OXYGEN REGULATOR

MODEL NO: SGA30

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

9Always have a fire extinguisher nearby.

8Never use oxygen or fuel gas to blow soot or dirt from your clothes.

8DO NOT wear ragged clothes, as sparks can ignite the ragged or loose ends.

9Secure cylinders to a trolley, wall or post to prevent them from falling.

9All cylinders should be used and stored in an upright position.

8Never drop or strike a cylinder. DO NOT use cylinders that have been dented.

9Cylinder caps should be used when storing or moving cylinders.

9Empty cylinders should be kept in specified areas and clearly marked ‘EMPTY’.

9Inspect fittings for damage. If any damage is found, replace immediately.

9Always use reverse flow check valves on torch and flashback arrestors on the regulator.

This greatly reduces the possibility of mixing gases in the regulator or hoses. Reverse flow check

valves are an important safety precaution.

9Keep all threads and unions clean and free from oil, dirt or grease.

8Never apply oil or grease to any thread, inlet or outlet connection or cylinder valves.

9For safety advice regarding gas bottles (oxygen and acetylene) refer to the supplier of the bottles.

9Make sure bottle keys are in place at all times so that in the event of an emergency the valves can be turned off quickly.

9LEAKING HOSES CAN KILL. Leak test all connections and valves prior to each use of the equipment.

9Remember at all times BLUE = OXYGEN ‘O’

RED = ACETYLENE ‘A’

9At no time may you interchange parts contained in this kit with those of other manufacturers. Only Sealey replacement items should be

used.

9The regulator in this kit has no user-serviceable parts. All repairs/calibrations must only be undertaken by a BCGAapproved service

agent.

2. INTRODUCTION

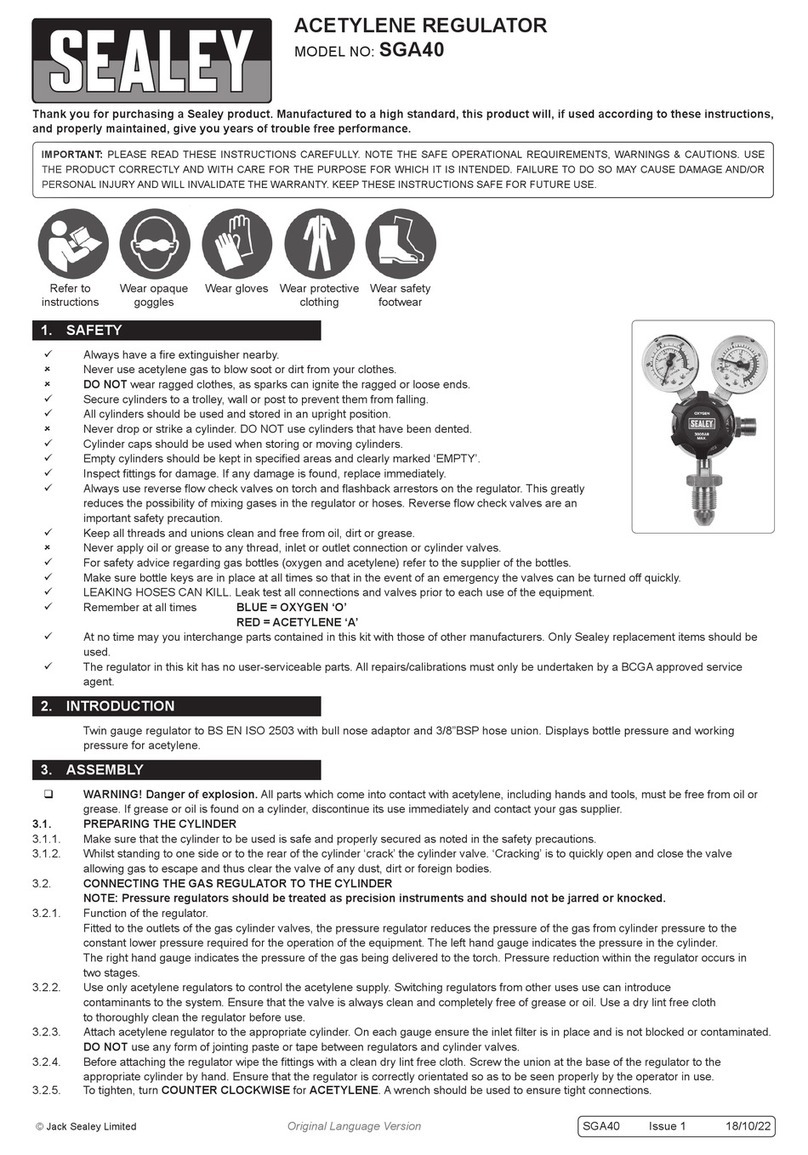

Twin gauge regulator complies to BS EN ISO 2503 with bull nose adaptor and 3/8”BSP hose union. Displays bottle pressure and

working pressure for oxygen.

3. ASSEMBLY

WARNING! Danger of explosion. All parts which come into contact with oxygen, including hands and tools, must be free from oil or

grease. If grease or oil is found on a cylinder, discontinue its use immediately and contact your gas supplier.

3.1. PREPARING THE CYLINDER

3.1.1. Make sure that the cylinder to be used is safe and properly secured as noted in the safety precautions.

3.1.2. Whilst standing to one side or to the rear of the cylinder ‘crack’ the cylinder valve. ‘Cracking’ is to quickly open and close the valve

allowing gas to escape and thus clear the valve of any dust, dirt or foreign bodies.

3.2. CONNECTING THE GAS REGULATOR TO THE CYLINDER

NOTE: Pressure regulators should be treated as precision instruments and should not be jarred or knocked.

3.2.1. Function of the regulator.

Fitted to the outlets of the gas cylinder valves, the pressure regulator reduces the pressure of the gas from cylinder pressure to the

constant lower pressure required for the operation of the equipment. The left hand gauge indicates the pressure in the cylinder.

The right hand gauge indicates the pressure of the gas being delivered to the torch. Pressure reduction within the regulator occurs in

two stages.

3.2.2. Use only oxygen regulators to control the oxygen supply. Switching regulators from non-oxygen to oxygen use can introduce

contaminants to the system. Ensure that the valve is always clean and completely free of grease or oil. Use a dry lint free cloth

to thoroughly clean the regulator before use. Never use an oxygen regulator for other gases.

3.2.3. Attach oxygen regulator to the appropriate cylinder and ensure the inlet filter is in place and is not blocked or contaminated.

Do not use any form of jointing paste or tape between regulator and cylinder valve.

3.2.4. Before attaching the regulator, wipe the fittings with a clean dry lint free cloth. Screw the union at the base of the regulator to the

appropriate cylinder by hand. Ensure that the regulator is correctly orientated so as to be seen properly by the operator in use.

Refer to

instructions Wear opaque

goggles Wear gloves Wear protective

clothing Wear safety

footwear

Original Language Version

© Jack Sealey Limited SGA30 Issue 1 17/10/22