

UNDERSTOOD AND APPLIED SECTION 1 SAFETY

INSTRUCTIONS.

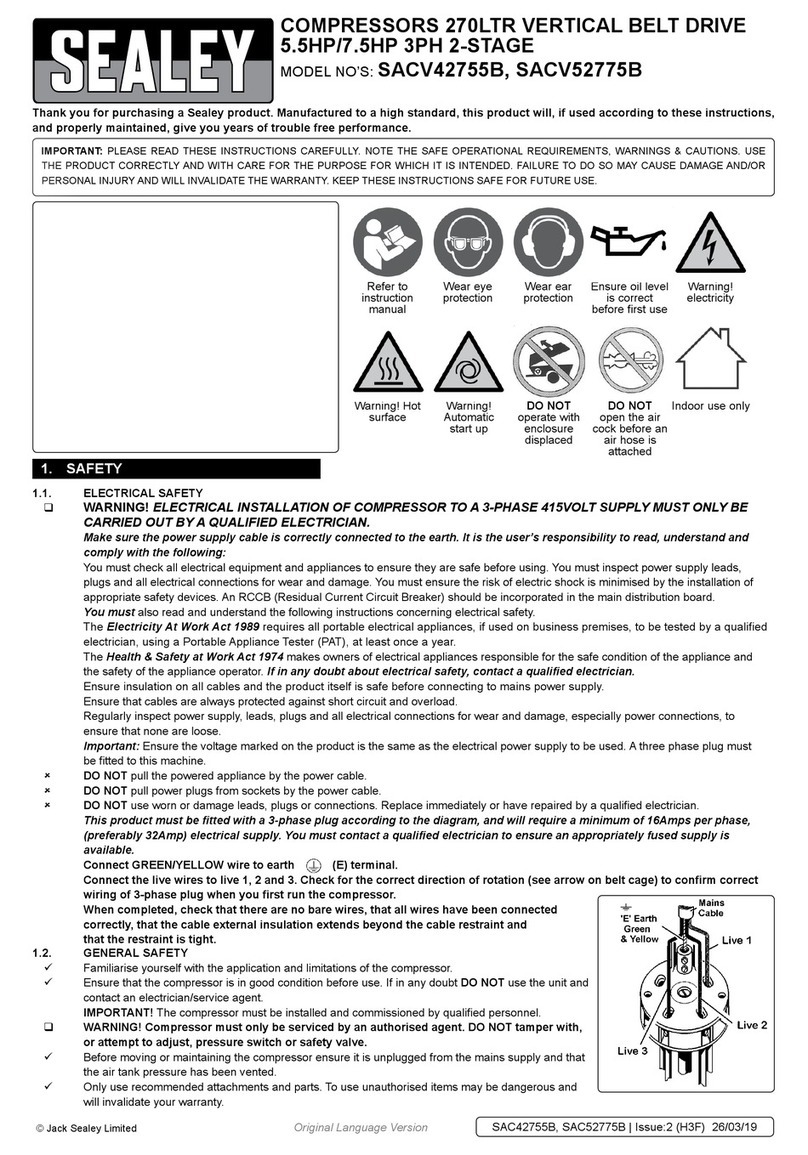

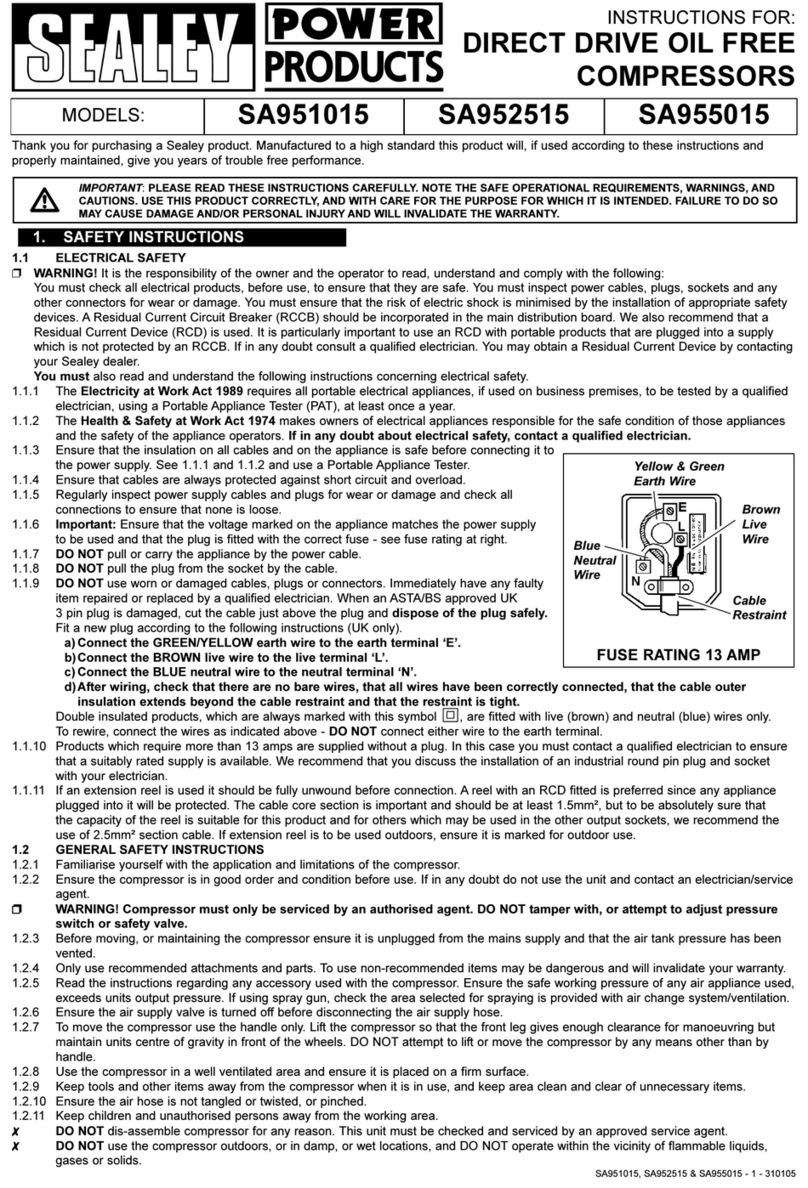

5.1. Make sure that the main switch (fig.5.1) is ‘OFF’ (down).

5.2. Check the oil level by looking through the sight glass (fig.3).

5.3. Ensure that the tank drain valve is closed (fig.1).

5.4. Connect the air tool required to the compressor via an air line

connected to the air outlet.

5.5. Plug the mains plug into the mains supply and start the

compressor by pulling up the main switch (fig.5.1).

5.6. Allow the pressure in the tank to rise to the maximum at

which point the compressor will automatically cut out. Tank

pressure is shown on the larger gauge (fig.5.6).

5.7. Begin to gradually open the regulator by turning the knob

clockwise (fig.5.2) until the small gauge registers the required

operating pressure specified for the tool to be used. Always

adjust up to the required pressure rather than down from a

higher pressure. The required setting, once achieved, can be

locked by screwing the locking ring (fig.5.3) up tight

underneath the adjusting knob.

5.8. You can now begin to use the tool. The compressor will

operate automatically cutting in and out as required to

restore the air pressure in the tank. The pressure switch

(fig.5.8) stops the motor when the maximum tank pressure is

reached and restarts it when pressure falls below the

minimum threshold - approx. 2 bar (29psi) less than the

maximum pressure.

Note: a)If the motor does not cut in and out, but runs continuously

when using an air appliance, the capacity of the compressor

may be too small for the appliance.

b)The main gauge (fig.5.6) indicates the pressure inside the

main tank, NOT the pressure supplied to the air equipment,

which is shown on the smaller gauge (fig.5.5). Should the

pressure in the main tank exceed the pre-set switch (fig.5.8)

maximum, the safety valve (fig.5.7) will activate.

WARNING! For this reason DO NOT tamper with, or

adjust, the switch or the safety valve.

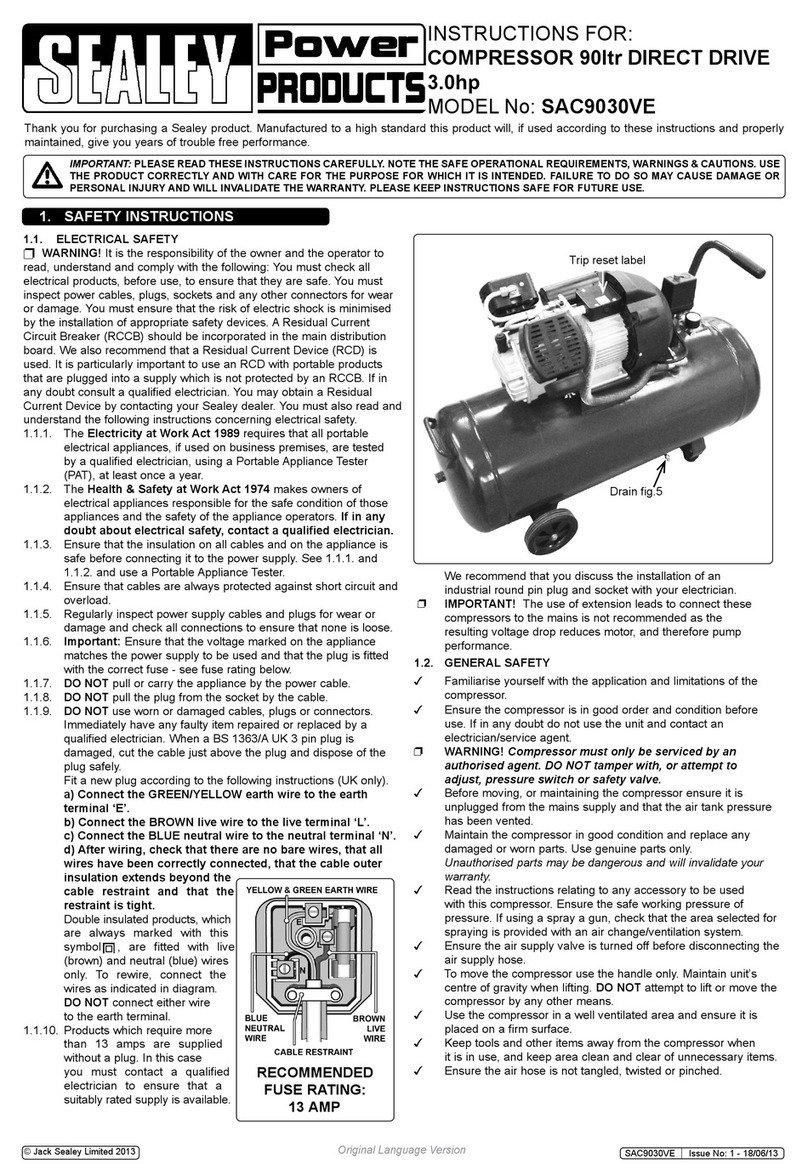

2. INTRODUCTION & SPECIFICATION

Model features aluminium cylinder head with cast iron cylinder giving

added resistance to wear over time. Suitable for general purpose

workshop applications. Pump head directly coupled to a heavy-duty

induction motor for reliable operation. Welded tank complies with latest

European standards. Fitted with fully automatic pressure cut-out switch

with twin gauges displaying tank and working pressures. Fitted with

BS EN 60309 approved 16A 110V plug

3. PREPARATION & ASSEMBLY

3.1. Remove the compressor from its packaging and inspect for

any shortages or damage. If anything is found to be missing

or damaged, contact your supplier.

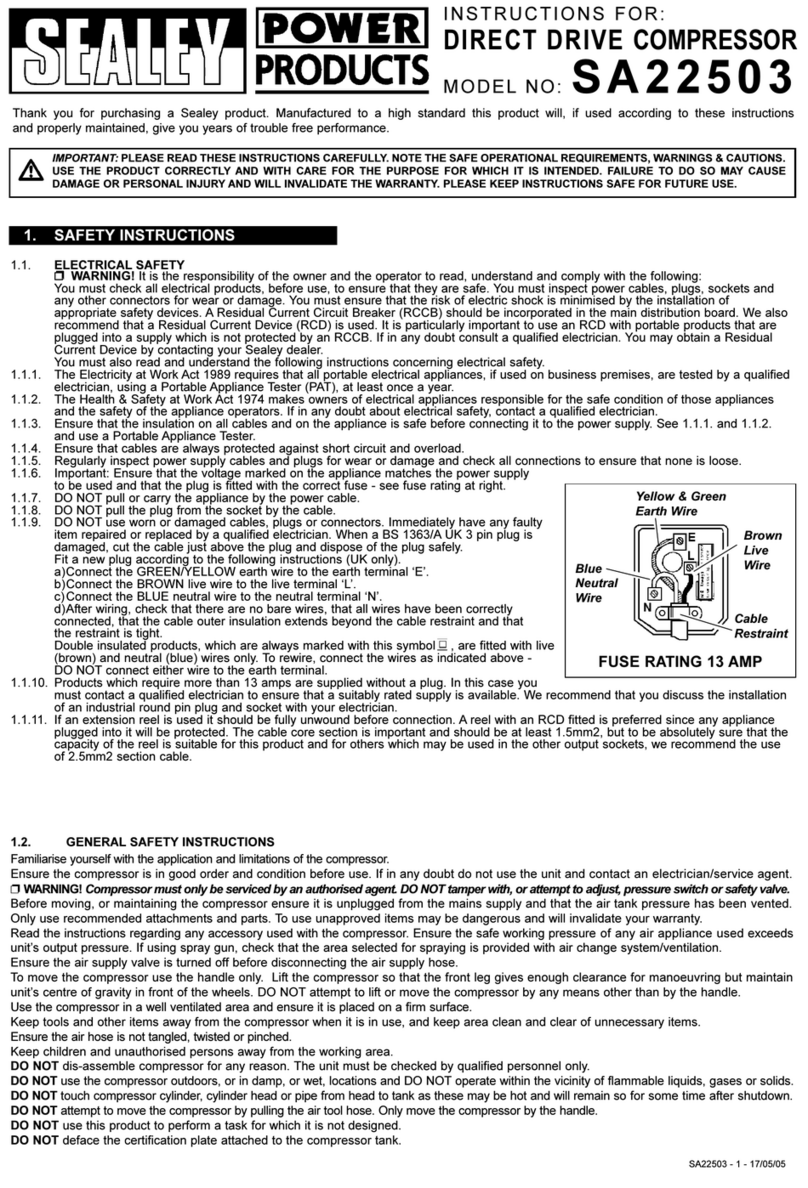

3.2. Confirm that the mains voltage corresponds with the voltage

shown on the compressor data plate.

3.3. The compressor should be installed on a flat surface, or one

that does not exceed 10°either transversely or longitudinally,

(see fig.2) and should be in a position that allows good air

circulation around the unit.

3.4. The compressor is supplied without oil in it. The oil is in a

separate container. Remove the oil filler/breather and pour oil

into the aperture until it has reached the correct level on the

sight (fig.3). Replace oil filler/breather.

3.5. Ensure that the air vent in the oil filler/breather is free

from debris. If the air vent is blocked, pressure can build

up in the crankcase causing damage to the compressor

and possible personal injury.

3.6. If it is not already fitted, screw the air filter holder into the

inlet port (fig.4).

MODEL: ..................................................... SAC2420E110V.V2

Motor output: ..................................................................... 2hp

Voltage/Phase: ........................................................110V - 1ph

Rated supply:..................................................................... 16A

Air displacement: ............................................. 6.3cfm(178/m)

Maximum free air delivery:............................. 4.6cfm(130l/m)

Tank capacity:................................................................... 24ltr

Maximum pressure: ..............................................116psi/8bar

Weight: ...........................................................................26.5kg

Dimensions (W x D x H): ........................ 600 x 290 x 585mm

fig.2

fig.3

fig.4

©Jack Sealey Limited

7 DO NOT disassemble compressor for any reason. The unit

must be checked by qualified personnel only.

7 DO NOT use the compressor outdoors, or in damp, or wet,

locations.

7DO NOT operate within the vicinity of flammable liquids,

gases or solids.

7 DO NOT touch compressor cylinder, cylinder head or pipe

from head to tank as these may be hot.

7 DO NOT use this product to perform a task for which it has

not been designed.

7 DO NOT deface the certification plate attached to the

compressor tank.

7 DO NOT cover the compressor or restrict air flow around the

unit whilst operating.

q DANGER! DO NOT direct the output jet of air towards

people or animals.

7DO NOT operate the compressor without an air filter.

7DO NOT allow anyone to operate the compressor unless

they have received full instructions.

WARNING! The air tank is a pressure vessel and the

following safety measures apply:

7DO NOT tamper with the safety valve, DO NOT modify or alter

the tank in any way and DO NOT strap anything to the tank.

7DO NOT subject the tank to impact, vibration or to heat and

DO NOT allow contact with abrasives or corrosives.

WARNING! If an electrical fuse blows, ensure it is replaced

with an identical fuse type and rating.

3When not in use, store the compressor carefully in a safe,

dry, childproof location.

Original Language Version SAC2420E110V.V2 Issue No:1 - 17/03/14