3. CONNECTION 5. STORAGE/MAINTENANCE

4. OPERATION

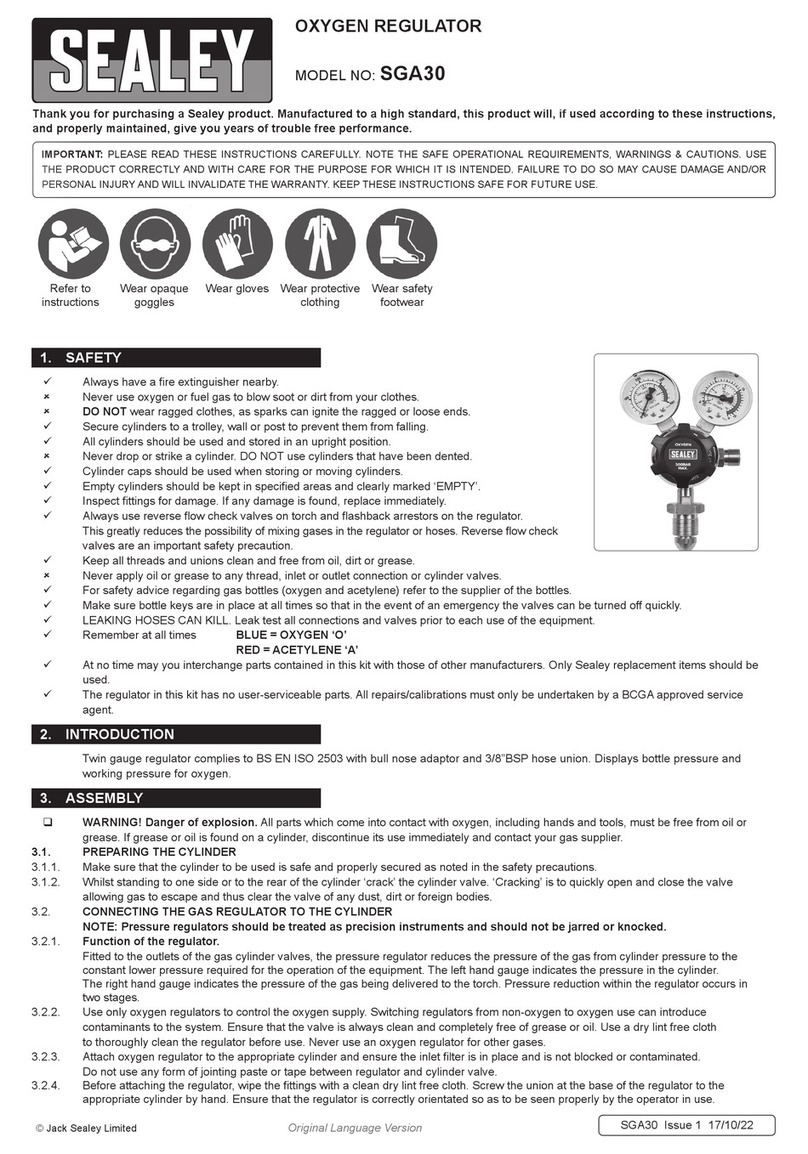

3.1 Connection of the regulator.

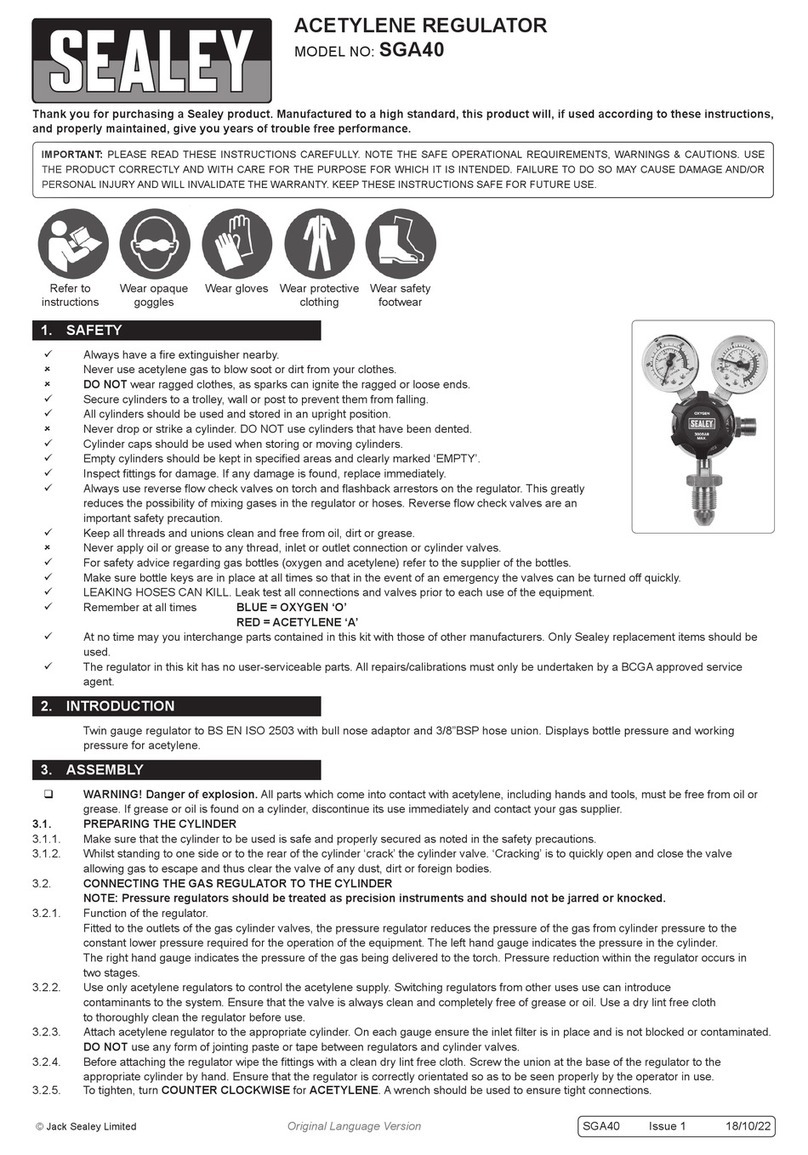

3.1.1 Check that the pressure regulator is correct both for the type of

gas and the pressure in the cylinder in use.

3.1.2 Turn the pressure adjusting knob (3) anticlockwise to ensure that

the regulator valve is closed.

3.1.3 Replace the inlet connection gasket if it is damaged or lost.

3.1.4 Before screwing on the regulator, briefly open the cylinder

valve, then close it, in order to remove any impurity (only for

rechargeable bottles).

WARNING! During this operation it is dangerous to stand, or

place your hands in front of the cylinder valve.

3.1.5 Screw the regulator to the cylinder valve and tighten using a

suitable spanner. DO NOT over-tighten.

3.2 Hose connection.

3.2.1 Attach hose to the hose connection of the outlet connection (5)

and secure it with a hose clamp.

WARNING! Only use hoses complying with EN 559-ISO3821.

4.1 Gas supply.

CAUTION! Before opening the cylinder valve, check that the

regulator is completely closed (turn the pressure adjusting knob

(3) anticlockwise).

4.1.1 Slowly open the cylinder valve. The high pressure gauge (1) will

show you the cylinder pressure.

4.1.2 Opening the cylinder valve too quickly may make gauges

malfunction.

4.1.3 Turn the pressure adjusting knob (3) very slowly clockwise. The

low pressure gauge (2) will show the outlet pressure

(REG/MT only).

4.2 Regulate pressure.

4.2.1 To increase pressure: continue slowly turning the regulator

pressure adjusting knob (3) clockwise.

4.2.2 To decrease pressure: slowly turn the regulator pressure

adjusting knob (3) anticlockwise.

4.2.3 Using the pressure adjusting knob (3) it is possible to

compensate for eventual pressure drop within the cylinder.

CAUTION! Outlet pressure must not be regulated higher than

the pressure you need to use.

Outlet pressure must not be regulated higher than the red

mark on the low pressure gauge (2). (REG/MT only)

4.3 Closing

4.3.1 Close the cylinder valve.

4.3.2 Release the gas until the regulator gauges indicate "zero".

4.3.3 Turn the pressure adjusting knob (3) anticlockwise until it is

completely closed.

4.3.4 Remove regulator from cylinder.

5.1 Storage.

5.1.1 The regulator must be treated as a precision instrument.

5.1.2 When the regulator is not to be used for long periods, store it in

its wrapping or in its box, to prevent contact with dust, oil and

other sources of dirt.

5.2 Maintenance.

5.2.1 Do not carry out maintenance or repairs, other than the

following:

Replacement of bottle seal.

Replacement of gauge.

Replacement of inlet connector.

5.2.2 Use only original spare parts and accessories.

5.2.3 Do not clean gauge glasses with petrol, solvents or any other

kind of detergent.

5.2.4 In case of failure return your regulator to the retailer.

5.3 Malfunctioning.

5.3.1 In case of malfunction (e.g. leaks in the gauges or in the relief

valves) stop use and close the cylinder valve immediately.

5.3.2 Unscrew immediately the regulator from the gas bottle0.

5.3.3 We suggest that the regulator be returned to the supplier to be

checked and repaired.

CAUTION! Do not use the regulator if there are the following

malfunctions:

The gasket (6) is damaged or lost.

The regulator or any of its parts (gauge, inlet connection, outlet

connection) are damaged or dirty, oily etc.

There are any leaky connections.

The relief valve adjustment has been modified or the valve

leaks.

5.4 Relief valve.(4)

5.4.1 Regulators are equipped with an excess pressure valve.

5.4.2 In case of malfunctioning, this valve allows the excess gas

pressure to escape.

CAUTION! Do not modify the calibration of the relief valve.

5.5 Checking the seal.

5.5.1 This check must be carried out only in the open air: use either

soapy water or a gas leak detector. Do not use flames.

5.5.2 Spray detector on the area to be checked.

5.5.3 The forming of bubbles or foam is a sign of a leak. If a leak is

detected remove regulator from service immidiately and have it

serviced by an authorised dealer.

For Jack Sealey Ltd. Sole importer into the UK of Sealey Power Welders.

GAS REGULATORS

Models: REG/MO, REG/MT

EN ISO 2503

11th September 2009

Declaration of Conformity. We, the sole importer into the UK, declare that the products listed here are in conformity with

the following standards and directives. The construction files for these products are held by the Manufacturer and may be inspected, by a national

authority, upon request to Jack Sealey Ltd.

Signed by Mark Sweetman

REG/MO.V2, REG/MT.V2 Issue No.1 11/09/09

01284 757500

01284 703534

sales@sealey.co.uk

Sole UK Distributor

Sealey Group,

Bury St. Edmunds, Suffolk.

www.sealey.co.uk

Web

email

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our catalogue and latest promotions call us on 01284 757525 and leave your full name, address anpostcode.

Parts support is available for this product. To obtain a parts listing and/or diagram, please log on to

www.sealey.co.uk, email sales@sealey.co.uk or phone 01284 757500.