Environmental Protection

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be

sorted, taken to a recycling centre and disposed of in a manner which is compatible with the environment.

Parts support is available for this product. To obtain a parts listing and/or diagram,

please log on to www.sealey.co.uk, email sales@sealey.co.uk or telephone 01284 757500.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

01284 757500

01284 703534

sales@sealey.co.uk

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

www.sealey.co.uk

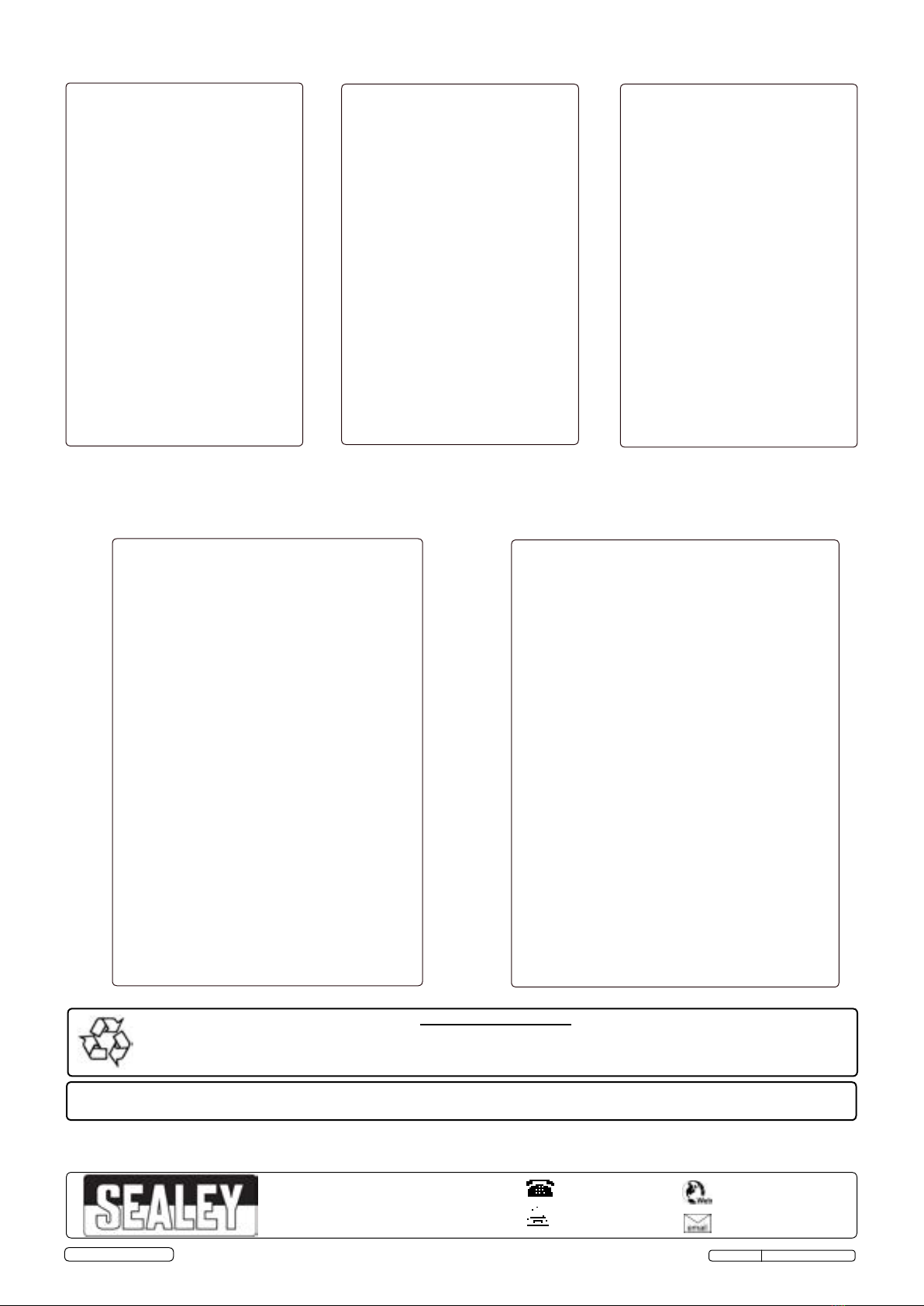

"x" Anvil size Spacer ring

159.5-160.5 160 No

160.5-161.5 160 1x1mm(10)

161.5-162.5 160 1x2mm(20)

162.5-163.5 160 1x3mm(30)

163.5-164.5 160 1x4mm(40)

164.5-165.5 165 No

165.5-166.5 165 1x1mm

166.5-167.5 165 1x2mm

167.5-168.5 165 1x3mm

168.5-169.5 165 1x4mm

169.5-170.5 170 No

170.5-171.5 170 1x1mm

171.5-172.5 170 1x2mm

172.5-173.5 170 1x3mm

173.5-174.5 170 1x4mm

174.5-175.5 175 No

175.5-176.5 175 1x1mm

176.5-177.5 175 1x2mm

177.5-178.5 175 1x3mm

178.5-179.5 175 1x4mm

"x" Anvil size Spacer ring

199.5 - 200.5 200 No

200.5-201.5 200 1x1mm

201.5-202.5 200 1x2mm

202.5-203.5 200 1x3mm

203.5-204.5 200 1x4mm

204.5-205.5 205 No

205.5-206.5 205 1x1mm

206.5-207.5 205 1x2mm

207.5-208.5 205 1x3mm

208.5-209.5 205 1x4mm

"x" Anvil size Spacer ring

179.5-180.5 180 No

180.5-181.5 180 1x1mm

181.5-182.5 180 1x2mm

182.5-183.5 180 1x3mm

183.5-184.5 180 1x4mm

184.5-185.5 185 No

185.5-186.5 185 1x1mm

186.5-187.5 185 1x2mm

187.5-188.5 185 1x3mm

188.5-189.5 185 1x4mm

189.5-190.5 190 No

190.5-191.5 190 1x1mm

191.5-192.5 190 1x2mm

192.5-193.5 190 1x3mm

193.5-194.5 190 1x4mm

194.5-195.5 195 No

195.5-196.5 195 1x1mm

196.5-197.5 195 1x2mm

197.5-198.5 195 1x3mm

198.5-199.5 195 1x4mm

"x" Anvil size Spacer ring Distance piece

209.5-210.5 160 No Yes

210.5-211.5 160 1x1mm Yes

211.5-212.5 160 1x2mm Yes

212.5-213.5 160 1x3mm Yes

213.5-214.5 160 1x4mm Yes

214.5-215.5 165 No Yes

215.5-216.5 165 1x1mm Yes

216.5-217.5 165 1x2mm Yes

217.5-218.5 165 1x3mm Yes

218.5-219.5 165 1x4mm Yes

219.5-220.5 170 No Yes

220.5-221.5 170 1x1mm Yes

221.5-222.5 170 1x2mm Yes

222.5-223.5 170 1x3mm Yes

223.5-224.5 170 1x4mm Yes

224.5-225.5 175 No Yes

225.5-226.5 175 1x1mm Yes

226.5-227.5 175 1x2mm Yes

227.5-228.5 175 1x3mm Yes

228.5-229.5 175 1x4mm Yes

229.5-230.5 180 No Yes

230.5-231.5 180 1x1mm Yes

231.5-232.5 180 1x2mm Yes

232.5-233.5 180 1x3mm Yes

233.5-234.5 180 1x4mm Yes

"x" Anvil size Spacer ring Distance piece

234.5-235.5 185 No Yes

235.5-236.5 185 1x1mm Yes

236.5-237.5 185 1x2mm Yes

237.5-238.5 185 1x3mm Yes

238.5-239.5 185 1x4mm Yes

239.5-240.5 190 No Yes

240.5-241.5 190 1x1mm Yes

241.5-242.5 190 1x2mm Yes

242.5-243.5 190 1x3mm Yes

243.5-244.5 190 1x4mm Yes

244.5-245.5 195 No Yes

245.5-246.5 195 1x1mm Yes

246.5-247.5 195 1x2mm Yes

247.5-248.5 195 1x3mm Yes

248.5-249.5 195 1x4mm Yes

249.5-250.5 200 No Yes

250.5-251.5 200 1x1mm Yes

251.5-252.5 200 1x2mm Yes

252.5-253.5 200 1x3mm Yes

253.5-254.5 200 1x4mm Yes

254.5-255.5 205 No Yes

255.5-256.5 205 1x1mm Yes

256.5-257.5 205 1x2mm Yes

257.5-258.5 205 1x3mm Yes

258.5-259.5 205 1x4mm Yes

Guide to Parts required versus measured size. (1mm graduations)

DBG5011 Issue: 1 - 23/06/15

Original Language Version

© Jack Sealey Limited