INSTRUCTIONS FOR:

AIR REGULATOR, FILTER, LUBRICATOR RANGE

Models: SA106, SA106FR, SA106F, SA106L, SA106R

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

1. SAFETY INSTRUCTIONS

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

!WARNING! Ensure Health & Safety, local authority, and general workshop practice regulations are adhered to when using this equipment.

!WARNING! Disconnect the equipment from the air supply before changing accessories, servicing or performing any maintenance.

"Keep the equipment clean and maintain it in good condition (use an authorised service agent).

"Replace or repair damaged parts. Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

!WARNING! Ensure that the correct air pressure is maintained and not exceeded.

"Keep air hoses away from heat, oil and sharp edges. Check hoses for wear before each use and ensure that all connections are secure.

#DO NOT direct air from the air hose at yourself, others or animals.

"Drain the compressor air tank daily. Water in the air line will damage your equipment.

"When work is complete ensure that the air supply is turned off.

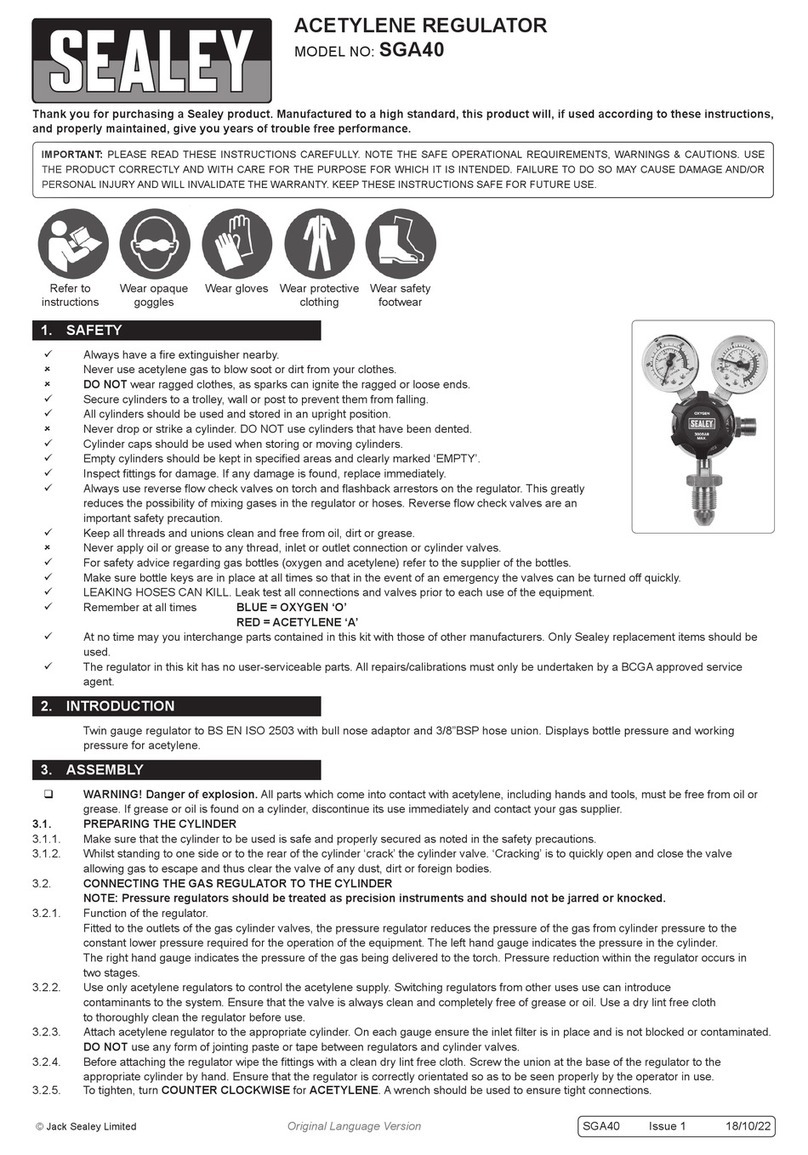

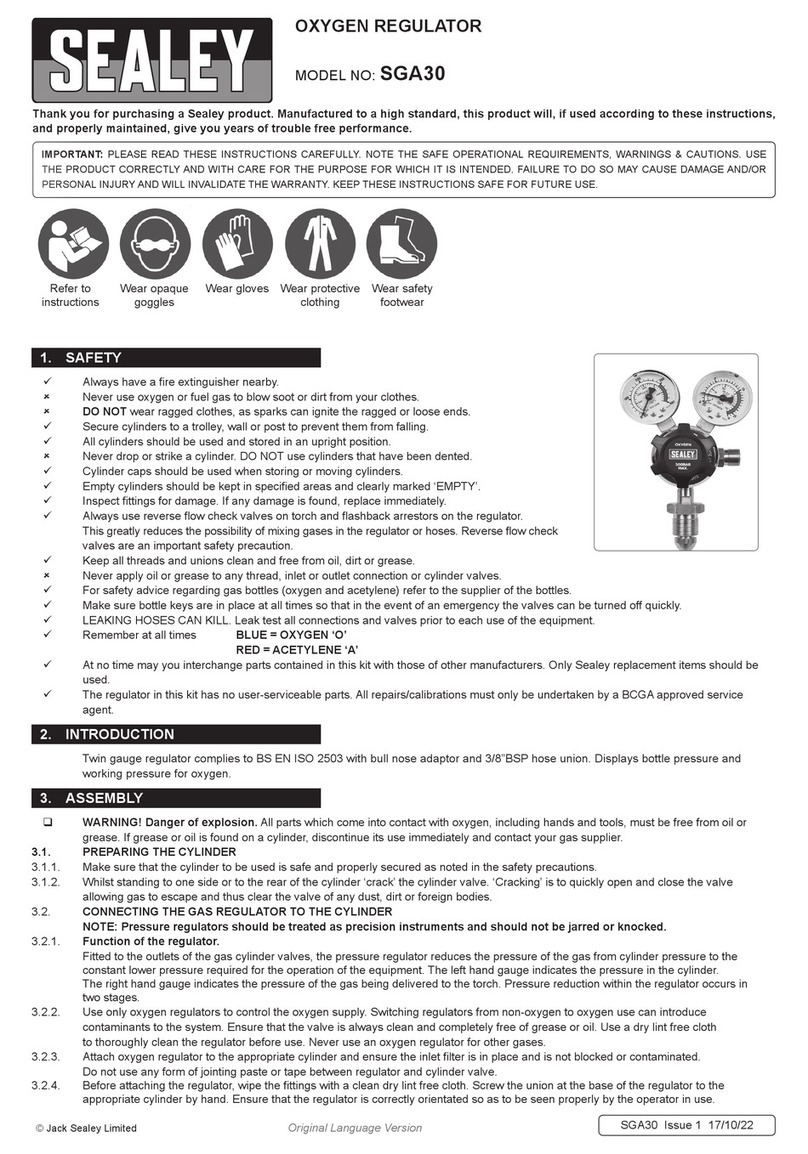

Suitable for workshop air supply set-ups. Regulator features locking control knob for pre-setting air pressure and pressure gauge. Filter has

manual drain facility with female 1/8”BSP outlet. Lubricator includes oil/air mix control and sight glass. Filter and lubricator are fitted with

metal bowl cages for protection. SA106, SA106FR and SA106R supplied with mounting bracket.

2. INTRODUCTION & SPECIFICATIONS

Filter/Lubricator/Regulator - SA106

Max. inlet pressure . . . . . . . . . . . . . . . . . . .150psi (10.3 bar)

Max. outlet pressure . . . . . . . . . . . . . . . . . . .125psi (8.6 bar)

Max. flow rate @ 100psi (6.9 bar) . . . . . . . . . . . . . . . .60cfm

Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25 micron

Lubricant . . . . . . .Sealey Air Tool Oil - ATO/500 or ATO/1000

Ports-Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/4”BSP

Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/4”BSP

Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/8”BSP

Filter/Regulator - SA106FR

Max. inlet pressure . . . . . . . . . . . . . . . . . . .150psi (10.3 bar)

Max. outlet pressure . . . . . . . . . . . . . . . . . . .125psi (8.6 bar)

Max. flow rate @ 100psi (6.9 bar) . . . . . . . . . . . . . . . .70cfm

Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25 micron

Ports-Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/4”BSP

Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/4”BSP

Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/8”BSP

Regulator - SA106R

Max. inlet pressure . . . . . . . . . . . . . . . . . . .150psi (10.3 bar)

Max. outlet pressure . . . . . . . . . . . . . . . . . . .125psi (8.6 bar)

Max. flow rate @ 100psi (6.9 bar) . . . . . . . . . . . . . . . .88cfm

Ports-Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/4”BSP

Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/4”BSP

Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/8”BSP

Filter - SA106F

Max. inlet pressure . . . . . . . . . . . . . . . . . . .150psi (10.3 bar)

Max. outlet pressure . . . . . . . . . . . . . . . . . . .125psi (8.6 bar)

Max. flow rate @ 100psi (6.9 bar) . . . . . . . . . . . . . . . .53cfm

Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25 micron

Ports-Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/4”BSP

Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/4”BSP

Lubricator - SA106L

Max. inlet pressure . . . . . . . . . . . . . . . . . . .150psi (10.3 bar)

Max. outlet pressure . . . . . . . . . . . . . . . . . . .125psi (8.6 bar)

Max. flow rate @ 100psi (6.9 bar) . . . . . . . . . . . . . . . .60cfm

Lubricant . . . . . . .Sealey Air Tool Oil - ATO/500 or ATO/1000

Ports-Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/4”BSP

Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/4”BSP

WARNING! Filter and lubricator bowls are manufactured

from polycarbonate and must not be used at temperatures

over 125OF (52OC) or for pressures over 218psi (15 bar).

Polycarbonate can be damaged and may fail if exposed to

certain solvents either internally or externally - strong

alkalies, compressor oils containing aromatic hydrocarbons

or fire retardant oils, or the fumes of any of these.

Clean with warm water only.

SA106/106FR/106F/106L/106R - 1 - 120406

SA106 SA106FR SA106F SA106L SA106R