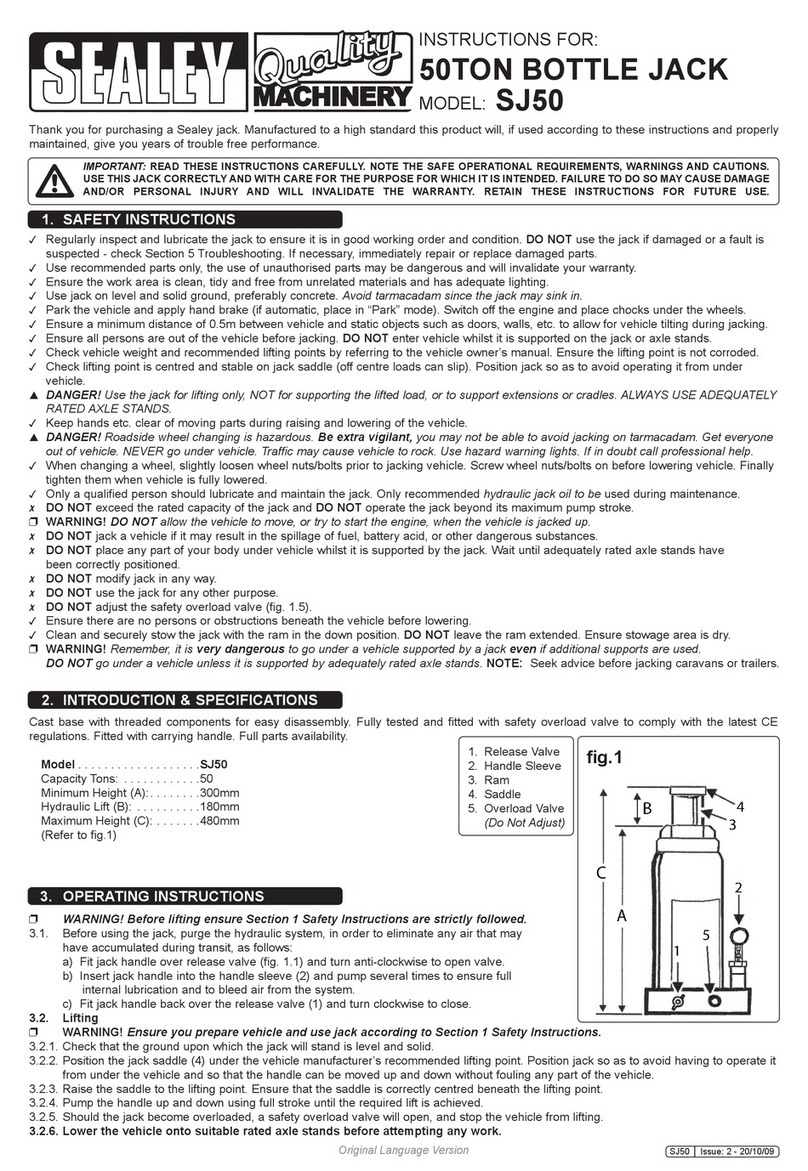

4. OPERATION

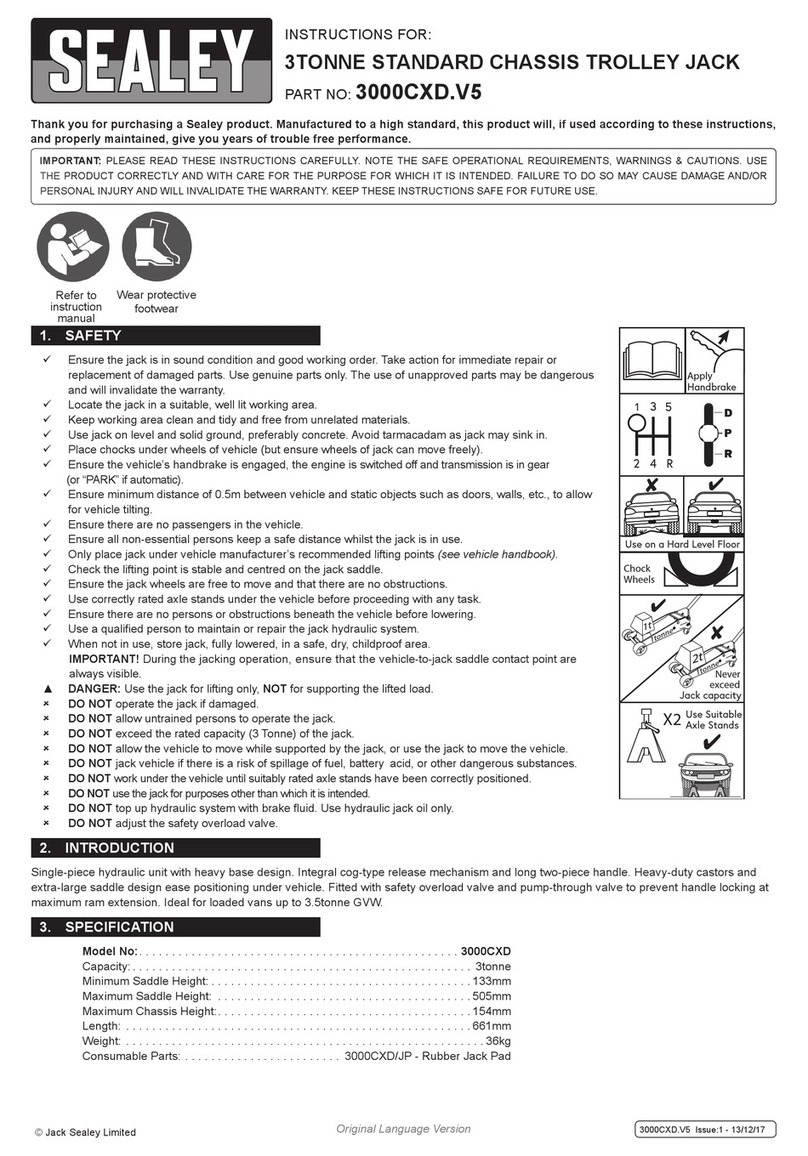

IMPORTANT SAFETY WARNING! ALWAYS USE RATED STANDS

Please remember a jack is a lifting and lowering device and is not designed to support a load. Never get underneath a vehicle supported

only by a jack; your life is at risk. We stock a comprehensive range of axle stands, for example, please see relevant catalogue section for

full details. The jack is not limited to vehicle use only, with many applications in the engineering and construction industries.

WARNING! Before use refer to section 1. SAFETY

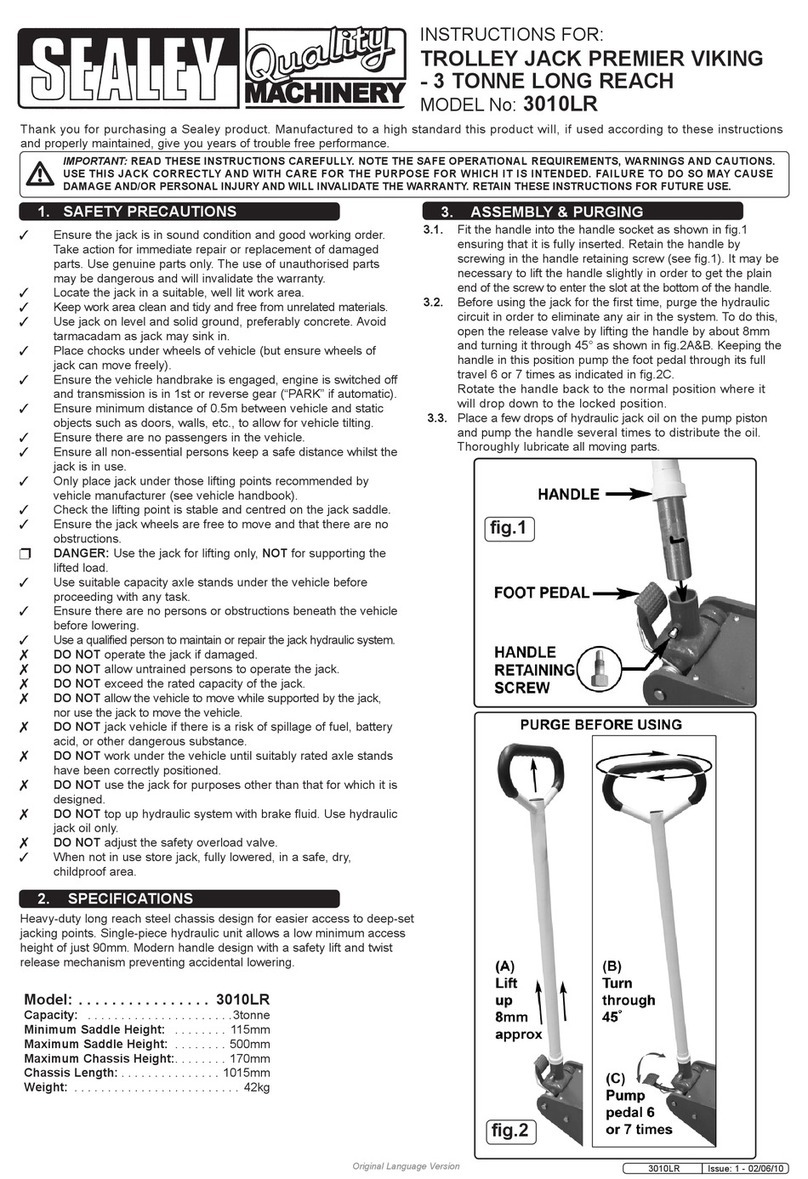

4.1. PURGING THE JACK

Purge the hydraulic system in order to eliminate any air that may have accumulated in transit or whilst stored:

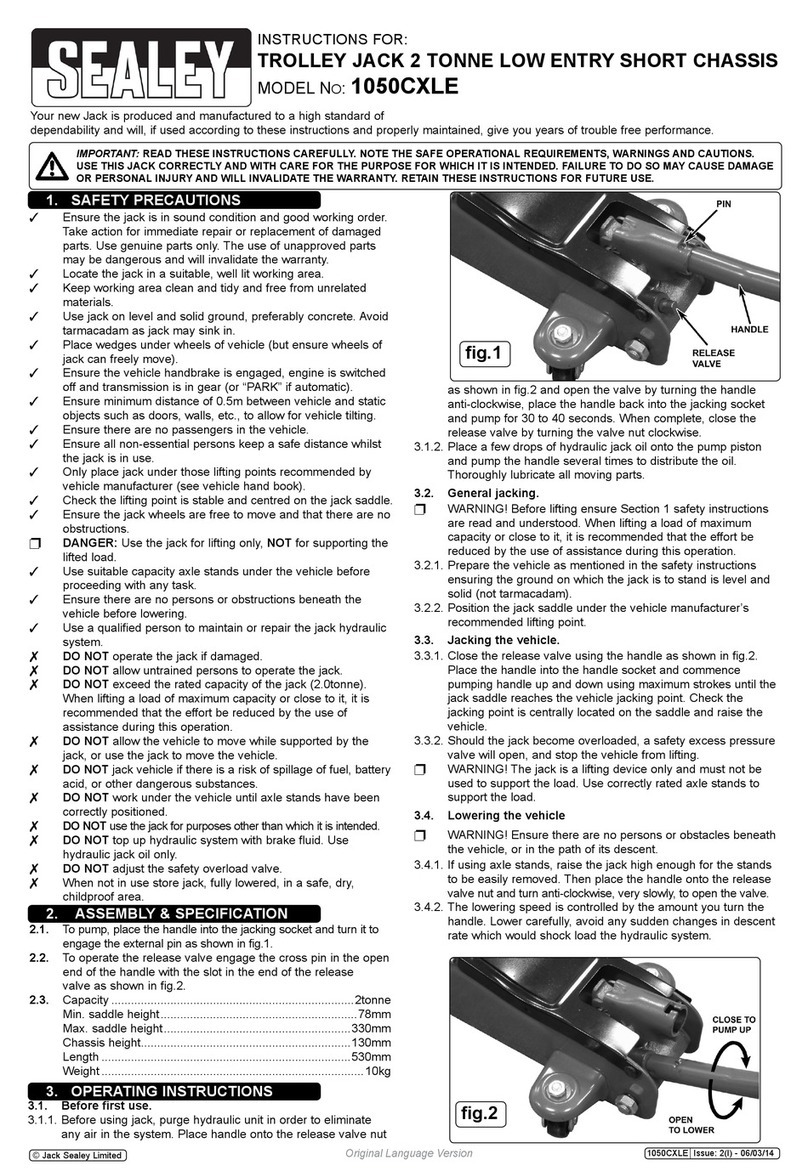

a) Place the telescopic jack lever over the release valve and turn anti clockwise to open the valve.

b) Insert the telescopic jack lever into the sleeve of the hydraulic pump.

c) Pump several times to ensure complete evacuation of air from the system.

d) When complete place the telescopic lever over the release valve and turn clockwise to close.

PBJ20, PBJ30, PBJ50 | Issue 3 (H,F) 17/01/19

Original Language Version

© Jack Sealey Limited

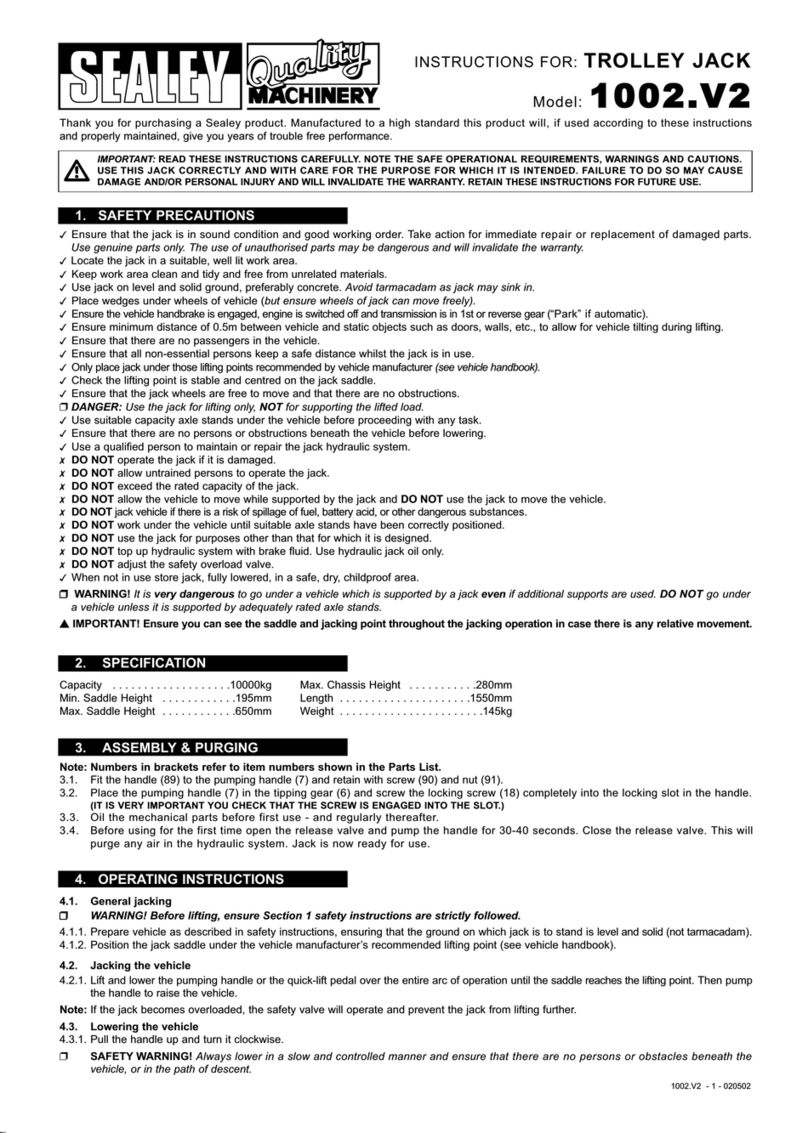

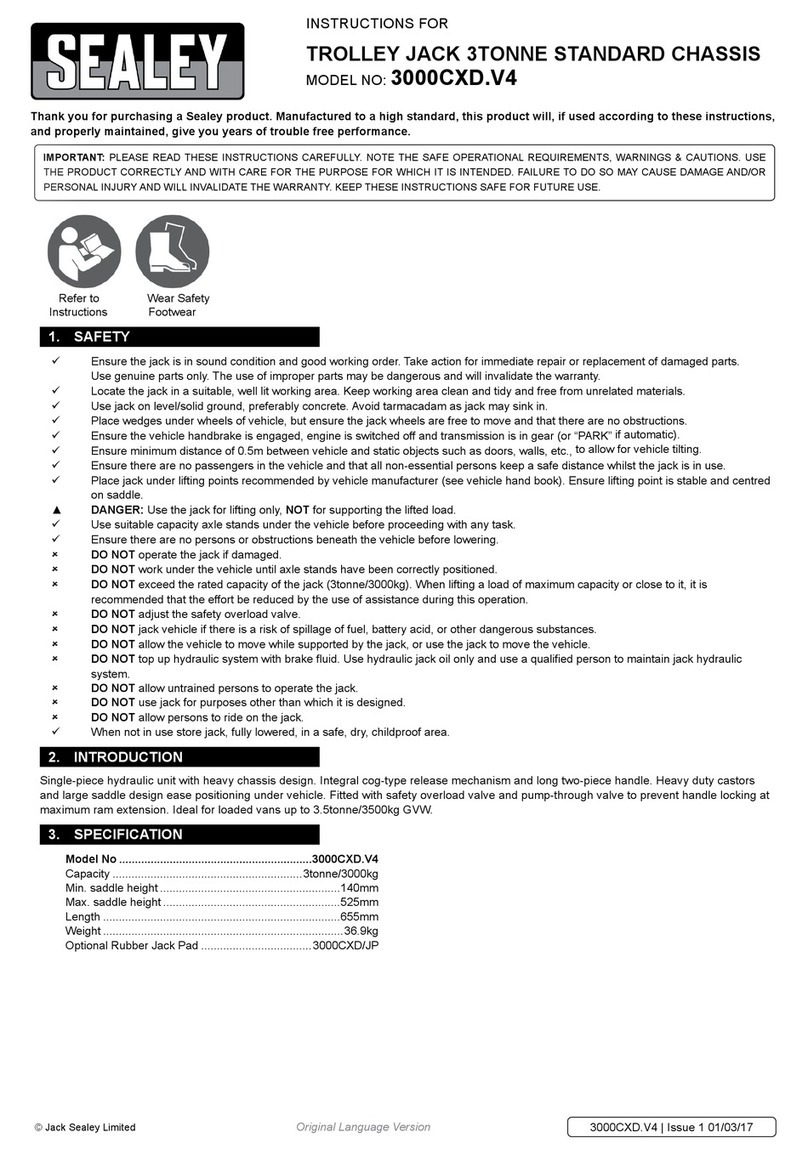

Lubricate leadscrew,

piston rod, pump

spindle and linkages.

4.2. LIFTING THE LOAD

4.2.1. Position the jack beneath the jacking point of the load to be lifted and on to an area that is solid and level.

4.2.2. Depending upon the height to be lifted, adjust the extension screw to suit.

4.2.3. Insert the telescopic jack lever into the sleeve of the hydraulic pump until the spring catch engages. Pump the lever, full stroke range,

so that the saddle quickly reaches the load to be lifted. Depress the spring catch with a screwdriver to remove.

4.2.4. Observe carefully the load and jack whilst elevating to the required height.

4.2.5. When the load is at the required height, place correctly rated stand or stands beneath the load near the jacking point.

4.2.6. Lower the load carefully and slowly on to the stand or stands. Place the telescopic jack lever over the release valve and turn

anticlockwise to open the valve. Remove the jack if required for access.

4.3. LOWERING THE LOAD

4.3.1. Position the jack beneath the jacking point of the load to be lifted and on to an area that is solid and level.

4.3.2. Depending upon the height to be lifted, adjust the extension screw to suit.

4.3.3. Insert the telescopic jack lever into the sleeve of the hydraulic pump until the spring catch engages. Pump the lever, full stroke range,

so that the saddle quickly reaches the load to be lifted. Depress the spring catch with a screwdriver to remove.

4.3.4. Observe carefully the load and jack whilst elevating to the required height.

4.3.5. Remove the stand or stands.

4.3.6. Lowertheloadcarefullyandslowlyontotheoor.Placethetelescopicjackleveroverthereleasevalveand

turn anticlockwise to open the valve. Control the speed of descent by partially opening the valve before opening

fully. To lower with no load, use the lever and and push down with your foot. (See icon).

5. MAINTENANCE

IMPORTANT! REPAIR AND MAINTENANCE OF THE JACK TO BE CARRIED OUT BY FULLY QUALIFIED PERSONNEL ONLY

WARNING! DO NOT usebrakeuid,oranyuidotherthanSealeyhydraulicjackuid.Useofnonpreferredjackoilmaycause

damage and invalidate the warranty.

5.1. When the jack is not in use, store with the ram and thread fully contracted, minimising ingress and corrosion.

5.2. Keep the jack clean and lubricate all moving parts with an acid free lubricating oil regularly.

5.3. Checkthejackreservoiroillevelregularlybyremovingthellerplug.Theoillevelshouldbeatthellerport.Topupasrequired.

5.4. Afterayearofextensiveuse,theoilshouldbereplacedwithnew.Todraintheoil,removethellerplugandvalve.Workcleanto

ensure zero ingress. Ensure the waste oil is recycled in accordance with local authority regulations.

5.5. Topupwithnewoilwiththeramfullyretracted.Pumptheunloadedjackveorsixtimestoexpelanyair.Pumpthejacktofull

height;allowexcessoiltoescapebeforerettingplug.

5.6. Visually check the jack before each use for mechanical integrity, cracked welds, worn parts etc... If any damage is found, remove

the jack from service.

5.7. Keep the piston rod clean and free of corrosion, clean exposed rod with a clean oiled cloth.

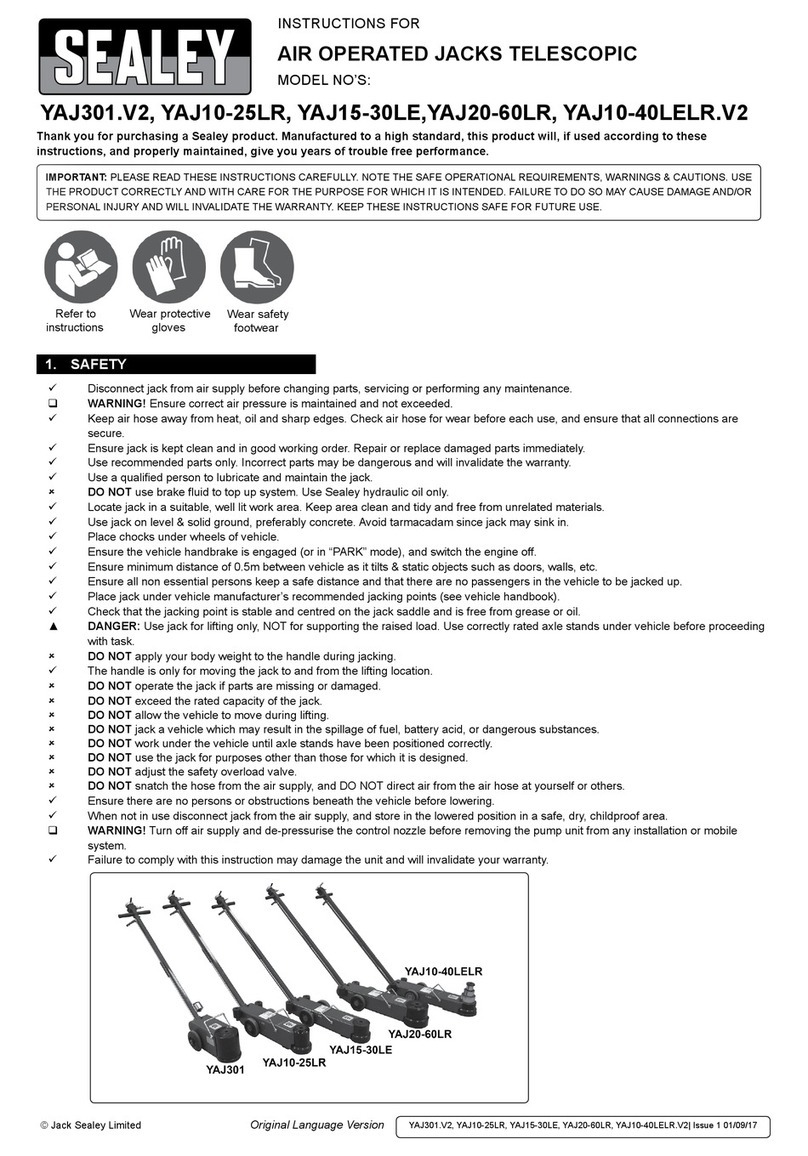

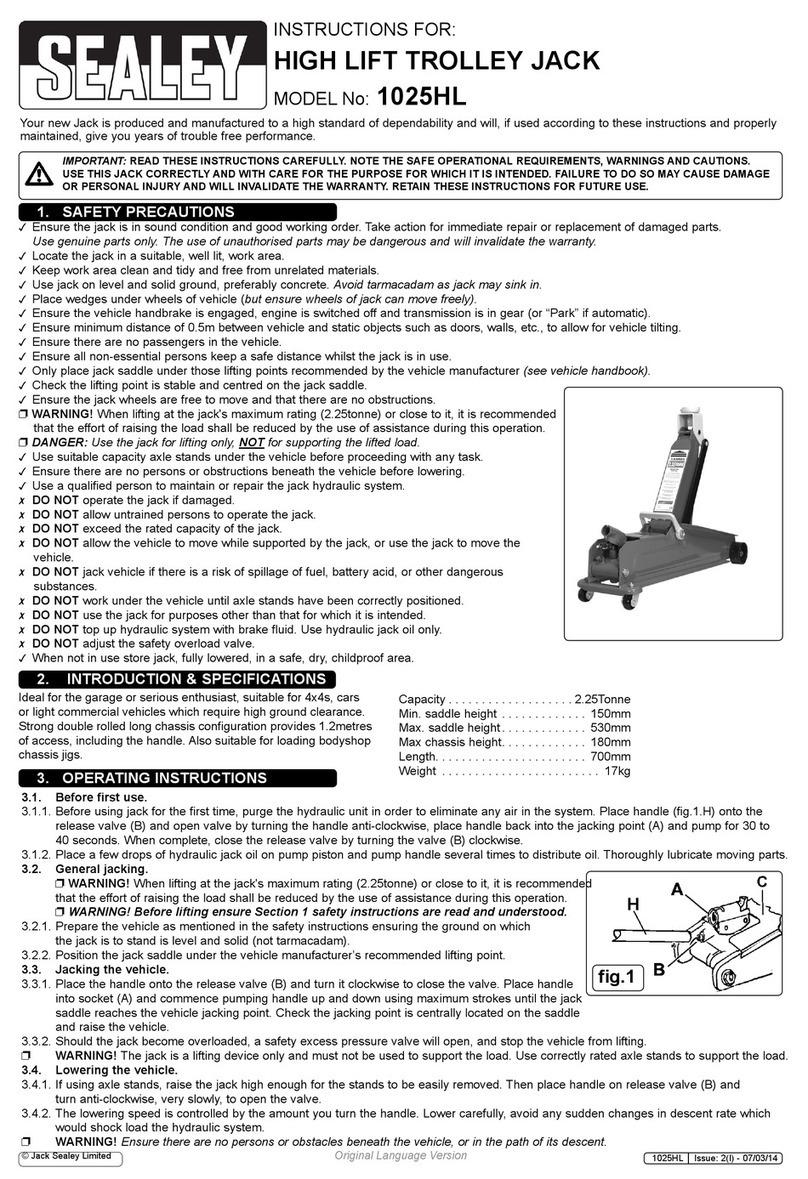

PBJ50

Carry

Handle

Safety

Valve

(do not adjust)

Pump

Valve

(open acw to descend,

cw to elevate)

Removable Telescopic

Operating Lever

Spring Catch

in Sleeve Slot

PBJ30

Piston Rod

Saddle

Leadscrew

(Not on PBJ50)

Filler Plug

PBJ20