4.1.5. When assembly is complete, securely tighten all nuts.

WARNING! DO NOT use AB7081 without the support frame fully assembled.

4.2. ASSEMBLING TOP HANDLE

4.2.1. Align the holes in the handle with the holes in the upper housing. Insert and tighten the screws provided with a cross headed screwdriver

as shown in fig.4.

4.3. ASSEMBLING THE CABLE TIDIES FOR AB708

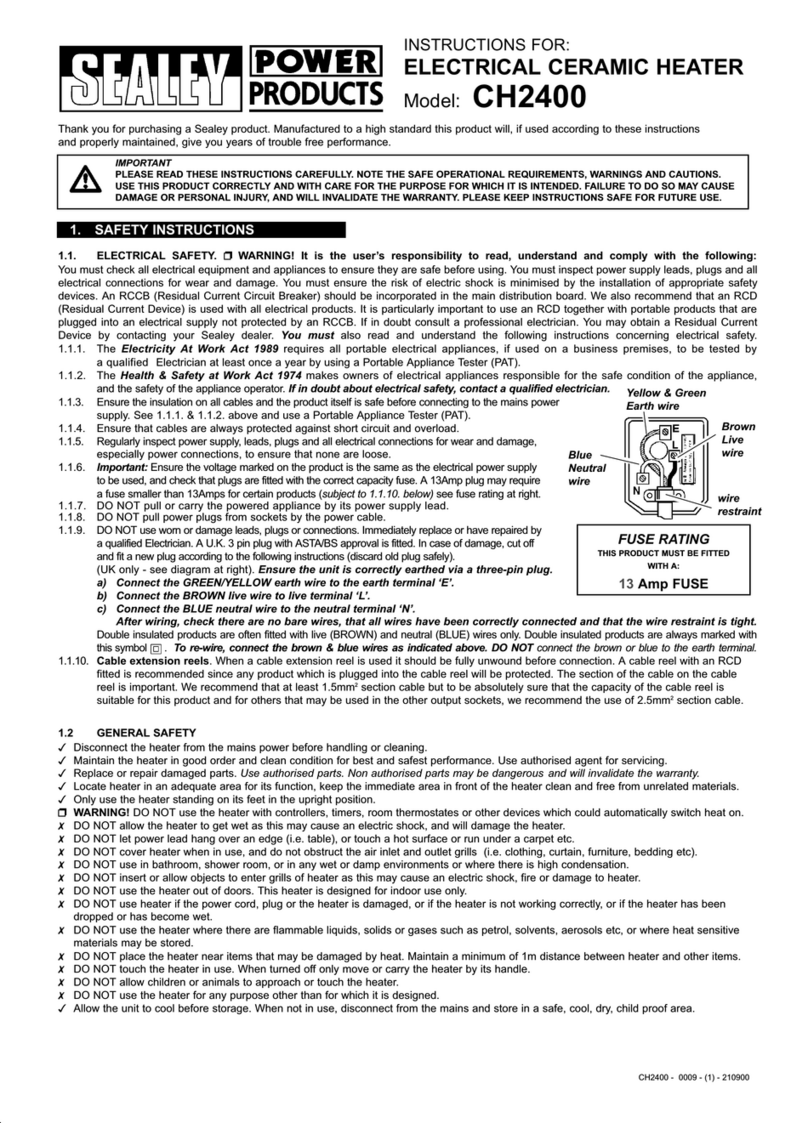

4.3.1. Mount the cable tidies onto either end of the panel on the other side of the heater from the main control panel, as shown in fig.1. Hook

the two tabs on each moulding into the holes at either end of the panel. The tongue on each moulding should now be lying on the face of

the panel. Secure each moulding in place with a screw through the tongue and into the ready made holes in the panel.

5. OPERATING CONDITIONS

5.1. PARAFFIN, KEROSENE AND DIESEL FUEL USAGE

These AB heaters are factory adjusted to give the most efficient burn on paraffin and kerosene but will also burn diesel. Note that

paraffin and kerosene will tend to burn more cleanly than diesel. Care should be taken to provide at least the minimum amount of

ventilation recommended when burning diesel.

WARNING! Never use any other fuel such as petrol, benzene, alcohol, camping stove fuel, paint thinners or other oil

compounds. USE OF THESE VOLATILE FUELS MAY CAUSE A FIRE OR EXPLOSION.

5.2. STORAGE OF FUEL

Always store paraffin, kerosene and diesel in a well ventilated area well away from general living space. Do not store in direct sunlight

or near a source of heat or other source of ignition such as a torch or a portable generator. Do not use fuel that has been stored from

one season to the next as it may have deteriorated and will not burn properly in the heater. Store the fuel in a suitable container which

complieswithrequirementssetoutinlocalauthorityregulations.

5.3. FILLING THE FUEL TANK

Never fill the fuel tank indoors. Always fill the fuel tank outdoors on a level surface. Take note of the position of the fuel gauge whilst

filling the tank and do not overfill it. Never refill the tank whilst the heater is operating or is still hot.

5.4. VENTILATION REQUIREMENTS

Usethisheateronlyinawellventilatedarea.Youshouldprovideanopeningtotheoutsideairofatleasta3squarefeet(0.9M²)for

every 100,000 BTU/hr of heat output. Provide a larger opening if more than one heater is being used.

5.5. SIGHTING THE HEATER

Always install the heater so that it will not be directly exposed to water spray, rain, dripping water or wind. The heater should not be

placed near to any combustible materials. The minimum clearance from combustibles is 1.2m from the top of the heater, 1.2m from

the sides of the heater and 2.4m from the front of the heater. Never use the heater in spaces which contain products such as petrol,

solvents, paint thinners, dust particles, volatile or airborne combustibles, or any unknown chemicals.

WARNING! Air contaminants taken into the heater may affect the heat output, damage the unit and may cause health

problems. Example: Bodyshop filler dust / paint overspray will damage the motor bearing, clog the filter and pump and

contaminate the combustion chamber causing flame flutter and health hazards. Please note that any parts damaged by filler

dust / paint overspray will not be covered by warranty. Additionally, a cleaning charge will be made for any heaters damaged

by filler dust.

6. THEORY OF OPERATION

6.1. FUEL SYSTEM.Theheaterisequippedwithanairpumpthatoperatesofftheelectricmotor.Thepumpforcesairthroughtheairline

connected to the fuel tank, drawing fuel to the nozzle in the burning head. Air also passes through the nozzle where it mixes with the

fuel and is sprayed into the combustion chamber in a fine mist.

6.2. QUICK FIRE IGNITION. A transformer sends high voltage to a two pronged spark plug. The resultant spark ignites the fuel air mixture

as it is sprayed into the combustion chamber.

6.3. AIR SYSTEM. Afan is turned by the heavy duty motor which forces air around and into the combustion chamber, where it is super

heated and forced out of the front of the chamber.

6.4. TEMPERATURE LIMIT CONTROL.Theheaterisequippedwithatemperaturelimitcontroldesignedtoturntheheateroffshouldthe

internaltemperaturerisetoanunsafelevel.Ifthisdeviceactivatesandturnsyourheateroff,itmayrequireservicing.Oncethe

temperature falls below the reset temperature, you will be able to restart the heater.

6.5. ELECTRICAL SYSTEM PROTECTION. The heater’s electrical system is protected by a circuit breaker that protects the systems

components from damage. If the heater ceases to work, check the fuse first and replace if necessary. See maintenance section 8.6.

6.6. FLAME SENSOR. The heater uses a photocell to ‘see’ the flame in the combustion chamber. Should the flame extinguish, the sensor

will cut off the electrical current and the heater will shut down.

7. OPERATION

7.1. TO START THE HEATER

7.1.1. Fill the tank with fuel until the fuel gauge points to “F”. Do not overfill.

7.1.2. Ensure that the fuel cap is replaced and fully tightened down.

7.1.3. Unwind the mains cable from cable tidies and plug the heater into the mains power

supply.

7.1.4. Turn the thermostat control knob to the desired temperature. The range is from 40°F to

110°F. (4.4°C to 43°C)

7.1.5. Push the power switch to the ON position.

7.1.6. The power lamp will illuminate and the heater will start. The heater will run up to

thepre-settemperatureandthenswitchonandoffautomaticallytomaintainthepre-set

temperature.

7.1.7. If the heater will not start, the temperature may be set too low. Turn the temperature

control knob to a higher setting until the heater fires. If the heater still does not start turn the power switch to OFF, then turn back ON. If

the heater still does not fire refer to the troubleshooting guide.

NOTE: The electrical components of these heaters are protected by a fuse mounted on the PC board. If the heater will not fire, check this fuse

first and replace if necessary. Also check that the proper voltage is being supplied to the heater.

g.5

Original Language Version

© Jack Sealey Limited AB708.V2, AB7081.V2 Issue:8 (ERP) 12/07/19