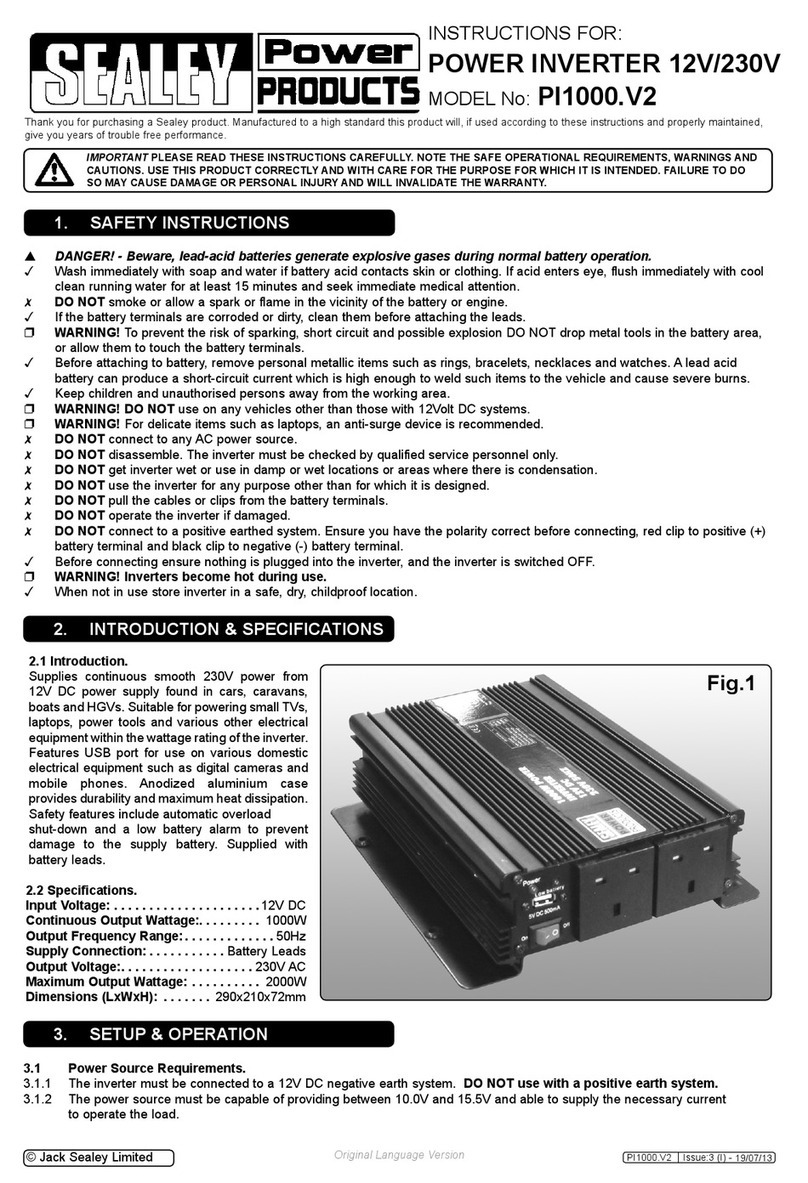

INSTRUCTIONS FOR:

INVERTERS

MODEL No's: MW131, MW151, MW151PLUS

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and properly maintained,

give you years of trouble free performance.

IMPORTANT: BEFORE USING THIS PRODUCT, PLEASE READ THE INSTRUCTIONS CAREFULLY. MAKE CAREFUL NOTE OF SAFETY INSTRUCTIONS,

WARNINGS AND CAUTIONS. THIS PRODUCT SHOULD ONLY BE USED FOR ITS INTENDED PURPOSE. FAILURE TO DO SO MAY CAUSE DAMAGE

AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. RETAIN THESE INSTRUCTIONS FOR FUTURE USE.

1. SAFETY INSTRUCTIONS

1.1. ELECTRICAL SAFETY

WARNING! It is the responsibility of the owner and the operator to read, understand and comply with the following:

You must check all electrical products, before use, to ensure that they are safe. You must inspect power cables, plugs, sockets and any

other connectors for wear or damage. You must ensure that the risk of electric shock is minimised by the installation of appropriate safety

devices. A Residual Current Circuit Breaker (RCCB) should be incorporated in the main distribution board. We also recommend that a

Residual Current Device (RCD) is used. It is particularly important to use an RCD with portable products that are plugged into a supply

which is not protected by an RCCB. If in any doubt consult a qualified electrician. You may obtain a Residual Current Device by contacting

your Sealey dealer.

You must also read and understand the following instructions concerning electrical safety:

1.1.1. The Electricity at Work Act 1989 requires that all portable electrical appliances, if used on business premises, are tested by a qualified

electrician, using a Portable Appliance Tester (PAT), at least once a year.

1.1.2. The Health & Safety at Work Act 1974 makes owners of electrical appliances responsible for the safe condition of those appliances

and the safety of the appliance operators. If in any doubt about electrical safety, contact a qualified electrician.

1.1.3. Ensure that the insulation on all cables and on the appliance is safe before connecting it to the power supply. See 1.1.1. and 1.1.2.

and use a Portable Appliance Tester.

1.1.4. Ensure that cables are always protected against short circuit and overload.

1.1.5. Regularly inspect power supply cables and plugs for wear or damage and check all connections to

ensure that none are loose.

1.1.6. Important: Ensure that the voltage marked on the appliance matches the power supply to be used

and that the plug is fitted with the correct fuse.

1.1.7. DO NOT pull or carry the appliance by the power cable.

1.1.8. DO NOT pull the plug from the socket by the cable.

1.1.9. DO NOT use worn or damaged cables, plugs or connectors. Immediately have any faulty item

repaired or replaced by a qualified electrician. When a BS 1363/A UK 3 pin plug is damaged, cut

the cable just above the plug and dispose of the plug safely.

Fit a new plug according to the following instructions (UK only).

a) Connect the GREEN/YELLOW earth wire to the earth terminal ‘E’.

b) Connect the BROWN live wire to the live terminal ‘L’.

c) Connect the BLUE neutral wire to the neutral terminal ‘N’.

d) After wiring, check that there are no bare wires, that all wires have been correctly connected, that the cable outer insulation

extends beyond the cable restraint and that the restraint is tight.

Double insulated products, which are always marked with this symbol , are fitted with live (brown) and neutral (blue) wires only.

To rewire, connect the wires as indicated above - DO NOT connect either wire to the earth terminal.

1.1.10. Products which require more than 13 amps are supplied without a plug. In this case you must contact a qualified electrician to ensure

that a suitably rated supply is available. We recommend that you discuss the installation of an industrial round pin plug and socket with

your electrician.

1.1.11. If an extension reel is used it should be fully unwound before connection. A reel with an RCD fitted is preferred since any appliance

plugged into it will be protected. The cable core section is important and should be at least 1.5mm², but to be absolutely sure that the

capacity of the reel is suitable for this product and for others which may be used in the other output sockets, we recommend the use of

2.5mm² section cable.

WARNING! Be very cautious if using a diesel generator. The generator must be stable with regard to frequency (H3), voltage

and wave form. The output must be higher than the power (kVA) of the inverter. The diesel generator must also be self

regulating. If any A.M. feature is not respected the working of the regulation card may be affected.

Use of a generator without a regulator may be dangerous and will invalidate your inverter warranty.

RECOMMENDED FUSE RATING

13AMP

Blue

Neutral

Wire

Yellow & Green

Earth Wire

Cable

Restraint

Brown

Live

Wire

1.2. GENERAL SAFETY

DANGER! Unplug the inverter from the mains power supply before connecting or disconnect cables or performing maintenance or

service. Direct contact with the inverter circuit is dangerous.

Keep the inverter and cables in good working order and condition. Take immediate action to repair or replace damaged parts.

Use genuine parts and accessories only. Unapproved parts may be dangerous and will invalidate the warranty.

Keep the inverter clean for best and safest performance.

Locate the inverter in a suitable work area. Ensure that the area has adequate ventilation as welding fumes are harmful.

WARNING! Cable connectors must be turned fully into the quick plugs to ensure a good electrical contact. Loose connections will

cause overheating, rapid deterioration and loss in efficiency.

Ensure that there is no obstruction to the flow of clean, cool air and ensure that there are no conductive dusts, corrosive vapours or humidity

which could enter the inverter and cause serious damage.

Keep the work area clean and tidy and free from unrelated materials. Also ensure that the work area has adequate lighting.

WARNING: Use welding head shield to protect eyes and avoid exposing skin to ultraviolet rays given off by electric arc. Wear safety

welding gauntlets.

Remove ill fitting clothing, remove ties, watches, rings and other loose jewellery and contain long hair.

Ensure that the workpiece is correctly secured before operating the inverter.

Avoid unintentional contact with workpiece. Accidental or uncontrolled arcing on the electrode holder may be dangerous.

Protect cables from heat and sharp or abrasive items.

Keep unauthorised persons away from the work area. Any persons working within the area must adorn the same protective items.

Stand correctly keeping a good footing and balance, ensure that the floor is not slippery and wear non-slip shoes.

Original Language Version MW131, MW151, MW151PLUS Issue No.1 24/10/11